Photocatalytic Surfaces with Anti Fouling Functionality

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Anti-Fouling Technology Background and Objectives

Photocatalytic anti-fouling technology represents a significant advancement in surface engineering, emerging from decades of research into semiconductor photocatalysis that began in the 1970s. The fundamental principle involves the activation of semiconductor materials, primarily titanium dioxide (TiO₂), by light energy to generate reactive oxygen species that decompose organic contaminants on surfaces. This technology has evolved from basic photocatalytic reactions to sophisticated surface modifications with multifunctional capabilities.

The historical trajectory of photocatalytic anti-fouling technology shows accelerated development since the early 2000s, with notable breakthroughs in nanomaterial synthesis, visible light activation, and composite material formulations. Initial applications focused primarily on self-cleaning glass and air purification, but recent advancements have expanded potential applications to marine environments, medical devices, and industrial equipment where biofouling presents significant operational challenges.

Current technological trends indicate a shift toward developing photocatalytic surfaces with enhanced durability, broader spectrum light utilization, and improved efficiency under low-light conditions. Research is increasingly focused on creating surfaces that maintain anti-fouling properties over extended periods without performance degradation, addressing a key limitation of early-generation photocatalytic materials.

The primary objective of photocatalytic anti-fouling technology research is to develop surfaces that actively resist the accumulation of biological and chemical contaminants through continuous photocatalytic activity. This represents a paradigm shift from traditional anti-fouling approaches that rely on biocide release or physical deterrence mechanisms, which typically have limited lifespans or environmental concerns.

Specific technical goals include: enhancing photocatalytic efficiency under visible light to enable functionality in indoor and low-light environments; improving the adhesion and durability of photocatalytic coatings on diverse substrate materials; developing composite systems that combine photocatalytic activity with other functional properties such as hydrophobicity or mechanical strength; and creating scalable manufacturing processes for commercial viability.

The evolution of this technology is increasingly driven by environmental regulations restricting traditional anti-fouling compounds, particularly in marine applications, creating market pull for sustainable alternatives. Additionally, growing concerns about hospital-acquired infections and food safety have expanded potential applications into healthcare and food processing industries, where surface contamination presents significant risks.

Looking forward, the technology trajectory suggests convergence with other advanced materials technologies, including self-healing surfaces, stimuli-responsive materials, and antimicrobial nanostructures, potentially leading to next-generation surfaces with programmable anti-fouling properties that can adapt to environmental conditions.

The historical trajectory of photocatalytic anti-fouling technology shows accelerated development since the early 2000s, with notable breakthroughs in nanomaterial synthesis, visible light activation, and composite material formulations. Initial applications focused primarily on self-cleaning glass and air purification, but recent advancements have expanded potential applications to marine environments, medical devices, and industrial equipment where biofouling presents significant operational challenges.

Current technological trends indicate a shift toward developing photocatalytic surfaces with enhanced durability, broader spectrum light utilization, and improved efficiency under low-light conditions. Research is increasingly focused on creating surfaces that maintain anti-fouling properties over extended periods without performance degradation, addressing a key limitation of early-generation photocatalytic materials.

The primary objective of photocatalytic anti-fouling technology research is to develop surfaces that actively resist the accumulation of biological and chemical contaminants through continuous photocatalytic activity. This represents a paradigm shift from traditional anti-fouling approaches that rely on biocide release or physical deterrence mechanisms, which typically have limited lifespans or environmental concerns.

Specific technical goals include: enhancing photocatalytic efficiency under visible light to enable functionality in indoor and low-light environments; improving the adhesion and durability of photocatalytic coatings on diverse substrate materials; developing composite systems that combine photocatalytic activity with other functional properties such as hydrophobicity or mechanical strength; and creating scalable manufacturing processes for commercial viability.

The evolution of this technology is increasingly driven by environmental regulations restricting traditional anti-fouling compounds, particularly in marine applications, creating market pull for sustainable alternatives. Additionally, growing concerns about hospital-acquired infections and food safety have expanded potential applications into healthcare and food processing industries, where surface contamination presents significant risks.

Looking forward, the technology trajectory suggests convergence with other advanced materials technologies, including self-healing surfaces, stimuli-responsive materials, and antimicrobial nanostructures, potentially leading to next-generation surfaces with programmable anti-fouling properties that can adapt to environmental conditions.

Market Analysis for Self-Cleaning Surface Applications

The global market for self-cleaning surfaces is experiencing robust growth, driven by increasing awareness of hygiene and cleanliness across various sectors. The photocatalytic surfaces with anti-fouling functionality represent a significant segment within this market, valued at approximately $3.5 billion in 2022 and projected to reach $5.7 billion by 2027, growing at a CAGR of 10.2%.

Construction and building materials constitute the largest application segment, accounting for nearly 40% of the market share. The demand for self-cleaning windows, facades, and roofing materials continues to rise, particularly in urban areas with high pollution levels where maintenance costs are substantial. Commercial buildings alone spend between $0.15-0.35 per square foot annually on external cleaning, creating a compelling economic case for photocatalytic solutions.

Automotive applications form the second-largest market segment at 25%, with manufacturers increasingly incorporating self-cleaning coatings on windshields, mirrors, and body panels. Consumer willingness to pay premium prices for vehicles with reduced maintenance requirements has accelerated adoption in mid to high-end vehicle models.

Healthcare facilities represent the fastest-growing segment with 15.3% annual growth, driven by stringent hygiene requirements and infection control protocols. The COVID-19 pandemic has significantly accelerated this trend, with hospitals and clinics increasingly specifying antimicrobial and self-cleaning surfaces for high-touch areas.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 38% of global demand, followed by Europe (32%) and North America (24%). China and Japan lead in both production and consumption of photocatalytic materials, while European countries demonstrate the highest per capita spending on self-cleaning technologies.

Consumer electronics, marine applications, and solar panel efficiency maintenance are emerging as promising new application areas. The solar energy sector particularly benefits from photocatalytic coatings that can maintain panel efficiency by preventing dust and organic matter accumulation, potentially increasing energy yield by 3-5% annually.

Market challenges include price sensitivity in mass-market applications, durability concerns in extreme weather conditions, and competition from alternative technologies such as hydrophobic coatings. However, technological advancements in nanostructured photocatalysts and hybrid systems are gradually addressing these limitations while expanding the potential application spectrum.

Construction and building materials constitute the largest application segment, accounting for nearly 40% of the market share. The demand for self-cleaning windows, facades, and roofing materials continues to rise, particularly in urban areas with high pollution levels where maintenance costs are substantial. Commercial buildings alone spend between $0.15-0.35 per square foot annually on external cleaning, creating a compelling economic case for photocatalytic solutions.

Automotive applications form the second-largest market segment at 25%, with manufacturers increasingly incorporating self-cleaning coatings on windshields, mirrors, and body panels. Consumer willingness to pay premium prices for vehicles with reduced maintenance requirements has accelerated adoption in mid to high-end vehicle models.

Healthcare facilities represent the fastest-growing segment with 15.3% annual growth, driven by stringent hygiene requirements and infection control protocols. The COVID-19 pandemic has significantly accelerated this trend, with hospitals and clinics increasingly specifying antimicrobial and self-cleaning surfaces for high-touch areas.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 38% of global demand, followed by Europe (32%) and North America (24%). China and Japan lead in both production and consumption of photocatalytic materials, while European countries demonstrate the highest per capita spending on self-cleaning technologies.

Consumer electronics, marine applications, and solar panel efficiency maintenance are emerging as promising new application areas. The solar energy sector particularly benefits from photocatalytic coatings that can maintain panel efficiency by preventing dust and organic matter accumulation, potentially increasing energy yield by 3-5% annually.

Market challenges include price sensitivity in mass-market applications, durability concerns in extreme weather conditions, and competition from alternative technologies such as hydrophobic coatings. However, technological advancements in nanostructured photocatalysts and hybrid systems are gradually addressing these limitations while expanding the potential application spectrum.

Current Photocatalytic Anti-Fouling Technologies and Challenges

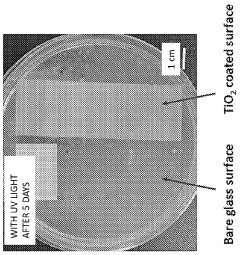

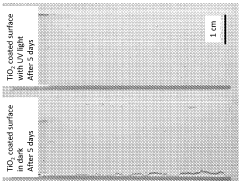

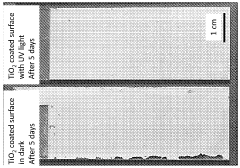

Photocatalytic anti-fouling technologies have emerged as promising solutions for surface protection against biological and chemical fouling. Currently, titanium dioxide (TiO2) remains the most widely utilized photocatalyst due to its chemical stability, non-toxicity, and cost-effectiveness. When exposed to UV light, TiO2 generates reactive oxygen species (ROS) that decompose organic contaminants and kill microorganisms, providing a self-cleaning effect on surfaces.

Recent advancements have focused on enhancing the visible light activity of photocatalysts through various modification strategies. Doping TiO2 with metals (Ag, Cu, Fe) or non-metals (N, S, C) has successfully reduced its band gap, enabling activation under visible light. Additionally, composite photocatalysts combining TiO2 with other semiconductors like ZnO, WO3, or graphene have demonstrated improved charge separation and extended light absorption range.

Another significant development is the integration of photocatalysts into various substrate materials. Polymer-based photocatalytic coatings offer flexibility and ease of application, while ceramic-based systems provide durability in harsh environments. Textile industries have incorporated photocatalytic nanoparticles into fabrics for antimicrobial and self-cleaning properties, and construction materials with photocatalytic surfaces have shown promising air-purifying capabilities.

Despite these advancements, several challenges impede widespread adoption of photocatalytic anti-fouling technologies. The primary limitation remains the UV dependency of most photocatalysts, restricting their effectiveness in indoor or low-light environments. Although visible-light-active photocatalysts exist, they typically exhibit lower efficiency compared to their UV-activated counterparts.

Durability presents another significant challenge, as photocatalytic coatings often suffer from mechanical wear, leaching, and gradual performance degradation over time. This is particularly problematic in marine environments where physical abrasion and high salinity accelerate coating deterioration.

Scalability and cost-effectiveness remain obstacles for commercial applications. Current manufacturing processes for advanced photocatalysts involve complex synthesis routes and expensive precursors, limiting large-scale production. Additionally, the long-term environmental impact of nanoparticle-based photocatalysts requires further investigation, as concerns exist regarding potential ecotoxicity.

Standardization issues further complicate industry adoption, as there is a lack of universally accepted testing protocols to evaluate photocatalytic anti-fouling performance across different applications and environments. This makes it difficult for manufacturers to validate claims and for consumers to compare products effectively.

Recent advancements have focused on enhancing the visible light activity of photocatalysts through various modification strategies. Doping TiO2 with metals (Ag, Cu, Fe) or non-metals (N, S, C) has successfully reduced its band gap, enabling activation under visible light. Additionally, composite photocatalysts combining TiO2 with other semiconductors like ZnO, WO3, or graphene have demonstrated improved charge separation and extended light absorption range.

Another significant development is the integration of photocatalysts into various substrate materials. Polymer-based photocatalytic coatings offer flexibility and ease of application, while ceramic-based systems provide durability in harsh environments. Textile industries have incorporated photocatalytic nanoparticles into fabrics for antimicrobial and self-cleaning properties, and construction materials with photocatalytic surfaces have shown promising air-purifying capabilities.

Despite these advancements, several challenges impede widespread adoption of photocatalytic anti-fouling technologies. The primary limitation remains the UV dependency of most photocatalysts, restricting their effectiveness in indoor or low-light environments. Although visible-light-active photocatalysts exist, they typically exhibit lower efficiency compared to their UV-activated counterparts.

Durability presents another significant challenge, as photocatalytic coatings often suffer from mechanical wear, leaching, and gradual performance degradation over time. This is particularly problematic in marine environments where physical abrasion and high salinity accelerate coating deterioration.

Scalability and cost-effectiveness remain obstacles for commercial applications. Current manufacturing processes for advanced photocatalysts involve complex synthesis routes and expensive precursors, limiting large-scale production. Additionally, the long-term environmental impact of nanoparticle-based photocatalysts requires further investigation, as concerns exist regarding potential ecotoxicity.

Standardization issues further complicate industry adoption, as there is a lack of universally accepted testing protocols to evaluate photocatalytic anti-fouling performance across different applications and environments. This makes it difficult for manufacturers to validate claims and for consumers to compare products effectively.

Current Photocatalytic Anti-Fouling Surface Solutions

01 TiO2-based photocatalytic coatings for anti-fouling

Titanium dioxide (TiO2) is widely used as a photocatalyst in anti-fouling surface applications. When exposed to UV light, TiO2 generates reactive oxygen species that can decompose organic contaminants and kill microorganisms on the surface. These coatings can be applied to various substrates to provide self-cleaning and anti-fouling properties, making them suitable for marine structures, building exteriors, and other surfaces exposed to biological fouling.- TiO2-based photocatalytic coatings for anti-fouling: Titanium dioxide (TiO2) is widely used as a photocatalyst in anti-fouling surface applications. When exposed to UV light, TiO2 generates reactive oxygen species that can decompose organic contaminants and kill microorganisms on the surface. These coatings can be applied to various substrates to provide self-cleaning and anti-fouling properties, making them suitable for marine structures, building exteriors, and other applications where surface cleanliness is important.

- Nanostructured photocatalytic surfaces for enhanced anti-fouling: Nanostructured photocatalytic surfaces offer improved anti-fouling performance due to their increased surface area and enhanced photocatalytic activity. These surfaces can be engineered with specific morphologies, such as nanorods, nanotubes, or hierarchical structures, to optimize light absorption and photocatalytic efficiency. The nanostructuring also contributes to superhydrophilic or superhydrophobic properties, which further enhance the anti-fouling capabilities by preventing the initial attachment of fouling organisms.

- Visible light-responsive photocatalytic materials: Traditional photocatalysts like TiO2 are primarily activated by UV light, limiting their effectiveness in indoor or low-light environments. Recent developments focus on modifying photocatalysts to respond to visible light, expanding their practical applications. This can be achieved through doping with metals or non-metals, creating heterojunctions, or developing new photocatalytic materials altogether. These visible light-responsive materials enable anti-fouling surfaces to work effectively under normal indoor lighting conditions or natural daylight.

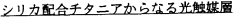

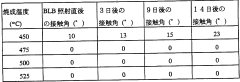

- Composite photocatalytic coatings with enhanced durability: Composite photocatalytic coatings combine photocatalysts with other materials to enhance durability and performance. These composites often incorporate polymers, silica, or other inorganic materials to improve adhesion to substrates, mechanical strength, and longevity of the anti-fouling properties. Some formulations also include additional functional components such as hydrophobic agents or antimicrobial compounds to create multifunctional surfaces that resist various types of fouling under different environmental conditions.

- Application methods for photocatalytic anti-fouling surfaces: Various methods can be used to apply photocatalytic materials to surfaces, including spray coating, dip coating, spin coating, and more advanced techniques like chemical vapor deposition or electrospinning. The choice of application method affects the coating's uniformity, adhesion, and overall anti-fouling performance. Some techniques allow for the creation of self-assembled or patterned surfaces that optimize the photocatalytic activity while minimizing material usage. The application method must be compatible with the substrate material and intended use environment.

02 Nanostructured photocatalytic surfaces for enhanced anti-fouling performance

Nanostructured photocatalytic surfaces offer improved anti-fouling performance due to their increased surface area and enhanced photocatalytic activity. These surfaces can be engineered with specific morphologies, such as nanorods, nanotubes, or hierarchical structures, to optimize light absorption and photocatalytic efficiency. The nanostructuring also contributes to superhydrophilic or superhydrophobic properties, which further enhance the anti-fouling capabilities by preventing the initial attachment of fouling organisms.Expand Specific Solutions03 Visible light-responsive photocatalytic materials for continuous anti-fouling

Traditional photocatalysts like TiO2 are primarily active under UV light, limiting their effectiveness in low-light conditions. Advanced photocatalytic materials have been developed to respond to visible light, enabling continuous anti-fouling activity even under indoor lighting or cloudy conditions. These materials include doped semiconductors, heterojunctions, and composite photocatalysts that can harness a broader spectrum of light energy, making them more practical for real-world anti-fouling applications.Expand Specific Solutions04 Photocatalytic anti-fouling systems for marine applications

Marine environments present particularly challenging conditions for anti-fouling technologies due to the diversity of fouling organisms and harsh conditions. Specialized photocatalytic systems have been developed specifically for marine applications, including ship hulls, underwater structures, and aquaculture equipment. These systems often combine photocatalytic materials with other anti-fouling strategies, such as controlled release of biocides or physical surface modifications, to provide comprehensive protection against marine biofouling while minimizing environmental impact.Expand Specific Solutions05 Self-cleaning photocatalytic surfaces for building materials and infrastructure

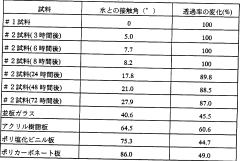

Photocatalytic self-cleaning surfaces are increasingly being incorporated into building materials and infrastructure to maintain aesthetic appearance and functionality over time. These surfaces use photocatalytic reactions to break down organic contaminants, preventing the accumulation of dirt, algae, and other fouling agents. Applications include self-cleaning glass, concrete, ceramic tiles, and exterior paints. The technology not only reduces maintenance costs but can also contribute to air purification by breaking down airborne pollutants that come in contact with the surface.Expand Specific Solutions

Leading Companies and Research Institutions in Photocatalytic Field

The photocatalytic surfaces with anti-fouling functionality market is in a growth phase, with increasing applications across marine, construction, and healthcare sectors. The global market size is expanding due to rising environmental concerns and demand for self-cleaning materials. Leading players include TOTO Ltd., a pioneer in photocatalytic technology with established commercial applications; Nitto Denko and Asahi Kasei, which leverage their materials expertise; and Chugoku Marine Paints, specializing in marine anti-fouling solutions. Research institutions like Naval Research Laboratory and Fraunhofer-Gesellschaft contribute significant technological advancements. The technology shows varying maturity levels, with basic photocatalytic coatings being well-established while advanced functionalities combining anti-fouling with other properties remain in development stages, particularly at companies like FUJIFILM, LG Chem, and Kyocera.

TOTO Ltd.

Technical Solution: TOTO has developed advanced photocatalytic technology called "HYDROTECT" that utilizes titanium dioxide (TiO2) coatings activated by UV light. When exposed to sunlight, these surfaces generate reactive oxygen species that decompose organic contaminants and kill bacteria. TOTO's innovation lies in their proprietary method of creating nano-scale TiO2 particles with optimized crystal structure for maximum photocatalytic efficiency. Their technology incorporates a hydrophilic component that creates a thin water layer on the surface when exposed to light, helping to wash away decomposed contaminants. This self-cleaning mechanism is particularly effective for exterior building materials, sanitaryware, and glass surfaces. TOTO has enhanced their formulation to work under visible light conditions, not just UV, expanding application possibilities to indoor environments.

Strengths: Long-lasting anti-fouling effect without chemical additives; environmentally friendly solution that reduces cleaning frequency and chemical use; proven commercial success in architectural applications. Weaknesses: Requires light exposure to maintain effectiveness; initial cost higher than conventional surfaces; performance may degrade over time in harsh environments.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its expertise in thin film technology and nanomaterials to develop advanced photocatalytic surfaces with anti-fouling functionality. Their approach utilizes proprietary silver-modified titanium dioxide nanoparticles that exhibit enhanced photocatalytic activity under both UV and visible light. FUJIFILM's technology incorporates a multilayer coating structure with a protective top layer that prevents degradation of the underlying substrate while maintaining photocatalytic activity at the surface. Their formulation includes hydrophilic polymers that create a water-attracting surface layer, working in conjunction with photocatalytic decomposition to remove contaminants. The company has developed specialized application methods that ensure uniform distribution of photocatalytic particles and optimal surface morphology for anti-fouling performance. FUJIFILM has adapted this technology for various applications including medical devices, optical components, and consumer electronics surfaces that require maintained cleanliness and reduced biofilm formation.

Strengths: Excellent thin film uniformity leveraging FUJIFILM's core expertise; enhanced visible light activity through silver modification; versatile application to various substrates including plastics and glass. Weaknesses: Higher manufacturing complexity than simple TiO2 coatings; potential concerns about silver release in some applications; requires specialized application equipment for optimal performance.

Key Patents and Scientific Breakthroughs in Photocatalytic Materials

Method of photocatalytically making the surface of base material ultrahydrophilic, base material having ultrahydrophilic and photocatalytic surface, and process for producing said material

PatentWO1996029375A1

Innovation

- A photocatalytic coating of photocatalytic semiconductor material is applied to the substrate, which becomes superhydrophilic when irradiated with light above its bandgap energy, creating a uniform water film and preventing water droplet formation, and maintaining hydrophilicity even in the presence of contaminants.

Photocatalytic surfaces for Anti-biofouling

PatentWO2024044665A2

Innovation

- A photocatalytic surface coated with nanoparticles like anatase titania or zinc oxide, combined with an embedded UV light source, which activates photocatalytic decomposition of organic and biological materials, preventing biofouling through surface oxidation.

Environmental Impact and Sustainability Assessment

Photocatalytic surfaces with anti-fouling functionality represent a significant advancement in sustainable materials science, offering environmental benefits that extend far beyond their primary application. These surfaces utilize photocatalytic reactions to break down organic contaminants and prevent biofouling without relying on traditional toxic anti-fouling compounds, thereby reducing the release of harmful substances into aquatic ecosystems.

The environmental impact assessment of these surfaces reveals substantial positive outcomes across multiple dimensions. Most notably, photocatalytic anti-fouling technologies can reduce or eliminate the need for copper-based and tributyltin (TBT) compounds traditionally used in marine anti-fouling applications, which have been documented to cause severe ecological damage including shell deformities in mollusks and endocrine disruption in various marine species.

Life cycle assessment (LCA) studies indicate that photocatalytic surfaces demonstrate favorable environmental profiles compared to conventional anti-fouling technologies. The reduction in cleaning frequency and chemical usage translates to lower carbon footprints and decreased water pollution. Quantitative analyses suggest that vessels utilizing photocatalytic coatings can reduce their environmental impact by up to 30% through decreased fuel consumption resulting from smoother hull surfaces and extended maintenance intervals.

From a sustainability perspective, these surfaces contribute significantly to circular economy principles. The extended service life of photocatalytic coatings—often 1.5 to 2 times longer than conventional alternatives—reduces resource consumption and waste generation. Additionally, many photocatalytic materials can be formulated using abundant elements like titanium, reducing dependence on scarce or geopolitically sensitive resources.

Water conservation represents another critical environmental benefit. Traditional cleaning methods for fouled surfaces typically require large volumes of freshwater and chemical detergents. Photocatalytic surfaces with self-cleaning properties can reduce water consumption by 40-60% in maintenance operations, a particularly valuable attribute in water-stressed regions.

Energy efficiency gains also merit consideration in sustainability assessments. By maintaining cleaner surfaces on solar panels, heat exchangers, and other energy-related infrastructure, photocatalytic coatings can improve operational efficiency by 5-15%, indirectly reducing fossil fuel consumption and associated greenhouse gas emissions.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions implementing preferential treatment for photocatalytic technologies in environmental compliance standards. This regulatory support further accelerates adoption and continued research investment, creating a positive feedback loop for environmental innovation in this field.

The environmental impact assessment of these surfaces reveals substantial positive outcomes across multiple dimensions. Most notably, photocatalytic anti-fouling technologies can reduce or eliminate the need for copper-based and tributyltin (TBT) compounds traditionally used in marine anti-fouling applications, which have been documented to cause severe ecological damage including shell deformities in mollusks and endocrine disruption in various marine species.

Life cycle assessment (LCA) studies indicate that photocatalytic surfaces demonstrate favorable environmental profiles compared to conventional anti-fouling technologies. The reduction in cleaning frequency and chemical usage translates to lower carbon footprints and decreased water pollution. Quantitative analyses suggest that vessels utilizing photocatalytic coatings can reduce their environmental impact by up to 30% through decreased fuel consumption resulting from smoother hull surfaces and extended maintenance intervals.

From a sustainability perspective, these surfaces contribute significantly to circular economy principles. The extended service life of photocatalytic coatings—often 1.5 to 2 times longer than conventional alternatives—reduces resource consumption and waste generation. Additionally, many photocatalytic materials can be formulated using abundant elements like titanium, reducing dependence on scarce or geopolitically sensitive resources.

Water conservation represents another critical environmental benefit. Traditional cleaning methods for fouled surfaces typically require large volumes of freshwater and chemical detergents. Photocatalytic surfaces with self-cleaning properties can reduce water consumption by 40-60% in maintenance operations, a particularly valuable attribute in water-stressed regions.

Energy efficiency gains also merit consideration in sustainability assessments. By maintaining cleaner surfaces on solar panels, heat exchangers, and other energy-related infrastructure, photocatalytic coatings can improve operational efficiency by 5-15%, indirectly reducing fossil fuel consumption and associated greenhouse gas emissions.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions implementing preferential treatment for photocatalytic technologies in environmental compliance standards. This regulatory support further accelerates adoption and continued research investment, creating a positive feedback loop for environmental innovation in this field.

Scalability and Industrial Application Potential

The scalability of photocatalytic surfaces with anti-fouling functionality represents a critical factor in determining their commercial viability and widespread adoption across various industries. Current laboratory-scale production methods demonstrate promising results but face significant challenges when transitioning to mass production environments. The primary scaling obstacles include maintaining uniform coating thickness, ensuring consistent photocatalytic activity across large surface areas, and developing cost-effective production techniques that can be integrated into existing manufacturing processes.

Several manufacturing approaches show potential for industrial-scale implementation. Sol-gel deposition techniques offer versatility and relatively low equipment costs, making them suitable for coating diverse substrate geometries. Physical vapor deposition provides excellent coating uniformity but requires substantial capital investment. Emerging spray-coating technologies present a promising middle ground, combining reasonable equipment costs with acceptable coating consistency for large-area applications.

Cost considerations remain paramount for industrial adoption. Raw material expenses, particularly for noble metal-based photocatalysts like platinum or palladium-doped TiO2, constitute a significant portion of production costs. Recent research focusing on earth-abundant alternatives such as iron, copper, and nitrogen-doped photocatalysts shows promise for reducing material expenses while maintaining acceptable performance metrics. Energy consumption during manufacturing represents another substantial cost factor, particularly for high-temperature sintering processes required to achieve optimal crystallinity in certain photocatalytic formulations.

The industrial application potential spans numerous sectors. Marine and offshore industries could benefit significantly from photocatalytic coatings on ship hulls and underwater infrastructure, potentially reducing maintenance costs by 30-40% according to preliminary economic analyses. Building materials incorporating self-cleaning photocatalytic surfaces have demonstrated market traction in urban environments with high pollution levels. The healthcare sector presents another high-value application area, where photocatalytic surfaces could supplement existing sterilization protocols in hospitals and medical facilities.

Regulatory considerations will influence adoption timelines across different sectors. Environmental regulations generally favor photocatalytic technologies due to their reduced reliance on toxic biocides for anti-fouling applications. However, novel nanomaterials in certain photocatalytic formulations may face additional scrutiny regarding their environmental fate and potential health impacts, necessitating comprehensive safety assessments before widespread implementation.

Several manufacturing approaches show potential for industrial-scale implementation. Sol-gel deposition techniques offer versatility and relatively low equipment costs, making them suitable for coating diverse substrate geometries. Physical vapor deposition provides excellent coating uniformity but requires substantial capital investment. Emerging spray-coating technologies present a promising middle ground, combining reasonable equipment costs with acceptable coating consistency for large-area applications.

Cost considerations remain paramount for industrial adoption. Raw material expenses, particularly for noble metal-based photocatalysts like platinum or palladium-doped TiO2, constitute a significant portion of production costs. Recent research focusing on earth-abundant alternatives such as iron, copper, and nitrogen-doped photocatalysts shows promise for reducing material expenses while maintaining acceptable performance metrics. Energy consumption during manufacturing represents another substantial cost factor, particularly for high-temperature sintering processes required to achieve optimal crystallinity in certain photocatalytic formulations.

The industrial application potential spans numerous sectors. Marine and offshore industries could benefit significantly from photocatalytic coatings on ship hulls and underwater infrastructure, potentially reducing maintenance costs by 30-40% according to preliminary economic analyses. Building materials incorporating self-cleaning photocatalytic surfaces have demonstrated market traction in urban environments with high pollution levels. The healthcare sector presents another high-value application area, where photocatalytic surfaces could supplement existing sterilization protocols in hospitals and medical facilities.

Regulatory considerations will influence adoption timelines across different sectors. Environmental regulations generally favor photocatalytic technologies due to their reduced reliance on toxic biocides for anti-fouling applications. However, novel nanomaterials in certain photocatalytic formulations may face additional scrutiny regarding their environmental fate and potential health impacts, necessitating comprehensive safety assessments before widespread implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!