Smart Responsive Coatings with Anti Fouling Function

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Anti-Fouling Coatings Background and Objectives

Smart anti-fouling coatings represent a significant advancement in surface protection technology, evolving from traditional passive coatings to dynamic, responsive systems. The development trajectory began in the 1970s with simple non-stick coatings and has progressed through several technological generations, culminating in today's smart responsive materials that can adapt to environmental changes and biological challenges.

The evolution of these coatings has been driven by increasing environmental regulations restricting toxic biocides, growing economic pressures from fouling-related costs in marine and industrial applications, and advancements in material science enabling novel surface functionalities. Current research focuses on creating surfaces that can respond to specific stimuli such as pH, temperature, light, or mechanical stress to prevent or release accumulated fouling.

Smart anti-fouling coatings aim to address the $15-30 billion annual global cost of biofouling in marine industries alone, while also finding applications in medical devices, food processing equipment, and water treatment systems. The market for these advanced coatings is projected to grow at a CAGR of 7.8% through 2028, highlighting their increasing economic significance.

The primary technical objectives in this field include developing coatings that demonstrate prolonged effectiveness without environmental harm, creating multi-functional surfaces that combine anti-fouling with other properties like corrosion resistance or self-healing capabilities, and designing systems that minimize maintenance requirements while maximizing service life.

A key challenge being addressed is the development of environmentally benign solutions that avoid the ecological damage caused by traditional biocide-based approaches. This has led to biomimetic strategies inspired by natural anti-fouling mechanisms found in marine organisms like sharks, mussels, and certain algae species.

Recent technological breakthroughs include stimuli-responsive polymers that change surface properties in response to environmental triggers, self-polishing copolymers that gradually erode to reveal fresh anti-fouling surfaces, and hybrid organic-inorganic nanocomposites that combine multiple anti-fouling mechanisms.

The ultimate goal of current research is to create a new generation of smart coatings that can autonomously detect fouling formation and respond appropriately, potentially through integration with IoT systems for real-time monitoring and adaptive response. These advanced materials promise to revolutionize surface protection across multiple industries while addressing critical sustainability concerns.

The evolution of these coatings has been driven by increasing environmental regulations restricting toxic biocides, growing economic pressures from fouling-related costs in marine and industrial applications, and advancements in material science enabling novel surface functionalities. Current research focuses on creating surfaces that can respond to specific stimuli such as pH, temperature, light, or mechanical stress to prevent or release accumulated fouling.

Smart anti-fouling coatings aim to address the $15-30 billion annual global cost of biofouling in marine industries alone, while also finding applications in medical devices, food processing equipment, and water treatment systems. The market for these advanced coatings is projected to grow at a CAGR of 7.8% through 2028, highlighting their increasing economic significance.

The primary technical objectives in this field include developing coatings that demonstrate prolonged effectiveness without environmental harm, creating multi-functional surfaces that combine anti-fouling with other properties like corrosion resistance or self-healing capabilities, and designing systems that minimize maintenance requirements while maximizing service life.

A key challenge being addressed is the development of environmentally benign solutions that avoid the ecological damage caused by traditional biocide-based approaches. This has led to biomimetic strategies inspired by natural anti-fouling mechanisms found in marine organisms like sharks, mussels, and certain algae species.

Recent technological breakthroughs include stimuli-responsive polymers that change surface properties in response to environmental triggers, self-polishing copolymers that gradually erode to reveal fresh anti-fouling surfaces, and hybrid organic-inorganic nanocomposites that combine multiple anti-fouling mechanisms.

The ultimate goal of current research is to create a new generation of smart coatings that can autonomously detect fouling formation and respond appropriately, potentially through integration with IoT systems for real-time monitoring and adaptive response. These advanced materials promise to revolutionize surface protection across multiple industries while addressing critical sustainability concerns.

Market Analysis for Anti-Fouling Solutions

The global anti-fouling solutions market is experiencing robust growth, driven by increasing maritime activities and growing awareness about the economic and environmental impacts of biofouling. Currently valued at approximately 7.1 billion USD in 2023, the market is projected to reach 9.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.7%.

Marine transportation remains the dominant application segment, accounting for nearly 58% of the total market share. This dominance stems from the critical need to maintain vessel efficiency and reduce fuel consumption, as biofouling can increase drag by up to 40% and fuel consumption by 30%. The International Maritime Organization's (IMO) stringent regulations on invasive species transfer have further accelerated demand for effective anti-fouling solutions in this sector.

Regionally, Asia-Pacific leads the market with 39% share, followed by Europe (27%) and North America (21%). China, South Korea, and Japan are particularly significant markets due to their extensive shipbuilding industries and maritime activities. The Middle East and Africa regions are showing the fastest growth rates, albeit from smaller bases.

Consumer preferences are shifting notably toward environmentally friendly solutions. Traditional copper and tributyltin (TBT) based coatings are facing regulatory restrictions due to their environmental toxicity. This has created substantial market opportunities for smart responsive coatings that offer effective anti-fouling properties without environmental harm. The eco-friendly segment is growing at 9.3% annually, outpacing the overall market.

Industry analysis reveals significant price sensitivity among end-users, particularly in commercial shipping where operational costs are carefully managed. Premium solutions command approximately 15-20% higher prices but must demonstrate clear return on investment through extended service intervals or improved performance metrics.

The healthcare and aquaculture sectors represent emerging high-growth niches, with respective annual growth rates of 8.2% and 7.9%. Medical device applications, particularly for implantable devices and catheters, are driving innovation in biocompatible anti-fouling technologies. Similarly, aquaculture operations increasingly require sustainable solutions to maintain infrastructure without harming cultivated species.

Market forecasts indicate that smart responsive coatings with switchable properties could capture up to 25% of the total anti-fouling market by 2030, representing a significant opportunity for innovation. The ability to respond to environmental triggers while maintaining long-term effectiveness addresses the key market need for solutions that balance performance, durability, environmental safety, and cost-effectiveness.

Marine transportation remains the dominant application segment, accounting for nearly 58% of the total market share. This dominance stems from the critical need to maintain vessel efficiency and reduce fuel consumption, as biofouling can increase drag by up to 40% and fuel consumption by 30%. The International Maritime Organization's (IMO) stringent regulations on invasive species transfer have further accelerated demand for effective anti-fouling solutions in this sector.

Regionally, Asia-Pacific leads the market with 39% share, followed by Europe (27%) and North America (21%). China, South Korea, and Japan are particularly significant markets due to their extensive shipbuilding industries and maritime activities. The Middle East and Africa regions are showing the fastest growth rates, albeit from smaller bases.

Consumer preferences are shifting notably toward environmentally friendly solutions. Traditional copper and tributyltin (TBT) based coatings are facing regulatory restrictions due to their environmental toxicity. This has created substantial market opportunities for smart responsive coatings that offer effective anti-fouling properties without environmental harm. The eco-friendly segment is growing at 9.3% annually, outpacing the overall market.

Industry analysis reveals significant price sensitivity among end-users, particularly in commercial shipping where operational costs are carefully managed. Premium solutions command approximately 15-20% higher prices but must demonstrate clear return on investment through extended service intervals or improved performance metrics.

The healthcare and aquaculture sectors represent emerging high-growth niches, with respective annual growth rates of 8.2% and 7.9%. Medical device applications, particularly for implantable devices and catheters, are driving innovation in biocompatible anti-fouling technologies. Similarly, aquaculture operations increasingly require sustainable solutions to maintain infrastructure without harming cultivated species.

Market forecasts indicate that smart responsive coatings with switchable properties could capture up to 25% of the total anti-fouling market by 2030, representing a significant opportunity for innovation. The ability to respond to environmental triggers while maintaining long-term effectiveness addresses the key market need for solutions that balance performance, durability, environmental safety, and cost-effectiveness.

Current Challenges in Smart Responsive Coating Technology

Despite significant advancements in smart responsive coating technologies with anti-fouling properties, several critical challenges continue to impede widespread industrial adoption and optimal performance. The durability of these coatings remains a primary concern, with many current formulations exhibiting performance degradation under prolonged exposure to harsh marine environments, UV radiation, and mechanical abrasion. Most smart responsive coatings demonstrate effective anti-fouling capabilities initially but fail to maintain these properties beyond 1-2 years in real-world applications, falling short of the 5+ year industry standard.

The stimuli-response mechanisms, while innovative, often present reliability issues. Environmental triggers such as pH, temperature, or light can vary unpredictably in natural settings, leading to inconsistent coating performance. The challenge lies in developing robust response mechanisms that maintain functionality across diverse and fluctuating environmental conditions without compromising the coating's primary protective functions.

Scalability presents another significant hurdle. Laboratory-scale successes frequently encounter difficulties when transitioning to industrial-scale production. The complex chemistries involved in smart responsive coatings often require precise control over reaction conditions, which becomes increasingly challenging at larger scales. Additionally, the specialized materials and processing techniques necessary for these advanced coatings contribute to prohibitively high production costs, limiting commercial viability.

Biocompatibility concerns persist, particularly for applications in sensitive environments. Many effective anti-fouling mechanisms rely on biocidal components or surface properties that may inadvertently impact non-target organisms. Regulatory frameworks worldwide are increasingly restricting traditional biocidal approaches, necessitating the development of environmentally benign alternatives that maintain efficacy without ecological harm.

The multifunctional requirements of modern coating applications further complicate development efforts. Beyond anti-fouling properties, coatings must often simultaneously provide corrosion protection, wear resistance, and aesthetic qualities. Balancing these sometimes competing requirements without compromising the smart responsive functionality represents a significant engineering challenge.

Integration with existing coating systems and application technologies poses additional difficulties. Many promising smart responsive materials require application methods incompatible with established industrial processes, creating barriers to adoption. The development of formulations compatible with conventional spray, brush, or dip-coating techniques would significantly enhance commercial potential.

Finally, performance standardization and testing methodologies remain underdeveloped. The absence of universally accepted protocols for evaluating smart responsive anti-fouling coatings makes comparative assessment challenging and hinders market acceptance. Establishing reliable accelerated testing methods that accurately predict long-term performance would greatly facilitate technology advancement and commercial adoption.

The stimuli-response mechanisms, while innovative, often present reliability issues. Environmental triggers such as pH, temperature, or light can vary unpredictably in natural settings, leading to inconsistent coating performance. The challenge lies in developing robust response mechanisms that maintain functionality across diverse and fluctuating environmental conditions without compromising the coating's primary protective functions.

Scalability presents another significant hurdle. Laboratory-scale successes frequently encounter difficulties when transitioning to industrial-scale production. The complex chemistries involved in smart responsive coatings often require precise control over reaction conditions, which becomes increasingly challenging at larger scales. Additionally, the specialized materials and processing techniques necessary for these advanced coatings contribute to prohibitively high production costs, limiting commercial viability.

Biocompatibility concerns persist, particularly for applications in sensitive environments. Many effective anti-fouling mechanisms rely on biocidal components or surface properties that may inadvertently impact non-target organisms. Regulatory frameworks worldwide are increasingly restricting traditional biocidal approaches, necessitating the development of environmentally benign alternatives that maintain efficacy without ecological harm.

The multifunctional requirements of modern coating applications further complicate development efforts. Beyond anti-fouling properties, coatings must often simultaneously provide corrosion protection, wear resistance, and aesthetic qualities. Balancing these sometimes competing requirements without compromising the smart responsive functionality represents a significant engineering challenge.

Integration with existing coating systems and application technologies poses additional difficulties. Many promising smart responsive materials require application methods incompatible with established industrial processes, creating barriers to adoption. The development of formulations compatible with conventional spray, brush, or dip-coating techniques would significantly enhance commercial potential.

Finally, performance standardization and testing methodologies remain underdeveloped. The absence of universally accepted protocols for evaluating smart responsive anti-fouling coatings makes comparative assessment challenging and hinders market acceptance. Establishing reliable accelerated testing methods that accurately predict long-term performance would greatly facilitate technology advancement and commercial adoption.

Current Smart Anti-Fouling Coating Solutions

01 Stimuli-responsive polymer coatings

Smart coatings that respond to environmental stimuli such as temperature, pH, or light can be used for anti-fouling applications. These polymer-based coatings change their properties in response to external triggers, causing the release of accumulated fouling or preventing attachment of organisms. The responsive nature allows for self-cleaning surfaces that can adapt to different environmental conditions, making them effective for long-term anti-fouling protection.- Stimuli-responsive polymers for anti-fouling coatings: Smart coatings incorporating stimuli-responsive polymers can change their properties in response to environmental triggers such as temperature, pH, or light. These polymers can switch between hydrophilic and hydrophobic states, allowing the coating to actively repel fouling organisms or facilitate their easy removal. The responsive nature of these polymers creates a dynamic surface that prevents the attachment and growth of biological contaminants, making them effective for long-term anti-fouling applications.

- Nanostructured surfaces with anti-fouling properties: Coatings with engineered nanostructures can prevent biofouling through physical deterrence mechanisms. These surfaces mimic natural anti-fouling surfaces like lotus leaves or shark skin, creating topographies that reduce the contact area available for fouling organisms. Nanostructured coatings can incorporate features such as nanopillars, nanopores, or hierarchical structures that disrupt the attachment mechanisms of microorganisms and marine life, providing effective anti-fouling protection without relying solely on chemical biocides.

- Self-healing anti-fouling coatings: Self-healing smart coatings can repair damage automatically, maintaining their anti-fouling performance over extended periods. These coatings contain encapsulated healing agents that are released when the coating is scratched or damaged, restoring the protective barrier. The self-healing mechanism extends the service life of the coating and ensures continuous anti-fouling protection even in harsh environments where mechanical damage is common, reducing maintenance requirements and improving long-term performance.

- Environmentally-friendly anti-fouling technologies: Eco-friendly smart anti-fouling coatings utilize non-toxic mechanisms to prevent biofouling without harming marine ecosystems. These technologies include biodegradable polymers, natural enzymes that disrupt biofilm formation, and biomimetic approaches that avoid the use of harmful biocides. By incorporating sustainable materials and mechanisms, these coatings provide effective fouling protection while minimizing environmental impact, addressing growing regulatory concerns about traditional anti-fouling compounds.

- Multi-functional anti-fouling coating systems: Advanced anti-fouling coatings combine multiple protective mechanisms in a single system to enhance performance and durability. These multi-functional coatings may integrate anti-corrosion properties, wear resistance, and anti-fouling capabilities through layered structures or hybrid materials. By addressing multiple degradation pathways simultaneously, these smart coating systems provide comprehensive protection for surfaces in challenging environments such as marine settings, industrial equipment, or medical devices, extending service life and reducing maintenance costs.

02 Surface modification with hydrophobic/hydrophilic properties

Anti-fouling coatings can be designed with controlled surface energy through hydrophobic or hydrophilic modifications. These coatings create surfaces that either repel water and contaminants or form a hydration layer that prevents fouling organisms from attaching. By engineering the surface chemistry and topography, these coatings can significantly reduce biofouling in marine environments and other applications where surface contamination is problematic.Expand Specific Solutions03 Nanoparticle-enhanced anti-fouling coatings

Incorporating nanoparticles such as silver, copper, zinc oxide, or titanium dioxide into coating formulations enhances their anti-fouling properties. These nanoparticles can provide antimicrobial effects, photocatalytic self-cleaning capabilities, or modify surface topography to prevent organism attachment. The nanostructured surfaces create physical barriers that inhibit fouling while maintaining the coating's durability and effectiveness over extended periods.Expand Specific Solutions04 Environmentally friendly anti-fouling technologies

Eco-friendly alternatives to traditional biocide-based anti-fouling coatings utilize natural compounds, biodegradable polymers, or biomimetic approaches. These technologies provide effective fouling prevention without releasing harmful substances into the environment. Inspired by natural anti-fouling mechanisms found in marine organisms, these coatings can incorporate enzymes, peptides, or other biological compounds that disrupt the fouling process without environmental toxicity.Expand Specific Solutions05 Self-healing and regenerative anti-fouling coatings

Advanced coating systems with self-healing capabilities can repair damage and maintain anti-fouling performance over time. These coatings contain encapsulated healing agents that are released when the coating is damaged, or they incorporate materials that can regenerate their surface properties. This technology extends the service life of anti-fouling coatings and reduces maintenance requirements for marine vessels, underwater structures, and industrial equipment exposed to fouling conditions.Expand Specific Solutions

Key Industry Players in Smart Coating Development

The smart responsive anti-fouling coatings market is currently in a growth phase, with increasing demand across marine, medical, and industrial sectors. The global market size is estimated to reach $5-7 billion by 2025, growing at 4-6% CAGR. Technologically, the field shows varying maturity levels, with established players like Shin-Etsu Chemical, Nippon Paint, and Dow Silicones offering commercial solutions, while research institutions such as Zhejiang University, HKUST, and Naval Research Laboratory drive innovation in next-generation responsive coatings. PPG Industries and FUJIFILM are advancing industrial applications, while specialized players like Shanghai Nano Micro Coating and AKITA INNOVATIONS focus on niche segments. The competitive landscape features strategic collaborations between academic institutions and industry leaders to accelerate commercialization of environmentally friendly anti-fouling technologies.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative smart responsive anti-fouling coatings based on stimuli-responsive polymer brushes grafted onto various substrate materials. Their approach utilizes temperature-responsive polymers like poly(N-isopropylacrylamide) that undergo reversible phase transitions, creating surfaces that can switch between fouling-release and fouling-resistant properties. The university's research team has pioneered the incorporation of photosensitive molecules that enable light-triggered changes in surface wettability and adhesion properties. Their coating systems feature multi-functional nanoparticles with core-shell structures that provide both mechanical durability and controlled release of environmentally benign anti-fouling agents. Zhejiang University has also developed bio-inspired microstructured surfaces that mimic natural anti-fouling organisms, combined with responsive polymer coatings to create hierarchical structures with enhanced anti-fouling performance across diverse marine environments.

Strengths: Highly innovative approaches combining multiple anti-fouling mechanisms; excellent performance in laboratory and controlled field tests showing >90% reduction in fouling; environmentally friendly formulations meeting stringent ecological standards. Weaknesses: Limited large-scale commercial implementation to date; durability in real-world marine environments still being validated; higher production complexity compared to conventional anti-fouling solutions.

Nippon Paint Co., Ltd.

Technical Solution: Nippon Paint has developed innovative smart responsive anti-fouling coatings under their AQUATERRAS technology platform. Their approach utilizes biomimetic surface structures inspired by natural anti-fouling organisms like shark skin, combined with responsive polymer networks. The coating system features hydrophilic-hydrophobic switching capabilities triggered by changes in ionic concentration or pH levels in the surrounding water. Nippon's technology incorporates specially engineered microtopography that creates an unfavorable surface for organism settlement while maintaining hydrodynamic efficiency. Their coatings contain encapsulated natural repellents derived from marine organisms that are gradually released through hydrolysis mechanisms, providing sustained protection without harmful environmental effects. The company has also developed self-polishing copolymers with controlled erosion rates that continuously expose fresh anti-fouling surfaces, extending the effective lifetime of the coating system.

Strengths: Zero-biocide formulations meet stringent environmental regulations in sensitive marine areas; self-renewing surface maintains effectiveness for up to 5 years; reduced hull roughness improves vessel fuel efficiency by up to 8%. Weaknesses: Higher initial application costs compared to conventional solutions; requires specific surface preparation protocols; performance may vary depending on vessel operating conditions and geographical deployment areas.

Critical Patents and Research in Responsive Anti-Fouling Materials

Stimuli responsive self cleaning coating

PatentActiveIN3538MUM2012A

Innovation

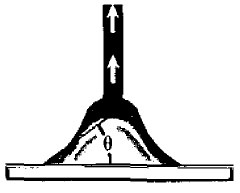

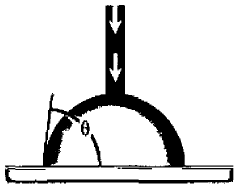

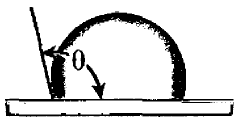

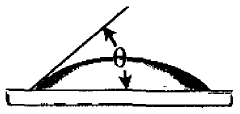

- A stimuli-responsive aqueous coating composition comprising a polymeric dispersion with an acrylic or fluorinated backbone, combined with hydrophobic and hydrophilic silicones and surface-treated particles, which exhibits low contact angle hysteresis and enhanced photocatalytic activity, allowing for reversible switching between superhydrophobic and superhydrophilic states in response to temperature, pH, and light variations.

Dynamic Coating of MF/UF Membranes for Fouling Mitigation

PatentInactiveUS20180169586A1

Innovation

- A dynamic anti-fouling layer is applied to MF/UF membranes, comprising a stimuli-responsive polymer layer and a dynamic protective layer formed by nanoparticles, which prevents foulant adhesion and can be easily removed during cleaning by applying physico-chemical stimuli, enhancing cleaning efficiency and extending membrane life.

Environmental Impact and Sustainability Considerations

The development of smart responsive coatings with anti-fouling functions necessitates careful consideration of their environmental impact and sustainability profile. Traditional anti-fouling solutions have historically relied on toxic biocides that leach into aquatic environments, causing significant ecological damage. Smart responsive coatings represent a paradigm shift toward more environmentally responsible approaches by utilizing physical or chemical mechanisms that minimize or eliminate the need for harmful substances.

Life cycle assessment (LCA) studies of these advanced coatings reveal promising environmental advantages compared to conventional alternatives. The reduced need for frequent cleaning and maintenance translates to lower water consumption and decreased use of harsh cleaning chemicals. Additionally, the extended service life of treated surfaces contributes to resource conservation by reducing the frequency of replacement and associated waste generation.

Biodegradability and biocompatibility have emerged as critical design parameters in the development of next-generation smart coatings. Research indicates that incorporating naturally derived polymers and biomimetic approaches can significantly reduce environmental persistence while maintaining effective anti-fouling performance. For instance, polysaccharide-based responsive coatings demonstrate favorable degradation profiles in marine environments without releasing harmful byproducts.

Regulatory frameworks worldwide are increasingly emphasizing the environmental credentials of anti-fouling technologies. The European Union's Biocidal Products Regulation and similar legislation in other regions have accelerated the transition away from environmentally harmful solutions. This regulatory landscape has catalyzed innovation in environmentally benign smart coating technologies that comply with increasingly stringent environmental protection standards.

Energy efficiency considerations also factor prominently in sustainability assessments. Smart responsive coatings can contribute to reduced energy consumption in various applications, such as marine vessels experiencing decreased drag resistance and consequently lower fuel consumption. Similarly, in building applications, these coatings can help maintain cleaner heat exchange surfaces, improving HVAC system efficiency.

Manufacturing processes for smart responsive coatings present both challenges and opportunities from a sustainability perspective. While some formulations require energy-intensive production methods or specialized materials with complex supply chains, advancements in green chemistry and sustainable manufacturing are progressively addressing these concerns. Water-based formulations and solvent-free processing techniques represent promising directions for reducing the environmental footprint of production processes.

The circular economy potential of smart responsive coatings warrants further exploration. Research into recyclable coating systems and recovery methods for valuable components could transform end-of-life management practices, closing material loops and minimizing waste. This approach aligns with global sustainability initiatives and offers economic advantages alongside environmental benefits.

Life cycle assessment (LCA) studies of these advanced coatings reveal promising environmental advantages compared to conventional alternatives. The reduced need for frequent cleaning and maintenance translates to lower water consumption and decreased use of harsh cleaning chemicals. Additionally, the extended service life of treated surfaces contributes to resource conservation by reducing the frequency of replacement and associated waste generation.

Biodegradability and biocompatibility have emerged as critical design parameters in the development of next-generation smart coatings. Research indicates that incorporating naturally derived polymers and biomimetic approaches can significantly reduce environmental persistence while maintaining effective anti-fouling performance. For instance, polysaccharide-based responsive coatings demonstrate favorable degradation profiles in marine environments without releasing harmful byproducts.

Regulatory frameworks worldwide are increasingly emphasizing the environmental credentials of anti-fouling technologies. The European Union's Biocidal Products Regulation and similar legislation in other regions have accelerated the transition away from environmentally harmful solutions. This regulatory landscape has catalyzed innovation in environmentally benign smart coating technologies that comply with increasingly stringent environmental protection standards.

Energy efficiency considerations also factor prominently in sustainability assessments. Smart responsive coatings can contribute to reduced energy consumption in various applications, such as marine vessels experiencing decreased drag resistance and consequently lower fuel consumption. Similarly, in building applications, these coatings can help maintain cleaner heat exchange surfaces, improving HVAC system efficiency.

Manufacturing processes for smart responsive coatings present both challenges and opportunities from a sustainability perspective. While some formulations require energy-intensive production methods or specialized materials with complex supply chains, advancements in green chemistry and sustainable manufacturing are progressively addressing these concerns. Water-based formulations and solvent-free processing techniques represent promising directions for reducing the environmental footprint of production processes.

The circular economy potential of smart responsive coatings warrants further exploration. Research into recyclable coating systems and recovery methods for valuable components could transform end-of-life management practices, closing material loops and minimizing waste. This approach aligns with global sustainability initiatives and offers economic advantages alongside environmental benefits.

Application Scenarios and Industry-Specific Requirements

Smart responsive coatings with anti-fouling functions find applications across diverse industries, each presenting unique requirements and operational challenges. In marine environments, these coatings are crucial for ship hulls, offshore structures, and underwater sensors, where they must withstand harsh saltwater conditions while preventing barnacle attachment and algae growth. The maritime industry specifically requires coatings that maintain effectiveness for extended periods (typically 3-5 years) without dry-docking, while also complying with increasingly stringent environmental regulations prohibiting toxic biocides.

The healthcare sector represents another critical application area, where anti-fouling coatings are essential for medical devices, implants, and hospital surfaces. These applications demand biocompatible materials that prevent bacterial biofilm formation while maintaining functionality in physiological environments. The coatings must not elicit immune responses or cytotoxicity, with particular emphasis on preventing catheter-associated infections and implant rejections.

In food processing industries, anti-fouling coatings applied to production equipment and surfaces must prevent bacterial contamination while meeting strict food safety regulations. These coatings need to withstand frequent cleaning cycles with aggressive sanitizing agents without degradation of their anti-fouling properties. Similarly, water treatment facilities require membranes and filtration systems with anti-fouling capabilities to maintain operational efficiency and reduce maintenance costs.

The energy sector presents unique challenges for smart responsive coatings, particularly in heat exchangers, cooling systems, and underwater power generation equipment. These applications require coatings that can function under extreme temperature variations while preventing both biological and mineral fouling. The economic impact of fouling in these systems is substantial, with efficiency losses estimated at 20-30% when fouling occurs.

Consumer electronics and optical devices represent emerging application areas, where anti-fingerprint and anti-smudge properties are increasingly valued. These applications require transparent coatings with minimal impact on device aesthetics while maintaining tactile functionality and user experience.

Cross-cutting requirements across all industries include durability under specific operational conditions, cost-effectiveness at scale, ease of application, and increasingly, environmental sustainability. The growing regulatory pressure to eliminate toxic compounds traditionally used in anti-fouling applications has accelerated research into smart responsive alternatives that can achieve performance targets without environmental harm. Additionally, industry-specific certification standards must be met, ranging from maritime classification societies to healthcare regulatory bodies and food safety certifications.

The healthcare sector represents another critical application area, where anti-fouling coatings are essential for medical devices, implants, and hospital surfaces. These applications demand biocompatible materials that prevent bacterial biofilm formation while maintaining functionality in physiological environments. The coatings must not elicit immune responses or cytotoxicity, with particular emphasis on preventing catheter-associated infections and implant rejections.

In food processing industries, anti-fouling coatings applied to production equipment and surfaces must prevent bacterial contamination while meeting strict food safety regulations. These coatings need to withstand frequent cleaning cycles with aggressive sanitizing agents without degradation of their anti-fouling properties. Similarly, water treatment facilities require membranes and filtration systems with anti-fouling capabilities to maintain operational efficiency and reduce maintenance costs.

The energy sector presents unique challenges for smart responsive coatings, particularly in heat exchangers, cooling systems, and underwater power generation equipment. These applications require coatings that can function under extreme temperature variations while preventing both biological and mineral fouling. The economic impact of fouling in these systems is substantial, with efficiency losses estimated at 20-30% when fouling occurs.

Consumer electronics and optical devices represent emerging application areas, where anti-fingerprint and anti-smudge properties are increasingly valued. These applications require transparent coatings with minimal impact on device aesthetics while maintaining tactile functionality and user experience.

Cross-cutting requirements across all industries include durability under specific operational conditions, cost-effectiveness at scale, ease of application, and increasingly, environmental sustainability. The growing regulatory pressure to eliminate toxic compounds traditionally used in anti-fouling applications has accelerated research into smart responsive alternatives that can achieve performance targets without environmental harm. Additionally, industry-specific certification standards must be met, ranging from maritime classification societies to healthcare regulatory bodies and food safety certifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!