Fluorinated Surface Coatings for Anti Fouling Applications

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluorinated Coatings Background and Objectives

Fluorinated surface coatings have emerged as a significant technological advancement in the field of anti-fouling applications over the past several decades. These specialized coatings leverage the unique properties of fluorinated compounds, particularly their low surface energy characteristics, to create surfaces that resist the adhesion of contaminants ranging from biological organisms to industrial deposits. The evolution of this technology can be traced back to the mid-20th century with the discovery of polytetrafluoroethylene (PTFE), commonly known as Teflon, which demonstrated remarkable non-stick properties.

The development trajectory of fluorinated coatings has been characterized by continuous innovation, moving from simple fluoropolymer applications to sophisticated multi-functional coating systems. Early iterations focused primarily on hydrophobicity, while contemporary research has expanded to incorporate additional properties such as oleophobicity, durability, transparency, and environmental sustainability. This technological progression has been driven by increasing demands across various industries including marine, medical, food processing, and architectural applications.

Current research objectives in fluorinated anti-fouling coatings center on addressing several key challenges. Foremost among these is the development of environmentally benign alternatives to traditional fluorinated compounds, particularly those containing long-chain perfluoroalkyl substances (PFAS) which have raised significant environmental and health concerns. Researchers aim to maintain or enhance performance characteristics while reducing environmental impact through novel molecular designs and alternative chemistries.

Another critical objective involves improving the longevity and mechanical durability of these coatings under harsh operational conditions. Marine applications, for instance, require coatings that can withstand prolonged exposure to saltwater, UV radiation, and mechanical abrasion while maintaining their anti-fouling properties. This necessitates innovations in both the chemical composition and physical structure of the coatings.

The integration of fluorinated coatings with other emerging technologies represents a promising frontier. Researchers are exploring synergistic combinations with antimicrobial agents, self-healing materials, and stimuli-responsive polymers to create next-generation coatings with enhanced functionality and adaptability. These hybrid approaches aim to overcome the limitations of traditional fluorinated coatings while expanding their application range.

The ultimate technological goal in this field is to develop universal anti-fouling solutions that combine exceptional performance with sustainability, cost-effectiveness, and ease of application. This involves not only material innovations but also advances in application methods, curing processes, and quality control techniques to ensure consistent performance across diverse substrates and environmental conditions.

The development trajectory of fluorinated coatings has been characterized by continuous innovation, moving from simple fluoropolymer applications to sophisticated multi-functional coating systems. Early iterations focused primarily on hydrophobicity, while contemporary research has expanded to incorporate additional properties such as oleophobicity, durability, transparency, and environmental sustainability. This technological progression has been driven by increasing demands across various industries including marine, medical, food processing, and architectural applications.

Current research objectives in fluorinated anti-fouling coatings center on addressing several key challenges. Foremost among these is the development of environmentally benign alternatives to traditional fluorinated compounds, particularly those containing long-chain perfluoroalkyl substances (PFAS) which have raised significant environmental and health concerns. Researchers aim to maintain or enhance performance characteristics while reducing environmental impact through novel molecular designs and alternative chemistries.

Another critical objective involves improving the longevity and mechanical durability of these coatings under harsh operational conditions. Marine applications, for instance, require coatings that can withstand prolonged exposure to saltwater, UV radiation, and mechanical abrasion while maintaining their anti-fouling properties. This necessitates innovations in both the chemical composition and physical structure of the coatings.

The integration of fluorinated coatings with other emerging technologies represents a promising frontier. Researchers are exploring synergistic combinations with antimicrobial agents, self-healing materials, and stimuli-responsive polymers to create next-generation coatings with enhanced functionality and adaptability. These hybrid approaches aim to overcome the limitations of traditional fluorinated coatings while expanding their application range.

The ultimate technological goal in this field is to develop universal anti-fouling solutions that combine exceptional performance with sustainability, cost-effectiveness, and ease of application. This involves not only material innovations but also advances in application methods, curing processes, and quality control techniques to ensure consistent performance across diverse substrates and environmental conditions.

Market Analysis for Anti-Fouling Solutions

The global anti-fouling solutions market is experiencing robust growth, driven by increasing maritime activities and growing awareness about the economic and environmental impacts of biofouling. Currently valued at approximately 6.7 billion USD in 2023, the market is projected to reach 9.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.9%.

Marine applications dominate the anti-fouling market, accounting for nearly 65% of the total market share. This segment includes coatings for ships, offshore structures, and aquaculture equipment. The shipping industry alone faces annual losses of 7-12 billion USD due to increased fuel consumption caused by hull fouling, creating a substantial demand for effective anti-fouling solutions.

Fluorinated surface coatings represent a premium segment within this market, currently holding about 18% market share but growing at an accelerated rate of 9.3% annually. These advanced coatings command higher prices due to their superior performance characteristics, including extended service life and reduced environmental impact compared to traditional copper-based solutions.

Regionally, Asia-Pacific leads the market with 42% share, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 28% market share, where stringent environmental regulations are accelerating the adoption of eco-friendly fluorinated coatings. North America accounts for 21% of the market, with particular growth in specialized industrial applications.

Customer segmentation reveals distinct needs across different sectors. Commercial shipping operators prioritize long-term cost efficiency and compliance with international regulations. Naval defense seeks high-performance solutions with minimal maintenance requirements. The offshore energy sector demands extreme durability under harsh conditions, while aquaculture requires non-toxic formulations safe for food production.

Market drivers include increasingly strict environmental regulations limiting the use of biocides, rising fuel costs making fuel-efficient solutions more attractive, and growing awareness of invasive species transport via biofouling. The International Maritime Organization's (IMO) Biofouling Guidelines and regional regulations like the EU's Biocidal Products Regulation are reshaping market demands toward more sustainable solutions.

Pricing trends indicate premium positioning for fluorinated coatings, with costs 30-40% higher than conventional alternatives but offering lifecycle cost advantages through extended service intervals and improved performance. The market shows willingness to pay this premium when total ownership costs demonstrate clear advantages.

AI-driven predictive maintenance and integration with smart coating technologies represent emerging opportunities, with potential to create new value-added service models around anti-fouling solutions.

Marine applications dominate the anti-fouling market, accounting for nearly 65% of the total market share. This segment includes coatings for ships, offshore structures, and aquaculture equipment. The shipping industry alone faces annual losses of 7-12 billion USD due to increased fuel consumption caused by hull fouling, creating a substantial demand for effective anti-fouling solutions.

Fluorinated surface coatings represent a premium segment within this market, currently holding about 18% market share but growing at an accelerated rate of 9.3% annually. These advanced coatings command higher prices due to their superior performance characteristics, including extended service life and reduced environmental impact compared to traditional copper-based solutions.

Regionally, Asia-Pacific leads the market with 42% share, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 28% market share, where stringent environmental regulations are accelerating the adoption of eco-friendly fluorinated coatings. North America accounts for 21% of the market, with particular growth in specialized industrial applications.

Customer segmentation reveals distinct needs across different sectors. Commercial shipping operators prioritize long-term cost efficiency and compliance with international regulations. Naval defense seeks high-performance solutions with minimal maintenance requirements. The offshore energy sector demands extreme durability under harsh conditions, while aquaculture requires non-toxic formulations safe for food production.

Market drivers include increasingly strict environmental regulations limiting the use of biocides, rising fuel costs making fuel-efficient solutions more attractive, and growing awareness of invasive species transport via biofouling. The International Maritime Organization's (IMO) Biofouling Guidelines and regional regulations like the EU's Biocidal Products Regulation are reshaping market demands toward more sustainable solutions.

Pricing trends indicate premium positioning for fluorinated coatings, with costs 30-40% higher than conventional alternatives but offering lifecycle cost advantages through extended service intervals and improved performance. The market shows willingness to pay this premium when total ownership costs demonstrate clear advantages.

AI-driven predictive maintenance and integration with smart coating technologies represent emerging opportunities, with potential to create new value-added service models around anti-fouling solutions.

Current State and Challenges in Fluorinated Surface Technology

Fluorinated surface coatings have emerged as a leading technology in anti-fouling applications, with significant advancements achieved globally over the past decade. Currently, these coatings leverage the unique properties of fluoropolymers, including low surface energy, chemical inertness, and thermal stability, to create surfaces that resist adhesion of biological and chemical contaminants. The global market for fluorinated anti-fouling coatings reached approximately $3.2 billion in 2022, with a compound annual growth rate of 5.7%, indicating robust industrial adoption.

Despite these achievements, the technology faces several critical challenges. Environmental concerns represent the most pressing issue, as traditional fluorinated compounds, particularly those containing long-chain perfluoroalkyl substances (PFAS), have been linked to bioaccumulation and potential toxicity. Regulatory bodies worldwide, including the European Chemicals Agency and the U.S. Environmental Protection Agency, have implemented increasingly stringent restrictions on these materials, necessitating the development of more environmentally benign alternatives.

Technical limitations also persist in current fluorinated coating technologies. Durability remains a significant challenge, with many coatings exhibiting performance degradation under harsh conditions such as high-pressure water jets, abrasive environments, or prolonged UV exposure. Studies indicate that most commercial fluorinated coatings lose 30-50% of their anti-fouling efficacy after 12-18 months of real-world deployment, particularly in marine environments.

Scalability presents another substantial hurdle. Current manufacturing processes for high-performance fluorinated coatings often involve complex multi-step procedures, specialized equipment, and controlled environments, resulting in high production costs. This limits widespread adoption across industries where cost-sensitivity is paramount, such as consumer goods and large-scale infrastructure.

Geographically, the development of advanced fluorinated coating technologies shows distinct patterns. North America and Europe lead in research output and patent filings, with approximately 65% of innovations originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, have demonstrated accelerated growth in both research activities and commercial applications over the past five years, with annual patent filings increasing by 23% compared to the previous decade.

The integration of fluorinated coatings with other emerging technologies represents both a challenge and opportunity. Current research indicates promising synergies with nanotechnology, smart materials, and sustainable chemistry, though these interdisciplinary approaches remain predominantly at laboratory scale rather than commercial implementation. The technical complexity of these hybrid systems presents significant barriers to mass production and standardization.

Despite these achievements, the technology faces several critical challenges. Environmental concerns represent the most pressing issue, as traditional fluorinated compounds, particularly those containing long-chain perfluoroalkyl substances (PFAS), have been linked to bioaccumulation and potential toxicity. Regulatory bodies worldwide, including the European Chemicals Agency and the U.S. Environmental Protection Agency, have implemented increasingly stringent restrictions on these materials, necessitating the development of more environmentally benign alternatives.

Technical limitations also persist in current fluorinated coating technologies. Durability remains a significant challenge, with many coatings exhibiting performance degradation under harsh conditions such as high-pressure water jets, abrasive environments, or prolonged UV exposure. Studies indicate that most commercial fluorinated coatings lose 30-50% of their anti-fouling efficacy after 12-18 months of real-world deployment, particularly in marine environments.

Scalability presents another substantial hurdle. Current manufacturing processes for high-performance fluorinated coatings often involve complex multi-step procedures, specialized equipment, and controlled environments, resulting in high production costs. This limits widespread adoption across industries where cost-sensitivity is paramount, such as consumer goods and large-scale infrastructure.

Geographically, the development of advanced fluorinated coating technologies shows distinct patterns. North America and Europe lead in research output and patent filings, with approximately 65% of innovations originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, have demonstrated accelerated growth in both research activities and commercial applications over the past five years, with annual patent filings increasing by 23% compared to the previous decade.

The integration of fluorinated coatings with other emerging technologies represents both a challenge and opportunity. Current research indicates promising synergies with nanotechnology, smart materials, and sustainable chemistry, though these interdisciplinary approaches remain predominantly at laboratory scale rather than commercial implementation. The technical complexity of these hybrid systems presents significant barriers to mass production and standardization.

Current Fluorinated Anti-Fouling Technical Solutions

01 Fluoropolymer coatings for marine anti-fouling

Fluoropolymer coatings provide excellent anti-fouling properties for marine applications due to their low surface energy and chemical resistance. These coatings create a smooth, non-stick surface that prevents marine organisms from adhering to ship hulls and other submerged structures. The hydrophobic and oleophobic nature of fluorinated polymers reduces the attachment of biological materials, resulting in improved vessel performance, reduced fuel consumption, and extended maintenance intervals.- Fluoropolymer coatings for marine anti-fouling: Fluoropolymer coatings provide excellent anti-fouling properties for marine applications due to their low surface energy and chemical resistance. These coatings create a smooth, non-stick surface that prevents marine organisms from adhering to ship hulls and other underwater structures. The hydrophobic and oleophobic nature of fluorinated polymers reduces biofouling accumulation, improving vessel efficiency and reducing maintenance costs.

- Perfluoropolyether-based anti-fouling coatings: Perfluoropolyether (PFPE) compounds are utilized in anti-fouling coatings due to their exceptional chemical stability and low surface energy. These fluorinated materials form durable coatings that resist degradation in harsh marine environments while preventing the attachment of biological organisms. PFPE-based coatings can be applied to various substrates and provide long-lasting protection against biofouling without releasing harmful substances into the environment.

- Fluorinated silane surface treatments: Fluorinated silanes are employed as surface treatments to impart anti-fouling properties to various materials. These compounds form covalent bonds with substrate surfaces while presenting fluorinated groups at the interface, creating a low-energy, water-repellent barrier. The combination of silane chemistry for adhesion and fluorinated groups for surface properties results in durable coatings that resist biological fouling in marine and industrial applications.

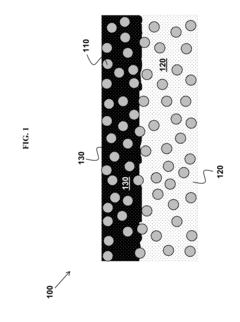

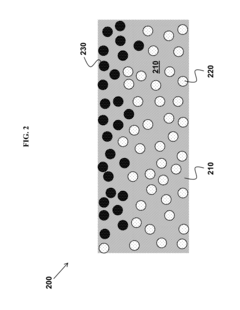

- Fluorinated nanoparticle composite coatings: Incorporating fluorinated nanoparticles into coating formulations enhances anti-fouling performance by creating hierarchical surface structures with superhydrophobic properties. These composite coatings combine the low surface energy of fluorinated compounds with the textured topography provided by nanoparticles, resulting in surfaces that minimize contact area for fouling organisms. The nanostructured fluorinated coatings demonstrate improved durability and fouling resistance compared to conventional smooth coatings.

- Environmentally friendly fluorinated anti-fouling systems: Recent developments focus on environmentally friendly fluorinated anti-fouling systems that maintain effectiveness while reducing ecological impact. These systems utilize novel fluorinated polymers and compounds that resist fouling without releasing biocides or harmful substances. The coatings rely on physical fouling deterrence through surface properties rather than chemical toxicity, making them suitable for sensitive marine environments and compliant with increasingly stringent environmental regulations.

02 Perfluoropolyether-based anti-fouling coatings

Perfluoropolyether (PFPE) compounds are utilized in anti-fouling coatings due to their exceptional chemical stability and low surface energy. These fluorinated materials form highly repellent surfaces that resist biofouling in various environments. PFPE-based coatings can be applied to different substrates and provide long-lasting protection against the adhesion of microorganisms, algae, and other fouling agents. The unique molecular structure of PFPE compounds contributes to their superior performance in preventing biological contamination.Expand Specific Solutions03 Fluorinated silane surface treatments

Fluorinated silane compounds are effective for creating anti-fouling surface treatments through the formation of self-assembled monolayers. These treatments modify the surface properties of various materials by introducing fluorinated groups that reduce surface energy and increase hydrophobicity. The silane functionality allows for strong chemical bonding to substrates, while the fluorinated portions provide the anti-fouling properties. These treatments can be applied to glass, metals, ceramics, and other materials to prevent biological fouling and contamination.Expand Specific Solutions04 Fluorinated nanoparticle composite coatings

Incorporating fluorinated nanoparticles into coating formulations enhances anti-fouling performance through the creation of hierarchical surface structures. These composite coatings combine the low surface energy of fluorinated compounds with the unique properties of nanoparticles to create surfaces with both micro and nano-scale roughness. This hierarchical structure, inspired by natural anti-fouling surfaces like lotus leaves, significantly reduces the contact area available for biological adhesion. The nanoparticles also improve the mechanical durability and abrasion resistance of the anti-fouling coatings.Expand Specific Solutions05 Environmentally friendly fluorinated anti-fouling technologies

Recent developments in fluorinated anti-fouling coatings focus on environmentally friendly alternatives to traditional biocide-containing systems. These technologies utilize specific fluorinated polymers and compounds that prevent fouling through physical means rather than toxic effects. By carefully controlling the surface chemistry and topography, these coatings minimize environmental impact while maintaining effective anti-fouling performance. Research in this area aims to address regulatory concerns about conventional anti-fouling agents while providing sustainable solutions for marine and industrial applications.Expand Specific Solutions

Leading Companies and Research Institutions in Fluorinated Coatings

The anti-fouling fluorinated surface coatings market is currently in a growth phase, driven by increasing demand across marine, industrial, and medical sectors. The global market size is estimated to exceed $2 billion, with projected annual growth of 5-7%. Leading players include established chemical giants like Shin-Etsu Chemical, AGC, and DAIKIN INDUSTRIES, who possess mature fluoropolymer technologies. The Chemours Co. and Solvay Specialty Polymers demonstrate strong technical capabilities in high-performance fluorinated materials. Asian manufacturers, particularly Japanese firms like DIC Corp. and FUJIFILM, are rapidly advancing their technological portfolios. Research institutions including Naval Research Laboratory and Cornell University contribute significant innovations, while companies like PPG Industries and Akzo Nobel leverage their coating expertise to develop specialized anti-fouling solutions with enhanced durability and environmental compliance.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu has developed innovative fluorinated anti-fouling coatings based on their expertise in silicone and fluorosilicone chemistry. Their approach combines fluoroalkyl functional silanes with silicone backbones to create hybrid materials with exceptional durability and fouling resistance. Shin-Etsu's technology utilizes trifluoropropyl-modified silicones that create surfaces with water contact angles exceeding 105° while maintaining transparency and UV resistance. Their coatings incorporate a unique cross-linking mechanism that forms covalent bonds with substrate materials, ensuring adhesion even in wet environments with demonstrated durability exceeding 3,000 hours in salt spray testing. Shin-Etsu has pioneered fluorosilicone copolymers with precisely controlled segment distribution, creating surfaces with nanoscale heterogeneity that disrupts protein adsorption and cell attachment mechanisms. Recent innovations include fluorinated silicone quaternary ammonium compounds that combine passive fouling resistance with active antimicrobial properties, showing >99.9% reduction in bacterial colonization in standardized testing. Their coatings have found particular success in optical applications where transparency and fouling resistance must be combined with long-term environmental stability.

Strengths: World-leading expertise in silicone chemistry; vertically integrated manufacturing from silicon metal to finished coatings; strong position in electronics and optical applications; excellent weathering and UV resistance properties. Weaknesses: Less fluorine content than pure fluoropolymer competitors may limit ultimate repellency performance; higher cost compared to conventional silicones; some formulations require specialized curing conditions.

Solvay Specialty Polymers Italy SpA

Technical Solution: Solvay has developed sophisticated fluorinated anti-fouling coatings based on their Tecnoflon® and Algoflon® fluoropolymer platforms. Their approach utilizes partially fluorinated copolymers that balance performance with cost-effectiveness and environmental considerations. Solvay's technology incorporates fluorinated acrylic and methacrylic monomers with carefully selected comonomers to create surfaces with water contact angles exceeding 105° and oil contact angles above 65°. Their coatings feature a unique amphiphilic character where hydrophobic fluorinated segments are combined with hydrophilic non-fluorinated segments, creating a dynamic surface that resists protein adsorption through conformational mobility. Solvay has pioneered fluoroelastomer-based coatings that provide flexibility and durability in demanding environments, with demonstrated service life exceeding 5 years in marine field testing. Recent innovations include water-based fluoropolymer dispersions with VOC content below 50 g/L, addressing environmental regulations while maintaining performance. Their coatings have shown particular efficacy in preventing biofilm formation in industrial water systems, reducing cleaning frequency by up to 75% compared to untreated surfaces.

Strengths: Broad portfolio of fluoropolymer chemistries allowing application-specific optimization; strong position in industrial and high-performance applications; advanced polymer science capabilities; established European manufacturing base. Weaknesses: Less market presence in consumer applications compared to competitors; some formulations require high-temperature processing; relatively higher cost position compared to Asian manufacturers.

Key Patents and Innovations in Fluorinated Surface Chemistry

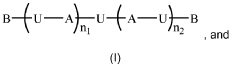

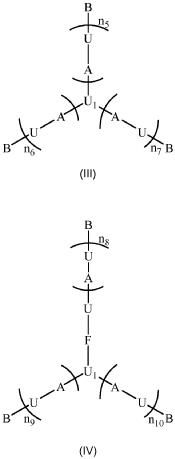

Fluorinate polyacrylate coating composition, the preparation method therefore and use thereof

PatentWO2019129692A1

Innovation

- A fluorinated polyacrylate coating composition is developed using a one-pot multicomponent synthesis process, combining oligomers with isocyanate, diol or polyol, and monomers with double bonds and hydroxyl groups, including fluorinated diols or perfluoropolyethers, to create a durable and curable coating with enhanced anti-stain and anti-scratch properties.

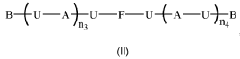

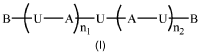

Bugphobic and icephobic compositions with fluid additives

PatentActiveUS20190023910A1

Innovation

- Development of an anti-fouling segmented copolymer composition comprising fluoropolymers, polyesters or polyethers, isocyanate species, and a fluid additive, which microphase-separates to create regions for enhanced lubricity and ice suppression, incorporating a fluid additive such as a freezing-point depressant or lubricant to improve debris and ice release.

Environmental Impact and Sustainability Considerations

The environmental implications of fluorinated surface coatings present significant challenges for sustainable development in anti-fouling applications. Per- and polyfluoroalkyl substances (PFAS), the primary components of these coatings, demonstrate remarkable persistence in the environment, earning them the designation "forever chemicals." Their resistance to degradation results in bioaccumulation throughout ecosystems, with detection in wildlife, water systems, and human blood samples globally. This persistence raises substantial concerns regarding long-term environmental contamination and potential health impacts.

Regulatory frameworks worldwide are increasingly targeting fluorinated compounds. The European Union's REACH regulation has classified several PFAS as Substances of Very High Concern, while the United States Environmental Protection Agency has established health advisory levels for certain fluorinated compounds in drinking water. These regulatory pressures are driving industry transformation toward more sustainable alternatives.

The manufacturing processes for fluorinated coatings contribute additional environmental burdens through high energy consumption and greenhouse gas emissions. Production often involves fluorinated gas precursors with significant global warming potential, sometimes thousands of times more potent than carbon dioxide. End-of-life considerations further complicate the environmental profile, as these durable coatings typically lack effective recycling pathways and may release harmful compounds during incineration or landfill disposal.

Recent life cycle assessments reveal that while fluorinated coatings deliver exceptional performance benefits during use, their cumulative environmental impact often outweighs these advantages when considering the complete product lifecycle. This comprehensive evaluation has accelerated research into bio-based alternatives and environmentally benign surface modification techniques that can achieve comparable anti-fouling properties without the environmental liabilities.

The industry is responding with green chemistry initiatives focused on developing fluorine-free alternatives. Silicone-based coatings, hydrophilic polymer brushes, and biomimetic surface texturing represent promising approaches that balance performance requirements with reduced environmental impact. Several marine coating manufacturers have successfully commercialized partially or completely fluorine-free formulations that demonstrate competitive anti-fouling efficacy while significantly reducing environmental persistence.

Sustainability certification programs are emerging to recognize environmentally preferable anti-fouling solutions, creating market incentives for continued innovation. These programs typically evaluate factors including biodegradability, toxicity profiles, resource efficiency, and carbon footprint to provide comprehensive sustainability metrics beyond simple chemical composition considerations.

Regulatory frameworks worldwide are increasingly targeting fluorinated compounds. The European Union's REACH regulation has classified several PFAS as Substances of Very High Concern, while the United States Environmental Protection Agency has established health advisory levels for certain fluorinated compounds in drinking water. These regulatory pressures are driving industry transformation toward more sustainable alternatives.

The manufacturing processes for fluorinated coatings contribute additional environmental burdens through high energy consumption and greenhouse gas emissions. Production often involves fluorinated gas precursors with significant global warming potential, sometimes thousands of times more potent than carbon dioxide. End-of-life considerations further complicate the environmental profile, as these durable coatings typically lack effective recycling pathways and may release harmful compounds during incineration or landfill disposal.

Recent life cycle assessments reveal that while fluorinated coatings deliver exceptional performance benefits during use, their cumulative environmental impact often outweighs these advantages when considering the complete product lifecycle. This comprehensive evaluation has accelerated research into bio-based alternatives and environmentally benign surface modification techniques that can achieve comparable anti-fouling properties without the environmental liabilities.

The industry is responding with green chemistry initiatives focused on developing fluorine-free alternatives. Silicone-based coatings, hydrophilic polymer brushes, and biomimetic surface texturing represent promising approaches that balance performance requirements with reduced environmental impact. Several marine coating manufacturers have successfully commercialized partially or completely fluorine-free formulations that demonstrate competitive anti-fouling efficacy while significantly reducing environmental persistence.

Sustainability certification programs are emerging to recognize environmentally preferable anti-fouling solutions, creating market incentives for continued innovation. These programs typically evaluate factors including biodegradability, toxicity profiles, resource efficiency, and carbon footprint to provide comprehensive sustainability metrics beyond simple chemical composition considerations.

Regulatory Framework for Fluorinated Coating Applications

The regulatory landscape for fluorinated surface coatings has evolved significantly over the past decade, reflecting growing environmental and health concerns. In the United States, the Environmental Protection Agency (EPA) regulates these coatings primarily through the Toxic Substances Control Act (TSCA) and the Clean Water Act. Recent amendments to TSCA have increased scrutiny on per- and polyfluoroalkyl substances (PFAS), with several fluorinated compounds now subject to Significant New Use Rules (SNURs) requiring manufacturers to notify the EPA before using these chemicals in new applications.

The European Union has implemented even stricter regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. The European Chemicals Agency (ECHA) has classified several long-chain fluorinated compounds as Substances of Very High Concern (SVHCs), with some already placed on the Authorization List requiring specific approval for continued use. The EU's recent "Chemicals Strategy for Sustainability" further signals a move toward tighter restrictions on PFAS as a chemical class.

In Asia, regulatory frameworks vary significantly by country. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances have both been updated to include stricter provisions for fluorinated compounds. South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) closely mirrors the European approach.

Industry-specific regulations add another layer of complexity. In maritime applications, the International Maritime Organization (IMO) has established guidelines for environmentally acceptable anti-fouling systems through the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention). Food contact applications face additional scrutiny from agencies like the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

Recent scientific findings linking certain fluorinated compounds to environmental persistence, bioaccumulation, and potential health effects have accelerated regulatory action. The Stockholm Convention on Persistent Organic Pollutants has already listed several long-chain perfluorinated compounds for global phase-out, with more under review.

Companies developing fluorinated anti-fouling coatings must navigate this complex regulatory environment while anticipating future restrictions. This has driven significant investment in alternative chemistries, including short-chain fluorinated compounds and non-fluorinated technologies. Regulatory compliance now represents a major factor in research and development strategies, with companies increasingly adopting a "benign by design" approach to avoid regulatory obstacles later in product development.

The European Union has implemented even stricter regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. The European Chemicals Agency (ECHA) has classified several long-chain fluorinated compounds as Substances of Very High Concern (SVHCs), with some already placed on the Authorization List requiring specific approval for continued use. The EU's recent "Chemicals Strategy for Sustainability" further signals a move toward tighter restrictions on PFAS as a chemical class.

In Asia, regulatory frameworks vary significantly by country. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances have both been updated to include stricter provisions for fluorinated compounds. South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) closely mirrors the European approach.

Industry-specific regulations add another layer of complexity. In maritime applications, the International Maritime Organization (IMO) has established guidelines for environmentally acceptable anti-fouling systems through the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention). Food contact applications face additional scrutiny from agencies like the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

Recent scientific findings linking certain fluorinated compounds to environmental persistence, bioaccumulation, and potential health effects have accelerated regulatory action. The Stockholm Convention on Persistent Organic Pollutants has already listed several long-chain perfluorinated compounds for global phase-out, with more under review.

Companies developing fluorinated anti-fouling coatings must navigate this complex regulatory environment while anticipating future restrictions. This has driven significant investment in alternative chemistries, including short-chain fluorinated compounds and non-fluorinated technologies. Regulatory compliance now represents a major factor in research and development strategies, with companies increasingly adopting a "benign by design" approach to avoid regulatory obstacles later in product development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!