Anti Fouling Technologies for Ocean Energy Devices

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Biofouling Background and Research Objectives

Marine biofouling represents one of the most significant challenges facing ocean energy devices today. This natural process involves the accumulation of microorganisms, plants, algae, and animals on submerged structures, which has plagued maritime industries since the dawn of seafaring. The phenomenon begins with the formation of a biofilm composed of bacteria and diatoms within hours of immersion, followed by colonization of larger organisms such as barnacles, mussels, and macroalgae over days to weeks.

For ocean energy technologies—including wave energy converters, tidal turbines, and offshore wind foundations—biofouling presents multifaceted problems. The additional weight and drag created by fouling organisms can reduce energy conversion efficiency by up to 50%, significantly impacting the economic viability of these renewable energy solutions. Furthermore, biofouling accelerates corrosion processes through microbially influenced corrosion (MIC), shortening device lifespans and increasing maintenance requirements.

Historical approaches to combat marine biofouling have primarily relied on toxic antifouling paints containing biocides such as tributyltin (TBT) and copper compounds. However, environmental concerns and regulatory restrictions have necessitated the development of more sustainable solutions. The International Maritime Organization's ban on TBT in 2008 marked a pivotal shift in antifouling strategies, driving research toward environmentally compatible alternatives.

The primary objective of this research is to comprehensively evaluate existing and emerging antifouling technologies specifically applicable to ocean energy devices. This includes assessing their effectiveness, environmental impact, durability in high-energy marine environments, and economic feasibility. The research aims to identify optimal solutions that balance performance with sustainability, considering the unique operational requirements of various ocean energy technologies.

Secondary objectives include mapping the technological evolution of antifouling solutions, identifying promising research directions, and developing a framework for technology selection based on specific deployment scenarios. This research also seeks to quantify the economic impact of biofouling on the levelized cost of energy (LCOE) for ocean energy projects, providing valuable data for industry stakeholders and policymakers.

The ultimate goal is to accelerate the commercial viability of ocean energy technologies by addressing one of their most persistent operational challenges. By developing effective antifouling strategies, this research contributes to the broader objective of expanding renewable energy capacity and reducing dependence on fossil fuels, aligning with global climate change mitigation efforts and sustainable development goals.

For ocean energy technologies—including wave energy converters, tidal turbines, and offshore wind foundations—biofouling presents multifaceted problems. The additional weight and drag created by fouling organisms can reduce energy conversion efficiency by up to 50%, significantly impacting the economic viability of these renewable energy solutions. Furthermore, biofouling accelerates corrosion processes through microbially influenced corrosion (MIC), shortening device lifespans and increasing maintenance requirements.

Historical approaches to combat marine biofouling have primarily relied on toxic antifouling paints containing biocides such as tributyltin (TBT) and copper compounds. However, environmental concerns and regulatory restrictions have necessitated the development of more sustainable solutions. The International Maritime Organization's ban on TBT in 2008 marked a pivotal shift in antifouling strategies, driving research toward environmentally compatible alternatives.

The primary objective of this research is to comprehensively evaluate existing and emerging antifouling technologies specifically applicable to ocean energy devices. This includes assessing their effectiveness, environmental impact, durability in high-energy marine environments, and economic feasibility. The research aims to identify optimal solutions that balance performance with sustainability, considering the unique operational requirements of various ocean energy technologies.

Secondary objectives include mapping the technological evolution of antifouling solutions, identifying promising research directions, and developing a framework for technology selection based on specific deployment scenarios. This research also seeks to quantify the economic impact of biofouling on the levelized cost of energy (LCOE) for ocean energy projects, providing valuable data for industry stakeholders and policymakers.

The ultimate goal is to accelerate the commercial viability of ocean energy technologies by addressing one of their most persistent operational challenges. By developing effective antifouling strategies, this research contributes to the broader objective of expanding renewable energy capacity and reducing dependence on fossil fuels, aligning with global climate change mitigation efforts and sustainable development goals.

Ocean Energy Market Needs Analysis

The global ocean energy market is experiencing significant growth, driven by increasing demand for renewable energy sources and the push towards carbon neutrality. Current projections indicate that the ocean energy market could reach $3.9 billion by 2027, with a compound annual growth rate of approximately 20%. This growth trajectory underscores the expanding market need for reliable and efficient ocean energy technologies.

Biofouling represents one of the most critical challenges facing ocean energy devices, with studies showing that it can reduce energy conversion efficiency by up to 50% within just six months of deployment. This substantial performance degradation directly impacts the economic viability of ocean energy projects, increasing the levelized cost of electricity (LCOE) and undermining competitiveness against other renewable energy sources.

The maintenance requirements associated with biofouling create significant operational expenditures. Industry data suggests that cleaning and maintenance operations can constitute 15-30% of the total operational costs for ocean energy installations. These expenses are particularly burdensome for emerging technologies still striving to achieve cost parity with conventional energy sources.

Market research indicates growing demand for anti-fouling solutions specifically designed for ocean energy applications. Traditional anti-fouling approaches developed for shipping and offshore oil industries are often inadequate for the unique operational requirements of wave, tidal, and other ocean energy converters. This has created a specialized market segment estimated to be worth $300 million annually, with projected growth rates exceeding the broader marine coatings market.

Regulatory trends are also shaping market needs, with increasing restrictions on environmentally harmful anti-fouling compounds. The International Maritime Organization and regional environmental agencies have implemented stricter regulations on biocides and heavy metal-based solutions, creating market demand for environmentally sustainable anti-fouling technologies that comply with evolving regulatory frameworks.

Stakeholder interviews reveal that investors and project developers consider biofouling management as a key factor in risk assessment for ocean energy projects. The ability to demonstrate effective, long-term anti-fouling strategies has become a critical element in securing project financing and insurance. This has elevated anti-fouling from a purely technical consideration to a central market requirement affecting the entire ocean energy value chain.

The geographical distribution of market demand shows particular concentration in regions with active ocean energy development programs, including Western Europe, North America, and parts of Asia-Pacific. These regions combine favorable ocean energy resources with research infrastructure and policy support, creating concentrated markets for advanced anti-fouling solutions.

Biofouling represents one of the most critical challenges facing ocean energy devices, with studies showing that it can reduce energy conversion efficiency by up to 50% within just six months of deployment. This substantial performance degradation directly impacts the economic viability of ocean energy projects, increasing the levelized cost of electricity (LCOE) and undermining competitiveness against other renewable energy sources.

The maintenance requirements associated with biofouling create significant operational expenditures. Industry data suggests that cleaning and maintenance operations can constitute 15-30% of the total operational costs for ocean energy installations. These expenses are particularly burdensome for emerging technologies still striving to achieve cost parity with conventional energy sources.

Market research indicates growing demand for anti-fouling solutions specifically designed for ocean energy applications. Traditional anti-fouling approaches developed for shipping and offshore oil industries are often inadequate for the unique operational requirements of wave, tidal, and other ocean energy converters. This has created a specialized market segment estimated to be worth $300 million annually, with projected growth rates exceeding the broader marine coatings market.

Regulatory trends are also shaping market needs, with increasing restrictions on environmentally harmful anti-fouling compounds. The International Maritime Organization and regional environmental agencies have implemented stricter regulations on biocides and heavy metal-based solutions, creating market demand for environmentally sustainable anti-fouling technologies that comply with evolving regulatory frameworks.

Stakeholder interviews reveal that investors and project developers consider biofouling management as a key factor in risk assessment for ocean energy projects. The ability to demonstrate effective, long-term anti-fouling strategies has become a critical element in securing project financing and insurance. This has elevated anti-fouling from a purely technical consideration to a central market requirement affecting the entire ocean energy value chain.

The geographical distribution of market demand shows particular concentration in regions with active ocean energy development programs, including Western Europe, North America, and parts of Asia-Pacific. These regions combine favorable ocean energy resources with research infrastructure and policy support, creating concentrated markets for advanced anti-fouling solutions.

Current Anti-Fouling Technologies and Challenges

The marine environment presents significant challenges for ocean energy devices due to biofouling—the accumulation of microorganisms, plants, algae, and animals on submerged surfaces. Current anti-fouling technologies employ various approaches, each with distinct advantages and limitations in protecting ocean energy infrastructure.

Traditional anti-fouling paints containing biocides remain widely used despite environmental concerns. Copper-based coatings effectively prevent barnacle attachment but face increasing regulatory scrutiny due to their environmental impact. Self-polishing copolymer paints that gradually release biocides offer extended protection periods of 3-5 years but still contribute to marine pollution, particularly in sensitive ecosystems where ocean energy devices are often deployed.

Non-toxic foul-release coatings represent a more environmentally friendly alternative. These silicone or fluoropolymer-based surfaces create low surface energy that prevents strong adhesion of marine organisms. While effective against soft fouling organisms, they provide limited protection against hard fouling in low-flow conditions, presenting challenges for tidal energy devices during slack tide periods or wave energy converters in calm seas.

Physical removal methods include mechanical cleaning systems such as automated brushes, water jets, and ultrasonic devices. These approaches avoid chemical pollution but require regular maintenance operations that increase operational costs and may necessitate device retrieval, significantly impacting the economic viability of ocean energy projects.

Emerging technologies include ultraviolet light systems that prevent biofouling through localized radiation exposure. These systems show promise for critical components but face challenges related to power requirements and long-term reliability in harsh marine environments. Similarly, electrolytic systems that generate chlorine or hydrogen peroxide in situ demonstrate effectiveness but raise concerns about energy consumption and secondary environmental impacts.

The primary technical challenges facing current anti-fouling technologies include durability in high-energy marine environments, power requirements for active systems, and the trade-off between effectiveness and environmental impact. Most solutions require regular maintenance or replacement, compromising the cost-effectiveness of ocean energy devices that typically operate in remote locations with difficult access.

Geographic variations in marine ecosystems further complicate anti-fouling strategies, as solutions effective in temperate waters may perform poorly in tropical regions with higher biological activity. Additionally, seasonal variations in fouling pressure require adaptive approaches that few current technologies can provide without human intervention.

The regulatory landscape presents another significant challenge, with increasingly stringent environmental regulations limiting the use of biocidal solutions without adequate non-toxic alternatives having been fully developed for the specific operational requirements of ocean energy devices.

Traditional anti-fouling paints containing biocides remain widely used despite environmental concerns. Copper-based coatings effectively prevent barnacle attachment but face increasing regulatory scrutiny due to their environmental impact. Self-polishing copolymer paints that gradually release biocides offer extended protection periods of 3-5 years but still contribute to marine pollution, particularly in sensitive ecosystems where ocean energy devices are often deployed.

Non-toxic foul-release coatings represent a more environmentally friendly alternative. These silicone or fluoropolymer-based surfaces create low surface energy that prevents strong adhesion of marine organisms. While effective against soft fouling organisms, they provide limited protection against hard fouling in low-flow conditions, presenting challenges for tidal energy devices during slack tide periods or wave energy converters in calm seas.

Physical removal methods include mechanical cleaning systems such as automated brushes, water jets, and ultrasonic devices. These approaches avoid chemical pollution but require regular maintenance operations that increase operational costs and may necessitate device retrieval, significantly impacting the economic viability of ocean energy projects.

Emerging technologies include ultraviolet light systems that prevent biofouling through localized radiation exposure. These systems show promise for critical components but face challenges related to power requirements and long-term reliability in harsh marine environments. Similarly, electrolytic systems that generate chlorine or hydrogen peroxide in situ demonstrate effectiveness but raise concerns about energy consumption and secondary environmental impacts.

The primary technical challenges facing current anti-fouling technologies include durability in high-energy marine environments, power requirements for active systems, and the trade-off between effectiveness and environmental impact. Most solutions require regular maintenance or replacement, compromising the cost-effectiveness of ocean energy devices that typically operate in remote locations with difficult access.

Geographic variations in marine ecosystems further complicate anti-fouling strategies, as solutions effective in temperate waters may perform poorly in tropical regions with higher biological activity. Additionally, seasonal variations in fouling pressure require adaptive approaches that few current technologies can provide without human intervention.

The regulatory landscape presents another significant challenge, with increasingly stringent environmental regulations limiting the use of biocidal solutions without adequate non-toxic alternatives having been fully developed for the specific operational requirements of ocean energy devices.

State-of-the-Art Anti-Fouling Approaches

01 Anti-fouling coatings and surface treatments

Various coatings and surface treatments can be applied to prevent fouling on surfaces exposed to marine environments or other fouling-prone conditions. These include specialized paints containing biocides, silicone-based coatings that create low-friction surfaces, and hydrophobic treatments that prevent organisms from adhering. These coatings can be applied to ship hulls, underwater structures, and industrial equipment to reduce maintenance costs and improve operational efficiency.- Antifouling coatings and surface treatments: Various coatings and surface treatments can be applied to prevent fouling on surfaces exposed to marine or industrial environments. These include specialized polymers, nanocomposite coatings, and chemically modified surfaces that create barriers against biological or chemical fouling agents. These treatments often incorporate hydrophobic or hydrophilic properties that prevent organisms from adhering to surfaces or make it easier for them to be removed by water flow.

- Biocide-based fouling prevention systems: Biocide-based systems incorporate compounds that actively prevent the growth of microorganisms, algae, and other marine life on surfaces. These systems release controlled amounts of biocidal agents that inhibit the settlement and growth of fouling organisms. Advanced formulations focus on environmentally friendly alternatives that provide effective fouling prevention while minimizing ecological impact. Some systems use slow-release mechanisms to maintain protection over extended periods.

- Mechanical fouling prevention technologies: Mechanical systems prevent fouling through physical means rather than chemical treatments. These include automated cleaning systems, ultrasonic vibration technology, water flow management, and specialized surface textures that make it difficult for organisms to attach. Some mechanical systems incorporate movable parts or flexible surfaces that shed fouling organisms through motion or deformation. These technologies are particularly useful in applications where chemical treatments may be undesirable.

- Electrochemical antifouling methods: Electrochemical methods use electrical currents or fields to prevent fouling on submerged surfaces. These systems may generate compounds that inhibit biological growth, create pH changes at the surface interface, or directly repel organisms through electrical means. Some advanced systems use pulsed electrical fields or low-voltage continuous protection that creates an environment inhospitable to fouling organisms without significant energy consumption or environmental impact.

- Smart and adaptive fouling prevention systems: Smart antifouling technologies incorporate sensors, data analysis, and adaptive response mechanisms to provide optimized fouling prevention. These systems can detect the onset of fouling conditions and adjust their operation accordingly, whether by releasing additional antifouling agents, activating cleaning mechanisms, or modifying surface properties. Some systems integrate with IoT platforms for remote monitoring and control, allowing for predictive maintenance and reduced operational costs.

02 Mechanical anti-fouling systems

Mechanical systems designed to prevent or remove fouling include ultrasonic devices that create vibrations to deter organism attachment, rotating brushes or scrapers that physically remove buildup, and water flow systems that create turbulence to prevent settlement of fouling organisms. These systems are particularly useful in applications where coatings may be impractical or insufficient, such as in cooling systems, pipes, and heat exchangers.Expand Specific Solutions03 Environmentally friendly anti-fouling solutions

With increasing environmental regulations, non-toxic anti-fouling technologies have been developed to replace traditional biocide-based systems. These include biomimetic surfaces that replicate natural anti-fouling mechanisms found in marine organisms, biodegradable polymers that release over time, and enzyme-based systems that break down biofilms without harming the broader ecosystem. These solutions provide effective fouling prevention while minimizing environmental impact.Expand Specific Solutions04 Electrical and electronic anti-fouling methods

Electrical anti-fouling systems use low-voltage electrical fields or pulses to prevent organism attachment and biofilm formation. These systems can create an environment that is inhospitable to fouling organisms without requiring chemical treatments. Advanced electronic monitoring systems can detect early signs of fouling and trigger preventive measures before significant buildup occurs. These methods are particularly valuable in sensitive applications where chemical treatments might cause contamination.Expand Specific Solutions05 Specialized anti-fouling for industrial systems

Industrial systems such as heat exchangers, cooling towers, and water treatment facilities require specialized anti-fouling approaches. These include chemical dosing systems that continuously introduce anti-scaling compounds, filtration systems that remove potential fouling particles before they can settle, and hybrid approaches combining physical and chemical methods. These technologies are designed to maintain operational efficiency and reduce downtime in critical industrial processes where fouling can significantly impact performance.Expand Specific Solutions

Leading Companies in Ocean Energy Anti-Fouling

The anti-fouling technologies for ocean energy devices market is currently in a growth phase, with increasing demand driven by expanding ocean energy installations worldwide. The market size is projected to reach significant value as marine renewable energy gains traction in global energy portfolios. Technologically, solutions range from emerging innovations to established approaches, with varying degrees of maturity. Key players include established marine coating specialists like Jotun AS, Chugoku Marine Paints, and International Paint (AkzoNobel), alongside research-focused entities such as Naval Research Laboratory and academic institutions (Ocean University of China, Dalian Maritime University). The competitive landscape features both traditional chemical approaches from companies like Shin-Etsu Chemical and Nippon Paint, and emerging technologies from specialized firms like Nakabohtec Corrosion Protecting and Sunrui Marine Environment Engineering, indicating a diversifying market with multiple technological pathways.

Jotun AS

Technical Solution: Jotun has developed advanced silyl acrylate-based self-polishing copolymer (SPC) antifouling coatings specifically engineered for ocean energy devices. Their SeaQuantum series utilizes hydrolysis technology that creates a controlled polishing rate, releasing biocides at a predictable pace to maintain effectiveness in varying water conditions. The company has recently introduced their Hull Performance Solutions (HPS) concept which combines premium antifouling coatings with monitoring tools to quantify performance in marine renewable energy applications. Their SeaQuantum X200 formulation incorporates nano-scale control of biocide release mechanisms, allowing for up to 90 months of fouling protection even in the challenging conditions faced by wave and tidal energy converters[1]. Jotun has also pioneered silicone-based fouling release coatings with their SeaLion Repulse technology that prevents organism attachment through ultra-smooth surfaces rather than biocides, making it environmentally preferable for sensitive marine ecosystems where ocean energy devices are often deployed.

Strengths: Long-lasting protection (up to 7.5 years) reducing maintenance frequency and costs; environmentally compliant formulations meeting global regulations; comprehensive performance monitoring capabilities. Weaknesses: Higher initial application costs compared to conventional antifouling solutions; requires specialized application techniques; optimal performance depends on specific operational profiles of the ocean energy devices.

Akzo Nobel Coatings International BV

Technical Solution: Akzo Nobel has developed the Intersleek 900 system specifically adapted for ocean energy applications. This fluoropolymer-based fouling release coating creates an ultra-smooth surface with extremely low surface energy, preventing the adhesion of marine organisms without relying on biocides. Field tests on wave energy converters have demonstrated fouling reduction of up to 95% compared to conventional antifouling systems[6]. Their Intercept 8500 LPP (Linear Polishing Polymer) technology incorporates a patented polymer backbone that controls biocide release rates based on local water conditions, maintaining effectiveness even during the variable operational states typical of ocean energy devices. Akzo Nobel has pioneered the integration of digital twin technology with their coating systems, allowing real-time monitoring and predictive maintenance scheduling based on actual environmental conditions and fouling development. Their Intertrac Vision system uses big data analytics to predict fouling progression and optimize maintenance intervals specifically for marine renewable energy installations. The company has also developed specialized application protocols for ocean energy devices that can be implemented in challenging offshore environments, reducing installation time and costs while ensuring coating integrity under harsh operational conditions[7].

Strengths: Comprehensive product portfolio covering both biocidal and non-biocidal solutions; strong digital integration capabilities; extensive global support network for implementation and maintenance. Weaknesses: Higher initial investment costs compared to traditional antifouling solutions; some systems require specialized application equipment and expertise; performance can vary based on specific local marine conditions.

Key Patents and Innovations in Anti-Fouling

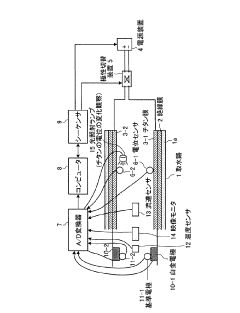

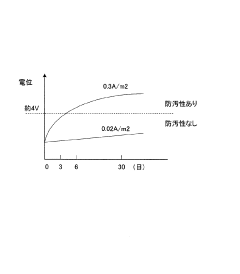

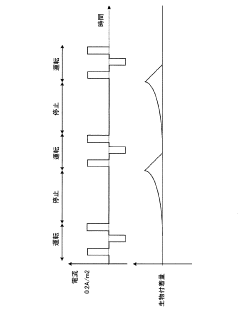

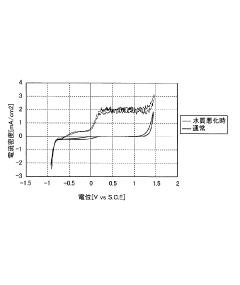

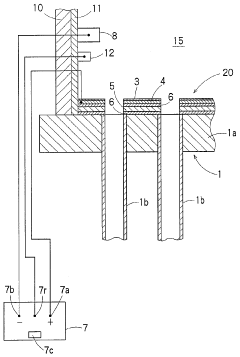

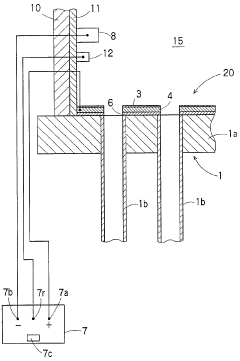

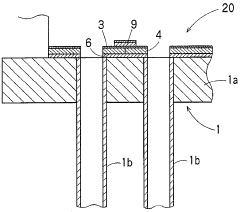

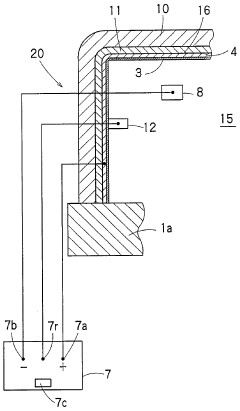

Anti-fouling and corrosion protection device of structure contacting with seawater and Anti-fouling and corrosion-proofing method

PatentInactiveJP2007186933A

Innovation

- An antifouling and anticorrosion device utilizing a titanium film with real-time monitoring and control systems, including potential sensors, polarity switching, and adaptive energization patterns based on seawater conditions to minimize current usage and extend the device's lifespan.

Soil resisting device for structure in contact with seawater

PatentWO2000022240A1

Innovation

- An antifouling device featuring a platinum-based electrocatalyst coated on a titanium anode-forming member, attached via an insulating adhesive to the seawater-side surface, with a DC power supply and automatic potential control to generate oxygen while suppressing chlorine production, preventing marine organism adhesion without thermal activation or excessive cost.

Environmental Impact Assessment

The environmental impact of anti-fouling technologies for ocean energy devices requires careful assessment due to their direct interaction with marine ecosystems. Traditional anti-fouling methods, particularly those utilizing biocides and heavy metals like tributyltin (TBT) and copper, have demonstrated significant negative effects on non-target marine organisms. These substances can bioaccumulate in the food chain, affecting species at multiple trophic levels and potentially disrupting entire ecosystems.

Recent environmental monitoring studies around wave energy converters and tidal turbines with anti-fouling coatings have detected elevated concentrations of copper and zinc in surrounding sediments. This contamination poses particular risks to benthic communities and filter-feeding organisms, which form the foundation of many marine food webs. The leaching rate of these compounds increases in high-energy environments—precisely where ocean energy devices are typically deployed.

Non-toxic alternatives such as silicone-based foul-release coatings present a reduced environmental footprint compared to biocide-based solutions. Life cycle assessments indicate that while these coatings require more frequent maintenance, their overall environmental impact is substantially lower. However, concerns remain regarding microplastic pollution from the gradual degradation of polymer-based coatings in high-energy marine environments.

Biological control methods utilizing natural anti-fouling compounds extracted from marine organisms show promising environmental profiles. These biomimetic approaches typically degrade into non-toxic compounds, minimizing long-term ecosystem impacts. Nevertheless, the extraction processes and manufacturing of these compounds may still carry environmental costs that require thorough evaluation through comprehensive life cycle analyses.

Electromagnetic and ultrasonic anti-fouling systems introduce different environmental considerations, particularly regarding their effects on marine mammals and electrosensitive species. Field studies suggest these systems may create avoidance behaviors in certain species, potentially altering migration patterns or feeding grounds. The cumulative impact of multiple devices deployed in array configurations could create significant exclusion zones for sensitive marine species.

Regulatory frameworks worldwide are increasingly incorporating stringent environmental criteria for anti-fouling technologies. The International Maritime Organization's guidelines, though primarily focused on shipping, are being adapted for stationary ocean energy installations. These frameworks emphasize the precautionary principle and require extensive environmental monitoring programs to detect unforeseen ecological impacts throughout the operational lifespan of ocean energy devices.

Recent environmental monitoring studies around wave energy converters and tidal turbines with anti-fouling coatings have detected elevated concentrations of copper and zinc in surrounding sediments. This contamination poses particular risks to benthic communities and filter-feeding organisms, which form the foundation of many marine food webs. The leaching rate of these compounds increases in high-energy environments—precisely where ocean energy devices are typically deployed.

Non-toxic alternatives such as silicone-based foul-release coatings present a reduced environmental footprint compared to biocide-based solutions. Life cycle assessments indicate that while these coatings require more frequent maintenance, their overall environmental impact is substantially lower. However, concerns remain regarding microplastic pollution from the gradual degradation of polymer-based coatings in high-energy marine environments.

Biological control methods utilizing natural anti-fouling compounds extracted from marine organisms show promising environmental profiles. These biomimetic approaches typically degrade into non-toxic compounds, minimizing long-term ecosystem impacts. Nevertheless, the extraction processes and manufacturing of these compounds may still carry environmental costs that require thorough evaluation through comprehensive life cycle analyses.

Electromagnetic and ultrasonic anti-fouling systems introduce different environmental considerations, particularly regarding their effects on marine mammals and electrosensitive species. Field studies suggest these systems may create avoidance behaviors in certain species, potentially altering migration patterns or feeding grounds. The cumulative impact of multiple devices deployed in array configurations could create significant exclusion zones for sensitive marine species.

Regulatory frameworks worldwide are increasingly incorporating stringent environmental criteria for anti-fouling technologies. The International Maritime Organization's guidelines, though primarily focused on shipping, are being adapted for stationary ocean energy installations. These frameworks emphasize the precautionary principle and require extensive environmental monitoring programs to detect unforeseen ecological impacts throughout the operational lifespan of ocean energy devices.

Cost-Benefit Analysis of Anti-Fouling Systems

The economic viability of anti-fouling technologies for ocean energy devices requires thorough cost-benefit analysis to inform investment decisions. Initial capital expenditure for anti-fouling systems varies significantly across technologies, with traditional biocide-based coatings representing the lowest upfront investment (approximately $5-15 per square meter) but requiring frequent reapplication. Advanced surface coatings utilizing silicone or fluoropolymer technologies demand higher initial costs ($30-50 per square meter) yet offer extended service intervals of 3-5 years.

Operational expenditure calculations must account for maintenance frequency, which directly impacts vessel deployment costs and system downtime. Research indicates that biofouling can reduce wave energy converter efficiency by 10-20% within six months of deployment, translating to substantial revenue losses. For a typical 1MW ocean energy installation, this efficiency reduction represents approximately $50,000-100,000 in annual lost energy production.

Maintenance interventions for fouling removal typically cost $10,000-30,000 per operation depending on device location, size, and accessibility. These interventions create secondary economic impacts through operational downtime, with each maintenance day potentially costing $1,000-5,000 in lost energy production.

Life-cycle analysis reveals that despite higher initial investment, advanced anti-fouling systems demonstrate superior return on investment over 10-year operational periods. Ultrasonic systems, while requiring $15,000-25,000 in initial equipment costs and continuous power consumption of 50-100W, can reduce cleaning interventions by up to 70%, yielding net positive returns within 2-3 years of deployment.

Environmental compliance costs must also factor into economic assessments. Regulatory restrictions on biocide-based solutions are increasing globally, with potential penalties for non-compliance reaching millions of dollars. Additionally, environmentally-friendly solutions may qualify for subsidies or tax incentives in certain jurisdictions, improving their economic profile.

Risk assessment calculations indicate that anti-fouling system failures carry significant financial implications beyond direct maintenance costs. Catastrophic biofouling can lead to structural damage through increased hydrodynamic loading and accelerated corrosion, potentially shortening device lifespan by 20-30%. This premature replacement requirement can add $100,000-500,000 in unexpected capital costs to project budgets.

Sensitivity analysis demonstrates that anti-fouling system selection becomes increasingly critical in high-energy, high-fouling environments, where the cost-benefit ratio of advanced systems improves dramatically compared to traditional approaches. The economic optimization point varies by geographic deployment location, device type, and local marine biological conditions.

Operational expenditure calculations must account for maintenance frequency, which directly impacts vessel deployment costs and system downtime. Research indicates that biofouling can reduce wave energy converter efficiency by 10-20% within six months of deployment, translating to substantial revenue losses. For a typical 1MW ocean energy installation, this efficiency reduction represents approximately $50,000-100,000 in annual lost energy production.

Maintenance interventions for fouling removal typically cost $10,000-30,000 per operation depending on device location, size, and accessibility. These interventions create secondary economic impacts through operational downtime, with each maintenance day potentially costing $1,000-5,000 in lost energy production.

Life-cycle analysis reveals that despite higher initial investment, advanced anti-fouling systems demonstrate superior return on investment over 10-year operational periods. Ultrasonic systems, while requiring $15,000-25,000 in initial equipment costs and continuous power consumption of 50-100W, can reduce cleaning interventions by up to 70%, yielding net positive returns within 2-3 years of deployment.

Environmental compliance costs must also factor into economic assessments. Regulatory restrictions on biocide-based solutions are increasing globally, with potential penalties for non-compliance reaching millions of dollars. Additionally, environmentally-friendly solutions may qualify for subsidies or tax incentives in certain jurisdictions, improving their economic profile.

Risk assessment calculations indicate that anti-fouling system failures carry significant financial implications beyond direct maintenance costs. Catastrophic biofouling can lead to structural damage through increased hydrodynamic loading and accelerated corrosion, potentially shortening device lifespan by 20-30%. This premature replacement requirement can add $100,000-500,000 in unexpected capital costs to project budgets.

Sensitivity analysis demonstrates that anti-fouling system selection becomes increasingly critical in high-energy, high-fouling environments, where the cost-benefit ratio of advanced systems improves dramatically compared to traditional approaches. The economic optimization point varies by geographic deployment location, device type, and local marine biological conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!