Copper Free Anti Fouling Coatings for Sustainable Shipping

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Copper-Free Antifouling Technology Background and Objectives

Antifouling technologies have been integral to maritime operations since ancient civilizations first ventured into open waters. The historical progression began with primitive methods such as coating hulls with wax, tar, and copper sheathing. By the mid-20th century, tributyltin (TBT) compounds emerged as revolutionary antifouling agents, offering unprecedented performance in preventing marine biofouling. However, their severe environmental impacts led to a global ban in 2008 under the International Maritime Organization's AFS Convention.

Copper-based coatings subsequently became the industry standard, utilizing copper oxide as the primary biocide. These systems effectively prevent the attachment of barnacles, algae, and other marine organisms that increase drag on vessel hulls. Despite their effectiveness, mounting evidence indicates that copper accumulation in marine environments causes significant ecological damage, particularly in harbors and coastal ecosystems with limited water exchange.

The shipping industry faces increasing regulatory pressure as environmental protection agencies worldwide implement stricter limitations on copper content in antifouling paints. The European Chemicals Agency has already proposed restrictions, while California and Washington have enacted legislation limiting copper leaching rates. This regulatory landscape is driving the urgent need for sustainable alternatives.

The technical evolution of antifouling solutions is now focused on developing copper-free technologies that maintain performance while eliminating environmental harm. Current research explores biomimetic approaches inspired by natural antifouling mechanisms found in marine organisms, surface modification techniques that create physical deterrents to biofouling, and controlled-release systems for environmentally benign biocides.

The primary objective of copper-free antifouling research is to develop coating systems that match or exceed the performance of copper-based products while eliminating ecotoxicity. These solutions must demonstrate durability in harsh marine environments, maintain effectiveness for extended periods (typically 3-5 years between dry-dockings), and remain economically viable for widespread industry adoption.

Additional technical goals include reducing greenhouse gas emissions through decreased hull friction, minimizing invasive species transfer via ship hulls, and developing application and maintenance protocols compatible with existing shipyard infrastructure. The ideal solution would provide a drop-in replacement for current copper-based systems without requiring significant changes to application equipment or procedures.

The successful development of copper-free antifouling technology represents a critical advancement toward sustainable shipping practices, aligning with broader industry initiatives to reduce environmental impact while maintaining operational efficiency in global maritime commerce.

Copper-based coatings subsequently became the industry standard, utilizing copper oxide as the primary biocide. These systems effectively prevent the attachment of barnacles, algae, and other marine organisms that increase drag on vessel hulls. Despite their effectiveness, mounting evidence indicates that copper accumulation in marine environments causes significant ecological damage, particularly in harbors and coastal ecosystems with limited water exchange.

The shipping industry faces increasing regulatory pressure as environmental protection agencies worldwide implement stricter limitations on copper content in antifouling paints. The European Chemicals Agency has already proposed restrictions, while California and Washington have enacted legislation limiting copper leaching rates. This regulatory landscape is driving the urgent need for sustainable alternatives.

The technical evolution of antifouling solutions is now focused on developing copper-free technologies that maintain performance while eliminating environmental harm. Current research explores biomimetic approaches inspired by natural antifouling mechanisms found in marine organisms, surface modification techniques that create physical deterrents to biofouling, and controlled-release systems for environmentally benign biocides.

The primary objective of copper-free antifouling research is to develop coating systems that match or exceed the performance of copper-based products while eliminating ecotoxicity. These solutions must demonstrate durability in harsh marine environments, maintain effectiveness for extended periods (typically 3-5 years between dry-dockings), and remain economically viable for widespread industry adoption.

Additional technical goals include reducing greenhouse gas emissions through decreased hull friction, minimizing invasive species transfer via ship hulls, and developing application and maintenance protocols compatible with existing shipyard infrastructure. The ideal solution would provide a drop-in replacement for current copper-based systems without requiring significant changes to application equipment or procedures.

The successful development of copper-free antifouling technology represents a critical advancement toward sustainable shipping practices, aligning with broader industry initiatives to reduce environmental impact while maintaining operational efficiency in global maritime commerce.

Market Analysis for Sustainable Marine Coatings

The global market for sustainable marine coatings, particularly copper-free anti-fouling solutions, is experiencing significant growth driven by increasingly stringent environmental regulations and heightened awareness of marine ecosystem preservation. The current market size for marine coatings is estimated at $6.5 billion, with anti-fouling coatings representing approximately $3.2 billion of this total. The sustainable, copper-free segment is growing at a compound annual growth rate of 7.8%, substantially outpacing the conventional coating market's 3.2% growth.

Geographically, Europe leads the sustainable marine coating market with approximately 38% market share, followed by Asia-Pacific at 32%, North America at 22%, and other regions comprising the remaining 8%. This distribution reflects the varying regulatory landscapes, with the European Union's Biocidal Products Regulation and the International Maritime Organization's guidelines driving adoption in European waters.

Customer segmentation reveals that commercial shipping fleets represent the largest market segment (62%), followed by naval vessels (18%), offshore structures (12%), and recreational vessels (8%). Within the commercial shipping sector, container ships and bulk carriers demonstrate the highest adoption rates of sustainable coatings due to their extensive global operations and exposure to diverse marine environments.

Key market drivers include regulatory pressure, with over 40 countries now implementing restrictions on copper-based coatings. Operational cost considerations also play a significant role, as improved hull performance can reduce fuel consumption by up to 10%, representing substantial savings for shipping operators. The increasing focus on corporate sustainability goals among shipping companies further accelerates market growth.

Market barriers include the higher initial cost of copper-free solutions, which typically command a 15-30% premium over conventional coatings. Performance concerns persist, particularly regarding longevity and effectiveness in challenging marine environments. The fragmented regulatory landscape also creates market uncertainty, with varying standards across different jurisdictions complicating global deployment strategies.

Future market projections indicate continued robust growth, with the copper-free segment expected to capture 45% of the total anti-fouling market by 2030, up from the current 22%. This growth trajectory is supported by technological advancements in biomimetic and enzyme-based solutions, which are demonstrating increasingly competitive performance metrics compared to traditional copper-based products.

Geographically, Europe leads the sustainable marine coating market with approximately 38% market share, followed by Asia-Pacific at 32%, North America at 22%, and other regions comprising the remaining 8%. This distribution reflects the varying regulatory landscapes, with the European Union's Biocidal Products Regulation and the International Maritime Organization's guidelines driving adoption in European waters.

Customer segmentation reveals that commercial shipping fleets represent the largest market segment (62%), followed by naval vessels (18%), offshore structures (12%), and recreational vessels (8%). Within the commercial shipping sector, container ships and bulk carriers demonstrate the highest adoption rates of sustainable coatings due to their extensive global operations and exposure to diverse marine environments.

Key market drivers include regulatory pressure, with over 40 countries now implementing restrictions on copper-based coatings. Operational cost considerations also play a significant role, as improved hull performance can reduce fuel consumption by up to 10%, representing substantial savings for shipping operators. The increasing focus on corporate sustainability goals among shipping companies further accelerates market growth.

Market barriers include the higher initial cost of copper-free solutions, which typically command a 15-30% premium over conventional coatings. Performance concerns persist, particularly regarding longevity and effectiveness in challenging marine environments. The fragmented regulatory landscape also creates market uncertainty, with varying standards across different jurisdictions complicating global deployment strategies.

Future market projections indicate continued robust growth, with the copper-free segment expected to capture 45% of the total anti-fouling market by 2030, up from the current 22%. This growth trajectory is supported by technological advancements in biomimetic and enzyme-based solutions, which are demonstrating increasingly competitive performance metrics compared to traditional copper-based products.

Current Challenges in Eco-Friendly Antifouling Solutions

Despite significant advancements in eco-friendly antifouling technologies, the maritime industry continues to face substantial challenges in developing truly sustainable solutions that can effectively replace copper-based coatings. The primary technical hurdle remains achieving comparable performance to copper-based systems without the associated environmental impacts. Current non-toxic alternatives often demonstrate reduced efficacy in preventing biofouling, particularly over extended periods in diverse marine environments.

Durability presents another significant challenge, as many environmentally friendly coatings exhibit shorter service lives compared to traditional copper-based products. This limitation translates to more frequent dry-docking requirements for vessels, resulting in increased operational costs and carbon footprints that partially offset the environmental benefits of using eco-friendly alternatives.

Cost-effectiveness remains a critical barrier to widespread adoption. The development, production, and application of novel eco-friendly antifouling technologies typically involve higher costs than conventional copper-based systems. These increased expenses create resistance within the industry, particularly among smaller shipping companies operating with tight profit margins.

Regulatory frameworks present a complex challenge for innovation in this sector. While environmental regulations increasingly restrict the use of copper and other biocides, the approval processes for new antifouling technologies often involve lengthy and costly testing procedures. This regulatory landscape creates uncertainty for manufacturers and slows the commercialization of promising solutions.

Technical scalability issues further complicate the transition to copper-free alternatives. Many innovative solutions demonstrate promising results in laboratory settings or small-scale applications but face significant challenges when scaled to commercial vessel dimensions. Manufacturing processes for novel coating technologies frequently require substantial modifications to existing production facilities.

Performance consistency across diverse marine environments represents another substantial challenge. The effectiveness of eco-friendly antifouling solutions can vary significantly depending on water temperature, salinity, and local marine species. Developing universally effective solutions that perform reliably across global shipping routes remains technically challenging.

The integration of new antifouling technologies with existing vessel maintenance protocols and infrastructure presents additional complications. Many innovative solutions require specialized application equipment or techniques that may not be readily available at all shipyards, limiting their practical implementation across the global fleet.

Durability presents another significant challenge, as many environmentally friendly coatings exhibit shorter service lives compared to traditional copper-based products. This limitation translates to more frequent dry-docking requirements for vessels, resulting in increased operational costs and carbon footprints that partially offset the environmental benefits of using eco-friendly alternatives.

Cost-effectiveness remains a critical barrier to widespread adoption. The development, production, and application of novel eco-friendly antifouling technologies typically involve higher costs than conventional copper-based systems. These increased expenses create resistance within the industry, particularly among smaller shipping companies operating with tight profit margins.

Regulatory frameworks present a complex challenge for innovation in this sector. While environmental regulations increasingly restrict the use of copper and other biocides, the approval processes for new antifouling technologies often involve lengthy and costly testing procedures. This regulatory landscape creates uncertainty for manufacturers and slows the commercialization of promising solutions.

Technical scalability issues further complicate the transition to copper-free alternatives. Many innovative solutions demonstrate promising results in laboratory settings or small-scale applications but face significant challenges when scaled to commercial vessel dimensions. Manufacturing processes for novel coating technologies frequently require substantial modifications to existing production facilities.

Performance consistency across diverse marine environments represents another substantial challenge. The effectiveness of eco-friendly antifouling solutions can vary significantly depending on water temperature, salinity, and local marine species. Developing universally effective solutions that perform reliably across global shipping routes remains technically challenging.

The integration of new antifouling technologies with existing vessel maintenance protocols and infrastructure presents additional complications. Many innovative solutions require specialized application equipment or techniques that may not be readily available at all shipyards, limiting their practical implementation across the global fleet.

Current Copper-Free Antifouling Technical Solutions

01 Silicone-based anti-fouling coatings

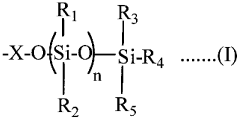

Silicone-based polymers and elastomers are used as copper-free alternatives in anti-fouling coatings. These materials create a low surface energy that prevents marine organisms from adhering to the surface. The silicone matrix can be combined with other components such as oils or non-toxic additives to enhance the release properties of the coating, making it difficult for fouling organisms to attach to the treated surface.- Silicone-based anti-fouling coatings: Silicone-based formulations provide effective copper-free anti-fouling solutions. These coatings create a low surface energy that prevents marine organisms from adhering to the treated surface. The silicone polymers can be combined with other components such as silica particles or specific additives to enhance their performance. These environmentally friendly coatings offer good durability and reduced drag in marine environments without relying on copper biocides.

- Zinc oxide-based anti-fouling systems: Zinc oxide serves as an effective alternative to copper in anti-fouling coatings. These formulations utilize zinc oxide particles, sometimes in nano form, to provide biocidal properties without the environmental concerns associated with copper. The zinc-based systems can be incorporated into various polymer matrices to create durable coatings that inhibit the settlement and growth of marine organisms while offering reduced environmental impact compared to traditional copper-based solutions.

- Polymer-based release coatings: These anti-fouling systems utilize specialized polymers that create surfaces from which marine organisms can be easily removed by water flow or minimal cleaning. The polymers may include fluoropolymers, hydrophobic acrylics, or modified epoxies that prevent strong adhesion of biofouling organisms. Some formulations incorporate controlled release mechanisms that gradually expose fresh coating surfaces, providing long-term protection without the need for copper or other heavy metal biocides.

- Natural compound-based anti-fouling solutions: These environmentally friendly formulations utilize natural compounds derived from marine organisms, plants, or other biological sources as alternatives to copper biocides. The natural compounds may include extracts from seaweeds, enzymes, peptides, or other biomolecules that have demonstrated anti-fouling properties. These bioinspired solutions mimic natural defense mechanisms found in marine organisms to prevent biofouling while minimizing environmental impact.

- Ceramic and inorganic particle-based coatings: These copper-free anti-fouling systems incorporate ceramic or other inorganic particles to create surfaces that resist biofouling. The particles may include modified silica, glass microspheres, or other engineered materials that create surface textures or properties unfavorable for marine organism attachment. Some formulations combine these particles with specific binders or resins to enhance durability and performance in marine environments without relying on copper compounds.

02 Biodegradable polymer-based anti-fouling systems

Environmentally friendly anti-fouling coatings based on biodegradable polymers offer copper-free alternatives that reduce environmental impact. These systems incorporate natural or synthetic biodegradable polymers that can release non-toxic compounds or create surfaces unfavorable for biofouling. The controlled degradation of these polymers provides a self-renewing surface that continuously prevents fouling without releasing harmful substances into marine environments.Expand Specific Solutions03 Zinc oxide and other metal oxide formulations

Metal oxides, particularly zinc oxide, are utilized as active ingredients in copper-free anti-fouling coatings. These compounds provide antimicrobial properties that inhibit the growth of marine organisms without the environmental concerns associated with copper. The formulations may include zinc oxide nanoparticles or other metal oxides that can be incorporated into various binder systems to create effective anti-fouling barriers with reduced environmental impact.Expand Specific Solutions04 Natural biocide incorporation techniques

Natural biocides derived from plants, marine organisms, or other biological sources are incorporated into anti-fouling coating formulations as copper-free alternatives. These natural compounds include extracts, essential oils, or isolated active molecules that demonstrate anti-fouling properties. The formulations may employ encapsulation or controlled-release mechanisms to maintain the effectiveness of these natural biocides over extended periods while minimizing their release into the environment.Expand Specific Solutions05 Surface modification technologies

Advanced surface modification technologies create copper-free anti-fouling coatings with physical or chemical properties that prevent organism attachment. These include micro-textured surfaces, hydrophobic or hydrophilic treatments, and grafted polymer brushes that create unfavorable conditions for biofouling. Some technologies employ stimuli-responsive materials that can change surface properties in response to environmental conditions, providing dynamic anti-fouling protection without relying on toxic compounds.Expand Specific Solutions

Key Industry Players in Sustainable Marine Coatings

The copper-free anti-fouling coatings market for sustainable shipping is currently in a growth phase, driven by increasing environmental regulations and sustainability demands. The market size is expanding rapidly as the shipping industry seeks eco-friendly alternatives to traditional copper-based solutions. From a technological maturity perspective, companies like Chugoku Marine Paints and PPG Industries are leading commercial development with advanced formulations, while research institutions such as Ocean University of China, Marine Chemical Research Institute, and Lanzhou Institute of Chemical Physics are advancing fundamental technologies. Jotun AS and Nippon Paint have established significant market presence with innovative solutions, while specialized players like Xiamen Sunrui Ship Coating and Bluestar Silicones are developing niche applications. The technology is transitioning from early adoption to mainstream implementation as performance improvements continue to match conventional copper-based alternatives.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed innovative copper-free antifouling coatings based on their SEAFLO NEO technology platform. Their solution utilizes biodegradable biopolymers combined with non-metallic biocides that create a self-polishing surface. The technology employs zinc acrylate copolymers with hydrolyzable ester linkages that gradually break down in seawater, creating a controlled release mechanism for the incorporated biocides. This approach maintains a consistently smooth hull surface throughout the coating's service life. Their latest formulations incorporate silyl acrylate polymers that hydrolyze at a predictable rate, ensuring consistent biocide release without copper leaching. The company has also integrated nano-structured silica particles that create a micro-textured surface unfavorable for marine organism settlement, enhancing the coating's effectiveness without relying on heavy metals.

Strengths: Excellent long-term performance with service life exceeding 60 months; significantly reduced environmental impact compared to copper-based alternatives; compatible with existing application equipment and processes. Weaknesses: Higher initial cost compared to conventional copper coatings; potentially less effective in certain high-fouling tropical environments; requires careful application to achieve optimal performance.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed a comprehensive copper-free antifouling solution called SIGMAGLIDE, utilizing advanced hydrophobic silicone-based polymers that create an ultra-smooth, low surface energy coating. This technology works primarily through physical deterrence rather than biocide release, making it environmentally sustainable. The coating's molecular structure creates a surface that marine organisms struggle to adhere to, causing them to detach under normal vessel movement. PPG's formulation incorporates proprietary cross-linking silicone polymers with fluoropolymer additives that enhance durability while maintaining the slippery surface characteristics. The coating system includes a specialized tie coat that ensures strong adhesion to conventional marine primers, addressing a common failure point in silicone-based systems. Recent innovations have incorporated nano-scale surface engineering to further reduce the coating's surface energy and improve its fouling-release properties without relying on toxic substances.

Strengths: Exceptional fuel efficiency benefits with documented fuel savings of 5-9% compared to conventional antifouling; extremely long service life exceeding 5 years; completely free of biocides and heavy metals. Weaknesses: Higher initial application cost; requires specialized application techniques and conditions; more susceptible to mechanical damage than conventional hard coatings; less effective when vessels remain stationary for extended periods.

Breakthrough Innovations in Biocide-Free Technologies

Coating resistant to biogrowth particularly in marine environments

PatentPendingUS20240409755A1

Innovation

- A brominated epoxy resin-based antifouling coating composition that includes copper-free and tri-organotin-free antifouling agents, along with a surface additive to reduce adhesion and improve foul-release, formulated without persistent toxic derivatives, providing effective fouling reduction and environmental sustainability.

Stain-proof coating composition, stain-proof coating film, substrate having coating film, stain-proof substrate, method for formation of coating film on surface of substrate, and method for stain-proofing of substrate

PatentWO2007026692A1

Innovation

- A copper-free antifouling paint composition incorporating a hydrolyzable copolymer with zinc sulfide as the primary antifouling agent, combined with organic antifouling agents like pyrithione and triorganoboron, to form a self-polishing coating film that effectively prevents marine organism adhesion while maintaining long-term antifouling performance.

Environmental Regulations Impact on Coating Development

Environmental regulations have become a pivotal force driving innovation in marine antifouling coatings, particularly accelerating the development of copper-free alternatives. The International Maritime Organization (IMO) has established increasingly stringent guidelines through its Marine Environmental Protection Committee, progressively limiting the use of biocides in antifouling systems. The landmark International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which entered into force in 2008, banned the application of tributyltin (TBT) compounds, previously the industry standard, due to their severe environmental impacts.

This regulatory shift created an immediate market gap that was initially filled by copper-based alternatives. However, mounting evidence of copper's detrimental effects on marine ecosystems has prompted further regulatory action. The European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's (EPA) Vessel General Permit program have both implemented restrictions on copper release rates from antifouling coatings, with some regional authorities in Washington State and California enforcing even stricter limitations.

The regulatory landscape continues to evolve toward a zero-discharge approach. The EU's Water Framework Directive has classified copper as a "priority substance," signaling potential future restrictions. Similarly, the International Maritime Organization's Ballast Water Management Convention, while not directly targeting antifouling coatings, reflects the growing regulatory emphasis on reducing shipping's environmental footprint, creating market pressure for holistic sustainable solutions.

These regulatory developments have fundamentally altered research priorities and investment patterns in the marine coatings industry. Major coating manufacturers have redirected significant R&D resources toward developing compliant alternatives, with annual industry investment in copper-free technologies estimated to have increased by over 300% in the past decade. This regulatory pressure has accelerated innovation timelines, with several major companies announcing copper-free product launches ahead of anticipated regulatory deadlines.

The geographical variation in regulatory stringency has created a complex global market for antifouling coatings. Regions with stricter regulations, particularly in Northern Europe and parts of North America, have become test markets for advanced copper-free solutions, while less regulated markets continue to rely predominantly on traditional copper-based products. This regulatory patchwork presents both challenges and opportunities for coating developers, requiring flexible product portfolios and region-specific market strategies.

This regulatory shift created an immediate market gap that was initially filled by copper-based alternatives. However, mounting evidence of copper's detrimental effects on marine ecosystems has prompted further regulatory action. The European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's (EPA) Vessel General Permit program have both implemented restrictions on copper release rates from antifouling coatings, with some regional authorities in Washington State and California enforcing even stricter limitations.

The regulatory landscape continues to evolve toward a zero-discharge approach. The EU's Water Framework Directive has classified copper as a "priority substance," signaling potential future restrictions. Similarly, the International Maritime Organization's Ballast Water Management Convention, while not directly targeting antifouling coatings, reflects the growing regulatory emphasis on reducing shipping's environmental footprint, creating market pressure for holistic sustainable solutions.

These regulatory developments have fundamentally altered research priorities and investment patterns in the marine coatings industry. Major coating manufacturers have redirected significant R&D resources toward developing compliant alternatives, with annual industry investment in copper-free technologies estimated to have increased by over 300% in the past decade. This regulatory pressure has accelerated innovation timelines, with several major companies announcing copper-free product launches ahead of anticipated regulatory deadlines.

The geographical variation in regulatory stringency has created a complex global market for antifouling coatings. Regions with stricter regulations, particularly in Northern Europe and parts of North America, have become test markets for advanced copper-free solutions, while less regulated markets continue to rely predominantly on traditional copper-based products. This regulatory patchwork presents both challenges and opportunities for coating developers, requiring flexible product portfolios and region-specific market strategies.

Performance Testing Standards for Marine Coatings

Performance testing standards for marine coatings, particularly for copper-free anti-fouling solutions, are critical for ensuring these environmentally friendly alternatives meet the rigorous demands of maritime operations. The International Maritime Organization (IMO) has established several key performance metrics that all marine coatings must satisfy, with additional considerations for sustainable alternatives that aim to reduce environmental impact.

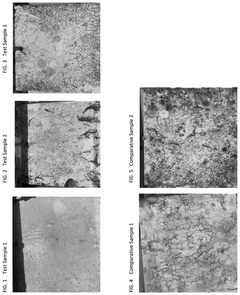

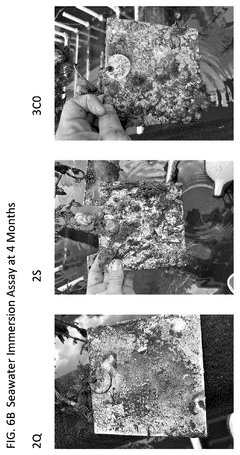

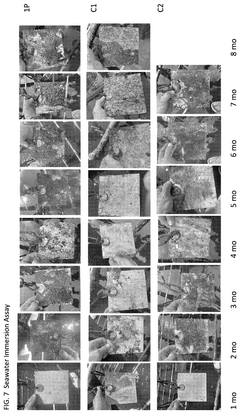

The ISO 15181 series provides standardized methods for determining the release rate of biocides from anti-fouling coatings, which is particularly relevant when evaluating copper-free alternatives. These standards help quantify the effectiveness of new formulations without relying on traditional copper compounds. Additionally, ASTM D6990 outlines procedures for evaluating the resistance of coatings to biofouling accumulation under natural seawater conditions.

For copper-free coatings specifically, performance testing must address several critical parameters. Fouling resistance testing typically involves both laboratory and field trials, with standardized protocols requiring exposure periods ranging from 6 to 36 months in various marine environments. The CEPE Antifouling Working Group has developed specific guidelines for evaluating the performance of environmentally acceptable alternatives to copper-based systems.

Mechanical durability testing follows standards such as ASTM D4060 for abrasion resistance and ISO 1522 for hardness determination. These are particularly important for copper-free formulations, as their physical properties often differ significantly from traditional copper-based coatings. Adhesion testing according to ISO 2409 (cross-cut test) and ASTM D4541 (pull-off test) ensures the coating maintains integrity throughout its service life.

Environmental performance metrics have gained prominence in recent years, with standards like ISO 14669 measuring toxicity to marine organisms. The EU's Biocidal Products Regulation (BPR) requires comprehensive environmental risk assessments for all active substances, creating a standardized framework for evaluating the ecological impact of copper-free alternatives.

Long-term performance validation typically follows the ASTM D3623 standard for in-service evaluation of anti-fouling coatings. This involves documenting fouling resistance, coating integrity, and fuel efficiency impacts over multiple years. The International Paint and Printing Ink Council (IPPIC) has established a working group specifically focused on developing standardized protocols for evaluating the long-term performance of sustainable anti-fouling technologies.

Emerging standards are now incorporating digital monitoring systems that allow for real-time performance assessment, with organizations like NACE International developing protocols for integrating sensor data into coating performance evaluation frameworks. These advanced testing methodologies are particularly valuable for novel copper-free technologies where historical performance data may be limited.

The ISO 15181 series provides standardized methods for determining the release rate of biocides from anti-fouling coatings, which is particularly relevant when evaluating copper-free alternatives. These standards help quantify the effectiveness of new formulations without relying on traditional copper compounds. Additionally, ASTM D6990 outlines procedures for evaluating the resistance of coatings to biofouling accumulation under natural seawater conditions.

For copper-free coatings specifically, performance testing must address several critical parameters. Fouling resistance testing typically involves both laboratory and field trials, with standardized protocols requiring exposure periods ranging from 6 to 36 months in various marine environments. The CEPE Antifouling Working Group has developed specific guidelines for evaluating the performance of environmentally acceptable alternatives to copper-based systems.

Mechanical durability testing follows standards such as ASTM D4060 for abrasion resistance and ISO 1522 for hardness determination. These are particularly important for copper-free formulations, as their physical properties often differ significantly from traditional copper-based coatings. Adhesion testing according to ISO 2409 (cross-cut test) and ASTM D4541 (pull-off test) ensures the coating maintains integrity throughout its service life.

Environmental performance metrics have gained prominence in recent years, with standards like ISO 14669 measuring toxicity to marine organisms. The EU's Biocidal Products Regulation (BPR) requires comprehensive environmental risk assessments for all active substances, creating a standardized framework for evaluating the ecological impact of copper-free alternatives.

Long-term performance validation typically follows the ASTM D3623 standard for in-service evaluation of anti-fouling coatings. This involves documenting fouling resistance, coating integrity, and fuel efficiency impacts over multiple years. The International Paint and Printing Ink Council (IPPIC) has established a working group specifically focused on developing standardized protocols for evaluating the long-term performance of sustainable anti-fouling technologies.

Emerging standards are now incorporating digital monitoring systems that allow for real-time performance assessment, with organizations like NACE International developing protocols for integrating sensor data into coating performance evaluation frameworks. These advanced testing methodologies are particularly valuable for novel copper-free technologies where historical performance data may be limited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!