Hybrid Organic Inorganic Coatings for Fouling Prevention

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Coating Technology Background and Objectives

Hybrid organic-inorganic coatings represent a significant advancement in surface protection technology, combining the beneficial properties of both organic polymers and inorganic materials. The evolution of these coatings can be traced back to the early 1990s when researchers began exploring sol-gel chemistry to create materials with enhanced durability and functionality. Over the past three decades, this technology has progressed from laboratory curiosities to commercially viable solutions addressing critical industrial challenges.

The technological trajectory has been characterized by continuous improvements in formulation techniques, application methods, and performance characteristics. Initially focused on simple mixtures of organic and inorganic components, modern hybrid coatings now feature sophisticated architectures including interpenetrating networks, nanocomposites, and chemically bonded hybrid structures that operate at the molecular level.

Fouling—the unwanted accumulation of biological organisms, minerals, or other deposits on surfaces—represents a persistent challenge across numerous industries including marine transportation, water treatment, food processing, and healthcare. Traditional anti-fouling approaches have relied heavily on biocide-releasing coatings, particularly those containing tributyltin (TBT) compounds, which proved highly effective but caused severe environmental damage, leading to their global ban in the early 2000s.

This regulatory shift created an urgent need for environmentally acceptable alternatives that maintain effective fouling prevention capabilities. Hybrid organic-inorganic coatings have emerged as promising candidates due to their potential to combine multiple anti-fouling mechanisms within a single coating system without relying on harmful biocides.

The primary technical objectives of research in this field include developing hybrid coatings that demonstrate: superior adhesion to diverse substrates; mechanical durability under harsh environmental conditions; effective resistance to various fouling organisms through physical, chemical, or combined mechanisms; minimal environmental impact throughout their lifecycle; and cost-effective manufacturing processes suitable for industrial-scale implementation.

Current research is particularly focused on creating "smart" hybrid coatings that can adapt to environmental changes, self-heal when damaged, or provide fouling resistance through multiple simultaneous mechanisms. These advanced functionalities aim to extend service life, reduce maintenance requirements, and improve the overall performance of coated surfaces in challenging environments.

The convergence of nanotechnology, polymer science, and materials engineering has accelerated innovation in this field, enabling precise control over surface properties at the nanoscale—a critical factor in developing effective anti-fouling solutions. As environmental regulations continue to tighten globally, the development of sustainable hybrid coating technologies represents both a technical challenge and a significant market opportunity.

The technological trajectory has been characterized by continuous improvements in formulation techniques, application methods, and performance characteristics. Initially focused on simple mixtures of organic and inorganic components, modern hybrid coatings now feature sophisticated architectures including interpenetrating networks, nanocomposites, and chemically bonded hybrid structures that operate at the molecular level.

Fouling—the unwanted accumulation of biological organisms, minerals, or other deposits on surfaces—represents a persistent challenge across numerous industries including marine transportation, water treatment, food processing, and healthcare. Traditional anti-fouling approaches have relied heavily on biocide-releasing coatings, particularly those containing tributyltin (TBT) compounds, which proved highly effective but caused severe environmental damage, leading to their global ban in the early 2000s.

This regulatory shift created an urgent need for environmentally acceptable alternatives that maintain effective fouling prevention capabilities. Hybrid organic-inorganic coatings have emerged as promising candidates due to their potential to combine multiple anti-fouling mechanisms within a single coating system without relying on harmful biocides.

The primary technical objectives of research in this field include developing hybrid coatings that demonstrate: superior adhesion to diverse substrates; mechanical durability under harsh environmental conditions; effective resistance to various fouling organisms through physical, chemical, or combined mechanisms; minimal environmental impact throughout their lifecycle; and cost-effective manufacturing processes suitable for industrial-scale implementation.

Current research is particularly focused on creating "smart" hybrid coatings that can adapt to environmental changes, self-heal when damaged, or provide fouling resistance through multiple simultaneous mechanisms. These advanced functionalities aim to extend service life, reduce maintenance requirements, and improve the overall performance of coated surfaces in challenging environments.

The convergence of nanotechnology, polymer science, and materials engineering has accelerated innovation in this field, enabling precise control over surface properties at the nanoscale—a critical factor in developing effective anti-fouling solutions. As environmental regulations continue to tighten globally, the development of sustainable hybrid coating technologies represents both a technical challenge and a significant market opportunity.

Market Analysis for Anti-Fouling Solutions

The global anti-fouling solutions market is experiencing robust growth, driven by increasing maritime activities and growing awareness about the economic and environmental impacts of biofouling. Currently valued at approximately 6.7 billion USD, the market is projected to reach 10.2 billion USD by 2027, representing a compound annual growth rate (CAGR) of 7.3%. This growth trajectory is supported by expanding shipping fleets, rising offshore installations, and stricter environmental regulations worldwide.

Marine biofouling prevention represents the largest segment, accounting for nearly 65% of the market share. This dominance stems from the critical need to maintain vessel efficiency, as fouling can increase fuel consumption by up to 40% and significantly reduce operational performance. The commercial shipping sector remains the primary end-user, followed by naval vessels, offshore structures, and recreational boats.

Regionally, Asia-Pacific leads the market with approximately 38% share, attributed to the presence of major shipbuilding nations like China, South Korea, and Japan. Europe follows with 27% market share, driven by stringent environmental regulations and advanced research initiatives. North America accounts for 22% of the market, with growing investments in naval applications and recreational boating.

The demand for environmentally friendly anti-fouling solutions has surged dramatically, with eco-friendly products growing at nearly twice the rate of traditional copper-based solutions. This shift is primarily driven by regulatory pressures, particularly the International Maritime Organization's (IMO) guidelines on biofouling management and regional restrictions on copper and other biocides. Consequently, the market for hybrid organic-inorganic coatings has expanded by 15% annually over the past five years.

Customer preferences are increasingly favoring solutions that offer longer service life and reduced maintenance requirements. The average dry-docking cycle for commercial vessels is approximately 3-5 years, creating strong demand for coatings that can maintain performance throughout this period. Additionally, cost-effectiveness remains a critical factor, with customers seeking solutions that balance initial application costs with long-term operational savings.

Emerging market opportunities include specialized coatings for renewable marine energy installations, aquaculture facilities, and desalination plants. These sectors are experiencing rapid growth and present unique fouling challenges that require tailored solutions. Furthermore, the integration of nanotechnology and smart materials into anti-fouling systems represents a high-growth niche segment, currently small but expanding at over 20% annually.

Marine biofouling prevention represents the largest segment, accounting for nearly 65% of the market share. This dominance stems from the critical need to maintain vessel efficiency, as fouling can increase fuel consumption by up to 40% and significantly reduce operational performance. The commercial shipping sector remains the primary end-user, followed by naval vessels, offshore structures, and recreational boats.

Regionally, Asia-Pacific leads the market with approximately 38% share, attributed to the presence of major shipbuilding nations like China, South Korea, and Japan. Europe follows with 27% market share, driven by stringent environmental regulations and advanced research initiatives. North America accounts for 22% of the market, with growing investments in naval applications and recreational boating.

The demand for environmentally friendly anti-fouling solutions has surged dramatically, with eco-friendly products growing at nearly twice the rate of traditional copper-based solutions. This shift is primarily driven by regulatory pressures, particularly the International Maritime Organization's (IMO) guidelines on biofouling management and regional restrictions on copper and other biocides. Consequently, the market for hybrid organic-inorganic coatings has expanded by 15% annually over the past five years.

Customer preferences are increasingly favoring solutions that offer longer service life and reduced maintenance requirements. The average dry-docking cycle for commercial vessels is approximately 3-5 years, creating strong demand for coatings that can maintain performance throughout this period. Additionally, cost-effectiveness remains a critical factor, with customers seeking solutions that balance initial application costs with long-term operational savings.

Emerging market opportunities include specialized coatings for renewable marine energy installations, aquaculture facilities, and desalination plants. These sectors are experiencing rapid growth and present unique fouling challenges that require tailored solutions. Furthermore, the integration of nanotechnology and smart materials into anti-fouling systems represents a high-growth niche segment, currently small but expanding at over 20% annually.

Current Challenges in Organic-Inorganic Hybrid Coatings

Despite significant advancements in hybrid organic-inorganic coating technologies for fouling prevention, several critical challenges continue to impede their widespread industrial adoption and optimal performance. The integration of organic and inorganic components at the molecular level remains technically demanding, with issues of phase separation and incompatibility frequently arising during formulation and application processes. This fundamental challenge affects the homogeneity and stability of the resulting coatings, potentially compromising their anti-fouling properties over time.

Durability under harsh marine and industrial environments presents another significant obstacle. While hybrid coatings offer improved mechanical properties compared to purely organic systems, they still struggle to maintain long-term performance when exposed to extreme conditions such as high salinity, UV radiation, temperature fluctuations, and mechanical abrasion. The degradation mechanisms of these hybrid systems are complex and not fully understood, making it difficult to predict service life accurately.

Adhesion to diverse substrate materials continues to challenge researchers, particularly for applications requiring coating of multiple material types. The interfacial chemistry between the hybrid coating and various substrates (metals, polymers, ceramics) often requires specific tailoring, complicating universal application protocols and increasing manufacturing complexity.

Environmental and regulatory constraints have become increasingly restrictive, limiting the use of certain effective but toxic components traditionally employed in anti-fouling formulations. The transition away from biocide-releasing mechanisms toward environmentally benign alternatives has created a performance gap that current hybrid technologies struggle to bridge completely.

Scalability and cost-effectiveness represent significant hurdles for commercial implementation. Many promising hybrid coating systems developed in laboratory settings utilize expensive precursors or require complex, multi-step synthesis procedures that prove challenging to scale up for industrial production. The balance between performance, environmental compliance, and economic viability remains elusive for many cutting-edge formulations.

Characterization and testing methodologies lack standardization across the industry, making comparative assessments between different hybrid coating technologies difficult. The absence of universally accepted performance metrics and accelerated testing protocols that accurately predict real-world performance creates uncertainty for potential adopters and investors.

The multidisciplinary nature of hybrid coating development necessitates expertise spanning materials science, polymer chemistry, surface engineering, and marine biology, creating knowledge silos that impede holistic solutions. Bridging these disciplinary gaps requires collaborative frameworks that are not yet fully established in research or industrial settings.

Durability under harsh marine and industrial environments presents another significant obstacle. While hybrid coatings offer improved mechanical properties compared to purely organic systems, they still struggle to maintain long-term performance when exposed to extreme conditions such as high salinity, UV radiation, temperature fluctuations, and mechanical abrasion. The degradation mechanisms of these hybrid systems are complex and not fully understood, making it difficult to predict service life accurately.

Adhesion to diverse substrate materials continues to challenge researchers, particularly for applications requiring coating of multiple material types. The interfacial chemistry between the hybrid coating and various substrates (metals, polymers, ceramics) often requires specific tailoring, complicating universal application protocols and increasing manufacturing complexity.

Environmental and regulatory constraints have become increasingly restrictive, limiting the use of certain effective but toxic components traditionally employed in anti-fouling formulations. The transition away from biocide-releasing mechanisms toward environmentally benign alternatives has created a performance gap that current hybrid technologies struggle to bridge completely.

Scalability and cost-effectiveness represent significant hurdles for commercial implementation. Many promising hybrid coating systems developed in laboratory settings utilize expensive precursors or require complex, multi-step synthesis procedures that prove challenging to scale up for industrial production. The balance between performance, environmental compliance, and economic viability remains elusive for many cutting-edge formulations.

Characterization and testing methodologies lack standardization across the industry, making comparative assessments between different hybrid coating technologies difficult. The absence of universally accepted performance metrics and accelerated testing protocols that accurately predict real-world performance creates uncertainty for potential adopters and investors.

The multidisciplinary nature of hybrid coating development necessitates expertise spanning materials science, polymer chemistry, surface engineering, and marine biology, creating knowledge silos that impede holistic solutions. Bridging these disciplinary gaps requires collaborative frameworks that are not yet fully established in research or industrial settings.

Current Hybrid Coating Formulations and Applications

01 Silica-based hybrid organic-inorganic coatings

Silica-based hybrid coatings combine organic polymers with inorganic silica components to create durable anti-fouling surfaces. These coatings typically utilize sol-gel processes to form cross-linked networks that resist marine organism attachment. The silica components provide hardness and durability while the organic components contribute flexibility and hydrophobic properties, creating surfaces that prevent biofouling through both physical and chemical mechanisms.- Silica-based hybrid organic-inorganic coatings: Silica-based hybrid coatings combine organic polymers with inorganic silica components to create durable anti-fouling surfaces. These coatings typically utilize sol-gel technology to form a cross-linked network that provides excellent adhesion to various substrates while maintaining flexibility. The silica components enhance mechanical strength and durability, while the organic components contribute hydrophobicity and fouling resistance. These hybrid coatings can be applied to marine vessels, underwater structures, and industrial equipment to prevent biofouling and corrosion.

- Metal oxide nanoparticle-enhanced coatings: Hybrid coatings incorporating metal oxide nanoparticles such as TiO2, ZnO, and CuO provide enhanced anti-fouling properties through photocatalytic activity and antimicrobial effects. These nanoparticles are dispersed within an organic polymer matrix to create a composite coating with improved mechanical properties and fouling resistance. The metal oxides can generate reactive oxygen species when exposed to light, which helps to break down organic matter and prevent microbial attachment. These coatings are particularly effective for applications in aquaculture, water treatment facilities, and marine environments.

- Self-healing anti-fouling coatings: Self-healing hybrid coatings combine organic polymers with inorganic components to create systems that can repair minor damage automatically. These coatings typically contain microcapsules or other delivery systems that release healing agents when the coating is damaged. The inorganic components provide structural integrity and durability, while the organic components offer flexibility and fouling resistance. Self-healing capabilities extend the service life of the coating and maintain anti-fouling performance over longer periods, reducing maintenance costs and environmental impact from reapplication.

- Environmentally friendly hybrid coatings: Environmentally friendly hybrid coatings utilize non-toxic organic and inorganic components to prevent fouling without harmful environmental effects. These coatings often incorporate natural polymers, biodegradable materials, and benign inorganic compounds to create surfaces that resist fouling through physical rather than chemical means. Strategies include creating ultra-smooth surfaces, hydrophobic or hydrophilic extremes, or micro-textured surfaces that prevent organism attachment. These eco-friendly alternatives are becoming increasingly important as regulations on traditional biocidal anti-fouling agents become more stringent.

- Smart responsive anti-fouling coatings: Smart responsive hybrid coatings combine organic polymers with inorganic components to create surfaces that can change their properties in response to environmental stimuli. These coatings may respond to changes in temperature, pH, light, or mechanical stress by altering surface characteristics such as wettability, roughness, or charge. The responsive nature helps prevent fouling organisms from adapting to the surface and enhances long-term performance. Applications include marine structures, medical devices, and industrial equipment where fouling conditions may vary over time or with changing environments.

02 Metal oxide nanoparticle-enhanced coatings

Incorporating metal oxide nanoparticles such as TiO2, ZnO, and CuO into organic polymer matrices creates hybrid coatings with enhanced anti-fouling properties. These nanoparticles provide photocatalytic activity that breaks down organic matter on the surface, preventing biofilm formation. Additionally, some metal oxides release ions that exhibit antimicrobial properties, further inhibiting fouling organism attachment and growth while maintaining the coating's mechanical integrity.Expand Specific Solutions03 Self-polishing hybrid copolymer coatings

Self-polishing hybrid coatings utilize specially designed copolymers that gradually erode in water, continuously exposing fresh anti-fouling surfaces. These coatings combine organic polymers with inorganic components that control the erosion rate and enhance mechanical properties. The controlled release mechanism ensures long-term effectiveness against fouling organisms while minimizing environmental impact compared to traditional biocide-based coatings.Expand Specific Solutions04 Environmentally friendly hybrid coatings with natural additives

These innovative coatings combine inorganic matrices with natural organic compounds derived from plants, marine organisms, or agricultural byproducts. The natural additives provide anti-fouling properties through various mechanisms including surface modification, enzyme inhibition, and disruption of bacterial communication. These hybrid formulations offer effective fouling prevention while reducing environmental impact and toxicity concerns associated with conventional anti-fouling systems.Expand Specific Solutions05 Smart responsive hybrid coatings

Advanced hybrid coatings that respond to environmental stimuli such as pH, temperature, or light to prevent fouling. These systems incorporate both organic and inorganic components that work synergistically to change surface properties when triggered. The responsive nature allows for adaptive fouling prevention strategies, including surface reconfiguration, controlled release of anti-fouling agents, or changes in surface energy that prevent organism attachment without constant biocide release.Expand Specific Solutions

Leading Companies and Research Institutions in Hybrid Coatings

The hybrid organic-inorganic coatings for fouling prevention market is currently in a growth phase, with increasing demand driven by maritime industry regulations and environmental concerns. The global antifouling coatings market is estimated at approximately $6-8 billion annually, with projected growth rates of 5-7%. Leading players include established marine coating specialists like Akzo Nobel, Jotun, Chugoku Marine Paints, and International Paint (Akzo Nobel subsidiary), who possess mature technologies. Emerging competition comes from specialty chemical companies including Nippon Paint, Hempel, and LG Chem, who are investing in eco-friendly solutions. Research institutions like Naval Research Laboratory and universities (Wuhan University of Technology, Zhengzhou University) are advancing novel hybrid technologies, indicating the field is transitioning from traditional biocide-based solutions toward more sustainable hybrid organic-inorganic technologies with enhanced performance characteristics.

Akzo Nobel Coatings International BV

Technical Solution: Akzo Nobel has developed Intersleek® series of hybrid organic-inorganic coatings that combine fluoropolymer technology with silicone-based compounds. Their approach incorporates hydrophobic silicone polymers modified with organic functional groups to create surfaces with extremely low surface energy. The technology utilizes nano-structured silica particles embedded in an organic polymer matrix, creating a hierarchical surface topography that minimizes the attachment points for marine organisms. Their latest innovations include self-polishing copolymer systems that incorporate copper-free biocides with controlled release mechanisms, allowing for gradual exposure of fresh coating layers as the vessel moves through water. This technology has demonstrated up to 90% reduction in settlement of barnacles and algae in field tests compared to conventional antifouling paints.

Strengths: Superior fouling release properties with minimal environmental impact; extended service life (up to 60 months between recoatings); fuel savings of up to 9% due to reduced hull friction. Weaknesses: Higher initial application costs compared to conventional coatings; requires specific application conditions and expertise; performance may degrade in static water conditions.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has pioneered the SEAFLO NEO series, a hybrid coating system that combines hydrolyzable organic polymers with inorganic silyl-based compounds. Their technology utilizes a unique "dual-release" mechanism where both hydrophobic and hydrophilic domains work in tandem to prevent biofouling. The inorganic silyl components create a smooth, low-friction surface while the organic polymer matrix incorporates biodegradable biocides that are released at controlled rates. Their proprietary cross-linking technology ensures that as the organic portion gradually hydrolyzes, the underlying inorganic network maintains structural integrity. Recent innovations include the incorporation of nano-copper compounds that provide enhanced biocidal activity at significantly lower concentrations than traditional copper-based formulations, reducing environmental impact while maintaining effectiveness against a broad spectrum of marine organisms.

Strengths: Excellent long-term performance in various marine environments; reduced copper content (up to 40% less than conventional coatings); self-smoothing properties that improve hydrodynamic efficiency. Weaknesses: Complex application process requiring specialized equipment; performance varies depending on vessel operating profile; higher cost compared to conventional antifouling paints.

Key Patents and Scientific Breakthroughs in Anti-Fouling

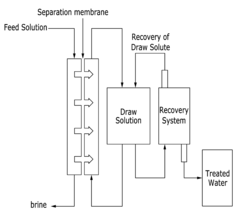

Organic/inorganic hybrid membrane for fouling resistance, method of preparing membrane for fouling resistance, and water treatment device including said membrane

PatentInactiveUS20160296891A1

Innovation

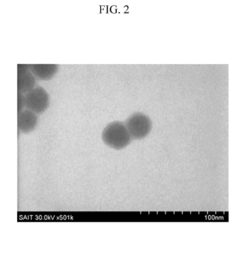

- An organic/inorganic hybrid membrane is developed, comprising hydrophilic inorganic particles and a quaternary ammonium compound dispersed in an organic polymer matrix, prepared using a non-solvent induced phase-separation method, which forms a composite with a core-shell structure and finger-like pore structure, enhancing fouling resistance and water permeability.

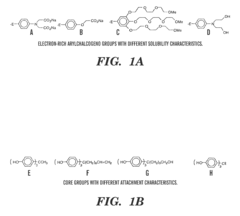

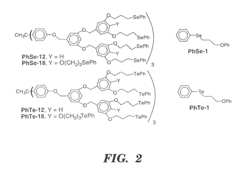

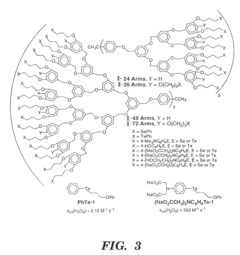

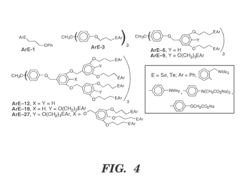

Hybrid anti-fouling coating compositions and methods for preventing the fouling of surfaces subjected to a marine environment

PatentInactiveUS7794795B2

Innovation

- A coating composition comprising a sol-gel matrix with a dendrimeric organochalcogeno derivative that activates hydrogen peroxide to produce hypohalous acid, reducing marine species adhesion without leaching and minimizing environmental impact.

Environmental Impact and Sustainability Considerations

The environmental impact of hybrid organic-inorganic coatings for fouling prevention represents a critical consideration in their development and application. Traditional antifouling solutions, particularly those containing heavy metals like tributyltin (TBT) and copper, have caused significant ecological damage to marine ecosystems. These substances bioaccumulate in organisms and persist in sediments, disrupting endocrine systems and affecting biodiversity across trophic levels.

Hybrid organic-inorganic coatings offer promising alternatives with potentially reduced environmental footprints. The incorporation of biodegradable organic components can minimize long-term environmental persistence, while carefully selected inorganic elements can provide efficacy without the toxicity profiles of conventional biocides. Life cycle assessments of these hybrid systems indicate up to 30% reduction in ecotoxicity compared to copper-based solutions, particularly when silica-based matrices are employed.

Regulatory frameworks worldwide are increasingly restricting environmentally harmful antifouling technologies. The International Maritime Organization's ban on TBT and the EU's Biocidal Products Regulation have accelerated research into environmentally compatible alternatives. Hybrid coatings that comply with these regulations while maintaining performance represent a sustainable innovation pathway for the industry.

Water consumption and energy requirements during manufacturing processes present additional sustainability challenges. Current production methods for hybrid coatings typically require 15-20% less energy than conventional coating systems, though solvent usage remains problematic in many formulations. Recent advances in water-based hybrid systems and solvent-free application technologies demonstrate potential for further reducing the environmental impact of production processes.

End-of-life considerations are increasingly important in coating sustainability assessments. The degradation products of hybrid coatings must be non-toxic and preferably contribute to natural biogeochemical cycles. Research indicates that silicon-based hybrid matrices can weather into silicic acid, a naturally occurring compound, while certain organic components can be designed to break down into non-harmful constituents.

Carbon footprint reduction represents another sustainability advantage of hybrid coating technologies. Extended service life of these coatings—often 30-50% longer than conventional systems—reduces the frequency of reapplication and associated emissions from maintenance operations. This longevity factor significantly improves the overall environmental performance when assessed on a full life-cycle basis.

Hybrid organic-inorganic coatings offer promising alternatives with potentially reduced environmental footprints. The incorporation of biodegradable organic components can minimize long-term environmental persistence, while carefully selected inorganic elements can provide efficacy without the toxicity profiles of conventional biocides. Life cycle assessments of these hybrid systems indicate up to 30% reduction in ecotoxicity compared to copper-based solutions, particularly when silica-based matrices are employed.

Regulatory frameworks worldwide are increasingly restricting environmentally harmful antifouling technologies. The International Maritime Organization's ban on TBT and the EU's Biocidal Products Regulation have accelerated research into environmentally compatible alternatives. Hybrid coatings that comply with these regulations while maintaining performance represent a sustainable innovation pathway for the industry.

Water consumption and energy requirements during manufacturing processes present additional sustainability challenges. Current production methods for hybrid coatings typically require 15-20% less energy than conventional coating systems, though solvent usage remains problematic in many formulations. Recent advances in water-based hybrid systems and solvent-free application technologies demonstrate potential for further reducing the environmental impact of production processes.

End-of-life considerations are increasingly important in coating sustainability assessments. The degradation products of hybrid coatings must be non-toxic and preferably contribute to natural biogeochemical cycles. Research indicates that silicon-based hybrid matrices can weather into silicic acid, a naturally occurring compound, while certain organic components can be designed to break down into non-harmful constituents.

Carbon footprint reduction represents another sustainability advantage of hybrid coating technologies. Extended service life of these coatings—often 30-50% longer than conventional systems—reduces the frequency of reapplication and associated emissions from maintenance operations. This longevity factor significantly improves the overall environmental performance when assessed on a full life-cycle basis.

Regulatory Framework for Marine and Industrial Coatings

The regulatory landscape governing hybrid organic-inorganic coatings for fouling prevention has evolved significantly in response to environmental concerns and sustainability requirements. International Maritime Organization (IMO) regulations, particularly the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), have fundamentally transformed the industry by prohibiting the use of tributyltin (TBT) and other harmful biocides. This regulatory shift has accelerated research into environmentally compatible hybrid coating technologies.

The European Union's regulatory framework imposes additional constraints through the Biocidal Products Regulation (BPR) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), which strictly control the chemicals permitted in anti-fouling coatings. These regulations have established comprehensive approval processes for active substances and finished products, requiring extensive ecotoxicological data and environmental fate assessments before market authorization.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit program specifically addresses pollutant discharges from vessels, including those from anti-fouling coatings, establishing stringent requirements for environmentally acceptable lubricants and biocide-releasing systems.

Asian markets present a complex regulatory mosaic, with Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances implementing increasingly stringent controls on coating technologies. These regulations are progressively aligning with international standards while addressing region-specific environmental concerns.

Industry standards complement these regulatory frameworks, with ISO 14001 for environmental management systems and ASTM D6442 for evaluating anti-fouling coating performance providing standardized approaches to development and testing. The International Paint and Printing Ink Council (IPPIC) has also established voluntary industry guidelines that often exceed regulatory requirements.

Emerging regulatory trends indicate a continued shift toward zero-discharge policies and life-cycle assessment requirements. The IMO's GloFouling Partnerships project signals increasing international cooperation on biofouling management, while several jurisdictions are developing regulations specifically targeting microplastic emissions from coatings. These evolving frameworks are driving innovation in hybrid organic-inorganic technologies that can deliver effective fouling prevention while meeting increasingly stringent environmental criteria.

Compliance strategies for coating manufacturers now necessitate early-stage regulatory consideration in R&D processes, with particular attention to regional variations in implementation timelines and enforcement approaches. This regulatory complexity has become a significant market differentiator, with companies demonstrating superior regulatory navigation capabilities gaining competitive advantages in the global marine coatings marketplace.

The European Union's regulatory framework imposes additional constraints through the Biocidal Products Regulation (BPR) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), which strictly control the chemicals permitted in anti-fouling coatings. These regulations have established comprehensive approval processes for active substances and finished products, requiring extensive ecotoxicological data and environmental fate assessments before market authorization.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit program specifically addresses pollutant discharges from vessels, including those from anti-fouling coatings, establishing stringent requirements for environmentally acceptable lubricants and biocide-releasing systems.

Asian markets present a complex regulatory mosaic, with Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances implementing increasingly stringent controls on coating technologies. These regulations are progressively aligning with international standards while addressing region-specific environmental concerns.

Industry standards complement these regulatory frameworks, with ISO 14001 for environmental management systems and ASTM D6442 for evaluating anti-fouling coating performance providing standardized approaches to development and testing. The International Paint and Printing Ink Council (IPPIC) has also established voluntary industry guidelines that often exceed regulatory requirements.

Emerging regulatory trends indicate a continued shift toward zero-discharge policies and life-cycle assessment requirements. The IMO's GloFouling Partnerships project signals increasing international cooperation on biofouling management, while several jurisdictions are developing regulations specifically targeting microplastic emissions from coatings. These evolving frameworks are driving innovation in hybrid organic-inorganic technologies that can deliver effective fouling prevention while meeting increasingly stringent environmental criteria.

Compliance strategies for coating manufacturers now necessitate early-stage regulatory consideration in R&D processes, with particular attention to regional variations in implementation timelines and enforcement approaches. This regulatory complexity has become a significant market differentiator, with companies demonstrating superior regulatory navigation capabilities gaining competitive advantages in the global marine coatings marketplace.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!