Nanocomposite Anti Fouling Coatings for Offshore Equipment

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocomposite Coatings Background and Objectives

Nanocomposite anti-fouling coatings represent a significant technological advancement in the protection of offshore equipment against biofouling and corrosion. The evolution of these coatings can be traced back to traditional anti-fouling paints containing tributyltin (TBT) compounds, which were highly effective but caused severe environmental damage, leading to their global ban in the early 2000s. This regulatory shift catalyzed research into environmentally friendly alternatives, driving the development of copper-based coatings and subsequently more sophisticated silicone and fluoropolymer-based solutions.

The emergence of nanotechnology in the late 1990s and its rapid advancement in the 2000s opened new possibilities for coating technologies. By incorporating nanomaterials such as nanosilica, carbon nanotubes, graphene, and metal oxide nanoparticles into polymer matrices, researchers discovered enhanced mechanical properties, improved adhesion, and superior anti-fouling capabilities compared to conventional coatings. This technological convergence marked the birth of nanocomposite anti-fouling coatings.

Recent trends in this field demonstrate a clear shift toward multifunctional coating systems that simultaneously address multiple challenges faced by offshore equipment. These advanced coatings not only prevent biofouling but also provide corrosion protection, reduce drag, and exhibit self-healing properties. The integration of stimuli-responsive nanomaterials has further expanded the functionality of these coatings, enabling controlled release of anti-fouling agents in response to environmental triggers.

The primary technical objectives for nanocomposite anti-fouling coatings include extending service life beyond the current industry standard of 3-5 years to 7-10 years, reducing maintenance frequency and associated costs. Additionally, there is a strong focus on developing formulations that maintain effectiveness while complying with increasingly stringent environmental regulations worldwide, particularly regarding copper and other biocide leaching.

Another critical objective is improving the mechanical durability of these coatings to withstand the harsh conditions encountered in offshore environments, including high-pressure water, abrasion from debris, and extreme temperature fluctuations. Researchers are also working to enhance the adhesion properties of nanocomposite coatings to various substrate materials commonly used in offshore equipment.

The ultimate goal is to develop next-generation nanocomposite anti-fouling coatings that offer superior performance with minimal environmental impact, thereby addressing the offshore industry's dual challenges of operational efficiency and environmental sustainability. This requires a multidisciplinary approach combining materials science, nanotechnology, marine biology, and environmental engineering to create innovative solutions that can withstand the demanding conditions of offshore operations while meeting global regulatory requirements.

The emergence of nanotechnology in the late 1990s and its rapid advancement in the 2000s opened new possibilities for coating technologies. By incorporating nanomaterials such as nanosilica, carbon nanotubes, graphene, and metal oxide nanoparticles into polymer matrices, researchers discovered enhanced mechanical properties, improved adhesion, and superior anti-fouling capabilities compared to conventional coatings. This technological convergence marked the birth of nanocomposite anti-fouling coatings.

Recent trends in this field demonstrate a clear shift toward multifunctional coating systems that simultaneously address multiple challenges faced by offshore equipment. These advanced coatings not only prevent biofouling but also provide corrosion protection, reduce drag, and exhibit self-healing properties. The integration of stimuli-responsive nanomaterials has further expanded the functionality of these coatings, enabling controlled release of anti-fouling agents in response to environmental triggers.

The primary technical objectives for nanocomposite anti-fouling coatings include extending service life beyond the current industry standard of 3-5 years to 7-10 years, reducing maintenance frequency and associated costs. Additionally, there is a strong focus on developing formulations that maintain effectiveness while complying with increasingly stringent environmental regulations worldwide, particularly regarding copper and other biocide leaching.

Another critical objective is improving the mechanical durability of these coatings to withstand the harsh conditions encountered in offshore environments, including high-pressure water, abrasion from debris, and extreme temperature fluctuations. Researchers are also working to enhance the adhesion properties of nanocomposite coatings to various substrate materials commonly used in offshore equipment.

The ultimate goal is to develop next-generation nanocomposite anti-fouling coatings that offer superior performance with minimal environmental impact, thereby addressing the offshore industry's dual challenges of operational efficiency and environmental sustainability. This requires a multidisciplinary approach combining materials science, nanotechnology, marine biology, and environmental engineering to create innovative solutions that can withstand the demanding conditions of offshore operations while meeting global regulatory requirements.

Market Analysis for Anti-Fouling Solutions in Offshore Industry

The global market for anti-fouling solutions in the offshore industry has experienced significant growth in recent years, driven by increasing offshore activities and stricter environmental regulations. The market value for marine anti-fouling coatings reached approximately $6.7 billion in 2022, with projections indicating growth to $9.3 billion by 2028, representing a compound annual growth rate of 5.6%.

Offshore equipment operators face substantial economic losses due to biofouling, estimated at $15-30 billion annually across the maritime industry. These costs stem from increased fuel consumption, maintenance expenses, and operational downtime. For offshore platforms specifically, biofouling can reduce operational efficiency by 10-15% and increase maintenance costs by up to 20%.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, followed by Europe (25%) and North America (20%). This distribution correlates with major offshore oil and gas activities and shipping routes. The Middle East and Africa regions are experiencing the fastest growth rates, driven by expanding offshore exploration activities.

By application segment, the market divides into several categories: offshore platforms (30%), subsea equipment (25%), vessels (35%), and others (10%). The demand for nanocomposite anti-fouling coatings is particularly strong in the subsea equipment segment, where traditional solutions have proven less effective against extreme conditions.

Customer requirements have evolved significantly, with increasing emphasis on environmentally sustainable solutions. The phase-out of tributyltin (TBT) compounds has created a market gap for effective yet eco-friendly alternatives. End-users now prioritize coatings with minimal environmental impact, long service life (5+ years), and reduced maintenance requirements.

Market research indicates that 78% of offshore operators consider biofouling a "significant" or "very significant" operational challenge. Furthermore, 65% express willingness to invest in premium anti-fouling solutions if they demonstrate clear return on investment through extended maintenance intervals and improved operational efficiency.

The competitive landscape features both established players and innovative startups. Traditional coating manufacturers hold approximately 60% market share, while specialized nanocomposite solution providers have captured 15% and are growing rapidly. This indicates significant market potential for advanced nanocomposite anti-fouling technologies that can address the specific challenges of offshore environments while meeting increasingly stringent environmental regulations.

Offshore equipment operators face substantial economic losses due to biofouling, estimated at $15-30 billion annually across the maritime industry. These costs stem from increased fuel consumption, maintenance expenses, and operational downtime. For offshore platforms specifically, biofouling can reduce operational efficiency by 10-15% and increase maintenance costs by up to 20%.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, followed by Europe (25%) and North America (20%). This distribution correlates with major offshore oil and gas activities and shipping routes. The Middle East and Africa regions are experiencing the fastest growth rates, driven by expanding offshore exploration activities.

By application segment, the market divides into several categories: offshore platforms (30%), subsea equipment (25%), vessels (35%), and others (10%). The demand for nanocomposite anti-fouling coatings is particularly strong in the subsea equipment segment, where traditional solutions have proven less effective against extreme conditions.

Customer requirements have evolved significantly, with increasing emphasis on environmentally sustainable solutions. The phase-out of tributyltin (TBT) compounds has created a market gap for effective yet eco-friendly alternatives. End-users now prioritize coatings with minimal environmental impact, long service life (5+ years), and reduced maintenance requirements.

Market research indicates that 78% of offshore operators consider biofouling a "significant" or "very significant" operational challenge. Furthermore, 65% express willingness to invest in premium anti-fouling solutions if they demonstrate clear return on investment through extended maintenance intervals and improved operational efficiency.

The competitive landscape features both established players and innovative startups. Traditional coating manufacturers hold approximately 60% market share, while specialized nanocomposite solution providers have captured 15% and are growing rapidly. This indicates significant market potential for advanced nanocomposite anti-fouling technologies that can address the specific challenges of offshore environments while meeting increasingly stringent environmental regulations.

Current Challenges in Nanocomposite Anti-Fouling Technology

Despite significant advancements in nanocomposite anti-fouling coatings for offshore equipment, several critical challenges continue to impede widespread adoption and optimal performance. The primary technical obstacle remains the long-term durability of these coatings in harsh marine environments. Current nanocomposite formulations often demonstrate promising anti-fouling properties in laboratory settings but fail to maintain effectiveness beyond 2-3 years in real-world applications, falling short of the 5+ year industry requirement for commercial viability.

Leaching of active components presents another significant challenge. Many nanocomposite coatings rely on controlled release mechanisms that gradually deplete over time, leading to diminished performance. The leaching rate is difficult to predict and control across varying environmental conditions, resulting in inconsistent protection and potential environmental concerns as nanomaterials enter marine ecosystems.

Adhesion failure between the nanocomposite coating and substrate materials represents a persistent technical hurdle. The integration of nanoparticles often disrupts polymer matrix cohesion, creating weak points vulnerable to mechanical stress, temperature fluctuations, and chemical exposure. This is particularly problematic for offshore equipment subjected to constant wave action, abrasion from suspended particles, and extreme weather conditions.

Scale-up and manufacturing consistency pose substantial challenges for commercialization. Laboratory-scale production methods that achieve uniform nanoparticle dispersion often prove difficult to replicate in industrial settings. Agglomeration of nanoparticles during large-batch production compromises coating performance and creates quality control issues that limit market acceptance.

Regulatory uncertainty surrounding nanomaterials in marine environments creates additional barriers. Environmental agencies worldwide are developing frameworks to assess potential ecological impacts of nanomaterials, but the lack of standardized testing protocols and clear guidelines complicates compliance efforts and increases development costs.

Cost-effectiveness remains a significant obstacle to widespread adoption. Current manufacturing processes for high-performance nanocomposite coatings involve expensive nanomaterials, complex formulation procedures, and specialized application techniques. The resulting price premium over conventional coatings is difficult to justify despite potential long-term benefits, particularly in price-sensitive market segments.

Mechanical property trade-offs continue to challenge formulators. Enhancing anti-fouling performance through nanoparticle incorporation often compromises other critical properties such as flexibility, impact resistance, and abrasion resistance. This creates a complex optimization problem that has yet to be fully resolved, particularly for equipment subjected to varied operational stresses.

Leaching of active components presents another significant challenge. Many nanocomposite coatings rely on controlled release mechanisms that gradually deplete over time, leading to diminished performance. The leaching rate is difficult to predict and control across varying environmental conditions, resulting in inconsistent protection and potential environmental concerns as nanomaterials enter marine ecosystems.

Adhesion failure between the nanocomposite coating and substrate materials represents a persistent technical hurdle. The integration of nanoparticles often disrupts polymer matrix cohesion, creating weak points vulnerable to mechanical stress, temperature fluctuations, and chemical exposure. This is particularly problematic for offshore equipment subjected to constant wave action, abrasion from suspended particles, and extreme weather conditions.

Scale-up and manufacturing consistency pose substantial challenges for commercialization. Laboratory-scale production methods that achieve uniform nanoparticle dispersion often prove difficult to replicate in industrial settings. Agglomeration of nanoparticles during large-batch production compromises coating performance and creates quality control issues that limit market acceptance.

Regulatory uncertainty surrounding nanomaterials in marine environments creates additional barriers. Environmental agencies worldwide are developing frameworks to assess potential ecological impacts of nanomaterials, but the lack of standardized testing protocols and clear guidelines complicates compliance efforts and increases development costs.

Cost-effectiveness remains a significant obstacle to widespread adoption. Current manufacturing processes for high-performance nanocomposite coatings involve expensive nanomaterials, complex formulation procedures, and specialized application techniques. The resulting price premium over conventional coatings is difficult to justify despite potential long-term benefits, particularly in price-sensitive market segments.

Mechanical property trade-offs continue to challenge formulators. Enhancing anti-fouling performance through nanoparticle incorporation often compromises other critical properties such as flexibility, impact resistance, and abrasion resistance. This creates a complex optimization problem that has yet to be fully resolved, particularly for equipment subjected to varied operational stresses.

Current Nanocomposite Anti-Fouling Technical Solutions

01 Nanocomposite coatings with metal-based additives

Metal-based nanoparticles such as silver, copper, and zinc oxide are incorporated into coating matrices to create effective antifouling surfaces. These nanoparticles provide antimicrobial properties that prevent the attachment and growth of microorganisms on surfaces. The controlled release of metal ions creates a hostile environment for fouling organisms while maintaining long-term effectiveness of the coating.- Metal-based nanocomposite antifouling coatings: Metal-based nanocomposites, including copper, silver, and zinc oxide nanoparticles, are incorporated into coating matrices to provide effective antifouling properties. These metal nanoparticles exhibit antimicrobial activity that prevents the attachment and growth of marine organisms on surfaces. The controlled release of metal ions from these nanocomposites creates an environment hostile to biofouling organisms while maintaining long-term effectiveness of the coating.

- Polymer-based nanocomposite antifouling coatings: Polymer matrices enhanced with nanoparticles create effective antifouling surfaces with improved mechanical properties. These coatings utilize polymers such as silicones, polyurethanes, and acrylics combined with various nanofillers to create surfaces that resist organism attachment. The polymer matrices can be engineered to have low surface energy, self-cleaning properties, or controlled release mechanisms that prevent biofouling while maintaining environmental compatibility.

- Environmentally friendly nanocomposite antifouling solutions: Eco-friendly nanocomposite antifouling coatings utilize natural compounds and biodegradable materials to reduce environmental impact while maintaining effectiveness. These formulations incorporate natural biocides, plant extracts, or enzymes with nanoparticles to create sustainable antifouling solutions. The nanocomposites are designed to degrade safely in marine environments after their functional lifetime, addressing concerns about toxicity to non-target marine organisms.

- Surface modification techniques for antifouling nanocomposites: Surface modification techniques enhance the antifouling properties of nanocomposite coatings by altering surface topography, chemistry, or charge. These methods include creating micro/nano-structured surfaces, hydrophobic or hydrophilic patterns, or charged surfaces that prevent organism attachment. The modified surfaces can disrupt the settlement mechanisms of fouling organisms through physical or chemical means without relying solely on biocidal activity.

- Self-healing nanocomposite antifouling coatings: Self-healing nanocomposite coatings incorporate materials that can repair damage automatically, extending the functional lifetime of antifouling surfaces. These advanced coatings contain encapsulated healing agents that are released when the coating is damaged, restoring the protective barrier. The self-healing mechanism helps maintain continuous antifouling performance by preventing the formation of defects that could serve as attachment points for marine organisms.

02 Polymer-based nanocomposite antifouling coatings

Polymer matrices enhanced with nanoparticles create surfaces with reduced adhesion properties. These coatings utilize polymers such as silicones, fluoropolymers, or polyurethanes combined with nanomaterials to modify surface energy and topography. The resulting hydrophobic or hydrophilic surfaces prevent the attachment of marine organisms and biofilm formation, providing effective and environmentally friendly antifouling protection.Expand Specific Solutions03 Carbon-based nanomaterials for antifouling applications

Carbon-based nanomaterials such as graphene, carbon nanotubes, and fullerenes are incorporated into coating formulations to enhance antifouling properties. These materials provide exceptional mechanical strength, thermal stability, and antimicrobial activity. The unique surface properties of carbon nanomaterials disrupt the attachment mechanisms of fouling organisms while improving the durability and performance of the coating system.Expand Specific Solutions04 Self-cleaning and self-polishing nanocomposite coatings

Self-cleaning and self-polishing nanocomposite coatings utilize controlled erosion mechanisms to continuously expose fresh antifouling surfaces. These coatings incorporate nanomaterials that enhance the controlled release of biocides or create surface topographies that prevent fouling organism attachment. The gradual erosion of the coating surface helps maintain antifouling effectiveness over extended periods while reducing the need for mechanical cleaning.Expand Specific Solutions05 Environmentally friendly nanocomposite antifouling technologies

Environmentally friendly nanocomposite antifouling coatings utilize non-toxic mechanisms to prevent biofouling. These formulations incorporate natural compounds, biodegradable polymers, and sustainable nanomaterials that create antifouling surfaces without harmful environmental impacts. The coatings work through physical deterrence, surface modification, or controlled release of natural repellents rather than toxic biocides, meeting increasingly stringent environmental regulations.Expand Specific Solutions

Key Industry Players in Nanocomposite Marine Coatings

The nanocomposite anti-fouling coatings market for offshore equipment is in a growth phase, with increasing demand driven by expanding offshore operations globally. The market size is projected to grow significantly as maritime industries seek more effective and environmentally sustainable solutions. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established chemical companies like Evonik Operations and Wacker Chemie providing advanced polymer solutions, marine coating specialists such as Chugoku Marine Paints, International Paint, and Hempel offering specialized products, and research institutions like Naval Research Laboratory and Korea Institute of Ocean Science & Technology driving fundamental innovations. Academic-industry partnerships, particularly with universities in China, are accelerating technological advancement in this competitive landscape.

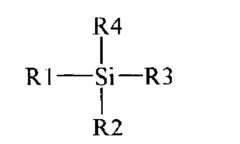

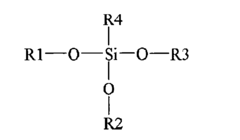

Evonik Operations GmbH

Technical Solution: Evonik has developed TEGO® nanocomposite anti-fouling technology utilizing silica nanoparticles functionalized with organosilanes to create superhydrophobic surfaces. Their approach combines nano-structured silica (15-25nm) with fluoropolymer matrices to achieve water contact angles exceeding 150°, preventing initial biofouling attachment. The company's proprietary surface modification technology creates nanoscale roughness patterns that trap air pockets, further enhancing anti-adhesion properties[2]. Evonik's latest innovation incorporates photocatalytic titanium dioxide nanoparticles that generate reactive oxygen species when exposed to sunlight, providing an additional anti-microbial mechanism without traditional biocides. Their formulations also feature nano-encapsulated natural repellents derived from marine organisms, which are gradually released through environmentally-triggered mechanisms. Laboratory testing has demonstrated fouling prevention efficacy comparable to conventional copper-based coatings but with significantly reduced environmental impact[5]. The technology has been successfully deployed on offshore wind turbine foundations, reducing maintenance frequency by approximately 40%.

Strengths: Environmentally friendly approach with minimal toxicity concerns; excellent durability with service life exceeding 5 years; versatile application across various offshore structures including wind energy installations. Weaknesses: Performance may be reduced in low-light underwater environments limiting photocatalytic effectiveness; higher initial cost compared to conventional solutions; potential challenges with large-scale manufacturing consistency.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed SEA PREMIER nanocomposite anti-fouling technology that incorporates zinc oxide nanoparticles (30-50nm) within a hydrolyzable polymer matrix. This system creates a self-polishing effect where the coating surface gradually erodes in seawater, continuously exposing fresh biocidal nanoparticles. Their proprietary nano-dispersion technology ensures uniform distribution of nanoparticles throughout the coating, preventing agglomeration that could compromise performance[1]. The company's latest innovation combines copper-free biocides with nanoscale silica particles modified with quaternary ammonium compounds, providing dual-action protection through both physical and chemical mechanisms. Chugoku's formulation achieves a controlled hydrophobic-hydrophilic balance that minimizes protein adhesion, the first step in biofouling. Laboratory testing has demonstrated up to 95% reduction in barnacle settlement compared to conventional coatings, with field trials showing effective protection for 60+ months in tropical waters[3]. The coating also incorporates carbon nanotubes to enhance mechanical strength and abrasion resistance.

Strengths: Excellent long-term performance in high-fouling environments; reduced copper content addressing environmental concerns; self-polishing mechanism ensuring consistent performance throughout service life. Weaknesses: Potential environmental concerns regarding nanoparticle release during the self-polishing process; higher manufacturing costs due to complex nano-dispersion requirements; performance may vary depending on vessel operational profile.

Critical Patents and Research in Anti-Fouling Nanocomposites

Marine antifouling paint composition

PatentInactiveEP1788042A2

Innovation

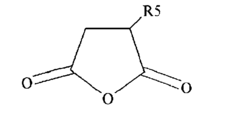

- A coating composition comprising 25-60% alcohol and paraffin, 2-10% epoxy resin, and 5-70% organosilicon compounds, synthesized through the sol-gel process, forming a porous nanocomposite that inhibits fouling through hydrolysis and condensation reactions, creating a covalently bonded, durable, and low-density surface with additives like nanozinc oxide and peroxide for enhanced adhesion and bactericidal properties.

Marine coating formulations

PatentWO2022032341A1

Innovation

- A marine coating formulation incorporating nano-active materials such as MgO powders with high porosity and surface area, combined with polymer binders and additives, including booster antifoulants and anticorrosion materials, to provide long-lasting antifouling and anti-corrosion properties without using toxic substances, allowing for reduced copper content and compatibility with aluminum substrates.

Environmental Regulations Impact on Coating Development

Environmental regulations have become a pivotal force shaping the development of nanocomposite anti-fouling coatings for offshore equipment. The most significant regulatory shift occurred in 2008 when the International Maritime Organization (IMO) banned tributyltin (TBT)-based coatings due to their severe environmental toxicity. This watershed moment catalyzed intensive research into environmentally acceptable alternatives, fundamentally altering the trajectory of anti-fouling technology development.

Current regulatory frameworks across major maritime nations increasingly emphasize the reduction of biocide leaching rates and the elimination of persistent, bioaccumulative, and toxic (PBT) substances. The European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's Vessel General Permit (VGP) program have established stringent requirements for coating performance validation and environmental impact assessment, directly influencing formulation strategies for nanocomposite coatings.

Regional variations in regulatory standards create significant challenges for global coating manufacturers. For instance, Scandinavian countries enforce stricter copper release limits than many other regions, while Australia and New Zealand have implemented unique testing protocols for novel biocides. These disparities necessitate the development of regionally adaptable coating formulations, increasing research complexity and commercialization costs.

The regulatory trend toward "zero discharge" policies is accelerating the shift from biocide-based solutions to physical deterrence mechanisms in nanocomposite coatings. This has spurred innovation in surface topography manipulation at the nanoscale and the development of slippery liquid-infused porous surfaces (SLIPS) that prevent fouling organism attachment without chemical toxicity.

Lifecycle assessment (LCA) requirements are increasingly embedded in regulatory frameworks, compelling manufacturers to consider the environmental impact of nanocomposite coatings from raw material extraction through disposal. This holistic approach has led to greater scrutiny of nanoparticle fate and behavior in marine environments, with particular concern regarding potential bioaccumulation of engineered nanomaterials.

Looking forward, anticipated regulatory developments include more comprehensive nanoparticle-specific regulations, standardized protocols for evaluating novel anti-fouling mechanisms, and potential carbon footprint requirements for coating production processes. These evolving regulatory landscapes are not merely constraints but are actively driving innovation toward truly sustainable nanocomposite anti-fouling solutions that balance performance requirements with environmental protection imperatives.

Current regulatory frameworks across major maritime nations increasingly emphasize the reduction of biocide leaching rates and the elimination of persistent, bioaccumulative, and toxic (PBT) substances. The European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's Vessel General Permit (VGP) program have established stringent requirements for coating performance validation and environmental impact assessment, directly influencing formulation strategies for nanocomposite coatings.

Regional variations in regulatory standards create significant challenges for global coating manufacturers. For instance, Scandinavian countries enforce stricter copper release limits than many other regions, while Australia and New Zealand have implemented unique testing protocols for novel biocides. These disparities necessitate the development of regionally adaptable coating formulations, increasing research complexity and commercialization costs.

The regulatory trend toward "zero discharge" policies is accelerating the shift from biocide-based solutions to physical deterrence mechanisms in nanocomposite coatings. This has spurred innovation in surface topography manipulation at the nanoscale and the development of slippery liquid-infused porous surfaces (SLIPS) that prevent fouling organism attachment without chemical toxicity.

Lifecycle assessment (LCA) requirements are increasingly embedded in regulatory frameworks, compelling manufacturers to consider the environmental impact of nanocomposite coatings from raw material extraction through disposal. This holistic approach has led to greater scrutiny of nanoparticle fate and behavior in marine environments, with particular concern regarding potential bioaccumulation of engineered nanomaterials.

Looking forward, anticipated regulatory developments include more comprehensive nanoparticle-specific regulations, standardized protocols for evaluating novel anti-fouling mechanisms, and potential carbon footprint requirements for coating production processes. These evolving regulatory landscapes are not merely constraints but are actively driving innovation toward truly sustainable nanocomposite anti-fouling solutions that balance performance requirements with environmental protection imperatives.

Durability and Performance Testing Methodologies

Testing methodologies for nanocomposite anti-fouling coatings must comprehensively evaluate both durability and performance under realistic offshore conditions. Standard laboratory tests include salt spray exposure (ASTM B117), which subjects coatings to continuous salt fog environments for periods ranging from 500 to 5,000 hours to assess corrosion resistance and adhesion retention. Accelerated weathering chambers utilizing UV radiation, temperature cycling, and humidity control (ASTM G154) provide critical data on coating degradation mechanisms.

Immersion testing represents a cornerstone methodology, where coated panels are submerged in natural seawater tanks or field deployment stations for extended periods, typically 6-24 months. These tests evaluate biofouling resistance through quantitative measurements of biomass accumulation, species identification, and coverage percentage. Advanced protocols incorporate flow dynamics to simulate water movement around offshore structures.

Mechanical durability assessments include abrasion resistance testing (ASTM D4060), impact resistance (ASTM D2794), and adhesion testing under wet and dry conditions (ASTM D3359, ISO 2409). These evaluations are particularly relevant for offshore equipment subjected to maintenance operations, debris impact, and wave action.

Chemical resistance protocols expose coatings to hydrocarbons, cleaning agents, and production chemicals commonly encountered in offshore operations. Standardized testing according to NACE TM0174 evaluates coating integrity after exposure to these substances under various temperature conditions.

Specialized methodologies for anti-fouling performance include rotating disk methods, which apply controlled hydrodynamic forces to evaluate coating performance under varying flow conditions. Barnacle adhesion strength tests quantify the force required to remove attached organisms, providing a direct measure of fouling-release properties.

Field testing remains indispensable despite laboratory advances, with test panels deployed at multiple geographic locations representing different marine ecosystems. These panels undergo periodic inspection and documentation using standardized rating systems (ASTM D6990, ASTM D3623) to evaluate performance under authentic conditions.

Emerging methodologies incorporate advanced analytical techniques such as electrochemical impedance spectroscopy (EIS) to monitor coating degradation in real-time, and confocal laser scanning microscopy to evaluate biofilm formation at microscopic scales. These techniques provide deeper insights into coating failure mechanisms and performance limitations.

Immersion testing represents a cornerstone methodology, where coated panels are submerged in natural seawater tanks or field deployment stations for extended periods, typically 6-24 months. These tests evaluate biofouling resistance through quantitative measurements of biomass accumulation, species identification, and coverage percentage. Advanced protocols incorporate flow dynamics to simulate water movement around offshore structures.

Mechanical durability assessments include abrasion resistance testing (ASTM D4060), impact resistance (ASTM D2794), and adhesion testing under wet and dry conditions (ASTM D3359, ISO 2409). These evaluations are particularly relevant for offshore equipment subjected to maintenance operations, debris impact, and wave action.

Chemical resistance protocols expose coatings to hydrocarbons, cleaning agents, and production chemicals commonly encountered in offshore operations. Standardized testing according to NACE TM0174 evaluates coating integrity after exposure to these substances under various temperature conditions.

Specialized methodologies for anti-fouling performance include rotating disk methods, which apply controlled hydrodynamic forces to evaluate coating performance under varying flow conditions. Barnacle adhesion strength tests quantify the force required to remove attached organisms, providing a direct measure of fouling-release properties.

Field testing remains indispensable despite laboratory advances, with test panels deployed at multiple geographic locations representing different marine ecosystems. These panels undergo periodic inspection and documentation using standardized rating systems (ASTM D6990, ASTM D3623) to evaluate performance under authentic conditions.

Emerging methodologies incorporate advanced analytical techniques such as electrochemical impedance spectroscopy (EIS) to monitor coating degradation in real-time, and confocal laser scanning microscopy to evaluate biofilm formation at microscopic scales. These techniques provide deeper insights into coating failure mechanisms and performance limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!