Graphene Based Anti Fouling Nanocomposite Coatings

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Coating Evolution and Research Objectives

Graphene, a two-dimensional carbon allotrope with exceptional properties, has revolutionized the field of anti-fouling coatings since its discovery in 2004. The evolution of graphene-based anti-fouling nanocomposite coatings represents a significant advancement in surface protection technologies, transitioning from traditional biocide-releasing systems to more environmentally sustainable solutions. This technological progression has been driven by increasing regulatory restrictions on conventional anti-fouling compounds and the growing demand for longer-lasting, more effective coating systems across marine, medical, and industrial applications.

The historical development of graphene coatings began with fundamental research on graphene's intrinsic properties, including its impermeability to most gases and liquids, exceptional mechanical strength, and unique surface characteristics. Early research focused on graphene oxide (GO) and reduced graphene oxide (rGO) as more economically viable alternatives to pristine graphene, establishing the foundation for practical applications in coating technologies.

By the mid-2010s, researchers successfully incorporated graphene materials into polymer matrices, creating the first generation of graphene-based nanocomposite coatings. These early formulations demonstrated improved barrier properties and mechanical durability compared to conventional coatings but faced challenges in dispersion uniformity and adhesion to substrates. Subsequent advancements addressed these limitations through surface functionalization techniques and improved manufacturing processes.

Recent developments have focused on synergistic combinations of graphene with other nanomaterials such as silver nanoparticles, titanium dioxide, and silica to enhance anti-fouling performance through multiple mechanisms. The integration of graphene into smart coating systems capable of responding to environmental stimuli represents the cutting edge of current research, enabling adaptive anti-fouling strategies that can maintain effectiveness under varying conditions.

The primary research objectives in this field now center on several key areas: optimizing graphene dispersion within various polymer matrices to ensure uniform performance; developing scalable and cost-effective production methods suitable for industrial implementation; enhancing the long-term stability and durability of graphene-based coatings under harsh environmental conditions; and quantifying the environmental impact and safety profiles of these advanced materials throughout their lifecycle.

Additionally, researchers aim to elucidate the fundamental mechanisms by which graphene-based coatings inhibit biofouling, focusing on surface energy manipulation, contact killing properties, and the disruption of microbial communication systems. Understanding these mechanisms will enable more targeted design approaches and potentially unlock new applications across diverse sectors including maritime transportation, healthcare facilities, food processing equipment, and water treatment infrastructure.

The convergence of nanotechnology, materials science, and surface engineering in this field points toward a future where graphene-based anti-fouling coatings could significantly reduce maintenance costs, extend asset lifespans, and minimize environmental impacts across multiple industries, representing a transformative technological advancement with substantial economic and ecological implications.

The historical development of graphene coatings began with fundamental research on graphene's intrinsic properties, including its impermeability to most gases and liquids, exceptional mechanical strength, and unique surface characteristics. Early research focused on graphene oxide (GO) and reduced graphene oxide (rGO) as more economically viable alternatives to pristine graphene, establishing the foundation for practical applications in coating technologies.

By the mid-2010s, researchers successfully incorporated graphene materials into polymer matrices, creating the first generation of graphene-based nanocomposite coatings. These early formulations demonstrated improved barrier properties and mechanical durability compared to conventional coatings but faced challenges in dispersion uniformity and adhesion to substrates. Subsequent advancements addressed these limitations through surface functionalization techniques and improved manufacturing processes.

Recent developments have focused on synergistic combinations of graphene with other nanomaterials such as silver nanoparticles, titanium dioxide, and silica to enhance anti-fouling performance through multiple mechanisms. The integration of graphene into smart coating systems capable of responding to environmental stimuli represents the cutting edge of current research, enabling adaptive anti-fouling strategies that can maintain effectiveness under varying conditions.

The primary research objectives in this field now center on several key areas: optimizing graphene dispersion within various polymer matrices to ensure uniform performance; developing scalable and cost-effective production methods suitable for industrial implementation; enhancing the long-term stability and durability of graphene-based coatings under harsh environmental conditions; and quantifying the environmental impact and safety profiles of these advanced materials throughout their lifecycle.

Additionally, researchers aim to elucidate the fundamental mechanisms by which graphene-based coatings inhibit biofouling, focusing on surface energy manipulation, contact killing properties, and the disruption of microbial communication systems. Understanding these mechanisms will enable more targeted design approaches and potentially unlock new applications across diverse sectors including maritime transportation, healthcare facilities, food processing equipment, and water treatment infrastructure.

The convergence of nanotechnology, materials science, and surface engineering in this field points toward a future where graphene-based anti-fouling coatings could significantly reduce maintenance costs, extend asset lifespans, and minimize environmental impacts across multiple industries, representing a transformative technological advancement with substantial economic and ecological implications.

Market Analysis for Anti-Fouling Nanocomposite Solutions

The global anti-fouling coatings market has been experiencing significant growth, valued at approximately $6.7 billion in 2022 and projected to reach $10.2 billion by 2028, with a compound annual growth rate (CAGR) of 7.2%. This growth is primarily driven by increasing maritime activities, expansion of offshore installations, and stricter environmental regulations regarding biocide usage in traditional anti-fouling solutions.

Marine applications currently dominate the market, accounting for nearly 65% of the total demand. The shipping industry alone faces annual losses of $7 billion due to increased fuel consumption caused by biofouling, creating a substantial economic incentive for effective solutions. Additionally, aquaculture, offshore energy installations, and underwater infrastructure represent rapidly expanding market segments with growth rates exceeding 9% annually.

Graphene-based anti-fouling nanocomposite coatings are positioned to capture a significant market share due to their superior performance characteristics. Current market penetration remains below 5%, indicating substantial growth potential as technology matures and production costs decrease. Early adopters include premium vessel operators, offshore energy companies, and specialized marine equipment manufacturers willing to invest in advanced protection systems.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global demand, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows at 28%, with stringent environmental regulations accelerating the adoption of eco-friendly alternatives. North America represents 21% of the market, with particular growth in specialized applications for naval vessels and offshore installations.

Customer segmentation shows distinct requirements across different sectors. Commercial shipping prioritizes durability and cost-effectiveness with coating lifespans exceeding five years. Naval and luxury vessel segments emphasize performance regardless of cost, while aquaculture operations focus on environmental compatibility and non-toxicity. These diverse needs create multiple entry points for graphene-based solutions tailored to specific applications.

Price sensitivity varies significantly across segments. While initial adoption faces challenges due to higher costs compared to traditional coatings (typically 2.5-3.5 times higher), the total cost of ownership analysis reveals potential savings of 15-20% over a five-year period when considering reduced maintenance requirements and fuel efficiency improvements. This economic advantage represents a key marketing opportunity for market penetration strategies.

Competitive analysis indicates that established coating manufacturers are increasingly incorporating graphene-based technologies through acquisitions and partnerships with nanomaterial specialists, signaling industry recognition of this technology's disruptive potential in the anti-fouling market landscape.

Marine applications currently dominate the market, accounting for nearly 65% of the total demand. The shipping industry alone faces annual losses of $7 billion due to increased fuel consumption caused by biofouling, creating a substantial economic incentive for effective solutions. Additionally, aquaculture, offshore energy installations, and underwater infrastructure represent rapidly expanding market segments with growth rates exceeding 9% annually.

Graphene-based anti-fouling nanocomposite coatings are positioned to capture a significant market share due to their superior performance characteristics. Current market penetration remains below 5%, indicating substantial growth potential as technology matures and production costs decrease. Early adopters include premium vessel operators, offshore energy companies, and specialized marine equipment manufacturers willing to invest in advanced protection systems.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global demand, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows at 28%, with stringent environmental regulations accelerating the adoption of eco-friendly alternatives. North America represents 21% of the market, with particular growth in specialized applications for naval vessels and offshore installations.

Customer segmentation shows distinct requirements across different sectors. Commercial shipping prioritizes durability and cost-effectiveness with coating lifespans exceeding five years. Naval and luxury vessel segments emphasize performance regardless of cost, while aquaculture operations focus on environmental compatibility and non-toxicity. These diverse needs create multiple entry points for graphene-based solutions tailored to specific applications.

Price sensitivity varies significantly across segments. While initial adoption faces challenges due to higher costs compared to traditional coatings (typically 2.5-3.5 times higher), the total cost of ownership analysis reveals potential savings of 15-20% over a five-year period when considering reduced maintenance requirements and fuel efficiency improvements. This economic advantage represents a key marketing opportunity for market penetration strategies.

Competitive analysis indicates that established coating manufacturers are increasingly incorporating graphene-based technologies through acquisitions and partnerships with nanomaterial specialists, signaling industry recognition of this technology's disruptive potential in the anti-fouling market landscape.

Global Graphene Anti-Fouling Technology Assessment

The graphene-based anti-fouling nanocomposite coatings market is experiencing significant growth globally, driven by increasing demand across marine, water treatment, and industrial sectors. The global market value was estimated at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2030, with a compound annual growth rate (CAGR) of 14.3%. This remarkable growth trajectory reflects the expanding applications and recognition of graphene's exceptional properties in anti-fouling solutions.

Asia-Pacific currently dominates the market with approximately 40% share, led by China, Japan, and South Korea's aggressive investments in advanced materials research and manufacturing capabilities. North America follows with 30% market share, where the focus is primarily on high-performance applications in defense and aerospace industries. Europe accounts for 25% of the market, with particular strength in marine and environmental applications, while the remaining 5% is distributed across other regions.

The marine industry represents the largest application segment, accounting for approximately 45% of the global market. Ship hulls and offshore structures coated with graphene-based anti-fouling materials demonstrate significant operational cost reductions through decreased fuel consumption and extended maintenance intervals. Water treatment applications constitute about 30% of the market, where membrane fouling prevention is critical for efficiency in desalination and filtration systems.

Industrial applications, including oil and gas, food processing, and medical devices, represent 25% of the market. These sectors benefit from the non-toxic nature of graphene-based coatings compared to traditional biocide-containing alternatives, aligning with increasingly stringent environmental regulations worldwide.

Consumer demand is primarily driven by performance factors, with end-users seeking coatings that provide longer service life, reduced maintenance requirements, and improved operational efficiency. Environmental compliance is becoming an equally important market driver as regulations against toxic anti-fouling compounds tighten globally, particularly in Europe and North America.

Market analysis indicates that premium graphene-based products command price points 30-50% higher than conventional anti-fouling solutions, yet the total cost of ownership is often lower due to extended service intervals and improved performance. This value proposition is particularly compelling in high-stakes applications where downtime is costly, such as commercial shipping and industrial processing.

Future market growth is expected to accelerate as manufacturing processes mature and economies of scale reduce production costs. The development of specialized formulations for specific industry applications represents a significant opportunity for market expansion and differentiation among competitors.

Asia-Pacific currently dominates the market with approximately 40% share, led by China, Japan, and South Korea's aggressive investments in advanced materials research and manufacturing capabilities. North America follows with 30% market share, where the focus is primarily on high-performance applications in defense and aerospace industries. Europe accounts for 25% of the market, with particular strength in marine and environmental applications, while the remaining 5% is distributed across other regions.

The marine industry represents the largest application segment, accounting for approximately 45% of the global market. Ship hulls and offshore structures coated with graphene-based anti-fouling materials demonstrate significant operational cost reductions through decreased fuel consumption and extended maintenance intervals. Water treatment applications constitute about 30% of the market, where membrane fouling prevention is critical for efficiency in desalination and filtration systems.

Industrial applications, including oil and gas, food processing, and medical devices, represent 25% of the market. These sectors benefit from the non-toxic nature of graphene-based coatings compared to traditional biocide-containing alternatives, aligning with increasingly stringent environmental regulations worldwide.

Consumer demand is primarily driven by performance factors, with end-users seeking coatings that provide longer service life, reduced maintenance requirements, and improved operational efficiency. Environmental compliance is becoming an equally important market driver as regulations against toxic anti-fouling compounds tighten globally, particularly in Europe and North America.

Market analysis indicates that premium graphene-based products command price points 30-50% higher than conventional anti-fouling solutions, yet the total cost of ownership is often lower due to extended service intervals and improved performance. This value proposition is particularly compelling in high-stakes applications where downtime is costly, such as commercial shipping and industrial processing.

Future market growth is expected to accelerate as manufacturing processes mature and economies of scale reduce production costs. The development of specialized formulations for specific industry applications represents a significant opportunity for market expansion and differentiation among competitors.

Current Anti-Fouling Graphene Coating Methodologies

01 Graphene oxide nanocomposite coatings for marine antifouling

Graphene oxide-based nanocomposite coatings can be applied to marine surfaces to prevent biofouling. These coatings utilize the unique properties of graphene oxide, such as its high surface area and mechanical strength, to create a barrier that inhibits the attachment of marine organisms. The nanocomposites often incorporate additional materials like polymers or metal oxides to enhance the antifouling properties, creating a durable and effective coating for ships, offshore structures, and other marine applications.- Graphene-polymer nanocomposite coatings for marine antifouling: Graphene-polymer nanocomposites can be formulated into marine coatings with excellent antifouling properties. These coatings combine the barrier properties of graphene with the flexibility and adhesion of polymers to create durable surfaces that resist biofouling. The graphene component provides a smooth surface that prevents the attachment of marine organisms, while the polymer matrix ensures good adhesion to substrates and environmental durability. These nanocomposite coatings offer an environmentally friendly alternative to traditional toxic antifouling paints.

- Graphene oxide-based antimicrobial coatings: Graphene oxide (GO) can be incorporated into nanocomposite coatings to provide antimicrobial properties that prevent biofouling. The oxygen-containing functional groups on GO sheets enable better dispersion in polymer matrices and interaction with microbial cell membranes. These coatings work by disrupting bacterial cell membranes and inhibiting biofilm formation. The antimicrobial activity can be enhanced by combining GO with other nanomaterials or by chemical functionalization, resulting in coatings that effectively prevent the attachment and growth of microorganisms on various surfaces.

- Reduced graphene oxide nanocomposites for enhanced corrosion resistance: Reduced graphene oxide (rGO) can be incorporated into nanocomposite coatings to provide both antifouling properties and enhanced corrosion resistance. The layered structure of rGO creates a tortuous path that prevents the diffusion of corrosive agents to the substrate. These nanocomposites can be applied to metal surfaces in marine environments where both biofouling and corrosion are concerns. The combination of antifouling properties and corrosion resistance makes these coatings particularly valuable for protecting ships, offshore structures, and underwater equipment.

- Graphene-metal oxide hybrid nanocomposite coatings: Hybrid nanocomposites combining graphene with metal oxides (such as TiO2, ZnO, or CuO) can be formulated into coatings with enhanced antifouling properties. The metal oxide components provide photocatalytic activity that generates reactive oxygen species under light exposure, which can destroy organic matter and prevent biofilm formation. Meanwhile, the graphene component improves the mechanical properties and provides a physical barrier against fouling organisms. These synergistic effects result in durable coatings with superior antifouling performance compared to coatings containing only graphene or metal oxides.

- Functionalized graphene nanocomposites for specific antifouling applications: Graphene can be chemically functionalized to enhance its compatibility with various polymer matrices and to impart specific antifouling properties. Functionalization can involve attaching hydrophilic, hydrophobic, or amphiphilic groups to graphene sheets, which can alter the surface energy and prevent the adhesion of fouling organisms. These functionalized graphene nanocomposites can be tailored for specific environments and applications, such as freshwater systems, marine environments, or medical devices. The ability to customize the surface properties makes these coatings versatile for addressing different types of biofouling challenges.

02 Graphene-polymer nanocomposites with antimicrobial properties

Nanocomposite coatings combining graphene with polymers can exhibit strong antimicrobial properties that prevent biofouling. The graphene components in these composites can disrupt bacterial cell membranes, while the polymer matrix provides stability and adhesion to various surfaces. These coatings can be engineered to release antimicrobial agents in a controlled manner or to create a surface that physically prevents microbial attachment. Such graphene-polymer nanocomposites are particularly useful in medical devices, water treatment systems, and food packaging applications.Expand Specific Solutions03 Functionalized graphene nanocomposites for enhanced antifouling

Functionalization of graphene surfaces within nanocomposite coatings can significantly improve their antifouling performance. By attaching specific functional groups to graphene sheets, the surface properties can be tailored to repel various foulants. These modifications can include hydrophilic or hydrophobic groups, charged moieties, or specific biomolecules that deter organism attachment. Functionalized graphene nanocomposites offer customizable solutions for different fouling environments and can be designed to maintain their effectiveness over extended periods.Expand Specific Solutions04 Metal-graphene hybrid nanocomposite antifouling coatings

Combining graphene with metal or metal oxide nanoparticles creates hybrid nanocomposite coatings with superior antifouling properties. These hybrids leverage the mechanical strength and barrier properties of graphene alongside the antimicrobial effects of metals such as silver, copper, or zinc. The synergistic interaction between the graphene sheets and metal components can provide multiple antifouling mechanisms, including contact killing, release of antimicrobial ions, and physical deterrence. These coatings are particularly effective in harsh environments where conventional antifouling solutions may fail.Expand Specific Solutions05 Environmental applications of graphene-based antifouling coatings

Graphene-based nanocomposite coatings offer environmentally friendly alternatives to traditional antifouling solutions. Unlike conventional antifouling paints that often contain toxic biocides, graphene nanocomposites can provide fouling protection through physical and mechanical mechanisms rather than chemical toxicity. These coatings can be applied to water filtration membranes, sensors, and monitoring equipment to prevent biofouling while minimizing environmental impact. The durability of graphene-based coatings also reduces the frequency of reapplication, further decreasing potential environmental contamination.Expand Specific Solutions

Industry Leaders in Graphene Nanocomposite Materials

The graphene-based anti-fouling nanocomposite coatings market is currently in a growth phase, with increasing applications across marine, industrial, and water treatment sectors. The global market size is estimated to reach $2.5 billion by 2027, growing at a CAGR of approximately 15%. Technologically, these coatings are advancing from experimental to commercial applications, with varying degrees of maturity. Major chemical corporations like BASF Corp., 3M Innovative Properties, and China Petroleum & Chemical Corp. lead commercial development, while specialized companies such as Enerage Inc. and Luminit LLC focus on niche applications. Academic institutions including Harvard College, University of Bologna, and Ohio State University contribute significant research advancements. PPG Industries and Xerox Holdings are leveraging their coating expertise to develop proprietary graphene-based solutions, indicating the technology's transition toward mainstream industrial adoption.

BASF Corp.

Technical Solution: BASF has developed advanced graphene-based anti-fouling nanocomposite coatings that incorporate functionalized graphene oxide (GO) into polymer matrices. Their proprietary technology involves chemical modification of GO sheets with silane coupling agents to enhance dispersion and interfacial bonding with various polymer systems. The resulting nanocomposites exhibit exceptional barrier properties with oxygen transmission rates reduced by up to 90% compared to conventional coatings. BASF's approach includes a scalable production method using controlled exfoliation techniques that maintain graphene's structural integrity while allowing industrial-scale manufacturing. Their coatings demonstrate remarkable hydrophobicity with water contact angles exceeding 150°, creating self-cleaning surfaces that prevent biofouling attachment. The technology incorporates antimicrobial silver nanoparticles anchored to graphene sheets for enhanced biocidal properties against marine microorganisms.

Strengths: Superior dispersion technology enabling uniform graphene distribution throughout polymer matrices; established manufacturing infrastructure allowing scale-up potential; comprehensive testing protocols across marine environments. Weaknesses: Higher production costs compared to conventional coatings; potential environmental concerns regarding nanoparticle release during weathering; requires specialized application equipment.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-layer graphene nanocomposite coating system specifically engineered for marine and industrial anti-fouling applications. Their technology utilizes a proprietary exfoliation process that produces few-layer graphene sheets with controlled lateral dimensions (1-5 μm) and exceptional aspect ratios. These graphene sheets are chemically functionalized with fluorinated compounds to enhance hydrophobicity and oleophobicity simultaneously. The coating architecture consists of a base layer containing graphene-reinforced epoxy for adhesion and corrosion protection, followed by a middle layer incorporating graphene-silica hybrids for mechanical durability, and topped with a release layer containing graphene-PTFE nanocomposites. This system creates a hierarchical surface topography mimicking natural anti-fouling surfaces like lotus leaves. Testing in accelerated marine exposure conditions has demonstrated fouling release performance maintaining over 95% clean surface area after 12 months of immersion, significantly outperforming conventional biocide-based coatings.

Strengths: Exceptional durability with documented 5+ year service life in harsh marine environments; environmentally friendly formulation containing no toxic biocides; compatible with existing application equipment. Weaknesses: Premium pricing positioning limits market penetration in cost-sensitive segments; requires specific surface preparation protocols; performance degradation in static water conditions versus dynamic flow environments.

Key Patents in Graphene Nanocomposite Anti-Fouling

Electrically conductive antifouling coating composition

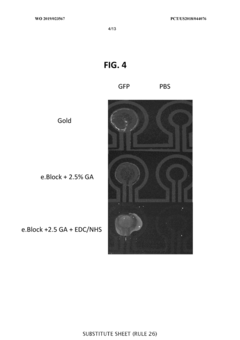

PatentWO2019023567A1

Innovation

- A conductive coating composition comprising a mixture of carbon allotropes, such as carbon nanotubes or graphene, with non-reversibly denatured proteinaceous materials like BSA, which is cross-linked and applied to electrodes to prevent fouling while preserving electrochemical signal sensitivity.

Composite Anti-fouling coatings and associated systems and methods

PatentPendingUS20230118162A1

Innovation

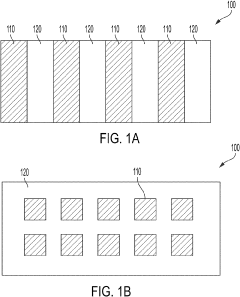

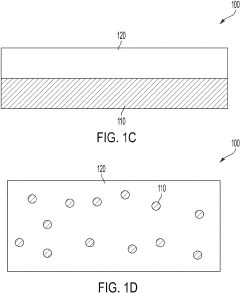

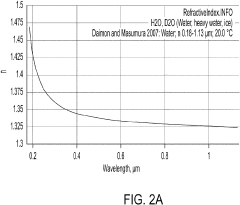

- A composite coating system with a first region and a second region, where the materials have optical properties that result in a low full-spectral Hamaker constant, reducing van der Waals forces and preventing foulant adhesion, is applied to substrates in these systems.

Environmental Impact and Sustainability Considerations

The environmental impact of graphene-based anti-fouling nanocomposite coatings represents a critical consideration in their development and application. These coatings offer significant potential to reduce the environmental footprint of marine vessels and underwater structures by minimizing the use of traditional toxic anti-fouling agents. Conventional anti-fouling solutions often contain heavy metals and biocides that leach into aquatic ecosystems, causing long-term environmental damage and bioaccumulation in marine organisms.

Graphene-based nanocomposite coatings present a more sustainable alternative through their physical anti-fouling mechanisms rather than chemical toxicity. The reduced need for frequent reapplication due to their enhanced durability translates to lower material consumption and waste generation over the lifecycle of treated surfaces. Life cycle assessment (LCA) studies indicate potential reductions in carbon footprint by up to 30% compared to conventional coating systems when considering manufacturing, application, maintenance, and disposal phases.

However, concerns remain regarding the potential environmental fate of graphene nanoparticles that may be released during weathering or mechanical damage of these coatings. Recent ecotoxicological studies have yielded mixed results, with some indicating minimal impact at expected environmental concentrations, while others suggest possible bioaccumulation in certain aquatic species. The long-term persistence of graphene in marine environments remains inadequately understood, necessitating further research into degradation pathways and transformation products.

From a sustainability perspective, the raw material sourcing for graphene production presents both challenges and opportunities. Current commercial production methods often rely on energy-intensive processes or hazardous chemicals. However, emerging green synthesis approaches utilizing biomass precursors or waste materials show promise for reducing the environmental burden of graphene production. Several research groups have demonstrated successful graphene synthesis from agricultural waste, potentially creating circular economy opportunities.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulation and similar initiatives in North America and Asia developing specific provisions for nanomaterial risk assessment. Manufacturers of graphene-based coatings must navigate these evolving regulatory landscapes while demonstrating environmental compliance through standardized testing protocols.

The water and energy consumption profiles of manufacturing processes for these coatings also warrant attention. Optimized production methods utilizing water-based formulations rather than solvent-based systems can significantly reduce volatile organic compound (VOC) emissions and associated environmental impacts. Additionally, the potential for these coatings to improve vessel fuel efficiency by reducing drag represents an indirect but substantial environmental benefit that should be quantified in comprehensive sustainability assessments.

Graphene-based nanocomposite coatings present a more sustainable alternative through their physical anti-fouling mechanisms rather than chemical toxicity. The reduced need for frequent reapplication due to their enhanced durability translates to lower material consumption and waste generation over the lifecycle of treated surfaces. Life cycle assessment (LCA) studies indicate potential reductions in carbon footprint by up to 30% compared to conventional coating systems when considering manufacturing, application, maintenance, and disposal phases.

However, concerns remain regarding the potential environmental fate of graphene nanoparticles that may be released during weathering or mechanical damage of these coatings. Recent ecotoxicological studies have yielded mixed results, with some indicating minimal impact at expected environmental concentrations, while others suggest possible bioaccumulation in certain aquatic species. The long-term persistence of graphene in marine environments remains inadequately understood, necessitating further research into degradation pathways and transformation products.

From a sustainability perspective, the raw material sourcing for graphene production presents both challenges and opportunities. Current commercial production methods often rely on energy-intensive processes or hazardous chemicals. However, emerging green synthesis approaches utilizing biomass precursors or waste materials show promise for reducing the environmental burden of graphene production. Several research groups have demonstrated successful graphene synthesis from agricultural waste, potentially creating circular economy opportunities.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulation and similar initiatives in North America and Asia developing specific provisions for nanomaterial risk assessment. Manufacturers of graphene-based coatings must navigate these evolving regulatory landscapes while demonstrating environmental compliance through standardized testing protocols.

The water and energy consumption profiles of manufacturing processes for these coatings also warrant attention. Optimized production methods utilizing water-based formulations rather than solvent-based systems can significantly reduce volatile organic compound (VOC) emissions and associated environmental impacts. Additionally, the potential for these coatings to improve vessel fuel efficiency by reducing drag represents an indirect but substantial environmental benefit that should be quantified in comprehensive sustainability assessments.

Scalability and Commercial Application Challenges

Despite the promising properties of graphene-based anti-fouling nanocomposite coatings, significant challenges remain in scaling production from laboratory to industrial levels. The primary obstacle lies in maintaining consistent quality and performance characteristics when transitioning from small-scale to mass production. Current manufacturing processes struggle to achieve uniform dispersion of graphene nanosheets within polymer matrices at industrial scales, leading to inconsistent anti-fouling performance across large surface areas.

Cost factors present another substantial barrier to commercialization. Raw material expenses, particularly for high-quality graphene, remain prohibitively high for widespread adoption. Production processes involving multiple steps and specialized equipment further increase manufacturing costs, making these coatings economically unviable for many potential applications despite their technical advantages.

Durability concerns also impact commercial viability. While laboratory tests show promising results, real-world applications expose these coatings to varied and harsh environmental conditions. The long-term stability of graphene-based coatings under UV exposure, mechanical abrasion, and chemical attack requires further investigation before widespread commercial deployment can be justified.

Regulatory hurdles compound these challenges. The novel nature of graphene nanomaterials raises questions about environmental impact and human health effects. Comprehensive toxicological studies are needed to satisfy regulatory requirements across different jurisdictions, adding time and cost to the commercialization pathway.

Integration with existing coating application systems presents technical difficulties. Many current industrial coating processes are not optimized for nanocomposite materials, requiring significant modifications to equipment and procedures. This creates resistance from potential industrial adopters who must weigh performance benefits against implementation costs.

Market acceptance faces additional obstacles related to industry conservatism. Traditional coating manufacturers and end-users often prefer established technologies with proven track records over innovative but less tested alternatives. Demonstrating clear value propositions through comprehensive performance data and cost-benefit analyses is essential to overcome this resistance.

Addressing these challenges requires coordinated efforts across the value chain. Research institutions must focus on developing scalable production methods, while industrial partners need to adapt existing manufacturing infrastructure. Government support through funding and regulatory guidance can accelerate this transition, potentially enabling graphene-based anti-fouling coatings to move from promising laboratory innovation to commercial reality.

Cost factors present another substantial barrier to commercialization. Raw material expenses, particularly for high-quality graphene, remain prohibitively high for widespread adoption. Production processes involving multiple steps and specialized equipment further increase manufacturing costs, making these coatings economically unviable for many potential applications despite their technical advantages.

Durability concerns also impact commercial viability. While laboratory tests show promising results, real-world applications expose these coatings to varied and harsh environmental conditions. The long-term stability of graphene-based coatings under UV exposure, mechanical abrasion, and chemical attack requires further investigation before widespread commercial deployment can be justified.

Regulatory hurdles compound these challenges. The novel nature of graphene nanomaterials raises questions about environmental impact and human health effects. Comprehensive toxicological studies are needed to satisfy regulatory requirements across different jurisdictions, adding time and cost to the commercialization pathway.

Integration with existing coating application systems presents technical difficulties. Many current industrial coating processes are not optimized for nanocomposite materials, requiring significant modifications to equipment and procedures. This creates resistance from potential industrial adopters who must weigh performance benefits against implementation costs.

Market acceptance faces additional obstacles related to industry conservatism. Traditional coating manufacturers and end-users often prefer established technologies with proven track records over innovative but less tested alternatives. Demonstrating clear value propositions through comprehensive performance data and cost-benefit analyses is essential to overcome this resistance.

Addressing these challenges requires coordinated efforts across the value chain. Research institutions must focus on developing scalable production methods, while industrial partners need to adapt existing manufacturing infrastructure. Government support through funding and regulatory guidance can accelerate this transition, potentially enabling graphene-based anti-fouling coatings to move from promising laboratory innovation to commercial reality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!