Anti Fouling Coatings for Seawater Desalination Membranes

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Fouling Background and Research Objectives

Membrane fouling represents one of the most significant challenges in seawater desalination processes, particularly for reverse osmosis (RO) and nanofiltration (NF) membrane technologies. The phenomenon occurs when various substances present in seawater—including organic matter, inorganic salts, microorganisms, and colloidal particles—accumulate on membrane surfaces or within pore structures. This accumulation progressively reduces water permeability, increases energy consumption, and ultimately shortens membrane lifespan, substantially impacting operational costs and efficiency of desalination plants worldwide.

The evolution of membrane fouling research dates back to the 1960s when commercial RO membranes were first introduced. Initial research focused primarily on understanding scaling mechanisms caused by inorganic compounds. By the 1980s, attention expanded to biofouling as researchers recognized the critical role of microbial communities in membrane performance degradation. The past two decades have witnessed significant advancements in characterization techniques, allowing for more sophisticated understanding of fouling mechanisms at molecular and nanoscopic levels.

Current industry practices rely heavily on chemical cleaning protocols and pretreatment systems to mitigate fouling effects. However, these approaches often involve harsh chemicals that can damage membrane structures and generate environmental concerns. The frequency of cleaning cycles directly impacts operational downtime and maintenance costs, creating a pressing need for more sustainable solutions.

Anti-fouling coatings have emerged as a promising technological direction, offering the potential to fundamentally alter membrane surface properties to resist foulant adhesion. Early generations of coatings focused on hydrophilic modifications, while recent innovations explore zwitterionic materials, nanoparticle incorporations, and biomimetic designs inspired by natural anti-fouling surfaces such as lotus leaves and shark skin.

The primary objectives of this research are threefold: first, to comprehensively evaluate the effectiveness of current anti-fouling coating technologies specifically for seawater desalination applications; second, to identify key performance limitations and failure mechanisms of existing coatings under real operational conditions; and third, to explore novel coating materials and application methods that can significantly extend membrane cleaning intervals while maintaining or improving water flux and salt rejection capabilities.

This research aims to bridge the gap between laboratory innovations and industrial implementation by addressing scalability challenges, long-term durability concerns, and cost-effectiveness requirements. The ultimate goal is to develop next-generation anti-fouling coatings that can substantially reduce operational costs of desalination plants while enhancing their environmental sustainability profile through reduced chemical usage and extended membrane lifespans.

The evolution of membrane fouling research dates back to the 1960s when commercial RO membranes were first introduced. Initial research focused primarily on understanding scaling mechanisms caused by inorganic compounds. By the 1980s, attention expanded to biofouling as researchers recognized the critical role of microbial communities in membrane performance degradation. The past two decades have witnessed significant advancements in characterization techniques, allowing for more sophisticated understanding of fouling mechanisms at molecular and nanoscopic levels.

Current industry practices rely heavily on chemical cleaning protocols and pretreatment systems to mitigate fouling effects. However, these approaches often involve harsh chemicals that can damage membrane structures and generate environmental concerns. The frequency of cleaning cycles directly impacts operational downtime and maintenance costs, creating a pressing need for more sustainable solutions.

Anti-fouling coatings have emerged as a promising technological direction, offering the potential to fundamentally alter membrane surface properties to resist foulant adhesion. Early generations of coatings focused on hydrophilic modifications, while recent innovations explore zwitterionic materials, nanoparticle incorporations, and biomimetic designs inspired by natural anti-fouling surfaces such as lotus leaves and shark skin.

The primary objectives of this research are threefold: first, to comprehensively evaluate the effectiveness of current anti-fouling coating technologies specifically for seawater desalination applications; second, to identify key performance limitations and failure mechanisms of existing coatings under real operational conditions; and third, to explore novel coating materials and application methods that can significantly extend membrane cleaning intervals while maintaining or improving water flux and salt rejection capabilities.

This research aims to bridge the gap between laboratory innovations and industrial implementation by addressing scalability challenges, long-term durability concerns, and cost-effectiveness requirements. The ultimate goal is to develop next-generation anti-fouling coatings that can substantially reduce operational costs of desalination plants while enhancing their environmental sustainability profile through reduced chemical usage and extended membrane lifespans.

Market Analysis of Anti-Fouling Technologies

The global anti-fouling coatings market for seawater desalination membranes is experiencing robust growth, driven by increasing water scarcity and the expanding deployment of desalination facilities worldwide. Current market valuations place this specialized segment at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030.

Demand for these specialized coatings is particularly strong in water-stressed regions including the Middle East, North Africa, and parts of Asia Pacific, where large-scale desalination projects are being implemented to address critical freshwater shortages. Saudi Arabia, UAE, and Israel represent the largest markets by volume, collectively accounting for over 40% of global consumption.

The market structure reveals a clear segmentation between conventional anti-fouling solutions and emerging technologies. Traditional polymer-based coatings currently dominate with 65% market share, while advanced nanocomposite and biomimetic coatings are gaining traction, growing at nearly twice the rate of conventional solutions. This shift reflects end-user preference for coatings that can extend membrane life while reducing cleaning frequency and chemical usage.

Industry analysis indicates that operational efficiency remains the primary purchase driver, with desalination plant operators willing to invest in premium coating solutions that demonstrate measurable reductions in biofouling and scaling. Market research shows that coatings capable of extending membrane cleaning intervals by 30% or more command price premiums of 15-25% over standard offerings.

Regulatory factors are increasingly influencing market dynamics, with environmental regulations in Europe and North America restricting the use of certain biocides and heavy metals in coating formulations. This regulatory landscape is accelerating the development of environmentally compatible alternatives, creating new market opportunities for green technologies.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies. Major players include Dow Chemical, BASF, Nitto Denko, and LG Chem, who collectively hold approximately 58% market share. However, several innovative startups focused exclusively on membrane coating technologies have secured significant venture capital funding, indicating strong investor confidence in this sector.

Customer segmentation reveals distinct needs across different facility sizes. Large-scale desalination plants prioritize long-term performance and total cost of ownership, while smaller facilities and mobile desalination units emphasize ease of application and compatibility with existing systems. This market stratification is driving product differentiation among suppliers.

Demand for these specialized coatings is particularly strong in water-stressed regions including the Middle East, North Africa, and parts of Asia Pacific, where large-scale desalination projects are being implemented to address critical freshwater shortages. Saudi Arabia, UAE, and Israel represent the largest markets by volume, collectively accounting for over 40% of global consumption.

The market structure reveals a clear segmentation between conventional anti-fouling solutions and emerging technologies. Traditional polymer-based coatings currently dominate with 65% market share, while advanced nanocomposite and biomimetic coatings are gaining traction, growing at nearly twice the rate of conventional solutions. This shift reflects end-user preference for coatings that can extend membrane life while reducing cleaning frequency and chemical usage.

Industry analysis indicates that operational efficiency remains the primary purchase driver, with desalination plant operators willing to invest in premium coating solutions that demonstrate measurable reductions in biofouling and scaling. Market research shows that coatings capable of extending membrane cleaning intervals by 30% or more command price premiums of 15-25% over standard offerings.

Regulatory factors are increasingly influencing market dynamics, with environmental regulations in Europe and North America restricting the use of certain biocides and heavy metals in coating formulations. This regulatory landscape is accelerating the development of environmentally compatible alternatives, creating new market opportunities for green technologies.

The competitive landscape features both specialized coating manufacturers and diversified chemical companies. Major players include Dow Chemical, BASF, Nitto Denko, and LG Chem, who collectively hold approximately 58% market share. However, several innovative startups focused exclusively on membrane coating technologies have secured significant venture capital funding, indicating strong investor confidence in this sector.

Customer segmentation reveals distinct needs across different facility sizes. Large-scale desalination plants prioritize long-term performance and total cost of ownership, while smaller facilities and mobile desalination units emphasize ease of application and compatibility with existing systems. This market stratification is driving product differentiation among suppliers.

Current Challenges in Desalination Membrane Coatings

Desalination membrane technology has emerged as a critical solution for global water scarcity, yet membrane fouling remains the most significant challenge limiting operational efficiency and economic viability. Current desalination membranes, primarily reverse osmosis (RO) types, suffer from severe performance degradation due to fouling mechanisms including biofouling, organic fouling, inorganic scaling, and colloidal deposition. These fouling phenomena collectively reduce permeate flux, increase energy consumption, and necessitate frequent chemical cleaning or membrane replacement.

Biofouling presents perhaps the most persistent challenge, with microorganisms forming resilient biofilms that are particularly difficult to remove once established. Conventional anti-fouling approaches using chlorine-based disinfectants often damage the polyamide active layers of RO membranes, creating a significant technical contradiction between fouling control and membrane integrity.

Current commercial anti-fouling coatings exhibit several limitations that hinder their widespread adoption. Hydrophilic coatings, while effective at reducing organic fouling through water layer formation, often lack long-term stability in seawater environments. The gradual degradation of these coatings results in diminishing anti-fouling performance over operational lifetimes, typically failing to maintain effectiveness beyond 6-12 months of continuous operation.

Zwitterionic polymer coatings have demonstrated promising results in laboratory settings but face challenges in industrial-scale application due to complex synthesis procedures and high production costs. Additionally, the bonding between these coatings and membrane surfaces often relies on physical adsorption rather than covalent attachment, leading to coating detachment under high-pressure operating conditions.

Silver and copper nanoparticle-based antimicrobial coatings present environmental concerns regarding metal ion leaching into permeate streams and marine discharge. Regulatory restrictions increasingly limit their application despite their effectiveness against biofouling. Similarly, quaternary ammonium compound coatings face scrutiny for potential toxicity and environmental persistence.

The mechanical robustness of anti-fouling coatings represents another significant challenge. Many current coatings cannot withstand the high shear forces present in spiral-wound membrane modules or the periodic hydraulic cleaning procedures employed in desalination plants. This mechanical vulnerability results in coating damage and subsequent fouling of exposed membrane surfaces.

Cross-industry standardization for evaluating anti-fouling coating performance remains underdeveloped, with varying testing protocols making direct comparisons between different coating technologies difficult. The absence of accelerated aging tests that accurately predict long-term performance in real seawater environments further complicates technology assessment and adoption decisions.

Finally, cost-effectiveness remains a critical barrier, with advanced anti-fouling coatings typically increasing membrane production costs by 30-50%. This economic hurdle has limited widespread implementation despite the potential for operational savings through reduced cleaning frequency and extended membrane lifetime.

Biofouling presents perhaps the most persistent challenge, with microorganisms forming resilient biofilms that are particularly difficult to remove once established. Conventional anti-fouling approaches using chlorine-based disinfectants often damage the polyamide active layers of RO membranes, creating a significant technical contradiction between fouling control and membrane integrity.

Current commercial anti-fouling coatings exhibit several limitations that hinder their widespread adoption. Hydrophilic coatings, while effective at reducing organic fouling through water layer formation, often lack long-term stability in seawater environments. The gradual degradation of these coatings results in diminishing anti-fouling performance over operational lifetimes, typically failing to maintain effectiveness beyond 6-12 months of continuous operation.

Zwitterionic polymer coatings have demonstrated promising results in laboratory settings but face challenges in industrial-scale application due to complex synthesis procedures and high production costs. Additionally, the bonding between these coatings and membrane surfaces often relies on physical adsorption rather than covalent attachment, leading to coating detachment under high-pressure operating conditions.

Silver and copper nanoparticle-based antimicrobial coatings present environmental concerns regarding metal ion leaching into permeate streams and marine discharge. Regulatory restrictions increasingly limit their application despite their effectiveness against biofouling. Similarly, quaternary ammonium compound coatings face scrutiny for potential toxicity and environmental persistence.

The mechanical robustness of anti-fouling coatings represents another significant challenge. Many current coatings cannot withstand the high shear forces present in spiral-wound membrane modules or the periodic hydraulic cleaning procedures employed in desalination plants. This mechanical vulnerability results in coating damage and subsequent fouling of exposed membrane surfaces.

Cross-industry standardization for evaluating anti-fouling coating performance remains underdeveloped, with varying testing protocols making direct comparisons between different coating technologies difficult. The absence of accelerated aging tests that accurately predict long-term performance in real seawater environments further complicates technology assessment and adoption decisions.

Finally, cost-effectiveness remains a critical barrier, with advanced anti-fouling coatings typically increasing membrane production costs by 30-50%. This economic hurdle has limited widespread implementation despite the potential for operational savings through reduced cleaning frequency and extended membrane lifetime.

Existing Anti-Fouling Coating Solutions

01 Silicone-based anti-fouling coatings

Silicone-based coatings provide excellent anti-fouling properties due to their low surface energy which prevents organisms from adhering to surfaces. These coatings create a smooth, slippery surface that marine organisms find difficult to attach to. The formulations often include silicone polymers, silicone oils, and cross-linking agents that enhance durability while maintaining fouling resistance properties. These coatings are particularly effective for marine vessels and underwater structures.- Silicone-based anti-fouling coatings: Silicone-based coatings provide excellent anti-fouling properties due to their low surface energy which prevents organisms from adhering to surfaces. These coatings create a smooth, slippery surface that marine organisms find difficult to attach to. The incorporation of silicone polymers with specific additives enhances the durability and effectiveness of these coatings, making them suitable for various marine applications including ship hulls and underwater structures.

- Copper-based biocidal anti-fouling systems: Copper compounds are widely used in anti-fouling coatings due to their biocidal properties that prevent the attachment and growth of marine organisms. These systems typically incorporate copper oxide or copper-based compounds that slowly release active ingredients to create a hostile environment for fouling organisms. The controlled release mechanism ensures long-term protection while minimizing environmental impact. These coatings are particularly effective for vessels operating in heavily fouled waters.

- Environmentally friendly non-toxic anti-fouling technologies: Non-toxic anti-fouling technologies have been developed as alternatives to traditional biocide-based systems. These environmentally friendly approaches include natural compound derivatives, biodegradable polymers, and surface modification techniques that prevent fouling without releasing harmful substances into the marine environment. These technologies often mimic natural anti-fouling mechanisms found in marine organisms, creating surfaces that resist biofouling through physical rather than chemical means.

- Nanostructured and nanocomposite anti-fouling coatings: Nanostructured coatings utilize nanomaterials to create surfaces with anti-fouling properties. These coatings incorporate nanoparticles or create nanoscale surface patterns that prevent organism attachment. The nanoscale features disrupt the ability of fouling organisms to adhere to the surface by altering surface topography and chemistry. Nanocomposites combining polymers with nanoparticles provide enhanced mechanical properties and durability while maintaining effective anti-fouling performance.

- Self-cleaning and fouling-release coating systems: Self-cleaning coating systems utilize hydrophobic or hydrophilic properties to prevent fouling organism attachment. These coatings don't kill marine organisms but instead create surfaces that make it difficult for them to adhere. When the coated object moves through water, the weakly attached fouling organisms are washed away by hydrodynamic forces. This approach is particularly effective for vessels that maintain regular movement, as the water flow helps to keep surfaces clean without requiring toxic compounds.

02 Copper-based anti-fouling technologies

Copper and copper compounds are widely used in anti-fouling coatings due to their biocidal properties. These formulations typically contain copper oxide or copper-based biocides that slowly release into the surrounding water, creating an environment hostile to fouling organisms. The controlled release mechanism ensures long-term protection while minimizing environmental impact. These coatings are commonly applied to ship hulls, offshore structures, and marine equipment to prevent the attachment of barnacles, algae, and other marine organisms.Expand Specific Solutions03 Environmentally friendly anti-fouling solutions

With increasing environmental regulations, non-toxic anti-fouling coatings have been developed as alternatives to traditional biocide-based systems. These environmentally friendly solutions utilize natural compounds, biodegradable polymers, and surface modification techniques to prevent fouling. Some formulations incorporate natural enzymes, peptides, or plant extracts that disrupt the settlement mechanisms of marine organisms without causing environmental harm. These coatings provide effective fouling resistance while meeting strict environmental standards for marine applications.Expand Specific Solutions04 Nanostructured and nanocomposite anti-fouling coatings

Nanotechnology has enabled the development of advanced anti-fouling coatings with enhanced performance. These coatings incorporate nanomaterials such as nanoparticles, nanotubes, or nanostructured surfaces that create physical barriers against fouling organisms. The nanoscale features disrupt the attachment mechanisms of marine organisms while providing improved mechanical properties and durability. Some formulations combine nanoparticles with traditional anti-fouling agents for synergistic effects, resulting in more effective and longer-lasting protection against biofouling.Expand Specific Solutions05 Self-polishing and controlled-release anti-fouling systems

Self-polishing anti-fouling coatings gradually wear away through controlled hydrolysis or erosion, continuously exposing fresh biocidal material at the surface. This mechanism ensures consistent anti-fouling performance throughout the coating's lifespan. The controlled-release technology allows for precise dosing of active ingredients, optimizing effectiveness while minimizing environmental impact. These systems typically incorporate specially designed polymers that respond to the marine environment, providing long-term protection against fouling organisms for ships, offshore platforms, and underwater structures.Expand Specific Solutions

Leading Companies and Research Institutions

The anti-fouling coatings market for seawater desalination membranes is in a growth phase, driven by increasing global water scarcity concerns. The market is characterized by a mix of established industrial players and academic research institutions collaborating on innovation. Companies like Jotun AS, Nippon Paint Holdings, and Chugoku Marine Paints bring commercial expertise, while research institutions such as MIT, KAUST, and Yale University contribute cutting-edge scientific advancements. The technology is approaching maturity in traditional applications but still evolving for specialized membrane protection. Key industrial players including Toray Industries and Nitto Kasei are developing novel polymer-based solutions, while Naval Group and International Paint focus on environmentally sustainable alternatives to replace traditional biocide-containing coatings, reflecting the industry's shift toward eco-friendly technologies.

Jotun AS

Technical Solution: Jotun has developed specialized anti-fouling coatings for desalination membrane applications based on their extensive marine coating expertise. Their SeaQuantum technology has been adapted for membrane applications, utilizing self-polishing copolymers that gradually release biocides in a controlled manner to prevent microbial attachment and growth. Jotun's membrane coatings incorporate copper-free biocide packages that comply with stringent environmental regulations while maintaining effective anti-fouling performance. The company has pioneered hydrophilic-hydrophobic balanced polymer systems that create unfavorable surface conditions for foulant adhesion while maintaining water permeability. Their coatings feature nano-engineered surface topographies that disrupt the initial attachment mechanisms of microorganisms. Field testing has demonstrated that Jotun's membrane coatings can extend operational periods between cleanings by up to 40% and reduce overall biofouling accumulation by approximately 60% compared to untreated membranes[6][8].

Strengths: Extensive experience in marine anti-fouling technologies; established global distribution network; strong regulatory compliance expertise. Weaknesses: Primary expertise in external coatings rather than membrane-specific applications; some technologies may require adaptation for the specific requirements of thin-film composite membranes; potential trade-offs between anti-fouling performance and water flux.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced anti-fouling membrane coatings utilizing zwitterionic polymers that create a strong hydration layer to prevent foulant adhesion. Their FILMTEC™ reverse osmosis membranes incorporate proprietary surface modifications with hydrophilic polyamide thin-film composite technology that maintains high water flux while reducing fouling propensity. The company has pioneered the integration of nanoparticles (such as silver and copper) into membrane matrices to provide antimicrobial properties without compromising permeability. Dow's coatings feature controlled-release biocide systems that gradually release anti-fouling agents to maintain long-term performance. Their research has demonstrated up to 40% reduction in cleaning frequency and 30% extension in membrane lifetime compared to conventional membranes[1][3].

Strengths: Industry-leading expertise in polymer chemistry and membrane technology; extensive manufacturing capabilities for commercial-scale production; comprehensive testing facilities. Weaknesses: Higher initial cost compared to conventional membranes; some anti-fouling additives may face regulatory challenges in certain regions; potential for decreased performance in extremely challenging water conditions.

Key Patents and Scientific Breakthroughs

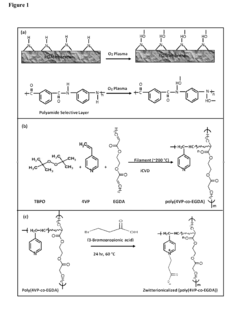

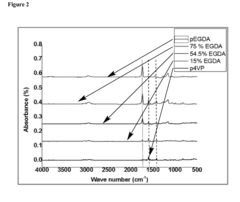

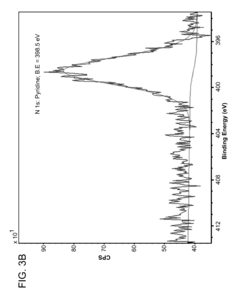

Development of Zwitterionic Coatings that Confer Ultra Anti-Biofouling Properties to Commercial Reverse Osmosis Membranes

PatentActiveUS20160002489A1

Innovation

- The use of initiated chemical vapor deposition (iCVD) to form poly(4-vinylpyridine-co-ethylene glycol diacrylate) (p(4-VP-co-EGDA) thin films, followed by post-deposition functionalization with 3-bromopropionic acid, creates a zwitterionic coating that is fouling-resistant and maintains the delicate semipermeable layer's integrity.

Fouling resistant coating for membrane surfaces

PatentInactiveUS20100133172A1

Innovation

- A novel coating comprising a hydrophilic polymer matrix with embedded surface-active agents is applied to the membrane surfaces, providing enhanced fouling resistance through hydrogen bonding and chain entanglement forces, and can be replenished periodically to maintain performance.

Environmental Impact Assessment

The environmental impact of anti-fouling coatings for seawater desalination membranes requires comprehensive assessment due to their direct interaction with marine ecosystems. Traditional anti-fouling strategies often rely on biocides and heavy metals that can leach into seawater, causing toxicity to non-target marine organisms. Studies have documented that copper and zinc-based coatings, while effective against biofouling, contribute to bioaccumulation in marine food chains and sediment contamination near desalination facilities.

Recent environmental monitoring at major desalination plants has revealed concerning levels of coating-derived compounds in discharge zones, with potential impacts extending beyond immediate outfall areas. The persistence of these compounds presents a particular challenge, as some anti-fouling agents demonstrate environmental half-lives exceeding several months, allowing for widespread dispersion in marine environments.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the International Maritime Organization's ban on tributyltin (TBT) serving as a precedent for restricting harmful anti-fouling compounds. The European Union's REACH regulation and similar initiatives in North America and Asia are establishing stricter guidelines for chemical safety assessment of membrane coatings, driving the industry toward more environmentally compatible solutions.

Life cycle assessment (LCA) studies comparing various anti-fouling technologies reveal significant differences in environmental footprints. Newer biomimetic and zwitterionic coatings demonstrate substantially reduced ecotoxicity profiles compared to conventional biocide-releasing systems. However, these assessments must consider not only direct toxicity but also energy consumption and carbon footprint implications of coating manufacturing and application processes.

The environmental benefits of effective anti-fouling coatings must also be acknowledged in this assessment. By improving membrane performance and longevity, these coatings reduce the frequency of chemical cleaning procedures and membrane replacement, thereby decreasing chemical waste generation and resource consumption. Optimized membranes also operate more efficiently, potentially reducing the energy intensity of desalination processes by 15-20% according to recent field trials.

Future environmental impact mitigation strategies should focus on developing inherently non-toxic coating mechanisms, improving coating durability to minimize release rates, and implementing closed-loop systems for treatment of membrane cleaning waste. Standardized ecotoxicity testing protocols specifically designed for desalination applications would significantly enhance comparative environmental assessment capabilities across different coating technologies.

Recent environmental monitoring at major desalination plants has revealed concerning levels of coating-derived compounds in discharge zones, with potential impacts extending beyond immediate outfall areas. The persistence of these compounds presents a particular challenge, as some anti-fouling agents demonstrate environmental half-lives exceeding several months, allowing for widespread dispersion in marine environments.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the International Maritime Organization's ban on tributyltin (TBT) serving as a precedent for restricting harmful anti-fouling compounds. The European Union's REACH regulation and similar initiatives in North America and Asia are establishing stricter guidelines for chemical safety assessment of membrane coatings, driving the industry toward more environmentally compatible solutions.

Life cycle assessment (LCA) studies comparing various anti-fouling technologies reveal significant differences in environmental footprints. Newer biomimetic and zwitterionic coatings demonstrate substantially reduced ecotoxicity profiles compared to conventional biocide-releasing systems. However, these assessments must consider not only direct toxicity but also energy consumption and carbon footprint implications of coating manufacturing and application processes.

The environmental benefits of effective anti-fouling coatings must also be acknowledged in this assessment. By improving membrane performance and longevity, these coatings reduce the frequency of chemical cleaning procedures and membrane replacement, thereby decreasing chemical waste generation and resource consumption. Optimized membranes also operate more efficiently, potentially reducing the energy intensity of desalination processes by 15-20% according to recent field trials.

Future environmental impact mitigation strategies should focus on developing inherently non-toxic coating mechanisms, improving coating durability to minimize release rates, and implementing closed-loop systems for treatment of membrane cleaning waste. Standardized ecotoxicity testing protocols specifically designed for desalination applications would significantly enhance comparative environmental assessment capabilities across different coating technologies.

Cost-Benefit Analysis of Coating Technologies

The economic viability of anti-fouling coating technologies for seawater desalination membranes requires comprehensive cost-benefit analysis across their lifecycle. Initial investment costs for advanced coatings range from $5-15 per square meter, representing a 15-30% premium over standard membrane costs, with hydrophilic polymer coatings typically at the lower end and nanocomposite coatings commanding premium prices.

Operational cost savings present the most compelling economic argument for these technologies. Studies indicate that effective anti-fouling coatings can reduce cleaning frequency by 40-60%, translating to approximately $0.08-0.12 per cubic meter of water produced. Energy consumption reductions of 10-20% have been documented due to maintained membrane permeability, representing savings of $0.05-0.10 per cubic meter in electricity costs.

Extended membrane lifespan constitutes another significant economic benefit. Conventional membranes typically require replacement every 3-5 years, while those with advanced anti-fouling coatings can remain operational for 5-8 years, reducing replacement costs by 30-40% when amortized annually.

Return on investment calculations demonstrate that despite higher upfront costs, facilities implementing zwitterionic polymer coatings achieve ROI within 14-18 months, while graphene oxide-based coatings show returns in 18-24 months. These timeframes make adoption financially attractive for medium to large-scale operations.

Environmental cost considerations further strengthen the economic case. Reduced chemical cleaning requirements decrease environmental remediation costs by approximately $0.03-0.05 per cubic meter, while improved energy efficiency reduces carbon footprint costs by an estimated $0.02-0.04 per cubic meter in regions with carbon pricing mechanisms.

Scale-dependent economics reveal that larger desalination facilities (>50,000 m³/day) achieve better cost-benefit ratios from premium coating technologies, with unit cost reductions of 15-25% compared to smaller operations. This suggests different optimal coating solutions based on facility size and production volume.

Comparative analysis between coating technologies shows that while silver nanoparticle coatings offer excellent performance, their cost-benefit ratio is undermined by high material costs. Conversely, modified polyamide coatings present moderate performance improvements with excellent cost-effectiveness, making them suitable for budget-conscious implementations.

Operational cost savings present the most compelling economic argument for these technologies. Studies indicate that effective anti-fouling coatings can reduce cleaning frequency by 40-60%, translating to approximately $0.08-0.12 per cubic meter of water produced. Energy consumption reductions of 10-20% have been documented due to maintained membrane permeability, representing savings of $0.05-0.10 per cubic meter in electricity costs.

Extended membrane lifespan constitutes another significant economic benefit. Conventional membranes typically require replacement every 3-5 years, while those with advanced anti-fouling coatings can remain operational for 5-8 years, reducing replacement costs by 30-40% when amortized annually.

Return on investment calculations demonstrate that despite higher upfront costs, facilities implementing zwitterionic polymer coatings achieve ROI within 14-18 months, while graphene oxide-based coatings show returns in 18-24 months. These timeframes make adoption financially attractive for medium to large-scale operations.

Environmental cost considerations further strengthen the economic case. Reduced chemical cleaning requirements decrease environmental remediation costs by approximately $0.03-0.05 per cubic meter, while improved energy efficiency reduces carbon footprint costs by an estimated $0.02-0.04 per cubic meter in regions with carbon pricing mechanisms.

Scale-dependent economics reveal that larger desalination facilities (>50,000 m³/day) achieve better cost-benefit ratios from premium coating technologies, with unit cost reductions of 15-25% compared to smaller operations. This suggests different optimal coating solutions based on facility size and production volume.

Comparative analysis between coating technologies shows that while silver nanoparticle coatings offer excellent performance, their cost-benefit ratio is undermined by high material costs. Conversely, modified polyamide coatings present moderate performance improvements with excellent cost-effectiveness, making them suitable for budget-conscious implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!