Polymer Matrix Design for Long Lasting Anti Fouling Films

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Antifouling Technology Background and Objectives

Polymer antifouling technology has evolved significantly over the past several decades, driven by the persistent challenges of biofouling across multiple industries. Initially developed in the 1970s, early polymer-based antifouling solutions primarily relied on biocide-releasing mechanisms that, while effective in the short term, posed significant environmental concerns due to their toxicity to non-target marine organisms. This environmental impact prompted a paradigm shift in the 1990s toward more sustainable approaches.

The evolution of polymer antifouling technology has followed three distinct generations. First-generation systems utilized copper and tributyltin (TBT) compounds embedded in polymer matrices, which were eventually banned due to environmental persistence. Second-generation technologies introduced controlled-release mechanisms and self-polishing copolymers (SPCs) that offered improved performance while reducing environmental impact. Current third-generation solutions focus on non-biocidal approaches, including amphiphilic polymer networks, zwitterionic polymers, and hydrophilic-hydrophobic balanced systems.

Recent technological advancements have centered on developing polymer matrices that can maintain long-term antifouling properties without releasing harmful substances. These include stimuli-responsive polymers that change properties in response to environmental triggers, biomimetic surfaces inspired by natural antifouling organisms like shark skin and lotus leaves, and hybrid organic-inorganic nanocomposites that combine the benefits of multiple materials.

The primary objective of current polymer antifouling research is to develop environmentally friendly, durable films that can maintain their performance for extended periods without maintenance. This includes creating polymer matrices with enhanced mechanical stability, resistance to degradation under harsh conditions, and persistent surface properties that prevent initial attachment of fouling organisms. Additionally, researchers aim to develop cost-effective manufacturing processes that can scale these advanced materials for commercial applications.

Another critical goal is to design versatile polymer systems adaptable to various substrates and environments, from marine vessels to medical implants and industrial membranes. This versatility requires fundamental understanding of fouling mechanisms across different environments and the development of tailored polymer architectures that can address specific fouling challenges.

The trajectory of polymer antifouling technology is increasingly moving toward multifunctional coatings that combine antifouling properties with other desirable characteristics such as corrosion resistance, self-healing capabilities, and reduced drag. These integrated approaches represent the frontier of research, promising solutions that address multiple performance requirements simultaneously while maintaining environmental compatibility.

The evolution of polymer antifouling technology has followed three distinct generations. First-generation systems utilized copper and tributyltin (TBT) compounds embedded in polymer matrices, which were eventually banned due to environmental persistence. Second-generation technologies introduced controlled-release mechanisms and self-polishing copolymers (SPCs) that offered improved performance while reducing environmental impact. Current third-generation solutions focus on non-biocidal approaches, including amphiphilic polymer networks, zwitterionic polymers, and hydrophilic-hydrophobic balanced systems.

Recent technological advancements have centered on developing polymer matrices that can maintain long-term antifouling properties without releasing harmful substances. These include stimuli-responsive polymers that change properties in response to environmental triggers, biomimetic surfaces inspired by natural antifouling organisms like shark skin and lotus leaves, and hybrid organic-inorganic nanocomposites that combine the benefits of multiple materials.

The primary objective of current polymer antifouling research is to develop environmentally friendly, durable films that can maintain their performance for extended periods without maintenance. This includes creating polymer matrices with enhanced mechanical stability, resistance to degradation under harsh conditions, and persistent surface properties that prevent initial attachment of fouling organisms. Additionally, researchers aim to develop cost-effective manufacturing processes that can scale these advanced materials for commercial applications.

Another critical goal is to design versatile polymer systems adaptable to various substrates and environments, from marine vessels to medical implants and industrial membranes. This versatility requires fundamental understanding of fouling mechanisms across different environments and the development of tailored polymer architectures that can address specific fouling challenges.

The trajectory of polymer antifouling technology is increasingly moving toward multifunctional coatings that combine antifouling properties with other desirable characteristics such as corrosion resistance, self-healing capabilities, and reduced drag. These integrated approaches represent the frontier of research, promising solutions that address multiple performance requirements simultaneously while maintaining environmental compatibility.

Market Analysis for Long-lasting Antifouling Solutions

The global market for antifouling solutions has witnessed substantial growth in recent years, driven primarily by increasing maritime activities and growing awareness about the economic and environmental impacts of biofouling. The market size for antifouling coatings was valued at approximately 6.7 billion USD in 2022 and is projected to reach 10.2 billion USD by 2028, representing a compound annual growth rate of 7.2%.

Marine transportation remains the dominant application segment, accounting for nearly 60% of the market share. This dominance is attributed to the critical need for efficient vessel operation, as biofouling can increase fuel consumption by up to 40% and maintenance costs by 30%. The shipping industry's push toward sustainability and fuel efficiency has further accelerated demand for advanced antifouling solutions.

Regionally, Asia-Pacific leads the market with approximately 40% share, followed by Europe and North America. China, South Korea, and Japan are key manufacturing hubs, while European countries focus on developing environmentally compliant solutions in response to stringent regulations.

Consumer preferences are shifting dramatically toward environmentally friendly antifouling technologies. Traditional copper and tributyltin-based solutions are facing regulatory restrictions due to their environmental toxicity. This has created significant market opportunities for polymer-based antifouling films that offer comparable performance without environmental harm.

The polymer matrix antifouling segment specifically is growing at 9.3% annually, outpacing the broader market. This accelerated growth reflects increasing adoption of advanced polymer technologies that provide longer service life and reduced environmental impact. Products offering 5+ years of protection command premium pricing, with consumers demonstrating willingness to pay 25-30% more for extended durability.

Key market drivers include increasingly stringent environmental regulations, rising fuel costs that amplify the economic impact of fouling, and growing installation of offshore structures for renewable energy. The International Maritime Organization's regulations on biocidal antifouling systems have particularly catalyzed innovation in non-toxic alternatives.

Market challenges include high initial costs of advanced polymer solutions, technical difficulties in achieving both durability and effectiveness, and varying performance requirements across different marine environments. Despite these challenges, the market trajectory remains strongly positive, with polymer matrix designs positioned as the leading technology for next-generation antifouling solutions.

Marine transportation remains the dominant application segment, accounting for nearly 60% of the market share. This dominance is attributed to the critical need for efficient vessel operation, as biofouling can increase fuel consumption by up to 40% and maintenance costs by 30%. The shipping industry's push toward sustainability and fuel efficiency has further accelerated demand for advanced antifouling solutions.

Regionally, Asia-Pacific leads the market with approximately 40% share, followed by Europe and North America. China, South Korea, and Japan are key manufacturing hubs, while European countries focus on developing environmentally compliant solutions in response to stringent regulations.

Consumer preferences are shifting dramatically toward environmentally friendly antifouling technologies. Traditional copper and tributyltin-based solutions are facing regulatory restrictions due to their environmental toxicity. This has created significant market opportunities for polymer-based antifouling films that offer comparable performance without environmental harm.

The polymer matrix antifouling segment specifically is growing at 9.3% annually, outpacing the broader market. This accelerated growth reflects increasing adoption of advanced polymer technologies that provide longer service life and reduced environmental impact. Products offering 5+ years of protection command premium pricing, with consumers demonstrating willingness to pay 25-30% more for extended durability.

Key market drivers include increasingly stringent environmental regulations, rising fuel costs that amplify the economic impact of fouling, and growing installation of offshore structures for renewable energy. The International Maritime Organization's regulations on biocidal antifouling systems have particularly catalyzed innovation in non-toxic alternatives.

Market challenges include high initial costs of advanced polymer solutions, technical difficulties in achieving both durability and effectiveness, and varying performance requirements across different marine environments. Despite these challenges, the market trajectory remains strongly positive, with polymer matrix designs positioned as the leading technology for next-generation antifouling solutions.

Current Challenges in Polymer Matrix Antifouling Films

Despite significant advancements in polymer matrix antifouling technologies, several persistent challenges continue to impede the development of truly long-lasting and effective antifouling films. The primary obstacle remains the inherent trade-off between fouling resistance and mechanical durability. Polymers with excellent antifouling properties often exhibit poor mechanical strength and adhesion to substrates, resulting in premature film degradation under real-world conditions.

Surface degradation presents another significant challenge, as polymer matrices are continuously exposed to harsh environmental conditions including UV radiation, temperature fluctuations, and mechanical abrasion from water flow. These factors accelerate the deterioration of the antifouling properties, with most current solutions maintaining optimal performance for only 1-3 years before requiring replacement or maintenance.

The leaching of active biocidal components poses both environmental and performance challenges. Traditional antifouling systems rely on the controlled release of biocides, but this approach inherently limits longevity as the active components are gradually depleted. Additionally, increasing regulatory restrictions on biocidal compounds have created an urgent need for alternative approaches that maintain effectiveness while meeting environmental standards.

Biofouling organisms have demonstrated remarkable adaptability, developing resistance to conventional antifouling mechanisms over time. This evolutionary arms race necessitates continuous innovation in polymer matrix design to counter emerging fouling strategies employed by marine microorganisms, algae, and invertebrates.

Scale-up and manufacturing consistency represent significant industrial challenges. Laboratory-scale successes often fail to translate to commercial production due to difficulties in maintaining uniform properties across large surface areas and ensuring batch-to-batch consistency in polymer formulations.

Cost-effectiveness remains a critical barrier to widespread adoption of advanced antifouling technologies. Current high-performance solutions typically involve complex synthesis procedures and expensive raw materials, making them economically viable only for high-value applications rather than general maritime use.

The development of universally effective solutions is hindered by the diverse nature of fouling organisms across different marine environments. A polymer matrix that performs excellently in temperate waters may fail completely in tropical conditions, necessitating either environment-specific formulations or truly adaptable systems that can respond to changing conditions.

Integration challenges with existing maritime infrastructure and coating systems further complicate implementation. New antifouling polymer matrices must be compatible with current application methods and maintenance schedules to achieve practical adoption in commercial settings.

Surface degradation presents another significant challenge, as polymer matrices are continuously exposed to harsh environmental conditions including UV radiation, temperature fluctuations, and mechanical abrasion from water flow. These factors accelerate the deterioration of the antifouling properties, with most current solutions maintaining optimal performance for only 1-3 years before requiring replacement or maintenance.

The leaching of active biocidal components poses both environmental and performance challenges. Traditional antifouling systems rely on the controlled release of biocides, but this approach inherently limits longevity as the active components are gradually depleted. Additionally, increasing regulatory restrictions on biocidal compounds have created an urgent need for alternative approaches that maintain effectiveness while meeting environmental standards.

Biofouling organisms have demonstrated remarkable adaptability, developing resistance to conventional antifouling mechanisms over time. This evolutionary arms race necessitates continuous innovation in polymer matrix design to counter emerging fouling strategies employed by marine microorganisms, algae, and invertebrates.

Scale-up and manufacturing consistency represent significant industrial challenges. Laboratory-scale successes often fail to translate to commercial production due to difficulties in maintaining uniform properties across large surface areas and ensuring batch-to-batch consistency in polymer formulations.

Cost-effectiveness remains a critical barrier to widespread adoption of advanced antifouling technologies. Current high-performance solutions typically involve complex synthesis procedures and expensive raw materials, making them economically viable only for high-value applications rather than general maritime use.

The development of universally effective solutions is hindered by the diverse nature of fouling organisms across different marine environments. A polymer matrix that performs excellently in temperate waters may fail completely in tropical conditions, necessitating either environment-specific formulations or truly adaptable systems that can respond to changing conditions.

Integration challenges with existing maritime infrastructure and coating systems further complicate implementation. New antifouling polymer matrices must be compatible with current application methods and maintenance schedules to achieve practical adoption in commercial settings.

Current Polymer Matrix Design Approaches

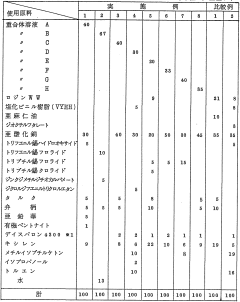

01 Polymer matrix coatings with biocidal agents

Polymer matrices can be formulated with biocidal agents to create anti-fouling coatings. These formulations typically incorporate active compounds that prevent the attachment and growth of microorganisms, algae, and other marine organisms on surfaces. The polymer matrix serves as a carrier system that controls the release rate of the biocidal agents, providing long-term protection against fouling. These coatings are particularly useful for marine applications where biofouling is a significant problem.- Polymer matrix coatings with biocidal agents: Polymer matrices can be formulated with biocidal agents to prevent fouling on surfaces. These formulations typically incorporate antimicrobial compounds into a polymer matrix that slowly releases the active ingredients, providing long-term protection against microbial colonization. The polymer matrix serves as a controlled release system, maintaining effective concentrations of the biocidal agents at the surface while minimizing environmental impact.

- Hydrophobic polymer matrices for marine applications: Hydrophobic polymer matrices can be used to create anti-fouling surfaces for marine applications. These matrices repel water and prevent the adhesion of marine organisms such as barnacles and algae. By incorporating specific hydrophobic compounds into the polymer structure, the resulting coating creates a surface that organisms find difficult to attach to, thereby reducing biofouling without relying solely on toxic compounds.

- Self-polishing polymer matrices: Self-polishing polymer matrices gradually erode in water, continuously exposing fresh layers of the anti-fouling surface. This controlled erosion mechanism helps maintain the effectiveness of the anti-fouling properties over extended periods. The polymer matrix is designed to hydrolyze or dissolve at a predetermined rate, shedding fouling organisms along with the eroded layer and revealing a new protective surface underneath.

- Environmentally friendly polymer matrices: Environmentally friendly polymer matrices for anti-fouling applications utilize biodegradable polymers and non-toxic additives. These formulations aim to provide effective fouling protection while minimizing environmental impact. The matrices often incorporate natural compounds or biomimetic approaches that deter organism settlement through non-toxic mechanisms such as surface topography modification or enzyme-based deterrents.

- Nanocomposite polymer matrices: Nanocomposite polymer matrices incorporate nanomaterials such as nanoparticles, nanotubes, or nanosheets to enhance anti-fouling properties. These nanomaterials can modify surface properties, increase durability, or provide additional functionality such as antimicrobial activity. The combination of nanomaterials with polymer matrices creates synergistic effects that improve the overall anti-fouling performance and longevity of the coating.

02 Self-polishing polymer matrices

Self-polishing polymer matrices represent an advanced approach to anti-fouling technology. These systems are designed to gradually erode or hydrolyze when exposed to water, continuously revealing fresh layers of the anti-fouling surface. This controlled erosion mechanism prevents the accumulation of fouling organisms by maintaining a smooth, renewable surface. The polymer matrix composition can be tailored to achieve specific erosion rates depending on the application environment and desired lifetime of the coating.Expand Specific Solutions03 Hydrophilic polymer matrices for fouling resistance

Hydrophilic polymer matrices create surfaces that resist fouling through the formation of a hydration layer that prevents protein adsorption and organism attachment. These matrices typically incorporate polymers with high water affinity, creating a slippery surface that organisms have difficulty adhering to. The hydrophilic nature of these coatings makes them particularly effective in preventing initial attachment of fouling organisms, which is the first step in the biofouling process. These systems are often used in applications where toxic biocides are undesirable.Expand Specific Solutions04 Nanocomposite polymer matrices

Nanocomposite polymer matrices incorporate nanomaterials such as nanoparticles, nanotubes, or nanosheets into the polymer structure to enhance anti-fouling properties. These nanomaterials can provide multiple mechanisms of fouling prevention, including surface roughness modification, photocatalytic activity, and antimicrobial effects. The combination of nanomaterials with polymers creates synergistic effects that improve the durability and effectiveness of anti-fouling coatings while potentially reducing the need for traditional biocides.Expand Specific Solutions05 Environmentally friendly polymer matrix systems

Environmentally friendly polymer matrix systems focus on developing anti-fouling solutions that minimize ecological impact while maintaining effectiveness. These systems often utilize biodegradable polymers, natural compounds with anti-fouling properties, or physical deterrence mechanisms rather than toxic biocides. The polymer matrices are designed to break down into non-harmful components at the end of their service life, reducing long-term environmental accumulation. These eco-friendly approaches are becoming increasingly important as environmental regulations become more stringent worldwide.Expand Specific Solutions

Key Industry Players in Antifouling Film Development

The anti-fouling film market is currently in a growth phase, with increasing demand driven by marine, industrial, and electronics applications. The global market size is estimated to exceed $5 billion, expanding at a CAGR of 5-7%. Technology maturity varies across different polymer matrix approaches, with companies demonstrating various levels of innovation. Leading players include Chugoku Marine Paints and Nippon Paint Marine Coatings with established marine anti-fouling technologies, while 3M, DuPont, and Daikin Industries leverage their polymer expertise for advanced film development. Research institutions like Xiamen University and Zhejiang University collaborate with industrial partners to develop next-generation environmentally friendly solutions, as regulatory pressure drives innovation toward non-toxic, long-lasting formulations.

Chugoku Marine Paints, Ltd.

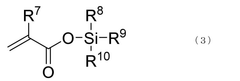

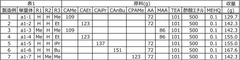

Technical Solution: Chugoku Marine Paints has developed advanced silyl acrylate polymer matrix technology for long-lasting antifouling coatings. Their flagship technology utilizes hydrolyzable silyl acrylate polymers that create a self-polishing effect when exposed to seawater. The polymer matrix is designed with hydrophobic side chains and hydrolyzable silyl groups that gradually hydrolyze in water, creating a controlled erosion mechanism that continuously exposes fresh biocide-containing layers. This self-renewing surface maintains antifouling efficacy for up to 90 months, significantly longer than conventional coatings. Their SEAFLO NEO series incorporates nanoscale control of polymer architecture to optimize the hydrolysis rate and mechanical properties, resulting in smoother hull surfaces that reduce fuel consumption by up to 8% compared to conventional antifouling paints.

Strengths: Industry-leading longevity (up to 90 months) compared to industry standard 60 months; controlled hydrolysis rate provides predictable performance; reduced environmental impact through optimized biocide release. Weaknesses: Higher initial cost compared to conventional antifouling solutions; performance can vary depending on vessel operating conditions and water temperature.

NIPPON PAINT MARINE COATINGS CO LTD

Technical Solution: Nippon Paint Marine has pioneered hydrophilic polymer matrix technology for antifouling applications through their AQUATERRAS and A-LF-Sea product lines. Their innovative approach uses a water-trapping hydrophilic polymer matrix that creates an ultra-smooth, low friction surface inhospitable to marine organisms. The technology employs specially designed acrylic-silicone hybrid polymers with hydrophilic functional groups that form a water layer barrier between the hull and marine organisms. This "water barrier" mechanism reduces the need for traditional biocides while maintaining effectiveness. Their latest generation incorporates nano-engineered polymer structures with precisely controlled cross-linking density that optimizes water absorption and retention properties. The technology has demonstrated fouling resistance for up to 60 months in various sea conditions while reducing CO2 emissions by approximately 10% through decreased hull friction.

Strengths: Environmentally friendly with reduced biocide content; excellent smoothness properties leading to fuel efficiency improvements; compatible with various vessel types and operating conditions. Weaknesses: May require more frequent reapplication in certain high-fouling environments; initial surface preparation requirements are more stringent than conventional systems.

Critical Patents in Long-lasting Antifouling Materials

Antifouling coating

PatentWO1980000571A1

Innovation

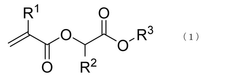

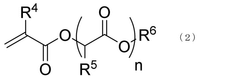

- A polymer matrix with moderate water solubility is developed using unsaturated acid ester monomers, such as dimethyl maleate and diethyl fumarate, which are copolymerized with other monomers to create a coating film that maintains a stable antifouling agent elution rate, preventing excessive initial elution and ensuring prolonged protection without relying on hydrolysis or free carboxyl groups, thus enhancing coating film strength and durability.

Antifouling coating material composition

PatentWO2022102492A1

Innovation

- A copolymer composition comprising monomers (a) and (b) is developed, where monomer (a) is composed of monomer (a1) and (a2), and monomer (b) is an ethylenically unsaturated monomer, with specific ratios to enhance coating film solubility and strength, and an antifouling agent is incorporated to maintain long-term antifouling performance.

Environmental Impact and Regulatory Compliance

The environmental impact of anti-fouling films has become a critical consideration in their development and deployment. Traditional anti-fouling coatings containing tributyltin (TBT) and other heavy metals have been progressively banned worldwide due to their severe ecological damage, including endocrine disruption in marine organisms and bioaccumulation in food chains. This regulatory shift has accelerated research into polymer matrix designs that maintain effectiveness while minimizing environmental harm.

Current polymer matrix designs for anti-fouling films must navigate an increasingly complex regulatory landscape. The International Maritime Organization's (IMO) ban on TBT-based coatings in 2008 marked a turning point, followed by regional regulations like the EU's Biocidal Products Regulation and the US EPA's Vessel General Permit program. These frameworks establish strict parameters for leaching rates, biodegradability, and toxicity profiles of anti-fouling systems.

Life cycle assessment (LCA) studies reveal that environmentally-optimized polymer matrices can reduce marine ecotoxicity by 67-89% compared to conventional systems. However, this improvement often comes with trade-offs in durability and performance. The challenge lies in developing matrices that balance longevity with minimal environmental footprint, as longer-lasting films reduce the frequency of reapplication and associated environmental disruption.

Biodegradable polymer matrices represent a promising direction, incorporating naturally derived polymers such as chitosan, alginate, and cellulose derivatives. These materials demonstrate controlled degradation in marine environments without releasing harmful byproducts. Recent innovations include self-polishing copolymers with hydrolyzable linkages that maintain surface activity while degrading into non-toxic components.

Compliance testing protocols have evolved to include comprehensive ecotoxicological assessments. Modern standards require evaluation of acute and chronic toxicity to representative marine species across multiple trophic levels. Additionally, bioaccumulation potential and endocrine disruption capabilities must be assessed before regulatory approval. These stringent requirements drive innovation toward inherently less toxic fouling-resistant mechanisms rather than biocide-releasing systems.

The economic implications of environmental compliance are substantial. While environmentally optimized polymer matrices typically increase initial production costs by 15-30%, they often deliver long-term economic benefits through reduced maintenance requirements and avoidance of regulatory penalties. Companies investing in green anti-fouling technologies gain competitive advantages in markets with stringent environmental standards and environmentally conscious consumers.

Future regulatory trends indicate movement toward harmonized global standards with increasingly stringent thresholds for environmental impact. Polymer matrix designers must anticipate these developments by incorporating environmental considerations from the earliest stages of material selection and formulation, rather than as afterthoughts to performance criteria.

Current polymer matrix designs for anti-fouling films must navigate an increasingly complex regulatory landscape. The International Maritime Organization's (IMO) ban on TBT-based coatings in 2008 marked a turning point, followed by regional regulations like the EU's Biocidal Products Regulation and the US EPA's Vessel General Permit program. These frameworks establish strict parameters for leaching rates, biodegradability, and toxicity profiles of anti-fouling systems.

Life cycle assessment (LCA) studies reveal that environmentally-optimized polymer matrices can reduce marine ecotoxicity by 67-89% compared to conventional systems. However, this improvement often comes with trade-offs in durability and performance. The challenge lies in developing matrices that balance longevity with minimal environmental footprint, as longer-lasting films reduce the frequency of reapplication and associated environmental disruption.

Biodegradable polymer matrices represent a promising direction, incorporating naturally derived polymers such as chitosan, alginate, and cellulose derivatives. These materials demonstrate controlled degradation in marine environments without releasing harmful byproducts. Recent innovations include self-polishing copolymers with hydrolyzable linkages that maintain surface activity while degrading into non-toxic components.

Compliance testing protocols have evolved to include comprehensive ecotoxicological assessments. Modern standards require evaluation of acute and chronic toxicity to representative marine species across multiple trophic levels. Additionally, bioaccumulation potential and endocrine disruption capabilities must be assessed before regulatory approval. These stringent requirements drive innovation toward inherently less toxic fouling-resistant mechanisms rather than biocide-releasing systems.

The economic implications of environmental compliance are substantial. While environmentally optimized polymer matrices typically increase initial production costs by 15-30%, they often deliver long-term economic benefits through reduced maintenance requirements and avoidance of regulatory penalties. Companies investing in green anti-fouling technologies gain competitive advantages in markets with stringent environmental standards and environmentally conscious consumers.

Future regulatory trends indicate movement toward harmonized global standards with increasingly stringent thresholds for environmental impact. Polymer matrix designers must anticipate these developments by incorporating environmental considerations from the earliest stages of material selection and formulation, rather than as afterthoughts to performance criteria.

Performance Testing Methodologies and Standards

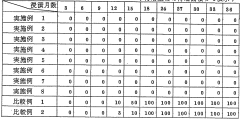

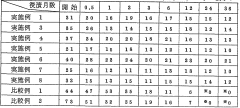

Standardized testing methodologies are essential for evaluating the performance and durability of anti-fouling polymer matrix films. The industry currently employs several established protocols that measure different aspects of film performance under various conditions. The ASTM D5618 standard provides guidelines for evaluating the resistance of coatings to biological growth, while ISO 15181 specifically addresses the laboratory testing of antifouling paints against marine organisms.

Field immersion testing remains the gold standard for performance evaluation, typically conducted in natural marine environments over periods ranging from 6 to 36 months. These tests involve submerging coated panels at different depths and locations to assess performance across varying environmental conditions. Complementary laboratory accelerated testing methods include rotary drum tests, water jet testing, and flow cell analysis, which simulate mechanical stresses and hydrodynamic conditions that films encounter in real-world applications.

Fouling release performance is commonly measured through pseudobarnacle adhesion tests, where the force required to remove standardized test bodies from the coating surface is quantified. The lower the removal force, the better the fouling release properties. Contact angle measurements provide critical data on surface wettability, with higher contact angles generally correlating with improved anti-fouling properties for hydrophobic systems.

Advanced analytical techniques such as Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) and X-ray Photoelectron Spectroscopy (XPS) are employed to monitor chemical changes in the polymer matrix over time. These methods can detect degradation of active components, crosslinking density changes, and surface composition alterations that may affect long-term performance.

Protein adsorption assays using fluorescently labeled proteins offer insights into the initial stages of biofouling, while bacterial attachment tests using model organisms like Pseudomonas aeruginosa or Escherichia coli provide data on microbial colonization resistance. For marine applications, settlement assays with barnacle cyprid larvae and algal spores are standard protocols for assessing anti-fouling efficacy against macrofouling organisms.

Durability testing includes artificial weathering chambers that simulate UV exposure, temperature cycling, and salt spray conditions according to standards like ASTM G154 and ISO 16474. Mechanical durability is evaluated through abrasion resistance tests (ASTM D4060), impact resistance (ASTM D2794), and adhesion testing (ASTM D3359). These standardized methods ensure reproducible results that can be compared across different formulations and research groups.

Field immersion testing remains the gold standard for performance evaluation, typically conducted in natural marine environments over periods ranging from 6 to 36 months. These tests involve submerging coated panels at different depths and locations to assess performance across varying environmental conditions. Complementary laboratory accelerated testing methods include rotary drum tests, water jet testing, and flow cell analysis, which simulate mechanical stresses and hydrodynamic conditions that films encounter in real-world applications.

Fouling release performance is commonly measured through pseudobarnacle adhesion tests, where the force required to remove standardized test bodies from the coating surface is quantified. The lower the removal force, the better the fouling release properties. Contact angle measurements provide critical data on surface wettability, with higher contact angles generally correlating with improved anti-fouling properties for hydrophobic systems.

Advanced analytical techniques such as Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) and X-ray Photoelectron Spectroscopy (XPS) are employed to monitor chemical changes in the polymer matrix over time. These methods can detect degradation of active components, crosslinking density changes, and surface composition alterations that may affect long-term performance.

Protein adsorption assays using fluorescently labeled proteins offer insights into the initial stages of biofouling, while bacterial attachment tests using model organisms like Pseudomonas aeruginosa or Escherichia coli provide data on microbial colonization resistance. For marine applications, settlement assays with barnacle cyprid larvae and algal spores are standard protocols for assessing anti-fouling efficacy against macrofouling organisms.

Durability testing includes artificial weathering chambers that simulate UV exposure, temperature cycling, and salt spray conditions according to standards like ASTM G154 and ISO 16474. Mechanical durability is evaluated through abrasion resistance tests (ASTM D4060), impact resistance (ASTM D2794), and adhesion testing (ASTM D3359). These standardized methods ensure reproducible results that can be compared across different formulations and research groups.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!