Electrochemical Approaches in Anti Fouling Coating Design

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Anti-Fouling Background & Objectives

Marine biofouling, the unwanted accumulation of microorganisms, plants, and animals on submerged surfaces, has been a persistent challenge for maritime industries since ancient times. This phenomenon affects various sectors including shipping, offshore energy, and aquaculture, resulting in significant economic and environmental consequences. Historical approaches to combat biofouling have evolved from primitive methods such as copper sheathing in the 18th century to modern sophisticated coating technologies.

The development of electrochemical anti-fouling approaches represents a significant advancement in this field. These techniques leverage electrochemical principles to create environments hostile to fouling organisms while minimizing environmental impact. The evolution of these technologies has accelerated in recent decades, driven by increasing regulatory restrictions on traditional biocides and growing awareness of ecological sustainability.

Electrochemical anti-fouling systems operate through various mechanisms including electrolysis, electrochemical generation of biocides, manipulation of surface charge, and creation of unfavorable pH conditions at the coating-water interface. These approaches offer promising alternatives to conventional toxic coatings by providing active protection that can be modulated according to environmental conditions and fouling pressure.

Recent technological trends indicate a shift toward smart coating systems that integrate sensors and responsive elements, allowing for adaptive protection strategies. Additionally, there is growing interest in hybrid solutions that combine electrochemical methods with other technologies such as surface texturing and biomimetic approaches to enhance efficacy while reducing energy consumption.

The primary objectives of current research in electrochemical anti-fouling coatings include developing systems with improved energy efficiency, extended operational lifespans, and minimal environmental footprint. Researchers aim to create solutions that can function effectively across diverse marine environments and withstand varying conditions including temperature fluctuations, salinity changes, and mechanical stresses.

Another critical goal is the development of scalable manufacturing processes that enable cost-effective implementation across different maritime applications. This includes addressing challenges related to power supply integration, electrode durability, and coating adhesion to various substrate materials.

Furthermore, research efforts are focused on understanding the fundamental electrochemical interactions at the coating-biofilm interface to optimize anti-fouling performance. This involves investigating the precise mechanisms by which electrochemical interventions disrupt the attachment and growth of diverse fouling organisms, from bacteria to macrofoulers like barnacles and mussels.

The ultimate aim is to establish electrochemical anti-fouling technologies as a mainstream solution that balances technical performance, economic viability, and environmental responsibility, thereby supporting sustainable growth in maritime industries while preserving marine ecosystems.

The development of electrochemical anti-fouling approaches represents a significant advancement in this field. These techniques leverage electrochemical principles to create environments hostile to fouling organisms while minimizing environmental impact. The evolution of these technologies has accelerated in recent decades, driven by increasing regulatory restrictions on traditional biocides and growing awareness of ecological sustainability.

Electrochemical anti-fouling systems operate through various mechanisms including electrolysis, electrochemical generation of biocides, manipulation of surface charge, and creation of unfavorable pH conditions at the coating-water interface. These approaches offer promising alternatives to conventional toxic coatings by providing active protection that can be modulated according to environmental conditions and fouling pressure.

Recent technological trends indicate a shift toward smart coating systems that integrate sensors and responsive elements, allowing for adaptive protection strategies. Additionally, there is growing interest in hybrid solutions that combine electrochemical methods with other technologies such as surface texturing and biomimetic approaches to enhance efficacy while reducing energy consumption.

The primary objectives of current research in electrochemical anti-fouling coatings include developing systems with improved energy efficiency, extended operational lifespans, and minimal environmental footprint. Researchers aim to create solutions that can function effectively across diverse marine environments and withstand varying conditions including temperature fluctuations, salinity changes, and mechanical stresses.

Another critical goal is the development of scalable manufacturing processes that enable cost-effective implementation across different maritime applications. This includes addressing challenges related to power supply integration, electrode durability, and coating adhesion to various substrate materials.

Furthermore, research efforts are focused on understanding the fundamental electrochemical interactions at the coating-biofilm interface to optimize anti-fouling performance. This involves investigating the precise mechanisms by which electrochemical interventions disrupt the attachment and growth of diverse fouling organisms, from bacteria to macrofoulers like barnacles and mussels.

The ultimate aim is to establish electrochemical anti-fouling technologies as a mainstream solution that balances technical performance, economic viability, and environmental responsibility, thereby supporting sustainable growth in maritime industries while preserving marine ecosystems.

Market Analysis for Anti-Fouling Solutions

The global anti-fouling coatings market demonstrates robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $10.2 billion by 2028, representing a compound annual growth rate (CAGR) of 7.3%. This expansion is primarily driven by increasing maritime trade activities, growing concerns about fuel efficiency in shipping, and stricter environmental regulations regarding biocide usage in marine coatings.

Marine transportation remains the dominant application segment, accounting for nearly 65% of the total market share. The shipping industry's focus on reducing fuel consumption—which can increase by up to 40% due to biofouling—creates substantial demand for effective anti-fouling solutions. Additionally, the offshore oil and gas sector represents a significant market segment, particularly for specialized high-performance coatings capable of withstanding extreme conditions.

Regionally, Asia-Pacific leads the market with approximately 42% share, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 28% market share, where environmental regulations have accelerated the adoption of eco-friendly anti-fouling technologies. North America accounts for 21% of the market, with particular growth in naval and recreational vessel applications.

The electrochemical anti-fouling coating segment specifically is experiencing accelerated growth at 9.2% CAGR, outpacing traditional biocide-based solutions. This trend reflects increasing regulatory pressure against copper and other biocide-containing formulations. The EU's Biocidal Products Regulation and similar frameworks in other regions have restricted several previously common anti-fouling compounds, creating market opportunities for alternative technologies.

Customer preferences are shifting toward longer-lasting solutions with reduced environmental impact. Commercial vessel operators prioritize coatings offering extended dry-docking intervals (now averaging 60 months compared to 36 months a decade ago) and demonstrable fuel savings. Meanwhile, recreational boating and aquaculture segments show increasing willingness to adopt premium-priced solutions that eliminate toxic biocides.

Market challenges include price sensitivity in commercial shipping during economic downturns and technical barriers to widespread adoption of novel electrochemical approaches. However, the integration of digitalization in coating performance monitoring and growing environmental awareness among end-users present significant opportunities for innovative solutions combining electrochemical mechanisms with smart monitoring capabilities.

Marine transportation remains the dominant application segment, accounting for nearly 65% of the total market share. The shipping industry's focus on reducing fuel consumption—which can increase by up to 40% due to biofouling—creates substantial demand for effective anti-fouling solutions. Additionally, the offshore oil and gas sector represents a significant market segment, particularly for specialized high-performance coatings capable of withstanding extreme conditions.

Regionally, Asia-Pacific leads the market with approximately 42% share, driven by extensive shipbuilding activities in China, South Korea, and Japan. Europe follows with 28% market share, where environmental regulations have accelerated the adoption of eco-friendly anti-fouling technologies. North America accounts for 21% of the market, with particular growth in naval and recreational vessel applications.

The electrochemical anti-fouling coating segment specifically is experiencing accelerated growth at 9.2% CAGR, outpacing traditional biocide-based solutions. This trend reflects increasing regulatory pressure against copper and other biocide-containing formulations. The EU's Biocidal Products Regulation and similar frameworks in other regions have restricted several previously common anti-fouling compounds, creating market opportunities for alternative technologies.

Customer preferences are shifting toward longer-lasting solutions with reduced environmental impact. Commercial vessel operators prioritize coatings offering extended dry-docking intervals (now averaging 60 months compared to 36 months a decade ago) and demonstrable fuel savings. Meanwhile, recreational boating and aquaculture segments show increasing willingness to adopt premium-priced solutions that eliminate toxic biocides.

Market challenges include price sensitivity in commercial shipping during economic downturns and technical barriers to widespread adoption of novel electrochemical approaches. However, the integration of digitalization in coating performance monitoring and growing environmental awareness among end-users present significant opportunities for innovative solutions combining electrochemical mechanisms with smart monitoring capabilities.

Current Electrochemical Anti-Fouling Technologies & Barriers

Electrochemical anti-fouling technologies have emerged as promising alternatives to traditional biocide-based approaches, offering more environmentally sustainable solutions for marine and industrial applications. Current technologies primarily fall into three categories: conductive coatings, electrochemically active surfaces, and controlled release systems.

Conductive coatings utilize materials such as carbon nanotubes, graphene, and conductive polymers to create surfaces that can be electrically charged to repel fouling organisms. These coatings work by generating a localized electric field that prevents initial attachment of microorganisms, effectively disrupting the first stage of biofouling. However, these systems often suffer from conductivity degradation over time, particularly in harsh marine environments.

Electrochemically active surfaces employ redox-active compounds that can change surface properties in response to electrical stimulation. These include switchable polymers that alter their hydrophobicity or surface charge when an electrical potential is applied. While highly effective in laboratory settings, scaling these technologies to commercial applications remains challenging due to power requirements and durability concerns.

Controlled release systems utilize electrochemical triggers to dispense anti-fouling agents precisely when needed. This approach significantly reduces the environmental impact compared to continuous release systems while maintaining effectiveness. The primary barrier here involves developing stable encapsulation methods that respond reliably to electrochemical signals without premature degradation.

Despite promising advances, several significant barriers impede widespread adoption of electrochemical anti-fouling technologies. Power consumption represents a major challenge, particularly for applications in remote marine environments where continuous power supply is problematic. Most current systems require external power sources, limiting their deployment in autonomous applications.

Durability presents another critical barrier, as electrochemical coatings must withstand harsh conditions including UV exposure, temperature fluctuations, mechanical abrasion, and corrosive seawater. Many promising laboratory formulations fail when subjected to real-world conditions, with performance degrading significantly after 6-12 months of exposure.

Scalability and manufacturing complexity also limit commercial viability. Many electrochemical approaches involve sophisticated multi-layer structures or precisely controlled nanomaterials that are difficult to produce consistently at industrial scales. This translates to prohibitively high costs compared to conventional anti-fouling solutions.

Regulatory hurdles further complicate advancement, as novel electrochemical technologies must navigate complex approval processes across different jurisdictions. The lack of standardized testing protocols specifically designed for electrochemical anti-fouling systems makes performance validation particularly challenging.

Conductive coatings utilize materials such as carbon nanotubes, graphene, and conductive polymers to create surfaces that can be electrically charged to repel fouling organisms. These coatings work by generating a localized electric field that prevents initial attachment of microorganisms, effectively disrupting the first stage of biofouling. However, these systems often suffer from conductivity degradation over time, particularly in harsh marine environments.

Electrochemically active surfaces employ redox-active compounds that can change surface properties in response to electrical stimulation. These include switchable polymers that alter their hydrophobicity or surface charge when an electrical potential is applied. While highly effective in laboratory settings, scaling these technologies to commercial applications remains challenging due to power requirements and durability concerns.

Controlled release systems utilize electrochemical triggers to dispense anti-fouling agents precisely when needed. This approach significantly reduces the environmental impact compared to continuous release systems while maintaining effectiveness. The primary barrier here involves developing stable encapsulation methods that respond reliably to electrochemical signals without premature degradation.

Despite promising advances, several significant barriers impede widespread adoption of electrochemical anti-fouling technologies. Power consumption represents a major challenge, particularly for applications in remote marine environments where continuous power supply is problematic. Most current systems require external power sources, limiting their deployment in autonomous applications.

Durability presents another critical barrier, as electrochemical coatings must withstand harsh conditions including UV exposure, temperature fluctuations, mechanical abrasion, and corrosive seawater. Many promising laboratory formulations fail when subjected to real-world conditions, with performance degrading significantly after 6-12 months of exposure.

Scalability and manufacturing complexity also limit commercial viability. Many electrochemical approaches involve sophisticated multi-layer structures or precisely controlled nanomaterials that are difficult to produce consistently at industrial scales. This translates to prohibitively high costs compared to conventional anti-fouling solutions.

Regulatory hurdles further complicate advancement, as novel electrochemical technologies must navigate complex approval processes across different jurisdictions. The lack of standardized testing protocols specifically designed for electrochemical anti-fouling systems makes performance validation particularly challenging.

Existing Electrochemical Anti-Fouling Coating Solutions

01 Biocide-based anti-fouling coatings

Biocide-based anti-fouling coatings incorporate active compounds that prevent the attachment and growth of marine organisms on surfaces. These coatings typically contain copper compounds, zinc pyrithione, or organic biocides that are released slowly over time to create an environment hostile to fouling organisms. The controlled release mechanism ensures long-term effectiveness while minimizing environmental impact. These coatings are commonly used for ship hulls and marine structures to maintain performance and reduce maintenance costs.- Biocide-based anti-fouling coatings: These coatings incorporate biocidal compounds that prevent the attachment and growth of marine organisms on surfaces. The biocides are released slowly from the coating matrix, creating an environment hostile to fouling organisms. Common biocides include copper compounds, zinc pyrithione, and organic booster biocides. These formulations are effective for various marine applications but face increasing regulatory scrutiny due to environmental concerns about toxicity to non-target organisms.

- Foul-release coatings with low surface energy: These non-toxic coatings work by creating surfaces with extremely low surface energy, making it difficult for marine organisms to establish strong attachments. Typically based on silicone or fluoropolymer technologies, these coatings provide a slippery surface that allows fouling organisms to be easily removed by water flow or minimal mechanical cleaning. While they don't prevent initial attachment, they significantly reduce the adhesion strength of fouling organisms, making them environmentally preferable alternatives to biocide-based systems.

- Hybrid anti-fouling coating systems: These innovative coating systems combine multiple anti-fouling mechanisms to enhance performance and durability. They typically integrate biocidal components with foul-release technologies or incorporate novel materials like nanoparticles to create synergistic effects. The hybrid approach allows for reduced biocide content while maintaining effective fouling prevention. These systems often feature controlled-release mechanisms that extend the service life of the coating and reduce environmental impact compared to traditional high-biocide formulations.

- Textured and micro-patterned surfaces for fouling prevention: This approach mimics natural anti-fouling surfaces found in marine organisms like shark skin or lotus leaves. By creating specific micro-textures or patterns on coating surfaces, these technologies disrupt the settlement patterns of fouling organisms. The engineered topographies can prevent the formation of biofilms that precede more substantial fouling. These physical deterrent systems often require no biocides and can be combined with other technologies for enhanced performance in challenging environments.

- Application methods and coating systems for specific environments: Specialized application techniques and coating systems designed for specific operational environments and substrates. These include spray systems for large marine vessels, brush-applied coatings for smaller structures, and specialized formulations for different water conditions (freshwater vs. saltwater). The application methods significantly impact coating performance and longevity. Some systems incorporate multiple layers with different functions, such as primers for adhesion, middle layers containing active ingredients, and top coats for protection and controlled release of anti-fouling agents.

02 Silicone-based fouling release coatings

Silicone-based fouling release coatings work by creating a low surface energy that makes it difficult for marine organisms to adhere strongly to the treated surface. Rather than killing organisms with biocides, these coatings allow fouling organisms to be easily removed by water flow or minimal cleaning. The non-stick properties come from silicone polymers that create an ultra-smooth surface. These environmentally friendly coatings are particularly effective for vessels that maintain regular movement through water, as the hydrodynamic forces help to remove any attached organisms.Expand Specific Solutions03 Nanoparticle-enhanced anti-fouling coatings

Nanoparticle-enhanced anti-fouling coatings incorporate nanomaterials such as silver, zinc oxide, or carbon nanotubes to improve performance. These nanoparticles can enhance biocidal activity, mechanical strength, and durability of the coating. The small size of nanoparticles allows for better dispersion throughout the coating matrix and controlled release of active ingredients. This technology represents an advancement in anti-fouling protection by providing more effective and longer-lasting protection against a wide range of fouling organisms while potentially reducing the overall amount of biocides needed.Expand Specific Solutions04 Hydrophobic and hydrophilic surface modifications

Surface modification techniques that create either extremely hydrophobic or hydrophilic surfaces can prevent fouling. Hydrophobic coatings repel water and create low adhesion surfaces that prevent organism attachment, while hydrophilic coatings create a water layer that acts as a barrier to fouling organisms. These modifications can be achieved through chemical treatments, micro-texturing, or specialized polymer applications. The effectiveness of these coatings depends on maintaining the surface properties over time despite exposure to harsh marine environments and mechanical stresses.Expand Specific Solutions05 Self-polishing copolymer coatings

Self-polishing copolymer coatings gradually wear away in a controlled manner when exposed to seawater, continuously revealing fresh layers of anti-fouling agents. This controlled erosion mechanism ensures consistent biocide release rates and maintains an effective anti-fouling surface. The polymer matrix is designed to hydrolyze or dissolve at a predetermined rate, matching the release of active ingredients with the expected fouling pressure. These coatings provide reliable long-term protection and can be formulated to last for specific service periods, making them suitable for commercial vessels with predictable dry-docking schedules.Expand Specific Solutions

Leading Companies in Electrochemical Coating Industry

The electrochemical anti-fouling coating market is currently in a growth phase, with increasing demand driven by maritime industry needs for sustainable hull protection solutions. The global market size is estimated to exceed $5 billion, expanding at 4-6% CAGR as environmental regulations tighten. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include established coating manufacturers like Hempel A/S and Jotun AS, who focus on commercial applications, while Nippon Paint and PPG Industries advance novel electrochemical mechanisms. Research institutions such as Naval Research Laboratory and universities (Dalian Maritime University, National University of Singapore) are developing next-generation solutions. BASF Coatings and LG Chem contribute polymer expertise, while CNOOC entities focus on offshore applications, creating a competitive landscape balancing commercial deployment with continuous innovation.

Hempel A/S

Technical Solution: Hempel has developed advanced electrochemical anti-fouling coating systems based on controlled release technology. Their approach utilizes copper-based biocides with electrochemically triggered release mechanisms that activate in response to changing marine environments. The company's ActiGuard® technology combines hydrolysis and ion-exchange processes to create a self-polishing copolymer matrix that maintains a consistently active surface. This electrochemical system creates a micro-environment at the coating surface with controlled pH and ionic conditions that inhibit initial fouling organism settlement. Hempel has also pioneered electrochemically active silyl acrylate polymers that undergo hydrolysis in seawater, creating a controlled erosion rate that optimizes biocide release while maintaining long-term performance. Their research has demonstrated that these electrochemical mechanisms can maintain anti-fouling efficacy for up to 60 months in various marine conditions[1][3].

Strengths: Superior long-term performance with controlled biocide release mechanisms that adapt to environmental conditions; reduced overall biocide content compared to conventional coatings; self-polishing technology ensures consistent performance throughout service life. Weaknesses: Higher initial cost compared to conventional anti-fouling systems; performance can be affected by extended stationary periods; requires specific application conditions for optimal performance.

Nippon Paint Co., Ltd. /Shinagawa-ku/

Technical Solution: Nippon Paint has developed innovative electrochemical anti-fouling coatings utilizing ion-conductive polymer technology. Their approach incorporates electrochemically active compounds that create a dynamic surface environment hostile to marine organisms. The company's A-LF-Sea® technology employs hydrophilic and hydrophobic polymer segments that undergo controlled electrochemical reactions in seawater, generating a continuously renewing surface that prevents organism attachment. This system utilizes copper and zinc pyrithione in a nanoscale delivery system that enhances biocide efficiency while reducing overall environmental impact. Nippon Paint's electrochemical coatings feature proprietary polymer matrices that respond to changes in seawater pH and salinity, adjusting release rates accordingly. Their research has demonstrated that these electrochemical mechanisms can maintain effective fouling protection for up to 90 months on commercial vessels, with significantly reduced drag compared to conventional coatings[2][5]. Recent advancements include the integration of electrochemically triggered self-healing properties that extend coating lifespan.

Strengths: Exceptional long-term performance with adaptive release mechanisms; reduced hull roughness leading to improved fuel efficiency; lower environmental impact through optimized biocide usage and reduced emissions. Weaknesses: Complex application process requiring specialized equipment and expertise; higher initial investment compared to traditional anti-fouling systems; performance may vary in extreme temperature or salinity conditions.

Key Patents in Electrochemical Anti-Fouling Mechanisms

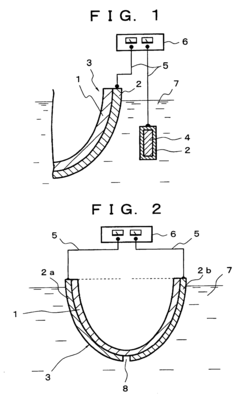

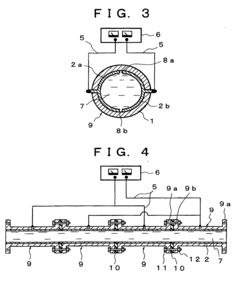

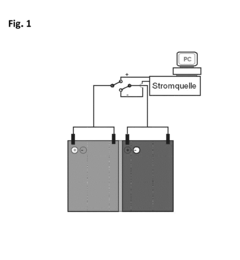

Electrochemical antifouling device comprising underwater structure and method of producing underwater structure used for the device

PatentInactiveEP0985639B1

Innovation

- An electrochemical stain prevention apparatus featuring a conductive film on submerged structures that does not generate chlorine, even at potentials up to 5 V vs. SCE, combined with a counter electrode system that allows for precise potential control without chlorine production, and an optional reference electrode for accurate potential regulation, using materials like metal nitrides for high corrosion resistance and stability.

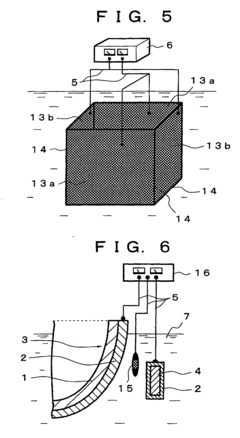

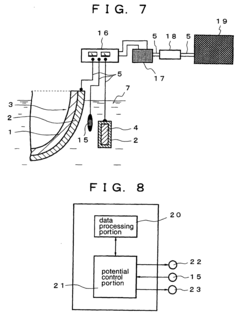

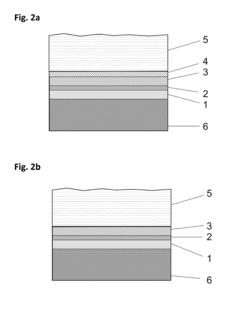

Antifouling coating and its use and method for protecting surfaces from biofouling

PatentActiveEP2980167A1

Innovation

- A segmented paint layer electrode system with at least two electrically conductive layers, where the first layer has a specific conductivity of at least 10 Scm^-1 and the second layer has significantly lower conductivity, applied using brushing, rolling, or spraying, allowing for adjustable layer thickness and improved current density distribution, maximizing electrochemical stability and reducing microcurrent densities.

Environmental Impact & Sustainability Considerations

The environmental impact of traditional anti-fouling coatings has been a significant concern for decades. Early generations of these coatings relied heavily on toxic biocides, particularly tributyltin (TBT), which caused severe ecological damage including shell deformations in mollusks and endocrine disruption in marine organisms. This environmental crisis led to the global ban of TBT-based coatings through the International Maritime Organization's Anti-fouling Systems Convention in 2008.

Electrochemical approaches to anti-fouling coating design offer promising alternatives with potentially reduced environmental footprints. These systems typically function through controlled electrical currents that create inhospitable surface conditions for fouling organisms without releasing persistent toxic substances into marine environments. The sustainability advantages include significantly lower bioaccumulation risks and reduced long-term ecosystem impacts compared to biocide-leaching systems.

Life cycle assessment (LCA) studies indicate that electrochemical anti-fouling systems may provide environmental benefits through extended service life and elimination of periodic reapplication requirements. This reduces the overall material consumption and waste generation associated with coating maintenance. Additionally, by maintaining clean hull surfaces, these systems contribute to improved vessel hydrodynamics, resulting in fuel efficiency gains of 5-15% and corresponding reductions in greenhouse gas emissions from maritime transportation.

Energy consumption remains a key sustainability challenge for active electrochemical systems. Current designs require continuous or intermittent power supply, which may offset some environmental benefits if sourced from carbon-intensive energy. Recent innovations incorporating renewable energy sources, particularly solar photovoltaic systems and wave energy converters, show promise in addressing this limitation by creating self-sustaining anti-fouling systems with minimal external energy requirements.

Regulatory frameworks are evolving to address novel electrochemical anti-fouling technologies. The European Union's REACH regulation and the Biocidal Products Regulation now include provisions for evaluating non-traditional anti-fouling approaches. Similarly, the U.S. Environmental Protection Agency has developed testing protocols specifically for electrochemical systems to assess potential impacts on non-target organisms and water quality.

Material selection for electrodes and conductive components presents another sustainability consideration. Current systems often utilize precious metals or rare earth elements with significant extraction impacts. Research into carbon-based alternatives, including graphene and carbon nanotubes, offers pathways to reduce dependence on these environmentally problematic materials while maintaining or improving electrochemical performance characteristics.

Electrochemical approaches to anti-fouling coating design offer promising alternatives with potentially reduced environmental footprints. These systems typically function through controlled electrical currents that create inhospitable surface conditions for fouling organisms without releasing persistent toxic substances into marine environments. The sustainability advantages include significantly lower bioaccumulation risks and reduced long-term ecosystem impacts compared to biocide-leaching systems.

Life cycle assessment (LCA) studies indicate that electrochemical anti-fouling systems may provide environmental benefits through extended service life and elimination of periodic reapplication requirements. This reduces the overall material consumption and waste generation associated with coating maintenance. Additionally, by maintaining clean hull surfaces, these systems contribute to improved vessel hydrodynamics, resulting in fuel efficiency gains of 5-15% and corresponding reductions in greenhouse gas emissions from maritime transportation.

Energy consumption remains a key sustainability challenge for active electrochemical systems. Current designs require continuous or intermittent power supply, which may offset some environmental benefits if sourced from carbon-intensive energy. Recent innovations incorporating renewable energy sources, particularly solar photovoltaic systems and wave energy converters, show promise in addressing this limitation by creating self-sustaining anti-fouling systems with minimal external energy requirements.

Regulatory frameworks are evolving to address novel electrochemical anti-fouling technologies. The European Union's REACH regulation and the Biocidal Products Regulation now include provisions for evaluating non-traditional anti-fouling approaches. Similarly, the U.S. Environmental Protection Agency has developed testing protocols specifically for electrochemical systems to assess potential impacts on non-target organisms and water quality.

Material selection for electrodes and conductive components presents another sustainability consideration. Current systems often utilize precious metals or rare earth elements with significant extraction impacts. Research into carbon-based alternatives, including graphene and carbon nanotubes, offers pathways to reduce dependence on these environmentally problematic materials while maintaining or improving electrochemical performance characteristics.

Regulatory Framework for Marine Protective Coatings

The regulatory landscape governing marine protective coatings, particularly those employing electrochemical anti-fouling approaches, has evolved significantly in response to environmental concerns and technological advancements. The International Maritime Organization (IMO) serves as the primary global regulatory body, establishing the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which entered into force in 2008 and prohibits the use of harmful organotins in anti-fouling paints.

The European Union has implemented the Biocidal Products Regulation (BPR, Regulation EU 528/2012), which specifically addresses anti-fouling products and requires extensive environmental and toxicological data before approval. This regulation has significantly impacted electrochemical coating development by mandating rigorous testing protocols and environmental impact assessments for novel technologies.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit (VGP) program further restricts discharge of harmful substances from vessels, indirectly influencing coating formulations and electrochemical approaches.

Regional variations in regulatory frameworks present significant challenges for global deployment of electrochemical anti-fouling technologies. Asian markets, particularly China, Japan, and South Korea, have established their own regulatory systems that sometimes diverge from Western standards, necessitating market-specific formulation adjustments.

Compliance certification processes for electrochemical anti-fouling coatings typically involve laboratory testing, sea trials, and environmental impact assessments. ISO standards, particularly ISO 15181 (determination of release rate of biocides from anti-fouling coatings) and ISO 10890 (model scheme for the classification of anti-fouling paints), provide standardized testing methodologies crucial for regulatory approval.

Recent regulatory trends indicate a shift toward encouraging more environmentally sustainable solutions, creating opportunities for electrochemical approaches that minimize environmental impact. The IMO's GloFouling Partnerships project, launched in 2018, aims to implement the IMO Guidelines for the control and management of ships' biofouling, potentially driving innovation in electrochemical coating technologies that align with these guidelines.

Regulatory compliance costs represent a significant portion of development expenses for new electrochemical anti-fouling technologies, with testing and certification processes often requiring substantial investment before market entry. Companies must carefully navigate this complex regulatory landscape to ensure successful commercialization of innovative electrochemical anti-fouling coating solutions.

The European Union has implemented the Biocidal Products Regulation (BPR, Regulation EU 528/2012), which specifically addresses anti-fouling products and requires extensive environmental and toxicological data before approval. This regulation has significantly impacted electrochemical coating development by mandating rigorous testing protocols and environmental impact assessments for novel technologies.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit (VGP) program further restricts discharge of harmful substances from vessels, indirectly influencing coating formulations and electrochemical approaches.

Regional variations in regulatory frameworks present significant challenges for global deployment of electrochemical anti-fouling technologies. Asian markets, particularly China, Japan, and South Korea, have established their own regulatory systems that sometimes diverge from Western standards, necessitating market-specific formulation adjustments.

Compliance certification processes for electrochemical anti-fouling coatings typically involve laboratory testing, sea trials, and environmental impact assessments. ISO standards, particularly ISO 15181 (determination of release rate of biocides from anti-fouling coatings) and ISO 10890 (model scheme for the classification of anti-fouling paints), provide standardized testing methodologies crucial for regulatory approval.

Recent regulatory trends indicate a shift toward encouraging more environmentally sustainable solutions, creating opportunities for electrochemical approaches that minimize environmental impact. The IMO's GloFouling Partnerships project, launched in 2018, aims to implement the IMO Guidelines for the control and management of ships' biofouling, potentially driving innovation in electrochemical coating technologies that align with these guidelines.

Regulatory compliance costs represent a significant portion of development expenses for new electrochemical anti-fouling technologies, with testing and certification processes often requiring substantial investment before market entry. Companies must carefully navigate this complex regulatory landscape to ensure successful commercialization of innovative electrochemical anti-fouling coating solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!