Silicone Based Anti Fouling Coatings for Marine Structures

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Biofouling Background and Objectives

Marine biofouling represents one of the most persistent challenges in maritime industries, causing significant economic and environmental impacts worldwide. This natural phenomenon involves the accumulation of microorganisms, plants, algae, and animals on submerged surfaces, including ship hulls, offshore platforms, aquaculture nets, and underwater sensors. The history of combating marine biofouling dates back centuries, with early solutions involving copper sheathing and toxic paints, evolving to modern sophisticated coating technologies.

The economic implications of biofouling are substantial, estimated to cost the global shipping industry over $7 billion annually through increased fuel consumption, maintenance requirements, and operational downtime. Additionally, biofouling serves as a vector for invasive species transportation across marine ecosystems, threatening biodiversity and ecological balance in various regions worldwide.

Traditional antifouling solutions have predominantly relied on biocide-releasing coatings, particularly those containing tributyltin (TBT) compounds. However, the severe environmental consequences of these toxic substances led to their global ban in the early 2000s, creating an urgent need for environmentally sustainable alternatives. This regulatory shift has accelerated research into non-toxic antifouling technologies, with silicone-based coatings emerging as a promising solution.

Silicone-based antifouling coatings operate primarily through physical rather than chemical mechanisms, creating low surface energy interfaces that prevent strong adhesion of marine organisms. These coatings offer the advantage of being environmentally benign while providing effective fouling protection, aligning with increasingly stringent international maritime regulations and sustainability goals.

The technical evolution of silicone coatings has progressed significantly over recent decades, moving from simple polydimethylsiloxane (PDMS) formulations to sophisticated hybrid systems incorporating various functional additives. Current research focuses on enhancing durability, mechanical strength, and long-term performance while maintaining the inherent fouling-release properties of silicone materials.

The primary objectives of advancing silicone-based antifouling technology include developing coatings with extended service life exceeding five years, improving mechanical durability to withstand harsh marine conditions, reducing installation and maintenance costs, and ensuring zero environmental impact throughout the product lifecycle. Additionally, researchers aim to create versatile formulations suitable for various marine structures beyond ship hulls, including static installations where fouling-release mechanisms face particular challenges.

Future technical goals include the integration of smart functionalities such as self-healing capabilities, responsive surfaces that adapt to environmental conditions, and potentially self-cleaning mechanisms that require minimal external intervention. These advancements would represent significant progress toward sustainable marine infrastructure protection systems that balance performance requirements with environmental responsibility.

The economic implications of biofouling are substantial, estimated to cost the global shipping industry over $7 billion annually through increased fuel consumption, maintenance requirements, and operational downtime. Additionally, biofouling serves as a vector for invasive species transportation across marine ecosystems, threatening biodiversity and ecological balance in various regions worldwide.

Traditional antifouling solutions have predominantly relied on biocide-releasing coatings, particularly those containing tributyltin (TBT) compounds. However, the severe environmental consequences of these toxic substances led to their global ban in the early 2000s, creating an urgent need for environmentally sustainable alternatives. This regulatory shift has accelerated research into non-toxic antifouling technologies, with silicone-based coatings emerging as a promising solution.

Silicone-based antifouling coatings operate primarily through physical rather than chemical mechanisms, creating low surface energy interfaces that prevent strong adhesion of marine organisms. These coatings offer the advantage of being environmentally benign while providing effective fouling protection, aligning with increasingly stringent international maritime regulations and sustainability goals.

The technical evolution of silicone coatings has progressed significantly over recent decades, moving from simple polydimethylsiloxane (PDMS) formulations to sophisticated hybrid systems incorporating various functional additives. Current research focuses on enhancing durability, mechanical strength, and long-term performance while maintaining the inherent fouling-release properties of silicone materials.

The primary objectives of advancing silicone-based antifouling technology include developing coatings with extended service life exceeding five years, improving mechanical durability to withstand harsh marine conditions, reducing installation and maintenance costs, and ensuring zero environmental impact throughout the product lifecycle. Additionally, researchers aim to create versatile formulations suitable for various marine structures beyond ship hulls, including static installations where fouling-release mechanisms face particular challenges.

Future technical goals include the integration of smart functionalities such as self-healing capabilities, responsive surfaces that adapt to environmental conditions, and potentially self-cleaning mechanisms that require minimal external intervention. These advancements would represent significant progress toward sustainable marine infrastructure protection systems that balance performance requirements with environmental responsibility.

Market Analysis for Marine Anti-fouling Solutions

The global marine anti-fouling coatings market demonstrates robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $10.2 billion by 2028, representing a compound annual growth rate (CAGR) of 7.3%. This expansion is primarily driven by increasing maritime trade activities, growing vessel fleet sizes, and stricter environmental regulations concerning marine pollution.

Asia-Pacific dominates the market landscape, accounting for nearly 45% of global demand, attributed to the region's extensive shipbuilding industry, particularly in China, South Korea, and Japan. Europe follows with a 28% market share, while North America represents approximately 18% of the global market.

The commercial shipping segment constitutes the largest application area, comprising about 65% of market demand. Offshore structures, including oil and gas platforms, wind farms, and aquaculture installations, represent a rapidly growing segment with an estimated 15% market share and projected growth exceeding 9% annually through 2028.

Environmental regulations have significantly reshaped market dynamics, particularly following the International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds. This regulatory shift has accelerated the transition toward environmentally friendly solutions, with silicone-based coatings emerging as a preferred alternative due to their non-toxic properties and superior performance characteristics.

Consumer preferences increasingly favor sustainable solutions that offer extended service life and reduced maintenance requirements. Silicone-based anti-fouling coatings, despite their premium pricing (typically 30-40% higher than conventional alternatives), demonstrate growing market acceptance due to their long-term cost-effectiveness through reduced fuel consumption and maintenance intervals.

Market competition features established players like PPG Industries, AkzoNobel, Jotun, and Hempel collectively holding approximately 65% market share. However, specialized manufacturers focusing exclusively on silicone-based technologies are gaining traction, with companies like Dow Corning and Momentive Performance Materials expanding their marine industry presence.

Future market growth will likely be driven by technological innovations addressing current limitations of silicone coatings, including mechanical durability and adhesion properties. The development of hybrid solutions combining silicone with other materials represents a particularly promising market segment, expected to grow at twice the rate of conventional solutions over the next five years.

Asia-Pacific dominates the market landscape, accounting for nearly 45% of global demand, attributed to the region's extensive shipbuilding industry, particularly in China, South Korea, and Japan. Europe follows with a 28% market share, while North America represents approximately 18% of the global market.

The commercial shipping segment constitutes the largest application area, comprising about 65% of market demand. Offshore structures, including oil and gas platforms, wind farms, and aquaculture installations, represent a rapidly growing segment with an estimated 15% market share and projected growth exceeding 9% annually through 2028.

Environmental regulations have significantly reshaped market dynamics, particularly following the International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds. This regulatory shift has accelerated the transition toward environmentally friendly solutions, with silicone-based coatings emerging as a preferred alternative due to their non-toxic properties and superior performance characteristics.

Consumer preferences increasingly favor sustainable solutions that offer extended service life and reduced maintenance requirements. Silicone-based anti-fouling coatings, despite their premium pricing (typically 30-40% higher than conventional alternatives), demonstrate growing market acceptance due to their long-term cost-effectiveness through reduced fuel consumption and maintenance intervals.

Market competition features established players like PPG Industries, AkzoNobel, Jotun, and Hempel collectively holding approximately 65% market share. However, specialized manufacturers focusing exclusively on silicone-based technologies are gaining traction, with companies like Dow Corning and Momentive Performance Materials expanding their marine industry presence.

Future market growth will likely be driven by technological innovations addressing current limitations of silicone coatings, including mechanical durability and adhesion properties. The development of hybrid solutions combining silicone with other materials represents a particularly promising market segment, expected to grow at twice the rate of conventional solutions over the next five years.

Current Silicone Coating Technologies and Challenges

Silicone-based antifouling coatings represent a significant advancement in marine protection technologies. Currently, these coatings primarily utilize polydimethylsiloxane (PDMS) as their base material due to its excellent water repellency, low surface energy, and chemical stability in marine environments. The most prevalent commercial formulations incorporate PDMS with various additives such as silica nanoparticles for mechanical reinforcement and specialized cross-linking agents to enhance durability under harsh oceanic conditions.

The fouling-release mechanism of silicone coatings differs fundamentally from traditional biocide-based solutions. Rather than killing marine organisms, these coatings create a surface to which organisms cannot strongly adhere. When vessels move through water, the hydrodynamic forces easily remove accumulated fouling organisms due to the weak adhesion to the silicone surface. This mechanism provides an environmentally friendly alternative to toxic antifouling paints containing copper or tributyltin compounds.

Despite their advantages, current silicone coating technologies face several significant challenges. Mechanical durability remains a primary concern, as silicone coatings typically exhibit lower abrasion resistance compared to conventional epoxy or polyurethane systems. This vulnerability becomes particularly problematic in high-wear areas such as the waterline zone and propeller regions, where ice, debris, and maintenance operations can damage the coating.

Adhesion to substrate materials presents another major technical hurdle. Silicone's inherently low surface energy, while beneficial for fouling release, creates difficulties in achieving strong bonds with ship hulls and other marine structures. This necessitates complex primer systems and surface preparation protocols, increasing application costs and complexity.

Biofouling resistance limitations also persist in static conditions. While effective when vessels are in motion, silicone coatings show reduced performance during extended stationary periods, allowing tenacious organisms like barnacles and tubeworms to eventually establish strong attachment points. This limitation restricts their application for permanently stationary structures such as offshore platforms and aquaculture installations.

Cost factors significantly impact widespread adoption, with silicone-based systems typically commanding premium prices 2-3 times higher than conventional antifouling paints. The specialized application requirements further increase total implementation costs, as these coatings generally require professional application under controlled conditions to achieve optimal performance.

Recent technological developments have focused on hybrid systems combining silicone matrices with controlled-release biocides or surface-modifying additives. These approaches aim to address the static immersion performance limitations while maintaining the environmental benefits of fouling-release technology. Additionally, research into silicone-epoxy hybrids shows promise for improving mechanical durability without sacrificing the essential fouling-release properties.

The fouling-release mechanism of silicone coatings differs fundamentally from traditional biocide-based solutions. Rather than killing marine organisms, these coatings create a surface to which organisms cannot strongly adhere. When vessels move through water, the hydrodynamic forces easily remove accumulated fouling organisms due to the weak adhesion to the silicone surface. This mechanism provides an environmentally friendly alternative to toxic antifouling paints containing copper or tributyltin compounds.

Despite their advantages, current silicone coating technologies face several significant challenges. Mechanical durability remains a primary concern, as silicone coatings typically exhibit lower abrasion resistance compared to conventional epoxy or polyurethane systems. This vulnerability becomes particularly problematic in high-wear areas such as the waterline zone and propeller regions, where ice, debris, and maintenance operations can damage the coating.

Adhesion to substrate materials presents another major technical hurdle. Silicone's inherently low surface energy, while beneficial for fouling release, creates difficulties in achieving strong bonds with ship hulls and other marine structures. This necessitates complex primer systems and surface preparation protocols, increasing application costs and complexity.

Biofouling resistance limitations also persist in static conditions. While effective when vessels are in motion, silicone coatings show reduced performance during extended stationary periods, allowing tenacious organisms like barnacles and tubeworms to eventually establish strong attachment points. This limitation restricts their application for permanently stationary structures such as offshore platforms and aquaculture installations.

Cost factors significantly impact widespread adoption, with silicone-based systems typically commanding premium prices 2-3 times higher than conventional antifouling paints. The specialized application requirements further increase total implementation costs, as these coatings generally require professional application under controlled conditions to achieve optimal performance.

Recent technological developments have focused on hybrid systems combining silicone matrices with controlled-release biocides or surface-modifying additives. These approaches aim to address the static immersion performance limitations while maintaining the environmental benefits of fouling-release technology. Additionally, research into silicone-epoxy hybrids shows promise for improving mechanical durability without sacrificing the essential fouling-release properties.

Silicone-Based Anti-fouling Formulations and Applications

01 Silicone-based polymers for anti-fouling coatings

Silicone-based polymers are widely used in anti-fouling coatings due to their low surface energy and smooth surface characteristics. These properties make it difficult for marine organisms to attach to surfaces coated with silicone-based materials. The formulations typically include polydimethylsiloxane (PDMS) or modified silicone polymers that create a slippery surface, preventing the adhesion of barnacles, algae, and other fouling organisms. These coatings are particularly effective for marine vessels and underwater structures.- Silicone-based antifouling coatings with biocides: Silicone-based coatings incorporating biocidal compounds provide effective antifouling properties. These formulations typically combine silicone polymers with active biocidal agents that prevent the attachment and growth of marine organisms. The silicone matrix allows for controlled release of the biocides, extending the effective life of the coating while maintaining environmental compliance. These coatings are particularly effective for vessels and marine structures exposed to high fouling conditions.

- Fouling-release silicone coatings with surface modifiers: These coatings utilize silicone polymers modified with surface-active compounds to create low surface energy interfaces that prevent strong adhesion of fouling organisms. Rather than killing organisms, these coatings make it difficult for them to attach firmly, allowing them to be easily removed by water flow or minimal cleaning. Surface modifiers such as fluoropolymers, siloxanes, and specialized additives enhance the non-stick properties while maintaining the flexibility and durability of the silicone base.

- Nanoparticle-enhanced silicone antifouling coatings: Incorporating nanoparticles into silicone matrices creates advanced antifouling coatings with enhanced performance. These formulations typically use nanoparticles such as silver, copper oxide, zinc oxide, or silica to provide antimicrobial properties and improve the mechanical characteristics of the coating. The nanoparticles can disrupt biofilm formation while the silicone base maintains fouling-release properties. This combination approach offers longer-lasting protection against both hard and soft fouling organisms.

- Environmentally friendly silicone antifouling systems: These innovative coating systems focus on environmentally sustainable approaches to antifouling using silicone technology. They avoid harmful biocides in favor of naturally-derived compounds, biodegradable additives, or physical deterrent mechanisms. Some formulations incorporate enzymes, natural extracts, or biomimetic surface patterns within the silicone matrix to prevent fouling without environmental harm. These coatings are designed to meet increasingly strict environmental regulations while still providing effective antifouling performance.

- Hybrid silicone-based antifouling coating systems: Hybrid coating systems combine silicone polymers with other materials such as epoxies, polyurethanes, or acrylics to create antifouling solutions with enhanced properties. These formulations aim to overcome limitations of pure silicone coatings by improving adhesion to substrates, increasing mechanical strength, or enhancing durability while maintaining antifouling performance. The hybrid approach allows for customization of coatings for specific applications ranging from ship hulls to underwater sensors and offshore structures.

02 Silicone coatings with biocidal additives

Silicone-based anti-fouling coatings can be enhanced by incorporating biocidal additives that actively prevent the growth of marine organisms. These additives include copper compounds, zinc pyrithione, and other environmentally acceptable biocides that are slowly released from the silicone matrix. The combination of the physical properties of silicone with the chemical action of biocides provides a dual-action approach to preventing fouling. These formulations offer longer-lasting protection compared to purely silicone-based systems.Expand Specific Solutions03 Self-polishing silicone copolymer coatings

Self-polishing silicone copolymer coatings combine the benefits of silicone with controlled erosion mechanisms. These coatings gradually wear away through hydrolysis or mechanical action, continuously exposing fresh anti-fouling surfaces. The silicone components provide low surface energy while the copolymer structure allows for controlled degradation. This technology offers extended service life and reduced maintenance requirements for marine structures and vessels, as the coating surface remains active throughout its lifespan.Expand Specific Solutions04 Nanoparticle-enhanced silicone anti-fouling coatings

Incorporating nanoparticles into silicone-based anti-fouling coatings significantly enhances their performance. Nanoparticles such as silica, titanium dioxide, or silver can improve the mechanical properties, durability, and anti-fouling capabilities of the coating. These particles create nano-scale surface roughness that disrupts the attachment mechanisms of fouling organisms while maintaining the low surface energy of silicone. Additionally, some nanoparticles provide antimicrobial properties, further preventing biofouling through multiple mechanisms.Expand Specific Solutions05 Environmentally friendly silicone anti-fouling formulations

Recent developments in silicone-based anti-fouling coatings focus on environmentally friendly formulations that minimize ecological impact. These coatings avoid harmful biocides and instead rely on physical deterrence mechanisms or naturally derived compounds. Some formulations incorporate biodegradable components or renewable resources while maintaining the anti-fouling properties of silicone. These eco-friendly alternatives are designed to comply with increasingly stringent environmental regulations while still providing effective protection against marine fouling.Expand Specific Solutions

Leading Companies in Marine Protective Coatings

The silicone-based anti-fouling coatings for marine structures market is currently in a growth phase, with increasing demand driven by stricter environmental regulations and the need for more efficient marine operations. The global market size is estimated to exceed $7 billion, growing at approximately 5-7% annually. Technologically, the field is moderately mature but continuously evolving, with companies like Hempel A/S, Chugoku Marine Paints, and International Paint (AkzoNobel) leading commercial applications. Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie dominate the silicone raw materials supply. Research institutions like Dalian Maritime University and Xiamen University are advancing next-generation formulations, while emerging players such as XIAMEN SUNRUI and Bluestar Silicones are gaining market share through specialized applications and regional expansion.

Hempel A/S

Technical Solution: Hempel's silicone-based anti-fouling technology, marketed under the Hempasil and Hempaguard product lines, utilizes hydrogel-based fouling release coatings that incorporate silicone polymers with specially engineered surface properties. Their X7 technology combines hydrogel and silicone technologies to create a smooth, low surface energy coating that prevents organisms from firmly attaching to marine structures. The technology employs a unique cross-linking system that ensures long-term stability in marine environments while maintaining flexibility to accommodate structural movement and expansion. Hempel's coatings feature self-smoothing properties that reduce drag and fuel consumption by up to 6% compared to conventional anti-fouling solutions. Their latest innovations include nano-scale surface modifications that enhance the hydrophobic properties of the silicone matrix, further improving fouling release performance without increasing environmental impact.

Strengths: Superior fouling release properties with documented fuel savings of up to 6%; exceptional longevity with effective performance for up to 90 months; low VOC content meeting strict environmental regulations. Weaknesses: Higher initial application costs compared to conventional coatings; requires specialized application techniques; optimal performance depends on vessel activity levels and may be less effective for static structures.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone-based anti-fouling coatings utilizing their proprietary silicone polymer technology. Their marine coatings incorporate specially formulated polydimethylsiloxane (PDMS) elastomers with optimized molecular weight distributions to create ultra-smooth, low surface energy interfaces. The company's technology employs a unique cross-linking system that maintains coating flexibility while ensuring durability in harsh marine environments. Their silicone formulations include specialized additives that enhance hydrophobicity and oleophobicity, creating surfaces that resist both water-based and oil-based fouling organisms. Shin-Etsu's coatings feature self-healing properties that help maintain surface integrity despite minor mechanical damage. The company has also pioneered the incorporation of non-leaching biocides within the silicone matrix, providing additional protection against hard-fouling organisms while minimizing environmental impact. Their latest innovations include silicone-fluoropolymer hybrid systems that combine the fouling release properties of silicones with the chemical resistance of fluoropolymers.

Strengths: Exceptional chemical stability and weathering resistance; superior fouling release performance against both hard and soft fouling; environmentally friendly with minimal leaching of toxic substances. Weaknesses: Relatively high cost compared to conventional anti-fouling systems; requires careful surface preparation and application procedures; may have limited effectiveness in static or slow-moving marine applications.

Key Patents and Research in Silicone Anti-fouling Technology

Method for establishing a fouling release coating system

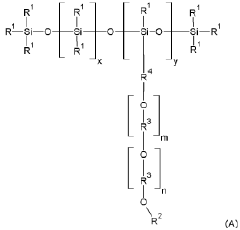

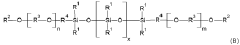

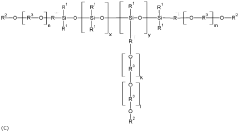

PatentWO2019233985A1

Innovation

- A fouling-release coating system comprising a primer layer, a silicone-containing tie-coat layer, and a polysiloxane-based fouling-release layer with poly(oxyalkylene) chains and sterically hindered amines, such as 2,2,6,6-tetraalkyl piperidine derivatives, to enhance bonding and stability.

Antifouling coating composition and method

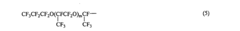

PatentInactiveEP2253682A1

Innovation

- An antifouling coating composition comprising diorganopolysiloxane capped with hydroxyl groups, an organosilicon compound with hydrolyzable groups, and a perfluoropolyether compound, which segregates on the surface and is incorporated into the crosslinked structure, allowing for a long-lasting antifouling effect without releasing harmful substances into the environment.

Environmental Regulations Impact on Coating Development

Environmental regulations have become increasingly stringent in the marine coating industry, significantly influencing the development trajectory of silicone-based anti-fouling coatings for marine structures. The International Maritime Organization (IMO) has implemented several key regulations, most notably the 2001 International Convention on the Control of Harmful Anti-fouling Systems on Ships, which banned tributyltin (TBT)-based coatings due to their severe environmental impacts on marine ecosystems.

This regulatory shift has accelerated research and development in environmentally friendly alternatives, with silicone-based coatings emerging as a leading solution. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has further restricted the use of certain biocides commonly found in traditional anti-fouling paints, creating additional market pressure for silicone-based technologies that rely on physical rather than chemical deterrence mechanisms.

Regional variations in environmental regulations present significant challenges for coating manufacturers. For instance, California's stricter copper leaching limits compared to federal standards require specialized formulations for vessels operating in these waters. Similarly, the Baltic Sea and North Sea have been designated as Special Areas under MARPOL Annex V, imposing additional restrictions on coating compositions used in these sensitive marine environments.

The regulatory landscape continues to evolve, with increasing focus on microplastic pollution. Silicone coatings must now be designed not only for effective anti-fouling performance but also to minimize shedding of microparticles during service life. This has prompted innovations in polymer cross-linking technologies and surface stabilization methods to enhance durability while maintaining environmental compliance.

Compliance certification processes have become more complex, requiring extensive ecotoxicological testing and environmental impact assessments before new coating formulations can enter the market. The ISO 14001 environmental management standard has become a de facto requirement for coating manufacturers, necessitating comprehensive life cycle assessments of silicone coating products from raw material extraction through disposal.

Looking forward, anticipated regulations targeting greenhouse gas emissions are likely to further influence coating development, with emphasis on formulations that reduce hull friction and consequently decrease fuel consumption and carbon emissions. The International Maritime Organization's strategy to reduce greenhouse gas emissions by at least 50% by 2050 will likely accelerate adoption of advanced silicone coatings that can demonstrate quantifiable contributions to vessel efficiency.

These regulatory pressures, while challenging, have ultimately driven positive innovation in the silicone coating sector, resulting in products that deliver superior performance while minimizing environmental impact—a rare win-win scenario in industrial development.

This regulatory shift has accelerated research and development in environmentally friendly alternatives, with silicone-based coatings emerging as a leading solution. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has further restricted the use of certain biocides commonly found in traditional anti-fouling paints, creating additional market pressure for silicone-based technologies that rely on physical rather than chemical deterrence mechanisms.

Regional variations in environmental regulations present significant challenges for coating manufacturers. For instance, California's stricter copper leaching limits compared to federal standards require specialized formulations for vessels operating in these waters. Similarly, the Baltic Sea and North Sea have been designated as Special Areas under MARPOL Annex V, imposing additional restrictions on coating compositions used in these sensitive marine environments.

The regulatory landscape continues to evolve, with increasing focus on microplastic pollution. Silicone coatings must now be designed not only for effective anti-fouling performance but also to minimize shedding of microparticles during service life. This has prompted innovations in polymer cross-linking technologies and surface stabilization methods to enhance durability while maintaining environmental compliance.

Compliance certification processes have become more complex, requiring extensive ecotoxicological testing and environmental impact assessments before new coating formulations can enter the market. The ISO 14001 environmental management standard has become a de facto requirement for coating manufacturers, necessitating comprehensive life cycle assessments of silicone coating products from raw material extraction through disposal.

Looking forward, anticipated regulations targeting greenhouse gas emissions are likely to further influence coating development, with emphasis on formulations that reduce hull friction and consequently decrease fuel consumption and carbon emissions. The International Maritime Organization's strategy to reduce greenhouse gas emissions by at least 50% by 2050 will likely accelerate adoption of advanced silicone coatings that can demonstrate quantifiable contributions to vessel efficiency.

These regulatory pressures, while challenging, have ultimately driven positive innovation in the silicone coating sector, resulting in products that deliver superior performance while minimizing environmental impact—a rare win-win scenario in industrial development.

Performance Testing and Durability Assessment Methods

Performance testing and durability assessment of silicone-based anti-fouling coatings for marine structures require comprehensive methodologies to evaluate their effectiveness in real-world conditions. The marine environment presents unique challenges including constant water exposure, varying salinity levels, UV radiation, temperature fluctuations, and mechanical stresses that can significantly impact coating performance over time.

Standard laboratory testing protocols typically include static immersion tests, where coated panels are submerged in seawater tanks for extended periods to assess fouling resistance. These tests are complemented by dynamic testing using rotating drums or flow chambers that simulate water movement across coated surfaces, providing insights into coating performance under hydrodynamic conditions.

Accelerated aging tests are crucial for predicting long-term durability without waiting for natural degradation processes. These include cyclic salt spray exposure, UV weathering chambers, and thermal cycling tests that compress years of environmental exposure into weeks or months. The ASTM D5479 standard specifically addresses the testing of marine antifouling coating systems, while ISO 19840 provides guidelines for thickness measurement and inspection.

Field testing remains the gold standard for performance validation, involving the installation of coated test panels on vessels or stationary marine structures. These panels are periodically inspected and photographed to document fouling progression, with assessment typically following the ASTM D3623 standard for rating antifouling performance.

Mechanical property evaluations focus on adhesion strength (ASTM D4541), abrasion resistance (ASTM D4060), and impact resistance (ASTM D2794). These tests are critical as silicone coatings must withstand physical stresses from waves, debris, and maintenance activities while maintaining their anti-fouling properties.

Advanced analytical techniques including scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and contact angle measurements provide deeper insights into surface morphology changes, chemical degradation, and hydrophobicity retention over time. These methods help identify failure mechanisms and inform coating formulation improvements.

Standardized performance metrics include fouling coverage percentage, fouling release efficiency, critical removal stress for attached organisms, and changes in surface roughness. The development of digital imaging analysis tools has enhanced the objectivity and reproducibility of fouling assessments, allowing for more precise quantification of coating performance degradation over time.

Emerging methodologies incorporate biological assessment protocols that evaluate the coating's impact on non-target marine organisms and ecosystems, addressing growing environmental concerns about marine coatings. These comprehensive testing approaches ensure that silicone-based anti-fouling solutions meet both performance requirements and environmental sustainability standards.

Standard laboratory testing protocols typically include static immersion tests, where coated panels are submerged in seawater tanks for extended periods to assess fouling resistance. These tests are complemented by dynamic testing using rotating drums or flow chambers that simulate water movement across coated surfaces, providing insights into coating performance under hydrodynamic conditions.

Accelerated aging tests are crucial for predicting long-term durability without waiting for natural degradation processes. These include cyclic salt spray exposure, UV weathering chambers, and thermal cycling tests that compress years of environmental exposure into weeks or months. The ASTM D5479 standard specifically addresses the testing of marine antifouling coating systems, while ISO 19840 provides guidelines for thickness measurement and inspection.

Field testing remains the gold standard for performance validation, involving the installation of coated test panels on vessels or stationary marine structures. These panels are periodically inspected and photographed to document fouling progression, with assessment typically following the ASTM D3623 standard for rating antifouling performance.

Mechanical property evaluations focus on adhesion strength (ASTM D4541), abrasion resistance (ASTM D4060), and impact resistance (ASTM D2794). These tests are critical as silicone coatings must withstand physical stresses from waves, debris, and maintenance activities while maintaining their anti-fouling properties.

Advanced analytical techniques including scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and contact angle measurements provide deeper insights into surface morphology changes, chemical degradation, and hydrophobicity retention over time. These methods help identify failure mechanisms and inform coating formulation improvements.

Standardized performance metrics include fouling coverage percentage, fouling release efficiency, critical removal stress for attached organisms, and changes in surface roughness. The development of digital imaging analysis tools has enhanced the objectivity and reproducibility of fouling assessments, allowing for more precise quantification of coating performance degradation over time.

Emerging methodologies incorporate biological assessment protocols that evaluate the coating's impact on non-target marine organisms and ecosystems, addressing growing environmental concerns about marine coatings. These comprehensive testing approaches ensure that silicone-based anti-fouling solutions meet both performance requirements and environmental sustainability standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!