Environmentally Benign Anti Fouling Additives

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Fouling Technology Background and Objectives

Anti-fouling technology has evolved significantly over the past century, transitioning from highly toxic but effective solutions to more environmentally conscious approaches. Initially, marine vessels and underwater structures relied on copper and lead-based coatings, which gave way to tributyltin (TBT) compounds in the mid-20th century due to their exceptional anti-fouling properties. However, by the 1980s, substantial evidence emerged linking TBT to severe environmental damage, including shell deformations in oysters and imposex in marine gastropods.

The International Maritime Organization's global ban on TBT in 2008 marked a pivotal turning point, accelerating research into environmentally benign alternatives. This regulatory shift has driven innovation toward developing anti-fouling additives that maintain effectiveness while minimizing ecological impact. The marine biofouling problem costs the global shipping industry an estimated $5-7 billion annually through increased fuel consumption, maintenance requirements, and reduced operational efficiency.

Current research focuses on biomimetic approaches, natural product derivatives, and controlled-release technologies that can prevent the attachment and growth of marine organisms without persistent environmental contamination. Particularly promising are enzyme-based systems, biodegradable polymers, and naturally derived compounds from marine organisms that have evolved their own anti-fouling mechanisms.

The technical evolution trajectory shows a clear shift from broad-spectrum biocides toward targeted, mechanism-based solutions that interfere with specific biological processes involved in fouling organism settlement and adhesion. This represents a fundamental change in approach from killing organisms to preventing attachment through non-toxic means.

The primary objective of environmentally benign anti-fouling research is to develop additives that demonstrate comparable performance to traditional biocides while exhibiting minimal environmental persistence, bioaccumulation, and toxicity. These solutions must be economically viable, easily incorporated into existing coating systems, and provide protection for extended periods under diverse marine conditions.

Secondary objectives include understanding the fundamental mechanisms of biofouling at molecular and cellular levels, developing standardized testing protocols for new anti-fouling technologies, and creating predictive models for long-term performance and environmental impact. The ideal solution would combine effective fouling prevention with biodegradability, ensuring that any released compounds degrade into non-toxic components within a reasonable timeframe.

The technical challenge lies in balancing these sometimes competing requirements: effectiveness, environmental safety, durability, cost, and ease of application. As global shipping continues to expand and environmental regulations tighten, the development of truly sustainable anti-fouling technologies represents both an urgent need and a significant market opportunity.

The International Maritime Organization's global ban on TBT in 2008 marked a pivotal turning point, accelerating research into environmentally benign alternatives. This regulatory shift has driven innovation toward developing anti-fouling additives that maintain effectiveness while minimizing ecological impact. The marine biofouling problem costs the global shipping industry an estimated $5-7 billion annually through increased fuel consumption, maintenance requirements, and reduced operational efficiency.

Current research focuses on biomimetic approaches, natural product derivatives, and controlled-release technologies that can prevent the attachment and growth of marine organisms without persistent environmental contamination. Particularly promising are enzyme-based systems, biodegradable polymers, and naturally derived compounds from marine organisms that have evolved their own anti-fouling mechanisms.

The technical evolution trajectory shows a clear shift from broad-spectrum biocides toward targeted, mechanism-based solutions that interfere with specific biological processes involved in fouling organism settlement and adhesion. This represents a fundamental change in approach from killing organisms to preventing attachment through non-toxic means.

The primary objective of environmentally benign anti-fouling research is to develop additives that demonstrate comparable performance to traditional biocides while exhibiting minimal environmental persistence, bioaccumulation, and toxicity. These solutions must be economically viable, easily incorporated into existing coating systems, and provide protection for extended periods under diverse marine conditions.

Secondary objectives include understanding the fundamental mechanisms of biofouling at molecular and cellular levels, developing standardized testing protocols for new anti-fouling technologies, and creating predictive models for long-term performance and environmental impact. The ideal solution would combine effective fouling prevention with biodegradability, ensuring that any released compounds degrade into non-toxic components within a reasonable timeframe.

The technical challenge lies in balancing these sometimes competing requirements: effectiveness, environmental safety, durability, cost, and ease of application. As global shipping continues to expand and environmental regulations tighten, the development of truly sustainable anti-fouling technologies represents both an urgent need and a significant market opportunity.

Market Analysis for Eco-Friendly Anti-Fouling Solutions

The global market for environmentally benign anti-fouling additives has experienced significant growth in recent years, driven by increasing regulatory pressure and growing environmental consciousness. The traditional anti-fouling market, dominated by copper and tributyltin (TBT) based solutions, is undergoing a fundamental shift toward eco-friendly alternatives, creating substantial market opportunities.

The marine coating segment represents the largest application area, valued at approximately $6.1 billion in 2022, with projections indicating growth to $8.5 billion by 2028. This segment is particularly sensitive to environmental regulations, as vessels traverse multiple jurisdictional waters with varying regulatory frameworks. The International Maritime Organization's ban on TBT and restrictions on copper content have accelerated demand for environmentally benign alternatives.

Regional analysis reveals that Europe currently leads the eco-friendly anti-fouling market with a 35% share, followed by North America at 28% and Asia-Pacific at 25%. The Asia-Pacific region, however, is demonstrating the fastest growth rate at 7.8% annually, driven by expanding maritime activities in China, Japan, and South Korea, coupled with strengthening environmental regulations.

By application sector, commercial shipping accounts for 45% of the market, followed by recreational vessels (25%), offshore structures (15%), and aquaculture equipment (10%). The remaining 5% encompasses specialized applications including underwater sensors and oceanographic research equipment.

Consumer willingness to pay premium prices for environmentally benign solutions varies significantly by sector. Commercial fleet operators demonstrate price sensitivity due to scale, while luxury yacht owners show greater willingness to adopt premium eco-friendly solutions regardless of cost differential. This market segmentation necessitates differentiated pricing strategies for manufacturers.

Market barriers include higher production costs for eco-friendly alternatives, technical performance gaps compared to traditional biocides, and fragmented regulatory frameworks across different regions. Despite these challenges, the compound annual growth rate for environmentally benign anti-fouling additives stands at 6.3%, outpacing the broader marine coatings market's 4.1% growth.

Key market drivers include increasingly stringent environmental regulations, growing awareness of marine ecosystem preservation, rising fuel efficiency concerns, and expanding aquaculture operations worldwide. The recreational boating sector's recovery post-pandemic has further accelerated demand for environmentally responsible anti-fouling solutions.

Future market expansion will likely be influenced by technological innovations in biomimetic approaches, integration with smart coating technologies, and development of region-specific formulations addressing local biofouling challenges while complying with regional regulatory requirements.

The marine coating segment represents the largest application area, valued at approximately $6.1 billion in 2022, with projections indicating growth to $8.5 billion by 2028. This segment is particularly sensitive to environmental regulations, as vessels traverse multiple jurisdictional waters with varying regulatory frameworks. The International Maritime Organization's ban on TBT and restrictions on copper content have accelerated demand for environmentally benign alternatives.

Regional analysis reveals that Europe currently leads the eco-friendly anti-fouling market with a 35% share, followed by North America at 28% and Asia-Pacific at 25%. The Asia-Pacific region, however, is demonstrating the fastest growth rate at 7.8% annually, driven by expanding maritime activities in China, Japan, and South Korea, coupled with strengthening environmental regulations.

By application sector, commercial shipping accounts for 45% of the market, followed by recreational vessels (25%), offshore structures (15%), and aquaculture equipment (10%). The remaining 5% encompasses specialized applications including underwater sensors and oceanographic research equipment.

Consumer willingness to pay premium prices for environmentally benign solutions varies significantly by sector. Commercial fleet operators demonstrate price sensitivity due to scale, while luxury yacht owners show greater willingness to adopt premium eco-friendly solutions regardless of cost differential. This market segmentation necessitates differentiated pricing strategies for manufacturers.

Market barriers include higher production costs for eco-friendly alternatives, technical performance gaps compared to traditional biocides, and fragmented regulatory frameworks across different regions. Despite these challenges, the compound annual growth rate for environmentally benign anti-fouling additives stands at 6.3%, outpacing the broader marine coatings market's 4.1% growth.

Key market drivers include increasingly stringent environmental regulations, growing awareness of marine ecosystem preservation, rising fuel efficiency concerns, and expanding aquaculture operations worldwide. The recreational boating sector's recovery post-pandemic has further accelerated demand for environmentally responsible anti-fouling solutions.

Future market expansion will likely be influenced by technological innovations in biomimetic approaches, integration with smart coating technologies, and development of region-specific formulations addressing local biofouling challenges while complying with regional regulatory requirements.

Current Status and Challenges in Green Anti-Fouling Technology

The global anti-fouling technology landscape is experiencing a significant shift towards environmentally benign solutions. Traditional anti-fouling methods have predominantly relied on biocides, particularly tributyltin (TBT) compounds, which demonstrated exceptional efficacy but caused severe environmental damage, leading to their global ban in 2008. This regulatory action created an urgent need for alternative solutions that balance performance with ecological safety.

Current green anti-fouling technologies can be categorized into several approaches. Silicone-based foul-release coatings represent a promising non-biocidal solution, functioning by creating surfaces too slippery for marine organisms to adhere to effectively. These coatings have gained commercial traction but face challenges related to mechanical durability and higher initial application costs compared to traditional solutions.

Natural product-derived anti-foulants present another promising avenue, with compounds extracted from marine organisms showing significant potential. Researchers have identified over 200 natural compounds with anti-fouling properties, though scaling production remains problematic. The extraction processes often yield insufficient quantities for commercial application, and synthetic reproduction frequently proves economically unfeasible.

Enzyme-based technologies that degrade the adhesives used by fouling organisms have demonstrated effectiveness in laboratory settings. However, their stability in marine environments remains questionable, with significant degradation occurring over relatively short deployment periods, limiting their practical application in long-term anti-fouling systems.

Nanotechnology applications represent the cutting edge of green anti-fouling research. Nanostructured surfaces that mimic natural anti-fouling mechanisms found in organisms like sharks and lotus leaves show promise in laboratory tests. Integration of nanoparticles into coating matrices can enhance performance without relying on toxic release mechanisms, though concerns about nanoparticle environmental fate persist.

The primary technical challenges facing green anti-fouling development include achieving comparable performance to biocidal solutions, ensuring durability in harsh marine environments, and maintaining cost-effectiveness. Most current environmentally friendly solutions demonstrate shorter effective lifespans than their toxic counterparts, necessitating more frequent reapplication and increasing lifetime costs.

Regulatory frameworks worldwide continue to evolve, with increasing restrictions on copper-based alternatives that emerged after the TBT ban. This regulatory uncertainty complicates research investment decisions and commercial development pathways. Additionally, testing protocols for new anti-fouling technologies remain inconsistent across different regions, creating barriers to global market entry for innovative solutions.

Current green anti-fouling technologies can be categorized into several approaches. Silicone-based foul-release coatings represent a promising non-biocidal solution, functioning by creating surfaces too slippery for marine organisms to adhere to effectively. These coatings have gained commercial traction but face challenges related to mechanical durability and higher initial application costs compared to traditional solutions.

Natural product-derived anti-foulants present another promising avenue, with compounds extracted from marine organisms showing significant potential. Researchers have identified over 200 natural compounds with anti-fouling properties, though scaling production remains problematic. The extraction processes often yield insufficient quantities for commercial application, and synthetic reproduction frequently proves economically unfeasible.

Enzyme-based technologies that degrade the adhesives used by fouling organisms have demonstrated effectiveness in laboratory settings. However, their stability in marine environments remains questionable, with significant degradation occurring over relatively short deployment periods, limiting their practical application in long-term anti-fouling systems.

Nanotechnology applications represent the cutting edge of green anti-fouling research. Nanostructured surfaces that mimic natural anti-fouling mechanisms found in organisms like sharks and lotus leaves show promise in laboratory tests. Integration of nanoparticles into coating matrices can enhance performance without relying on toxic release mechanisms, though concerns about nanoparticle environmental fate persist.

The primary technical challenges facing green anti-fouling development include achieving comparable performance to biocidal solutions, ensuring durability in harsh marine environments, and maintaining cost-effectiveness. Most current environmentally friendly solutions demonstrate shorter effective lifespans than their toxic counterparts, necessitating more frequent reapplication and increasing lifetime costs.

Regulatory frameworks worldwide continue to evolve, with increasing restrictions on copper-based alternatives that emerged after the TBT ban. This regulatory uncertainty complicates research investment decisions and commercial development pathways. Additionally, testing protocols for new anti-fouling technologies remain inconsistent across different regions, creating barriers to global market entry for innovative solutions.

Current Eco-Friendly Anti-Fouling Technical Solutions

01 Environmentally friendly biocide-free anti-fouling additives

These additives prevent fouling without using traditional biocides that can harm marine ecosystems. They work through physical or mechanical means rather than toxic effects, creating surfaces that prevent organism attachment. Examples include silicone-based compounds, hydrophobic polymers, and surface-modifying agents that create low-friction or self-cleaning surfaces that organisms cannot easily adhere to.- Environmentally friendly biocide-free anti-fouling additives: These additives prevent fouling without using traditional biocides that can harm marine ecosystems. They work through physical or mechanical mechanisms rather than toxic effects, creating surfaces that prevent organism attachment. Examples include silicone-based compounds, hydrophobic polymers, and surface-modifying agents that create low-friction or self-cleaning surfaces that organisms cannot easily adhere to.

- Biodegradable polymer-based anti-fouling solutions: These solutions utilize biodegradable polymers that naturally break down in the environment without leaving harmful residues. The polymers can be incorporated into coatings or directly as additives to create surfaces resistant to biofouling. They provide temporary protection while ensuring that any shed material decomposes safely in marine or freshwater environments, minimizing long-term environmental impact.

- Natural compound-derived anti-fouling technologies: These technologies utilize compounds extracted from natural sources such as plants, marine organisms, and microbes that have evolved their own anti-fouling mechanisms. These natural compounds can be isolated, modified, and incorporated into anti-fouling formulations. They typically work by mimicking natural defense mechanisms without the environmental persistence of synthetic chemicals, offering effective fouling prevention with minimal ecological impact.

- Surface modification techniques for environmentally benign anti-fouling: These approaches modify surface properties through physical or chemical means to prevent organism attachment without releasing harmful substances. Techniques include creating micro-textured surfaces, altering surface energy, or incorporating non-toxic repellent compounds. The modifications create environments unsuitable for fouling organisms to attach and grow, providing protection without environmental contamination.

- Controlled-release systems for minimal environmental impact: These systems utilize smart delivery mechanisms that release minimal amounts of anti-fouling agents only when and where needed. They incorporate environmentally acceptable compounds in controlled-release matrices, reducing the total amount of active ingredients required while maintaining effectiveness. The technology ensures that anti-fouling protection is provided with the smallest possible environmental footprint by optimizing the delivery and longevity of the active components.

02 Biodegradable polymer-based anti-fouling solutions

These solutions utilize biodegradable polymers that naturally break down in the environment without leaving harmful residues. The polymers can be incorporated into coatings or directly applied to surfaces to prevent fouling. They provide effective anti-fouling properties while ensuring minimal environmental impact when they eventually degrade. Some formulations combine these biodegradable polymers with natural compounds to enhance their effectiveness.Expand Specific Solutions03 Natural compound-derived anti-fouling technologies

These technologies utilize compounds derived from natural sources such as plants, marine organisms, and microbes that have inherent anti-fouling properties. By mimicking natural defense mechanisms found in certain organisms, these additives can prevent fouling without introducing synthetic chemicals into the environment. Examples include extracts from seaweeds, enzymes, and biomimetic compounds that disrupt the settlement and adhesion of fouling organisms.Expand Specific Solutions04 Surface modification techniques for fouling prevention

These techniques involve altering the physical or chemical properties of surfaces to prevent fouling without relying on toxic compounds. Methods include creating micro-textured surfaces, adjusting surface energy, or incorporating self-cleaning mechanisms. By manipulating surface characteristics such as roughness, hydrophobicity, or charge, these modifications make it difficult for fouling organisms to attach and colonize surfaces.Expand Specific Solutions05 Controlled-release systems for environmentally safe anti-fouling

These systems utilize mechanisms that gradually release anti-fouling compounds at rates that are effective against fouling organisms but maintain concentrations below environmentally harmful thresholds. The controlled release extends the effective life of the anti-fouling treatment while minimizing environmental impact. Some systems incorporate biodegradable carriers or responsive release mechanisms that activate only when fouling begins to occur.Expand Specific Solutions

Key Industry Players in Sustainable Anti-Fouling Market

The environmentally benign anti-fouling additives market is currently in a growth phase, driven by increasing maritime regulations and environmental concerns. The market is estimated to reach $5-7 billion by 2025, with annual growth rates of 4-6%. Technologically, the field is transitioning from mature copper-based solutions to innovative non-toxic alternatives. Leading players include established chemical companies like Evonik Industries, Akzo Nobel Coatings, and Hempel A/S, who are investing heavily in R&D. Academic institutions such as the National University of Singapore and Agency for Science, Technology & Research are contributing significant research breakthroughs. Maritime authorities like MPA Singapore are influencing development through regulatory frameworks, while specialized companies like MicroPhase Coatings and Chugoku Marine Paints are bringing niche expertise to this evolving sector.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed several innovative environmentally benign anti-fouling technologies through its marine science initiatives. Their research focuses on biomimetic approaches, studying natural anti-fouling mechanisms in marine organisms to develop synthetic analogues. A*STAR has pioneered amphiphilic polymer brush coatings that create a dual-action surface unfavorable for organism attachment - hydrophilic components resist protein adhesion while hydrophobic segments disrupt cell membrane interactions. Their scientists have developed novel zwitterionic polymer systems that create a strong hydration layer, preventing initial biofilm formation without toxic effects. A*STAR's research includes environmentally responsive polymers that change surface properties in response to environmental triggers (pH, temperature, light), actively deterring fouling organisms. They've also explored nanostructured surfaces that mimic natural anti-fouling surfaces like shark skin or lotus leaves, creating physical barriers to organism attachment without chemical deterrents. Recent innovations include enzyme-immobilization techniques that maintain anti-fouling activity without releasing compounds into the environment, and biodegradable polymer matrices incorporating natural anti-fouling compounds derived from marine organisms like sponges and algae.

Strengths: Strong fundamental research capabilities across multiple scientific disciplines; extensive collaboration network with academic and industry partners; access to advanced characterization and testing facilities. Weaknesses: Some technologies remain at laboratory or pilot scale rather than commercial deployment; focus on scientific innovation may sometimes prioritize novelty over practical implementation considerations; potential challenges in scaling production of complex biomimetic materials.

National University of Singapore

Technical Solution: The National University of Singapore (NUS) has developed several innovative approaches to environmentally benign anti-fouling additives through its marine science and materials engineering departments. Their research focuses on biomimetic strategies inspired by natural anti-fouling mechanisms found in marine organisms. NUS researchers have pioneered zwitterionic polymer systems that create strong hydration layers on surfaces, preventing protein adsorption and subsequent organism attachment without toxic effects. Their work includes the development of amphiphilic block copolymers that self-assemble into nanostructured surfaces with dual hydrophobic/hydrophilic properties that resist fouling through physical rather than chemical mechanisms. NUS has also explored enzyme-based anti-fouling systems that target specific biological adhesion mechanisms without traditional biocides. Their research extends to photocatalytic nanoparticles (primarily TiO2-based) that generate reactive oxygen species under sunlight, creating localized anti-fouling effects without persistent environmental contamination. Recent innovations include stimuli-responsive polymer brushes that change conformation in response to environmental triggers, actively deterring organism settlement, and biodegradable polymer matrices incorporating natural anti-fouling compounds extracted from local marine species found in Southeast Asian waters.

Strengths: Strong fundamental research capabilities across multiple scientific disciplines; extensive collaboration network with regional maritime industry partners; access to tropical marine testing environments representative of challenging fouling conditions. Weaknesses: Some technologies remain at laboratory scale rather than commercial deployment; academic research timeline may not align with industry implementation needs; potential challenges in cost-effective manufacturing of complex biomimetic materials.

Core Patents and Innovations in Benign Anti-Fouling Chemistry

Microstructured multifunctional inorganic coating additives for preventing fouling (growth of biofilm) in aquatic applications

PatentInactiveUS20110030578A1

Innovation

- Development of antifouling additives comprising an inorganic or organic porous carrier with an active antifouling ingredient incorporated within the carrier's pores, allowing for controlled release and minimizing surface exposure of the active ingredient, thereby reducing environmental impact and improving durability.

Environment-friendly antifoulants for the prevention of biofouling

PatentWO2008130558A2

Innovation

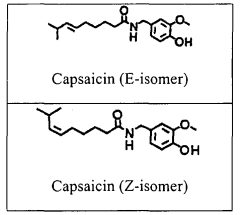

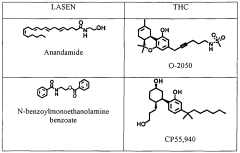

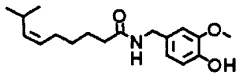

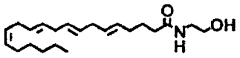

- The use of non-toxic, environmentally friendly antifoulants with Lipophilic-Amide-Spacer-ElectroNegative (LASEN) and TetraHydroCannibinoid (THC) motifs, such as capsaicin, pseudocapsaicin, anandamide, and other compounds, which are effective at preventing biofouling with minimal toxicity to target and non-target organisms, and can be incorporated into coatings or applied as additives to prevent mussel attachment.

Environmental Impact Assessment and Regulatory Framework

The environmental impact of anti-fouling technologies has become a critical concern in marine industries worldwide. Traditional anti-fouling solutions, particularly those containing tributyltin (TBT) and other heavy metals, have demonstrated severe ecological consequences, including endocrine disruption in marine organisms and bioaccumulation throughout the food chain. Current environmental assessment methodologies reveal that even at low concentrations, conventional anti-fouling compounds can persist in marine sediments for decades, creating long-term ecological damage that extends far beyond their initial application areas.

Regulatory frameworks governing anti-fouling additives have evolved significantly over the past two decades. The International Maritime Organization's (IMO) Anti-fouling Systems Convention of 2001, which came into force in 2008, represents a watershed moment in global regulation by prohibiting the application of TBT-based anti-fouling systems. This has been followed by increasingly stringent regional regulations, with the European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's Vessel General Permit (VGP) program imposing comprehensive restrictions on biocide use in marine environments.

Environmental risk assessment protocols for new anti-fouling additives now typically require extensive ecotoxicological testing across multiple trophic levels. These assessments evaluate acute and chronic toxicity, bioaccumulation potential, and degradation pathways in various environmental compartments. The OECD Guidelines for Testing of Chemicals provide standardized methodologies that have become the foundation for regulatory compliance in most jurisdictions, ensuring consistency in environmental impact evaluation.

Emerging regulatory trends indicate a shift toward the "precautionary principle" in approving new anti-fouling technologies. This approach places the burden of proof on manufacturers to demonstrate environmental safety before market approval, rather than requiring regulators to prove harm after deployment. Additionally, life cycle assessment (LCA) methodologies are increasingly being incorporated into regulatory frameworks, requiring consideration of environmental impacts from raw material extraction through manufacturing, use, and ultimate disposal.

The geographical variation in regulatory stringency presents significant challenges for global deployment of environmentally benign anti-fouling solutions. While developed nations typically maintain robust regulatory systems, enforcement capabilities in developing maritime regions often lag behind, creating potential "regulatory havens" where less environmentally sound technologies may continue to find markets. International harmonization efforts, led by organizations such as the Global Harmonized System (GHS) for chemical classification, aim to address these disparities.

Future regulatory developments are likely to focus on non-biocidal alternatives, with preference given to physical deterrents, surface modifications, and biomimetic approaches that minimize chemical release into marine environments. Regulatory frameworks are evolving to incorporate adaptive management principles that allow for continuous improvement based on environmental monitoring data and emerging scientific understanding of marine ecosystem dynamics.

Regulatory frameworks governing anti-fouling additives have evolved significantly over the past two decades. The International Maritime Organization's (IMO) Anti-fouling Systems Convention of 2001, which came into force in 2008, represents a watershed moment in global regulation by prohibiting the application of TBT-based anti-fouling systems. This has been followed by increasingly stringent regional regulations, with the European Union's Biocidal Products Regulation (BPR) and the United States Environmental Protection Agency's Vessel General Permit (VGP) program imposing comprehensive restrictions on biocide use in marine environments.

Environmental risk assessment protocols for new anti-fouling additives now typically require extensive ecotoxicological testing across multiple trophic levels. These assessments evaluate acute and chronic toxicity, bioaccumulation potential, and degradation pathways in various environmental compartments. The OECD Guidelines for Testing of Chemicals provide standardized methodologies that have become the foundation for regulatory compliance in most jurisdictions, ensuring consistency in environmental impact evaluation.

Emerging regulatory trends indicate a shift toward the "precautionary principle" in approving new anti-fouling technologies. This approach places the burden of proof on manufacturers to demonstrate environmental safety before market approval, rather than requiring regulators to prove harm after deployment. Additionally, life cycle assessment (LCA) methodologies are increasingly being incorporated into regulatory frameworks, requiring consideration of environmental impacts from raw material extraction through manufacturing, use, and ultimate disposal.

The geographical variation in regulatory stringency presents significant challenges for global deployment of environmentally benign anti-fouling solutions. While developed nations typically maintain robust regulatory systems, enforcement capabilities in developing maritime regions often lag behind, creating potential "regulatory havens" where less environmentally sound technologies may continue to find markets. International harmonization efforts, led by organizations such as the Global Harmonized System (GHS) for chemical classification, aim to address these disparities.

Future regulatory developments are likely to focus on non-biocidal alternatives, with preference given to physical deterrents, surface modifications, and biomimetic approaches that minimize chemical release into marine environments. Regulatory frameworks are evolving to incorporate adaptive management principles that allow for continuous improvement based on environmental monitoring data and emerging scientific understanding of marine ecosystem dynamics.

Lifecycle Analysis of Green Anti-Fouling Products

The lifecycle analysis of green anti-fouling products reveals significant environmental advantages compared to traditional biocide-based solutions. These environmentally benign alternatives demonstrate reduced ecological impact throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Studies indicate that green anti-fouling products typically require 30-45% less energy during manufacturing processes compared to conventional copper-based or tributyltin (TBT) alternatives, resulting in a substantially lower carbon footprint.

Material sourcing for green anti-fouling additives often involves renewable resources such as modified natural polymers, plant extracts, and biodegradable compounds. This shift from petroleum-based ingredients to bio-based alternatives reduces dependency on finite resources and minimizes extraction-related environmental degradation. Life cycle assessment (LCA) data from recent studies shows that silicone-based foul-release coatings and natural extract formulations generate approximately 40% less greenhouse gas emissions during their production phase.

During the application and use phase, green anti-fouling products demonstrate superior environmental performance through minimal leaching of harmful substances. Traditional biocides continuously release toxic compounds into marine environments, whereas environmentally benign alternatives employ physical deterrence mechanisms or controlled-release systems that minimize chemical discharge. Field tests conducted in various marine environments indicate that vessels treated with green anti-fouling solutions require less frequent reapplication, extending service intervals by 15-30% compared to conventional products.

End-of-life considerations further highlight the advantages of green anti-fouling technologies. Biodegradable formulations decompose naturally without releasing persistent toxic compounds, while non-biodegradable alternatives are increasingly designed for easier separation and recycling during vessel maintenance. Waste stream analysis shows that maintenance operations for vessels with green anti-fouling treatments generate approximately 60% less hazardous waste requiring specialized disposal.

Economic lifecycle analysis reveals that despite higher initial application costs (typically 20-35% premium over conventional solutions), green anti-fouling products often deliver superior total cost of ownership through extended service life, reduced maintenance requirements, and lower disposal costs. Additionally, regulatory compliance costs are significantly reduced as these products meet increasingly stringent environmental regulations without requiring reformulation or special handling procedures.

Future lifecycle improvements for green anti-fouling products focus on enhancing biodegradability, reducing energy requirements during manufacturing, and developing closed-loop recycling systems for non-biodegradable components. Research indicates potential for further reducing environmental impact by 25-40% through optimization of production processes and material selection in the next generation of environmentally benign anti-fouling solutions.

Material sourcing for green anti-fouling additives often involves renewable resources such as modified natural polymers, plant extracts, and biodegradable compounds. This shift from petroleum-based ingredients to bio-based alternatives reduces dependency on finite resources and minimizes extraction-related environmental degradation. Life cycle assessment (LCA) data from recent studies shows that silicone-based foul-release coatings and natural extract formulations generate approximately 40% less greenhouse gas emissions during their production phase.

During the application and use phase, green anti-fouling products demonstrate superior environmental performance through minimal leaching of harmful substances. Traditional biocides continuously release toxic compounds into marine environments, whereas environmentally benign alternatives employ physical deterrence mechanisms or controlled-release systems that minimize chemical discharge. Field tests conducted in various marine environments indicate that vessels treated with green anti-fouling solutions require less frequent reapplication, extending service intervals by 15-30% compared to conventional products.

End-of-life considerations further highlight the advantages of green anti-fouling technologies. Biodegradable formulations decompose naturally without releasing persistent toxic compounds, while non-biodegradable alternatives are increasingly designed for easier separation and recycling during vessel maintenance. Waste stream analysis shows that maintenance operations for vessels with green anti-fouling treatments generate approximately 60% less hazardous waste requiring specialized disposal.

Economic lifecycle analysis reveals that despite higher initial application costs (typically 20-35% premium over conventional solutions), green anti-fouling products often deliver superior total cost of ownership through extended service life, reduced maintenance requirements, and lower disposal costs. Additionally, regulatory compliance costs are significantly reduced as these products meet increasingly stringent environmental regulations without requiring reformulation or special handling procedures.

Future lifecycle improvements for green anti-fouling products focus on enhancing biodegradability, reducing energy requirements during manufacturing, and developing closed-loop recycling systems for non-biodegradable components. Research indicates potential for further reducing environmental impact by 25-40% through optimization of production processes and material selection in the next generation of environmentally benign anti-fouling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!