Antifungal and Algae Resistant Marine Coatings

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Coating Evolution and Research Objectives

Marine coatings have undergone significant evolution since their inception in the early 18th century. Initially, these protective layers consisted of simple tar and grease mixtures applied to wooden vessels. The mid-20th century marked a revolutionary shift with the introduction of tributyltin (TBT)-based antifouling paints, which demonstrated remarkable efficacy against biofouling organisms but were later discovered to cause severe environmental damage to marine ecosystems.

The global ban on TBT in 2008 by the International Maritime Organization catalyzed intensive research into environmentally acceptable alternatives. This regulatory shift represents a critical turning point in marine coating technology, driving innovation toward sustainable solutions that maintain performance without ecological harm. The industry has since witnessed the development of copper-based alternatives, silicone foul-release coatings, and more recently, biomimetic approaches inspired by natural antifouling mechanisms.

Current marine coating research is primarily focused on addressing the dual challenge of preventing fungal and algal colonization while minimizing environmental impact. These microorganisms contribute significantly to biofouling, which increases drag on vessel hulls, leading to higher fuel consumption, increased carbon emissions, and substantial economic losses estimated at $15 billion annually for the global shipping industry.

The technical trajectory indicates a clear movement toward multi-functional coating systems that combine physical and chemical deterrents. Recent advancements include nanostructured surfaces that prevent organism attachment, incorporation of natural biocides derived from marine organisms, and controlled-release technologies that optimize biocide efficacy while reducing overall environmental leaching.

This research aims to develop next-generation marine coatings with enhanced antifungal and algae-resistant properties while adhering to increasingly stringent environmental regulations. Specific objectives include identifying novel natural compounds with potent antifungal and algicidal properties, engineering surface topographies that inhibit microbial adhesion, and creating smart-release systems that respond to environmental triggers.

Additionally, the research seeks to establish comprehensive testing protocols that accurately predict coating performance in diverse marine environments, from tropical waters to polar regions. This includes accelerated aging tests to determine long-term efficacy and environmental impact assessments to ensure regulatory compliance across global markets.

The ultimate goal is to create a commercially viable coating system that extends service intervals to 5+ years, reduces fuel consumption by at least 8% compared to current technologies, and meets or exceeds all international environmental standards while maintaining cost competitiveness in the marine coating market.

The global ban on TBT in 2008 by the International Maritime Organization catalyzed intensive research into environmentally acceptable alternatives. This regulatory shift represents a critical turning point in marine coating technology, driving innovation toward sustainable solutions that maintain performance without ecological harm. The industry has since witnessed the development of copper-based alternatives, silicone foul-release coatings, and more recently, biomimetic approaches inspired by natural antifouling mechanisms.

Current marine coating research is primarily focused on addressing the dual challenge of preventing fungal and algal colonization while minimizing environmental impact. These microorganisms contribute significantly to biofouling, which increases drag on vessel hulls, leading to higher fuel consumption, increased carbon emissions, and substantial economic losses estimated at $15 billion annually for the global shipping industry.

The technical trajectory indicates a clear movement toward multi-functional coating systems that combine physical and chemical deterrents. Recent advancements include nanostructured surfaces that prevent organism attachment, incorporation of natural biocides derived from marine organisms, and controlled-release technologies that optimize biocide efficacy while reducing overall environmental leaching.

This research aims to develop next-generation marine coatings with enhanced antifungal and algae-resistant properties while adhering to increasingly stringent environmental regulations. Specific objectives include identifying novel natural compounds with potent antifungal and algicidal properties, engineering surface topographies that inhibit microbial adhesion, and creating smart-release systems that respond to environmental triggers.

Additionally, the research seeks to establish comprehensive testing protocols that accurately predict coating performance in diverse marine environments, from tropical waters to polar regions. This includes accelerated aging tests to determine long-term efficacy and environmental impact assessments to ensure regulatory compliance across global markets.

The ultimate goal is to create a commercially viable coating system that extends service intervals to 5+ years, reduces fuel consumption by at least 8% compared to current technologies, and meets or exceeds all international environmental standards while maintaining cost competitiveness in the marine coating market.

Market Analysis for Antifouling Marine Solutions

The global marine coatings market has witnessed substantial growth in recent years, with the antifouling segment emerging as a critical component. Currently valued at approximately $6.5 billion, the marine antifouling coatings market is projected to grow at a CAGR of 8.3% through 2028, driven primarily by expanding maritime trade and increasing vessel construction activities worldwide.

The demand for antifungal and algae resistant marine coatings stems from several key market factors. Biofouling—the accumulation of microorganisms, plants, and animals on submerged surfaces—significantly impacts vessel performance by increasing drag, which can elevate fuel consumption by up to 40%. This translates to an estimated $30 billion in additional fuel costs for the global shipping industry annually, creating a compelling economic case for effective antifouling solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global demand, with China, South Korea, and Japan leading in both production and consumption. Europe follows with a 30% market share, where stringent environmental regulations have accelerated the transition toward copper-free and biocide-free solutions. North America represents about 20% of the market, with particular emphasis on military and recreational vessel applications.

Customer segmentation shows commercial shipping as the largest end-user segment (65%), followed by offshore structures (15%), naval vessels (12%), and recreational crafts (8%). The commercial shipping sector's dominance is attributed to the massive global fleet of over 100,000 merchant vessels requiring regular maintenance and recoating.

Environmental regulations have become a primary market driver, with the International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds and increasing restrictions on copper-based formulations reshaping product development trajectories. The EU's Biocidal Products Regulation and similar frameworks in other regions have accelerated the shift toward environmentally sustainable alternatives.

Price sensitivity varies significantly across market segments, with commercial shipping operators demonstrating higher price sensitivity due to large-scale application requirements, while naval and premium recreational segments prioritize performance over cost considerations. The average cost of antifouling coatings ranges from $15-45 per liter, with premium solutions commanding higher prices based on durability and effectiveness claims.

Distribution channels are predominantly business-to-business, with direct sales to shipyards and maintenance facilities accounting for 70% of market transactions. The remaining 30% flows through specialized marine supply distributors and retailers serving smaller vessel operators and maintenance providers.

The demand for antifungal and algae resistant marine coatings stems from several key market factors. Biofouling—the accumulation of microorganisms, plants, and animals on submerged surfaces—significantly impacts vessel performance by increasing drag, which can elevate fuel consumption by up to 40%. This translates to an estimated $30 billion in additional fuel costs for the global shipping industry annually, creating a compelling economic case for effective antifouling solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global demand, with China, South Korea, and Japan leading in both production and consumption. Europe follows with a 30% market share, where stringent environmental regulations have accelerated the transition toward copper-free and biocide-free solutions. North America represents about 20% of the market, with particular emphasis on military and recreational vessel applications.

Customer segmentation shows commercial shipping as the largest end-user segment (65%), followed by offshore structures (15%), naval vessels (12%), and recreational crafts (8%). The commercial shipping sector's dominance is attributed to the massive global fleet of over 100,000 merchant vessels requiring regular maintenance and recoating.

Environmental regulations have become a primary market driver, with the International Maritime Organization's (IMO) ban on tributyltin (TBT) compounds and increasing restrictions on copper-based formulations reshaping product development trajectories. The EU's Biocidal Products Regulation and similar frameworks in other regions have accelerated the shift toward environmentally sustainable alternatives.

Price sensitivity varies significantly across market segments, with commercial shipping operators demonstrating higher price sensitivity due to large-scale application requirements, while naval and premium recreational segments prioritize performance over cost considerations. The average cost of antifouling coatings ranges from $15-45 per liter, with premium solutions commanding higher prices based on durability and effectiveness claims.

Distribution channels are predominantly business-to-business, with direct sales to shipyards and maintenance facilities accounting for 70% of market transactions. The remaining 30% flows through specialized marine supply distributors and retailers serving smaller vessel operators and maintenance providers.

Current Challenges in Antifungal and Algae Resistant Technologies

Despite significant advancements in marine coating technologies, the development of effective antifungal and algae resistant solutions continues to face substantial challenges. The primary obstacle remains the environmental impact of traditional biocide-based coatings. Copper-based compounds and other heavy metal additives, while effective against biofouling, pose serious threats to marine ecosystems. Regulatory bodies worldwide, including the International Maritime Organization (IMO) and the European Union's Biocidal Products Regulation, have progressively restricted the use of harmful substances, creating an urgent need for alternative solutions.

The development of environmentally friendly alternatives presents complex technical hurdles. Non-toxic coatings often struggle to match the performance and durability of their toxic counterparts. Silicone-based foul-release coatings, while promising, demonstrate reduced effectiveness at low vessel speeds and suffer from mechanical vulnerability, limiting their application range. Additionally, these coatings typically have higher initial costs, creating market adoption barriers despite potential long-term economic benefits through reduced maintenance.

Another significant challenge lies in the remarkable adaptability of marine microorganisms. Fungi and algae species continuously evolve resistance mechanisms against antifouling agents, necessitating ongoing innovation in coating formulations. This biological arms race requires substantial research investment and sophisticated testing protocols to ensure long-term effectiveness.

The geographic variability of marine environments further complicates coating development. A solution effective in temperate waters may perform poorly in tropical conditions due to different species compositions and growth rates. This necessitates either region-specific formulations or truly universal solutions capable of functioning across diverse marine environments.

Testing and validation methodologies present additional challenges. Laboratory tests often fail to accurately predict real-world performance, while field testing is time-consuming and expensive. The lack of standardized testing protocols across the industry makes comparative performance assessment difficult, hampering innovation and market transparency.

Manufacturing scalability remains problematic for many novel coating technologies. Promising laboratory formulations frequently encounter difficulties in industrial-scale production, with issues in quality control, shelf stability, and application consistency. These manufacturing challenges significantly slow the transition from research breakthrough to commercial product.

The interdisciplinary nature of the field creates knowledge integration barriers. Effective solutions require collaboration between marine biologists, polymer chemists, materials scientists, and environmental toxicologists. Bridging these disciplinary divides to create truly innovative approaches represents a substantial organizational challenge for research institutions and commercial enterprises alike.

The development of environmentally friendly alternatives presents complex technical hurdles. Non-toxic coatings often struggle to match the performance and durability of their toxic counterparts. Silicone-based foul-release coatings, while promising, demonstrate reduced effectiveness at low vessel speeds and suffer from mechanical vulnerability, limiting their application range. Additionally, these coatings typically have higher initial costs, creating market adoption barriers despite potential long-term economic benefits through reduced maintenance.

Another significant challenge lies in the remarkable adaptability of marine microorganisms. Fungi and algae species continuously evolve resistance mechanisms against antifouling agents, necessitating ongoing innovation in coating formulations. This biological arms race requires substantial research investment and sophisticated testing protocols to ensure long-term effectiveness.

The geographic variability of marine environments further complicates coating development. A solution effective in temperate waters may perform poorly in tropical conditions due to different species compositions and growth rates. This necessitates either region-specific formulations or truly universal solutions capable of functioning across diverse marine environments.

Testing and validation methodologies present additional challenges. Laboratory tests often fail to accurately predict real-world performance, while field testing is time-consuming and expensive. The lack of standardized testing protocols across the industry makes comparative performance assessment difficult, hampering innovation and market transparency.

Manufacturing scalability remains problematic for many novel coating technologies. Promising laboratory formulations frequently encounter difficulties in industrial-scale production, with issues in quality control, shelf stability, and application consistency. These manufacturing challenges significantly slow the transition from research breakthrough to commercial product.

The interdisciplinary nature of the field creates knowledge integration barriers. Effective solutions require collaboration between marine biologists, polymer chemists, materials scientists, and environmental toxicologists. Bridging these disciplinary divides to create truly innovative approaches represents a substantial organizational challenge for research institutions and commercial enterprises alike.

Existing Antifungal and Algae Resistant Coating Solutions

01 Metal-based antifouling compounds

Metal-based compounds such as copper, zinc, and silver are widely used in marine coatings for their effective antifungal and anti-algae properties. These metals release ions that inhibit the growth of microorganisms on the coated surface. The controlled release of these metal ions provides long-lasting protection against biofouling in marine environments. These compounds can be incorporated into various coating matrices to ensure sustained efficacy while minimizing environmental impact.- Metal-based antifouling compounds: Metal-based compounds such as copper, zinc, and silver are widely used in marine coatings for their effective antifungal and anti-algae properties. These metals can be incorporated in various forms including oxides, pyrithiones, and nanoparticles. The slow release of metal ions creates a toxic environment for marine organisms attempting to attach to the coated surface, preventing biofouling while maintaining long-term effectiveness in marine environments.

- Natural biocide formulations: Environmentally friendly antifouling coatings derived from natural sources provide alternatives to traditional toxic biocides. These formulations incorporate plant extracts, essential oils, enzymes, and other naturally occurring compounds that exhibit antifungal and anti-algae properties. The natural compounds disrupt the attachment mechanisms of marine organisms or create inhospitable surfaces without the environmental concerns associated with conventional metal-based solutions.

- Polymer-based release systems: Advanced polymer technologies enable controlled release of antifouling agents in marine coatings. These systems utilize specially designed polymers that either erode at a controlled rate to continuously expose fresh biocides or create surfaces with physical properties that prevent organism attachment. Self-polishing copolymers, hydrophobic matrices, and silicone-based formulations provide extended protection against fungal and algal growth while minimizing environmental impact through reduced biocide usage.

- Nanostructured coating technologies: Nanotechnology applications in marine coatings create surfaces with enhanced antifungal and anti-algae properties. These coatings incorporate nanomaterials such as nanoparticles, nanocomposites, and nanostructured surfaces that physically disrupt biofilm formation or release antimicrobial agents at the nanoscale. The unique surface properties created by these technologies prevent organism attachment while providing improved durability and reduced environmental impact compared to conventional coating systems.

- Hybrid antifouling systems: Hybrid approaches combine multiple antifouling mechanisms in a single coating system to enhance effectiveness against marine biofouling. These formulations integrate conventional biocides with novel technologies such as enzyme-based systems, surface-modifying additives, and physical deterrents. The synergistic effects of these combined approaches provide comprehensive protection against a wide range of marine organisms including fungi and algae, while potentially reducing the overall environmental impact through decreased reliance on any single biocidal component.

02 Natural biocide formulations

Natural compounds derived from plants, marine organisms, and other biological sources offer environmentally friendly alternatives to traditional chemical biocides. These natural formulations include extracts from seaweeds, essential oils, enzymes, and other bioactive compounds that demonstrate antifungal and anti-algae properties. The advantage of these natural biocides is their reduced environmental impact and lower toxicity to non-target marine organisms while still providing effective protection against biofouling.Expand Specific Solutions03 Polymer-based antifouling coatings

Advanced polymer technologies are employed in marine coatings to create surfaces that resist fungal and algae attachment. These include self-polishing copolymers, silicone-based polymers, and hydrophobic or hydrophilic polymer matrices that create unfavorable conditions for microorganism attachment. Some polymer coatings work by creating a slippery surface that prevents organisms from adhering, while others incorporate biocides that are gradually released over time. These polymer systems can be engineered to provide long-term protection in various marine environments.Expand Specific Solutions04 Nanoparticle-enhanced antifouling systems

Nanotechnology has enabled the development of highly effective antifouling coatings through the incorporation of nanoparticles. These include nano-sized metal oxides, carbon-based nanomaterials, and engineered nanostructures that provide enhanced biocidal properties and improved coating performance. The high surface area of nanoparticles allows for more efficient release of active ingredients and better distribution throughout the coating matrix. Additionally, some nanoparticles can create surface textures that physically deter the attachment of marine organisms.Expand Specific Solutions05 Environmentally compliant coating systems

With increasing environmental regulations, marine coating technologies have evolved to provide effective antifungal and anti-algae resistance while meeting strict environmental standards. These systems utilize low-leaching biocides, biodegradable compounds, and controlled-release mechanisms to minimize environmental impact. Some formulations incorporate multiple modes of action, combining physical and chemical deterrents to prevent biofouling. These environmentally compliant coatings are designed to maintain their effectiveness while reducing the ecological footprint of marine vessels and structures.Expand Specific Solutions

Leading Companies and Research Institutions in Marine Coatings

The marine antifungal and algae resistant coatings market is in a growth phase, driven by increasing maritime activities and stricter environmental regulations. The global market size is expanding steadily, estimated to reach several billion dollars by 2025. Technologically, the field shows moderate maturity with ongoing innovation focused on environmentally friendly solutions. Key players include established companies like Nippon Paint Marine Coatings and Chugoku Marine Paints, who lead with comprehensive product portfolios, while research institutions such as NDSU Research Foundation and Fraunhofer-Gesellschaft contribute significant R&D advancements. Chemical manufacturers including Arkema, Asahi Kasei, and FUJIFILM are developing novel compounds, while universities (North Carolina A&T, Shanghai Maritime) provide academic research support. The competitive landscape features collaboration between industry and academia to develop more effective, sustainable coating technologies that meet increasingly stringent environmental standards.

NDSU Research Foundation

Technical Solution: The NDSU Research Foundation has developed novel marine coating technologies based on their expertise in polymer chemistry and materials science. Their approach centers on renewable biobased coating materials derived from agricultural resources like soybean oil, linseed oil, and other plant-based feedstocks. These coatings incorporate specially designed crosslinking chemistries that create durable polymer networks resistant to hydrolysis in marine environments. Their technology includes the development of novel isocyanate-free polyurethane chemistry that eliminates toxic isocyanate compounds typically used in marine coatings while maintaining excellent adhesion and flexibility. The foundation has also pioneered work on self-healing coating technologies that incorporate microencapsulated healing agents that release when coating damage occurs, extending service life. Additionally, they've developed environmentally friendly antifouling additives based on modified natural compounds that disrupt quorum sensing mechanisms used by microorganisms for biofilm formation, providing effective fouling control without traditional biocides.

Strengths: Highly sustainable approach using renewable resources reduces environmental impact while maintaining performance. Their isocyanate-free chemistry improves worker safety during application. Weaknesses: Some biobased materials may have higher initial costs and potentially shorter service life in extreme marine conditions compared to conventional petroleum-based alternatives.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed innovative biomimetic approaches to antifouling marine coatings through their interdisciplinary research network. Their technology focuses on surface microstructuring inspired by natural antifouling surfaces like shark skin and lotus leaves. Using advanced polymer science, they've created hierarchical surface patterns at micro and nano scales that physically prevent organism attachment without relying on biocides. Their AMBIO (Advanced Nanostructured Surfaces for the Control of Biofouling) project has yielded promising results with amphiphilic polymer coatings that combine hydrophobic and hydrophilic properties in nanoscale patterns, creating surfaces unfavorable for biofilm formation. Additionally, they've pioneered work on stimuli-responsive polymers that can change surface properties in response to environmental triggers, actively deterring organism settlement. Their research also includes development of environmentally benign natural compound extracts with antifouling properties derived from marine organisms that naturally resist biofouling.

Strengths: Highly innovative biomimetic approaches reduce or eliminate the need for toxic biocides, offering environmentally superior solutions with potentially longer service life. Weaknesses: Some technologies remain in research phase with limited commercial-scale validation, and manufacturing complexity of precisely structured surfaces may increase production costs compared to conventional coatings.

Key Patents and Innovations in Biofouling Prevention

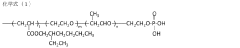

Antibacterial and antifungal coating material, algae-proof coating material, production method of antibacterial and antifungal member, and production method of algicidal member

PatentActiveJP2019099783A

Innovation

- A paint composition containing copper oxide particles with specific particle sizes and dispersants with defined acid values, along with solvents and optionally latex, is applied to substrates using various coating methods to form a coating film, ensuring excellent dispersion stability and coatability.

Marine coatings

PatentInactiveUS10544312B2

Innovation

- Development of marine coatings comprising copolymers with zwitterionic and hydrophobic components that form nanostructures, including block copolymers and polymers with hydrolyzable groups, which convert to zwitterionic polymers upon contact with seawater, offering self-polishing and non-fouling properties without compromising mechanical strength.

Environmental Impact and Regulatory Compliance

The environmental impact of marine coatings has become a critical concern in the maritime industry, particularly as awareness of marine ecosystem preservation grows. Traditional antifouling paints containing tributyltin (TBT) have been globally banned due to their severe ecological damage, including shell deformities in mollusks and endocrine disruption in various marine species. This regulatory shift has fundamentally altered the marine coating landscape, necessitating the development of environmentally compatible alternatives.

Current regulatory frameworks governing marine coatings vary globally but share common environmental protection objectives. The International Maritime Organization's (IMO) AFS Convention prohibits harmful antifouling systems, while regional regulations like the EU's Biocidal Products Regulation impose strict controls on active substances. In the United States, the EPA regulates antifouling agents under FIFRA, requiring extensive ecotoxicological data before approval.

Compliance challenges for manufacturers are substantial, involving complex registration processes, extensive toxicity testing, and continuous monitoring requirements. The regulatory landscape continues to evolve, with increasing restrictions on copper-based formulations in certain regions and growing scrutiny of zinc pyrithione and other biocides. This regulatory pressure drives innovation toward more sustainable solutions.

Emerging environmentally friendly technologies include biomimetic approaches that replicate natural antifouling mechanisms, biodegradable polymer coatings that minimize persistent environmental residues, and enzyme-based systems that disrupt biofilm formation without traditional biocides. These technologies aim to achieve effective antifouling performance while minimizing ecological footprints.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental impact of marine coatings, considering factors from raw material extraction through disposal. Studies indicate that while eco-friendly coatings may have higher initial production impacts, their reduced in-service environmental harm often results in superior overall ecological profiles compared to conventional solutions.

The industry faces a delicate balance between antifouling efficacy and environmental protection. Successful coating systems must demonstrate both performance and compliance with increasingly stringent regulations. This dual requirement is driving significant R&D investment toward solutions that can satisfy both technical and environmental demands, ultimately reshaping the marine coating sector toward greater sustainability.

Current regulatory frameworks governing marine coatings vary globally but share common environmental protection objectives. The International Maritime Organization's (IMO) AFS Convention prohibits harmful antifouling systems, while regional regulations like the EU's Biocidal Products Regulation impose strict controls on active substances. In the United States, the EPA regulates antifouling agents under FIFRA, requiring extensive ecotoxicological data before approval.

Compliance challenges for manufacturers are substantial, involving complex registration processes, extensive toxicity testing, and continuous monitoring requirements. The regulatory landscape continues to evolve, with increasing restrictions on copper-based formulations in certain regions and growing scrutiny of zinc pyrithione and other biocides. This regulatory pressure drives innovation toward more sustainable solutions.

Emerging environmentally friendly technologies include biomimetic approaches that replicate natural antifouling mechanisms, biodegradable polymer coatings that minimize persistent environmental residues, and enzyme-based systems that disrupt biofilm formation without traditional biocides. These technologies aim to achieve effective antifouling performance while minimizing ecological footprints.

Life cycle assessment (LCA) has become an essential tool for evaluating the environmental impact of marine coatings, considering factors from raw material extraction through disposal. Studies indicate that while eco-friendly coatings may have higher initial production impacts, their reduced in-service environmental harm often results in superior overall ecological profiles compared to conventional solutions.

The industry faces a delicate balance between antifouling efficacy and environmental protection. Successful coating systems must demonstrate both performance and compliance with increasingly stringent regulations. This dual requirement is driving significant R&D investment toward solutions that can satisfy both technical and environmental demands, ultimately reshaping the marine coating sector toward greater sustainability.

Performance Testing and Durability Assessment

Performance testing and durability assessment of antifungal and algae resistant marine coatings require rigorous methodologies to ensure their effectiveness in harsh marine environments. Standard laboratory tests include static immersion tests, where coating samples are submerged in seawater tanks with controlled conditions to monitor biofouling development over time. These tests typically run for 3-6 months, with regular assessments of surface coverage by microorganisms.

Accelerated aging tests are crucial for predicting long-term performance without waiting for actual service life periods. Salt spray chambers expose coatings to concentrated salt solutions at elevated temperatures, simulating years of exposure in weeks. UV resistance testing using weatherometers subjects coatings to intense ultraviolet radiation, replicating solar exposure damage that can compromise coating integrity and antifouling properties.

Field testing remains the gold standard for performance validation, involving the application of coatings to test panels or actual vessel sections deployed in various marine environments. These tests monitor performance across different water temperatures, salinity levels, and biological activity zones. The Naval Research Laboratory and major coating manufacturers maintain dedicated testing sites in tropical waters where biofouling pressure is highest.

Quantitative assessment metrics include percent surface coverage by fouling organisms, biomass accumulation, and changes in hydrodynamic properties. Advanced techniques such as confocal laser scanning microscopy enable detailed examination of biofilm formation at microscopic levels. Mechanical property evaluations measure adhesion strength, flexibility, and impact resistance before and after exposure to determine degradation rates.

Comparative performance benchmarking against commercial standards provides context for new formulations. The industry typically requires marine coatings to maintain at least 80% fouling resistance for a minimum of three years in commercial applications, with premium solutions targeting five-year performance. Military specifications often demand even higher performance standards, particularly for specialized vessels.

Leaching rate studies track the release of active antifouling compounds over time, which is critical for both performance prediction and environmental impact assessment. These studies employ techniques such as high-performance liquid chromatography to measure the concentration of biocides in surrounding water and remaining in the coating matrix after exposure periods.

Accelerated aging tests are crucial for predicting long-term performance without waiting for actual service life periods. Salt spray chambers expose coatings to concentrated salt solutions at elevated temperatures, simulating years of exposure in weeks. UV resistance testing using weatherometers subjects coatings to intense ultraviolet radiation, replicating solar exposure damage that can compromise coating integrity and antifouling properties.

Field testing remains the gold standard for performance validation, involving the application of coatings to test panels or actual vessel sections deployed in various marine environments. These tests monitor performance across different water temperatures, salinity levels, and biological activity zones. The Naval Research Laboratory and major coating manufacturers maintain dedicated testing sites in tropical waters where biofouling pressure is highest.

Quantitative assessment metrics include percent surface coverage by fouling organisms, biomass accumulation, and changes in hydrodynamic properties. Advanced techniques such as confocal laser scanning microscopy enable detailed examination of biofilm formation at microscopic levels. Mechanical property evaluations measure adhesion strength, flexibility, and impact resistance before and after exposure to determine degradation rates.

Comparative performance benchmarking against commercial standards provides context for new formulations. The industry typically requires marine coatings to maintain at least 80% fouling resistance for a minimum of three years in commercial applications, with premium solutions targeting five-year performance. Military specifications often demand even higher performance standards, particularly for specialized vessels.

Leaching rate studies track the release of active antifouling compounds over time, which is critical for both performance prediction and environmental impact assessment. These studies employ techniques such as high-performance liquid chromatography to measure the concentration of biocides in surrounding water and remaining in the coating matrix after exposure periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!