Carbon Capture Technologies: Challenges and Innovations

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Background and Objectives

Carbon capture technologies have evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. The fundamental principle of carbon capture involves the separation of carbon dioxide (CO2) from industrial and energy-related sources, preventing its release into the atmosphere. This technology emerged in response to growing concerns about climate change and the need to reduce greenhouse gas emissions while maintaining economic growth.

The historical development of carbon capture can be traced back to the 1970s when it was first used in natural gas processing. However, its application for climate change mitigation gained momentum only in the late 1990s and early 2000s as global awareness of climate issues increased. The Intergovernmental Panel on Climate Change (IPCC) has since recognized carbon capture as a critical technology for achieving climate targets, particularly in its 2018 report highlighting pathways to limit global warming to 1.5°C.

Current carbon capture technologies primarily fall into three categories: post-combustion, pre-combustion, and oxy-fuel combustion. Post-combustion capture, the most widely deployed approach, extracts CO2 from flue gases after fossil fuel combustion. Pre-combustion involves converting fuel into a mixture of hydrogen and CO2 before combustion, while oxy-fuel combustion uses pure oxygen for combustion, resulting in a more concentrated CO2 stream for easier capture.

The technological evolution continues with emerging approaches such as direct air capture (DAC), which extracts CO2 directly from ambient air, and bioenergy with carbon capture and storage (BECCS), combining biomass energy production with carbon capture for potentially negative emissions. These newer technologies represent the frontier of carbon capture innovation but face significant challenges in scaling and cost-effectiveness.

The primary objectives of carbon capture technology development include reducing implementation costs, improving energy efficiency, minimizing environmental impacts, and enhancing capture rates. Current systems typically capture 85-95% of CO2 emissions from point sources, but technological advancements aim to increase this efficiency while reducing the substantial energy penalty associated with capture processes.

Looking forward, the carbon capture field is moving toward more integrated systems that combine capture with utilization and storage (CCUS), creating economic value from captured carbon through conversion into useful products or secure geological storage. This evolution reflects a broader trend toward circular carbon economy concepts, where carbon is viewed as a resource rather than merely a waste product to be sequestered.

The ultimate goal remains developing economically viable carbon capture solutions that can be deployed at scale across various industries, particularly in hard-to-abate sectors like cement, steel, and chemicals manufacturing, where process emissions make complete decarbonization through electrification challenging.

The historical development of carbon capture can be traced back to the 1970s when it was first used in natural gas processing. However, its application for climate change mitigation gained momentum only in the late 1990s and early 2000s as global awareness of climate issues increased. The Intergovernmental Panel on Climate Change (IPCC) has since recognized carbon capture as a critical technology for achieving climate targets, particularly in its 2018 report highlighting pathways to limit global warming to 1.5°C.

Current carbon capture technologies primarily fall into three categories: post-combustion, pre-combustion, and oxy-fuel combustion. Post-combustion capture, the most widely deployed approach, extracts CO2 from flue gases after fossil fuel combustion. Pre-combustion involves converting fuel into a mixture of hydrogen and CO2 before combustion, while oxy-fuel combustion uses pure oxygen for combustion, resulting in a more concentrated CO2 stream for easier capture.

The technological evolution continues with emerging approaches such as direct air capture (DAC), which extracts CO2 directly from ambient air, and bioenergy with carbon capture and storage (BECCS), combining biomass energy production with carbon capture for potentially negative emissions. These newer technologies represent the frontier of carbon capture innovation but face significant challenges in scaling and cost-effectiveness.

The primary objectives of carbon capture technology development include reducing implementation costs, improving energy efficiency, minimizing environmental impacts, and enhancing capture rates. Current systems typically capture 85-95% of CO2 emissions from point sources, but technological advancements aim to increase this efficiency while reducing the substantial energy penalty associated with capture processes.

Looking forward, the carbon capture field is moving toward more integrated systems that combine capture with utilization and storage (CCUS), creating economic value from captured carbon through conversion into useful products or secure geological storage. This evolution reflects a broader trend toward circular carbon economy concepts, where carbon is viewed as a resource rather than merely a waste product to be sequestered.

The ultimate goal remains developing economically viable carbon capture solutions that can be deployed at scale across various industries, particularly in hard-to-abate sectors like cement, steel, and chemicals manufacturing, where process emissions make complete decarbonization through electrification challenging.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce greenhouse gas emissions. As of 2023, the market size for carbon capture technologies is valued at approximately $7.3 billion, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030, potentially reaching $35.6 billion by the end of the decade.

Geographically, North America currently dominates the carbon capture market, accounting for roughly 40% of global installations, followed by Europe at 30% and Asia-Pacific at 20%. This distribution reflects both regulatory environments and industrial concentrations. The United States, Canada, and Norway lead in deployment scale, while China is rapidly expanding its carbon capture infrastructure.

Demand segmentation reveals that power generation represents the largest application sector (35%), followed by oil and gas operations (25%), cement production (15%), and chemical manufacturing (10%). This distribution highlights the technology's critical role in decarbonizing energy-intensive industries where emissions are particularly challenging to abate through other means.

Investment patterns show accelerating capital flows into the sector, with venture capital funding increasing by 138% between 2020 and 2022. Corporate investments from major energy companies have similarly expanded, with BP, Shell, and ExxonMobil each committing over $1 billion to carbon capture initiatives in their five-year strategic plans.

Customer adoption analysis indicates varying willingness-to-pay across sectors. Early adopters primarily consist of companies facing stringent emissions regulations or carbon pricing mechanisms. The levelized cost of carbon capture currently ranges from $58-$120 per ton CO2, with significant variations based on technology type and application context.

Market barriers remain substantial, including high capital expenditure requirements, uncertain policy landscapes in many regions, and technical challenges in scaling solutions. The absence of widespread carbon pricing mechanisms in many markets creates economic disincentives for widespread adoption outside regulatory mandates.

Growth opportunities are emerging in several segments, particularly in direct air capture technologies, which show potential for 200% growth in the next five years, albeit from a small base. Integration with hydrogen production and utilization in hard-to-abate sectors represents another high-potential market segment with projected annual growth exceeding 25% through 2028.

Geographically, North America currently dominates the carbon capture market, accounting for roughly 40% of global installations, followed by Europe at 30% and Asia-Pacific at 20%. This distribution reflects both regulatory environments and industrial concentrations. The United States, Canada, and Norway lead in deployment scale, while China is rapidly expanding its carbon capture infrastructure.

Demand segmentation reveals that power generation represents the largest application sector (35%), followed by oil and gas operations (25%), cement production (15%), and chemical manufacturing (10%). This distribution highlights the technology's critical role in decarbonizing energy-intensive industries where emissions are particularly challenging to abate through other means.

Investment patterns show accelerating capital flows into the sector, with venture capital funding increasing by 138% between 2020 and 2022. Corporate investments from major energy companies have similarly expanded, with BP, Shell, and ExxonMobil each committing over $1 billion to carbon capture initiatives in their five-year strategic plans.

Customer adoption analysis indicates varying willingness-to-pay across sectors. Early adopters primarily consist of companies facing stringent emissions regulations or carbon pricing mechanisms. The levelized cost of carbon capture currently ranges from $58-$120 per ton CO2, with significant variations based on technology type and application context.

Market barriers remain substantial, including high capital expenditure requirements, uncertain policy landscapes in many regions, and technical challenges in scaling solutions. The absence of widespread carbon pricing mechanisms in many markets creates economic disincentives for widespread adoption outside regulatory mandates.

Growth opportunities are emerging in several segments, particularly in direct air capture technologies, which show potential for 200% growth in the next five years, albeit from a small base. Integration with hydrogen production and utilization in hard-to-abate sectors represents another high-potential market segment with projected annual growth exceeding 25% through 2028.

Current Status and Technical Barriers

Carbon capture technologies have evolved significantly over the past two decades, yet remain at varying stages of technological readiness. Currently, post-combustion capture dominates commercial applications, with approximately 65% of operational carbon capture facilities utilizing amine-based absorption methods. These established technologies achieve capture rates between 85-95% but face substantial energy penalties, typically consuming 15-30% of a power plant's energy output for the capture process alone.

The global carbon capture capacity stands at approximately 40 million tonnes per annum (Mtpa), with projections suggesting this needs to reach 5,600 Mtpa by 2050 to meet climate goals—highlighting a massive implementation gap. Geographically, North America leads with 65% of operational facilities, followed by Europe (20%) and Asia-Pacific (12%), revealing significant regional disparities in technology deployment.

Major technical barriers persist across the carbon capture value chain. For capture technologies, high energy requirements remain the primary challenge, with current systems requiring 2.5-3.5 GJ/tonne CO₂ captured. This translates to capture costs ranging from $40-120 per tonne, significantly above the carbon price in most markets. Material degradation in amine-based systems further compounds operational challenges, with solvent replacement accounting for 5-10% of operational costs.

Transport infrastructure represents another critical bottleneck, with only 6,500 km of dedicated CO₂ pipelines globally—predominantly in North America. The corrosive nature of impure CO₂ streams necessitates specialized materials and monitoring systems, increasing infrastructure costs by 30-45% compared to natural gas pipelines.

Storage verification and monitoring technologies remain underdeveloped, with current methodologies achieving only 85-90% accuracy in quantifying stored carbon. This creates significant uncertainty for carbon accounting and verification systems essential for carbon markets and regulatory compliance.

Emerging direct air capture (DAC) technologies face even greater challenges, with current energy requirements of 5-10 GJ/tonne CO₂ and costs exceeding $250-600 per tonne. Material science limitations, particularly sorbent durability and selectivity in ambient conditions, restrict operational lifetimes to 3-5 years before significant performance degradation occurs.

Integration challenges between capture systems and industrial processes further complicate implementation, with retrofitting existing facilities typically increasing capital costs by 40-70% compared to new-build installations. The intermittency of renewable energy sources also creates operational challenges for energy-intensive capture processes, necessitating complex system designs and energy storage solutions.

The global carbon capture capacity stands at approximately 40 million tonnes per annum (Mtpa), with projections suggesting this needs to reach 5,600 Mtpa by 2050 to meet climate goals—highlighting a massive implementation gap. Geographically, North America leads with 65% of operational facilities, followed by Europe (20%) and Asia-Pacific (12%), revealing significant regional disparities in technology deployment.

Major technical barriers persist across the carbon capture value chain. For capture technologies, high energy requirements remain the primary challenge, with current systems requiring 2.5-3.5 GJ/tonne CO₂ captured. This translates to capture costs ranging from $40-120 per tonne, significantly above the carbon price in most markets. Material degradation in amine-based systems further compounds operational challenges, with solvent replacement accounting for 5-10% of operational costs.

Transport infrastructure represents another critical bottleneck, with only 6,500 km of dedicated CO₂ pipelines globally—predominantly in North America. The corrosive nature of impure CO₂ streams necessitates specialized materials and monitoring systems, increasing infrastructure costs by 30-45% compared to natural gas pipelines.

Storage verification and monitoring technologies remain underdeveloped, with current methodologies achieving only 85-90% accuracy in quantifying stored carbon. This creates significant uncertainty for carbon accounting and verification systems essential for carbon markets and regulatory compliance.

Emerging direct air capture (DAC) technologies face even greater challenges, with current energy requirements of 5-10 GJ/tonne CO₂ and costs exceeding $250-600 per tonne. Material science limitations, particularly sorbent durability and selectivity in ambient conditions, restrict operational lifetimes to 3-5 years before significant performance degradation occurs.

Integration challenges between capture systems and industrial processes further complicate implementation, with retrofitting existing facilities typically increasing capital costs by 40-70% compared to new-build installations. The intermittency of renewable energy sources also creates operational challenges for energy-intensive capture processes, necessitating complex system designs and energy storage solutions.

Existing Carbon Capture Methodologies

01 Chemical absorption methods for carbon capture

Chemical absorption is a widely used method for carbon capture that involves the use of solvents to absorb CO2 from flue gases. This process typically uses amine-based solvents that chemically react with CO2, allowing for its separation from other gases. The captured CO2 can then be released through heating, and the regenerated solvent can be reused. This technology is particularly effective for post-combustion capture from power plants and industrial facilities.- Direct Air Capture Technologies: Direct air capture (DAC) technologies involve systems that extract carbon dioxide directly from the atmosphere. These technologies typically use sorbent materials or chemical solutions to selectively capture CO2 from ambient air. After capture, the CO2 can be concentrated, compressed, and either stored underground or utilized in various applications. DAC systems can be deployed in various locations regardless of emission sources and represent a promising approach for negative emissions.

- Post-Combustion Carbon Capture: Post-combustion carbon capture technologies focus on removing CO2 from flue gases after the combustion process in power plants and industrial facilities. These systems typically employ chemical solvents, solid sorbents, or membrane separation to selectively extract CO2 from exhaust streams. The captured carbon dioxide can then be compressed and transported for storage or utilization. This approach allows retrofitting existing facilities without major modifications to the primary industrial processes.

- Biological Carbon Sequestration Methods: Biological carbon sequestration leverages natural processes to capture and store carbon dioxide. These methods include enhanced forestry practices, algae-based capture systems, biochar production, and soil carbon enhancement techniques. Biological approaches often provide co-benefits such as improved soil health, increased biodiversity, and enhanced ecosystem services. These technologies can be implemented across various landscapes and offer cost-effective solutions for carbon removal while supporting sustainable land management practices.

- Mineral Carbonation and Enhanced Weathering: Mineral carbonation technologies accelerate natural weathering processes to convert CO2 into stable carbonate minerals. These approaches involve reacting carbon dioxide with calcium or magnesium-rich materials such as olivine, serpentine, or industrial waste products like steel slag and cement kiln dust. The resulting carbonates are environmentally benign and can provide permanent carbon storage. Enhanced weathering techniques can be applied to agricultural soils, mine tailings, or dedicated processing facilities to increase carbon sequestration rates.

- Carbon Capture Utilization and Storage (CCUS) Systems: CCUS systems integrate carbon capture with utilization pathways and long-term storage solutions. These comprehensive approaches capture CO2 from industrial sources or the atmosphere and either convert it into valuable products or securely store it underground. Utilization pathways include conversion to fuels, chemicals, building materials, or enhanced oil recovery. Storage options focus on geological sequestration in depleted oil and gas reservoirs, deep saline formations, or unminable coal seams, ensuring the carbon remains permanently isolated from the atmosphere.

02 Direct air capture technologies

Direct air capture (DAC) technologies extract CO2 directly from the atmosphere rather than from point sources like power plants. These systems typically use sorbent materials or chemical solutions that selectively capture CO2 from ambient air. Once captured, the CO2 can be released through heating or pressure changes, allowing for its subsequent storage or utilization. DAC technologies are particularly valuable for addressing distributed emissions and potentially achieving negative emissions.Expand Specific Solutions03 Membrane-based carbon capture systems

Membrane-based carbon capture systems utilize selective membranes that allow CO2 to pass through while blocking other gases. These membranes can be made from polymers, ceramics, or composite materials with specific pore sizes and chemical properties designed to maximize CO2 separation efficiency. Membrane technology offers advantages including lower energy requirements, compact design, and continuous operation capability, making it suitable for various industrial applications.Expand Specific Solutions04 Biological carbon capture methods

Biological carbon capture methods leverage natural biological processes to capture and store CO2. These approaches include microalgae cultivation, which uses photosynthesis to convert CO2 into biomass, and engineered microorganisms designed to enhance carbon fixation rates. Biological systems can be integrated with industrial facilities to capture emissions directly from flue gases or deployed in open environments. The captured carbon can be stored in biomass or converted into valuable products like biofuels or biochemicals.Expand Specific Solutions05 Carbon mineralization and geological storage

Carbon mineralization involves converting CO2 into stable mineral carbonates through reactions with metal oxides, particularly those containing calcium or magnesium. This process can occur naturally but can be accelerated through engineered approaches. Geological storage involves injecting captured CO2 into deep underground formations such as depleted oil and gas reservoirs or saline aquifers, where it can be trapped for long periods. These methods provide permanent storage solutions for captured carbon, preventing its release back into the atmosphere.Expand Specific Solutions

Leading Companies and Research Institutions

Carbon capture technology is currently in a growth phase, with the market expected to expand significantly due to increasing climate change concerns. The global carbon capture market size is projected to reach $7-10 billion by 2030, growing at a CAGR of approximately 15%. Technologically, the field is advancing from early commercial deployment to broader implementation, with varying maturity levels across capture methods. Leading players include energy giants like Saudi Aramco and Sinopec, who are leveraging their industrial infrastructure for large-scale implementation. Academic institutions such as Columbia University, Nanyang Technological University, and KAIST are driving fundamental research innovations. Specialized firms like NuScale Power and Pi Green Innovations are developing niche solutions, while national research institutes in China and Korea are accelerating technology transfer to address regional carbon reduction targets.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated carbon capture, utilization, and storage (CCUS) technology system focusing on post-combustion capture using advanced amine-based solvents. Their approach includes a proprietary solvent formulation that reduces regeneration energy by approximately 30% compared to conventional MEA solutions. Sinopec has implemented this technology at their Qilu Petrochemical facility, capturing over 1 million tons of CO2 annually and transporting it via pipeline to nearby oil fields for enhanced oil recovery (EOR). The company has also pioneered membrane separation technology specifically designed for high-pressure applications in natural gas processing, achieving separation efficiencies of up to 95% while reducing energy consumption by 25% compared to traditional methods. Sinopec's integrated approach connects capture facilities directly with utilization infrastructure, creating closed-loop carbon management systems across their industrial operations.

Strengths: Extensive industrial infrastructure allowing for immediate large-scale deployment; vertical integration capabilities from capture to utilization; significant financial resources for continued R&D. Weaknesses: Technologies primarily focused on enhancing fossil fuel recovery rather than permanent sequestration; high capital costs for retrofitting existing facilities; technology optimization still needed for non-petrochemical applications.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed a multi-faceted carbon capture technology portfolio centered around both pre-combustion and post-combustion capture systems. Their flagship technology is a proprietary advanced amine-based solvent system that demonstrates 15-20% lower regeneration energy requirements compared to conventional capture methods. Aramco has implemented mobile carbon capture units that can be deployed at various facilities, capturing up to 40 tons of CO2 daily with 85-90% efficiency. The company has also pioneered direct air capture (DAC) research through their CONVERGE program, focusing on metal-organic frameworks (MOFs) that show promising CO2 selectivity even at low atmospheric concentrations. Their carbon utilization pathway includes converting captured CO2 into polymers, construction materials, and enhanced oil recovery applications. Aramco's Uthmaniyah CO2-EOR demonstration project injects approximately 800,000 tons of captured CO2 annually, increasing oil recovery rates by 5-10% while permanently storing carbon underground.

Strengths: Massive financial resources for technology development; extensive existing infrastructure for CO2 transport and storage; ability to implement technologies at industrial scale. Weaknesses: Primary focus on EOR applications rather than permanent sequestration; technologies largely aimed at extending fossil fuel lifecycle rather than transitioning away; limited transparency regarding actual carbon permanence in storage applications.

Key Patents and Scientific Breakthroughs

Co2 capture and desorption using core-shell catalysts

PatentPendingUS20250018327A1

Innovation

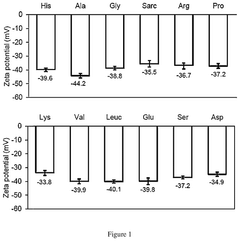

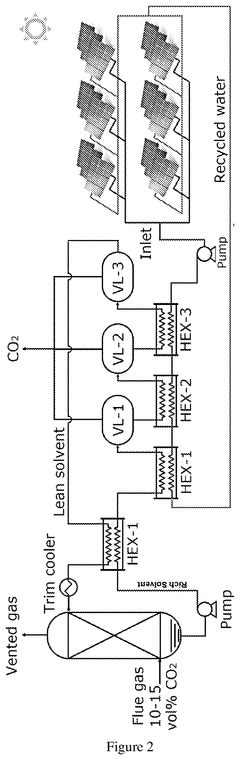

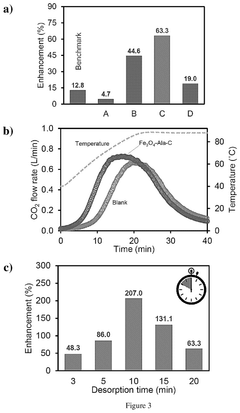

- A method involving an aqueous colloidal solution with a CO2 absorbent and a colloidal catalyst having a core-shell structure with proton-donor groups, which facilitates efficient thermal desorption of CO2 at lower temperatures, reducing energy consumption and eliminating the need for external supports.

Policy and Regulatory Framework

The global policy landscape for carbon capture technologies has evolved significantly over the past decade, reflecting growing recognition of climate change urgency. Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, have emerged as primary policy instruments driving carbon capture adoption. The European Union's Emissions Trading System represents the world's largest carbon market, while countries like Canada and Sweden have implemented carbon taxes that effectively incentivize carbon capture investments.

Tax incentives and direct subsidies form another critical component of the regulatory framework. The United States' 45Q tax credit provides up to $50 per metric ton of CO2 sequestered, significantly improving project economics for carbon capture facilities. Similarly, the UK's Contracts for Difference scheme guarantees price stability for low-carbon electricity generators, including those utilizing carbon capture technologies.

Regulatory standards for CO2 storage safety and monitoring have developed in parallel with financial incentives. These frameworks address liability concerns, long-term monitoring requirements, and verification protocols essential for public acceptance and environmental protection. The EU's CCS Directive and Australia's Offshore Petroleum and Greenhouse Gas Storage Act exemplify comprehensive regulatory approaches to carbon storage governance.

International cooperation mechanisms further shape the policy environment. The Paris Agreement's Article 6 creates pathways for cross-border collaboration on emissions reduction, potentially enabling carbon capture technology transfer and shared infrastructure development. Organizations like the Carbon Sequestration Leadership Forum facilitate knowledge exchange and policy harmonization across borders.

Emerging policy innovations include carbon removal procurement programs, where governments directly purchase negative emissions from technological solutions. The Nordic countries have pioneered this approach, creating guaranteed markets for carbon removal technologies. Additionally, low-carbon product standards are beginning to recognize embedded carbon reductions achieved through capture technologies in manufacturing processes.

Challenges in the policy landscape include regulatory fragmentation across jurisdictions, uncertainty regarding long-term liability for stored CO2, and insufficient coordination between industrial policy and climate objectives. The most effective policy frameworks combine predictable carbon pricing, direct support for early deployment, clear regulatory guidelines for storage, and integration with broader industrial strategy to create comprehensive ecosystems supporting carbon capture innovation and implementation.

Tax incentives and direct subsidies form another critical component of the regulatory framework. The United States' 45Q tax credit provides up to $50 per metric ton of CO2 sequestered, significantly improving project economics for carbon capture facilities. Similarly, the UK's Contracts for Difference scheme guarantees price stability for low-carbon electricity generators, including those utilizing carbon capture technologies.

Regulatory standards for CO2 storage safety and monitoring have developed in parallel with financial incentives. These frameworks address liability concerns, long-term monitoring requirements, and verification protocols essential for public acceptance and environmental protection. The EU's CCS Directive and Australia's Offshore Petroleum and Greenhouse Gas Storage Act exemplify comprehensive regulatory approaches to carbon storage governance.

International cooperation mechanisms further shape the policy environment. The Paris Agreement's Article 6 creates pathways for cross-border collaboration on emissions reduction, potentially enabling carbon capture technology transfer and shared infrastructure development. Organizations like the Carbon Sequestration Leadership Forum facilitate knowledge exchange and policy harmonization across borders.

Emerging policy innovations include carbon removal procurement programs, where governments directly purchase negative emissions from technological solutions. The Nordic countries have pioneered this approach, creating guaranteed markets for carbon removal technologies. Additionally, low-carbon product standards are beginning to recognize embedded carbon reductions achieved through capture technologies in manufacturing processes.

Challenges in the policy landscape include regulatory fragmentation across jurisdictions, uncertainty regarding long-term liability for stored CO2, and insufficient coordination between industrial policy and climate objectives. The most effective policy frameworks combine predictable carbon pricing, direct support for early deployment, clear regulatory guidelines for storage, and integration with broader industrial strategy to create comprehensive ecosystems supporting carbon capture innovation and implementation.

Economic Viability Assessment

The economic viability of carbon capture technologies remains a critical barrier to widespread adoption. Current cost estimates for carbon capture range from $40 to $120 per ton of CO2, depending on the technology and implementation context. This significant cost variance creates uncertainty for potential investors and adopters, particularly when compared to carbon prices in existing markets, which often fall below these capture costs.

Capital expenditure requirements present another substantial challenge. Initial investments for carbon capture facilities can range from hundreds of millions to billions of dollars, creating high barriers to entry. For example, large-scale post-combustion capture systems for power plants typically require investments of $400-800 million, with additional costs for transportation and storage infrastructure.

Operational expenses further impact long-term viability. Energy penalties—the additional energy required to power capture processes—typically reduce plant efficiency by 20-30%, significantly affecting operational economics. This "parasitic load" translates directly to higher production costs and reduced output capacity, challenging the business case for implementation.

Market mechanisms and policy frameworks play decisive roles in economic feasibility. Carbon pricing schemes, tax incentives, and regulatory requirements vary widely across regions, creating an uneven landscape for technology deployment. Markets with carbon prices below $50 per ton generally fail to incentivize substantial investment in capture technologies.

Recent innovations are gradually improving the economic outlook. Advanced solvents and membrane technologies have demonstrated potential to reduce energy penalties by 30-40% compared to first-generation systems. Additionally, emerging business models incorporating CO2 utilization pathways—such as enhanced oil recovery, building materials production, and synthetic fuel development—are creating value streams that partially offset capture costs.

Scale effects are beginning to materialize as deployment increases. Learning rates of approximately 10-15% cost reduction per doubling of installed capacity have been observed in early commercial projects, suggesting potential for significant cost improvements as the industry matures. This follows patterns seen in other environmental technologies like flue gas desulfurization and selective catalytic reduction systems.

The economic viability assessment must also consider externalities and co-benefits. When accounting for avoided climate damages, health benefits from reduced pollution, and potential job creation, the societal value proposition strengthens considerably, though these benefits remain challenging to monetize within traditional business models.

Capital expenditure requirements present another substantial challenge. Initial investments for carbon capture facilities can range from hundreds of millions to billions of dollars, creating high barriers to entry. For example, large-scale post-combustion capture systems for power plants typically require investments of $400-800 million, with additional costs for transportation and storage infrastructure.

Operational expenses further impact long-term viability. Energy penalties—the additional energy required to power capture processes—typically reduce plant efficiency by 20-30%, significantly affecting operational economics. This "parasitic load" translates directly to higher production costs and reduced output capacity, challenging the business case for implementation.

Market mechanisms and policy frameworks play decisive roles in economic feasibility. Carbon pricing schemes, tax incentives, and regulatory requirements vary widely across regions, creating an uneven landscape for technology deployment. Markets with carbon prices below $50 per ton generally fail to incentivize substantial investment in capture technologies.

Recent innovations are gradually improving the economic outlook. Advanced solvents and membrane technologies have demonstrated potential to reduce energy penalties by 30-40% compared to first-generation systems. Additionally, emerging business models incorporating CO2 utilization pathways—such as enhanced oil recovery, building materials production, and synthetic fuel development—are creating value streams that partially offset capture costs.

Scale effects are beginning to materialize as deployment increases. Learning rates of approximately 10-15% cost reduction per doubling of installed capacity have been observed in early commercial projects, suggesting potential for significant cost improvements as the industry matures. This follows patterns seen in other environmental technologies like flue gas desulfurization and selective catalytic reduction systems.

The economic viability assessment must also consider externalities and co-benefits. When accounting for avoided climate damages, health benefits from reduced pollution, and potential job creation, the societal value proposition strengthens considerably, though these benefits remain challenging to monetize within traditional business models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!