Evaluating Carbon Capture Technologies for Improved Efficiency

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. The fundamental principle behind carbon capture involves the separation of carbon dioxide (CO2) from industrial and energy-related sources, preventing its release into the atmosphere. This technology emerged in the 1970s primarily for enhanced oil recovery but has since expanded in scope and sophistication as climate change concerns have intensified.

The evolution of carbon capture technologies has followed three distinct generations. First-generation technologies focused on post-combustion capture using chemical solvents like monoethanolamine (MEA). Second-generation approaches introduced pre-combustion capture and oxyfuel combustion, while current third-generation technologies explore novel materials such as metal-organic frameworks (MOFs), advanced membranes, and direct air capture systems.

Global carbon emissions continue to rise, with approximately 35 billion tonnes of CO2 released annually. The Intergovernmental Panel on Climate Change (IPCC) has identified carbon capture as a critical component in limiting global warming to 1.5°C above pre-industrial levels. This urgency has accelerated research and development efforts worldwide, with significant investments from both public and private sectors.

The primary objective of current carbon capture technology development is to substantially improve efficiency while reducing implementation costs. Present systems typically require 25-40% of a power plant's energy output for operation, creating a significant energy penalty. The target is to reduce this energy requirement to below 15% while simultaneously decreasing capital costs by at least 30% compared to 2020 benchmarks.

Additional objectives include enhancing the CO2 absorption capacity of capture materials, improving their selectivity and stability under various operating conditions, and developing systems that can be retrofitted to existing infrastructure with minimal modifications. Scalability remains a crucial consideration, as effective climate impact requires deployment at industrial scales across multiple sectors.

Recent technological breakthroughs in materials science, process engineering, and system integration have created promising pathways toward these objectives. Innovations in solvent chemistry have yielded compounds with lower regeneration energy requirements, while advances in membrane technology have improved separation efficiency and durability under industrial conditions.

The convergence of carbon capture with utilization and storage technologies (CCUS) represents another important development trajectory, creating potential economic incentives through the conversion of captured CO2 into valuable products or its secure geological sequestration. This integrated approach aims to transform carbon capture from a cost center to a potential revenue stream, accelerating adoption across industries.

The evolution of carbon capture technologies has followed three distinct generations. First-generation technologies focused on post-combustion capture using chemical solvents like monoethanolamine (MEA). Second-generation approaches introduced pre-combustion capture and oxyfuel combustion, while current third-generation technologies explore novel materials such as metal-organic frameworks (MOFs), advanced membranes, and direct air capture systems.

Global carbon emissions continue to rise, with approximately 35 billion tonnes of CO2 released annually. The Intergovernmental Panel on Climate Change (IPCC) has identified carbon capture as a critical component in limiting global warming to 1.5°C above pre-industrial levels. This urgency has accelerated research and development efforts worldwide, with significant investments from both public and private sectors.

The primary objective of current carbon capture technology development is to substantially improve efficiency while reducing implementation costs. Present systems typically require 25-40% of a power plant's energy output for operation, creating a significant energy penalty. The target is to reduce this energy requirement to below 15% while simultaneously decreasing capital costs by at least 30% compared to 2020 benchmarks.

Additional objectives include enhancing the CO2 absorption capacity of capture materials, improving their selectivity and stability under various operating conditions, and developing systems that can be retrofitted to existing infrastructure with minimal modifications. Scalability remains a crucial consideration, as effective climate impact requires deployment at industrial scales across multiple sectors.

Recent technological breakthroughs in materials science, process engineering, and system integration have created promising pathways toward these objectives. Innovations in solvent chemistry have yielded compounds with lower regeneration energy requirements, while advances in membrane technology have improved separation efficiency and durability under industrial conditions.

The convergence of carbon capture with utilization and storage technologies (CCUS) represents another important development trajectory, creating potential economic incentives through the conversion of captured CO2 into valuable products or its secure geological sequestration. This integrated approach aims to transform carbon capture from a cost center to a potential revenue stream, accelerating adoption across industries.

Market Demand Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. Current market valuations place the carbon capture industry at approximately 2 billion USD in 2023, with projections indicating potential growth to reach 7 billion USD by 2030, representing a compound annual growth rate (CAGR) of 19.2%. This remarkable expansion reflects the urgent need for effective carbon reduction technologies across multiple industries.

Industrial sectors, particularly power generation, cement manufacturing, and steel production, demonstrate the highest demand for carbon capture solutions. These industries collectively contribute over 40% of global carbon emissions, making them prime targets for implementation. The power generation sector alone accounts for nearly 25% of the current market demand, as coal and natural gas plants seek compliance with increasingly stringent emission regulations.

Regional analysis reveals varying levels of market maturity. North America currently leads adoption rates, holding approximately 35% of the global market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the fastest growth trajectory, with China and India making substantial investments in carbon capture infrastructure as part of their climate commitments.

Consumer preferences are increasingly influencing corporate sustainability strategies, with 68% of global consumers expressing willingness to pay premium prices for products manufactured using low-carbon processes. This consumer-driven demand creates additional market pull for carbon capture technologies beyond regulatory compliance.

The economic viability of carbon capture solutions remains a critical factor affecting market penetration. Current capture costs range from 40-120 USD per ton of CO2, depending on the technology and implementation context. Market analysis indicates that widespread adoption will accelerate significantly once costs consistently fall below 50 USD per ton, a threshold expected to be reached within the next 5-7 years through technological improvements and economies of scale.

Government incentives and carbon pricing mechanisms are substantially influencing market dynamics. Regions with established carbon markets or tax systems show 3-4 times higher adoption rates compared to unregulated markets. The introduction of carbon border adjustment mechanisms by major economies is expected to further stimulate global demand for carbon capture technologies by creating economic incentives across international supply chains.

Emerging business models, such as Carbon Capture as a Service (CCaaS), are expanding market accessibility by reducing capital expenditure barriers for smaller industrial players. This service-based approach is projected to capture 15% of the market by 2025, opening new customer segments previously unable to invest in traditional carbon capture infrastructure.

Industrial sectors, particularly power generation, cement manufacturing, and steel production, demonstrate the highest demand for carbon capture solutions. These industries collectively contribute over 40% of global carbon emissions, making them prime targets for implementation. The power generation sector alone accounts for nearly 25% of the current market demand, as coal and natural gas plants seek compliance with increasingly stringent emission regulations.

Regional analysis reveals varying levels of market maturity. North America currently leads adoption rates, holding approximately 35% of the global market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the fastest growth trajectory, with China and India making substantial investments in carbon capture infrastructure as part of their climate commitments.

Consumer preferences are increasingly influencing corporate sustainability strategies, with 68% of global consumers expressing willingness to pay premium prices for products manufactured using low-carbon processes. This consumer-driven demand creates additional market pull for carbon capture technologies beyond regulatory compliance.

The economic viability of carbon capture solutions remains a critical factor affecting market penetration. Current capture costs range from 40-120 USD per ton of CO2, depending on the technology and implementation context. Market analysis indicates that widespread adoption will accelerate significantly once costs consistently fall below 50 USD per ton, a threshold expected to be reached within the next 5-7 years through technological improvements and economies of scale.

Government incentives and carbon pricing mechanisms are substantially influencing market dynamics. Regions with established carbon markets or tax systems show 3-4 times higher adoption rates compared to unregulated markets. The introduction of carbon border adjustment mechanisms by major economies is expected to further stimulate global demand for carbon capture technologies by creating economic incentives across international supply chains.

Emerging business models, such as Carbon Capture as a Service (CCaaS), are expanding market accessibility by reducing capital expenditure barriers for smaller industrial players. This service-based approach is projected to capture 15% of the market by 2025, opening new customer segments previously unable to invest in traditional carbon capture infrastructure.

Current Status and Challenges in Carbon Capture Technologies

Carbon capture technologies have evolved significantly over the past two decades, with three primary approaches currently dominating the field: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. Post-combustion technologies, particularly amine-based absorption systems, represent the most mature and widely deployed solution, with approximately 65% of existing large-scale carbon capture facilities utilizing this approach. However, these systems typically consume 15-30% of a power plant's energy output, significantly reducing overall efficiency.

Pre-combustion capture, while theoretically more efficient, has seen limited commercial deployment due to the substantial capital investment required for integrated gasification combined cycle (IGCC) plants. Only seven commercial-scale facilities worldwide currently employ this technology, despite its potential for higher capture rates of 85-95%.

Oxy-fuel combustion remains largely in the demonstration phase, with only three operational facilities globally. The technology's high oxygen production costs, typically accounting for 60% of the total operational expenses, present a significant barrier to widespread adoption.

The geographical distribution of carbon capture technology development shows clear regional leaders. North America hosts 43% of operational carbon capture facilities, followed by Europe (27%) and Asia (21%), with China rapidly expanding its research and deployment capabilities. This distribution largely correlates with regional climate policies and carbon pricing mechanisms.

Current technical challenges span multiple dimensions. Energy penalties remain the most significant barrier, with state-of-the-art systems requiring 0.7-1.2 GJ of energy per ton of CO₂ captured. This translates to efficiency losses of 20-30% in power generation applications. Material limitations also persist, particularly in sorbent degradation, with most amine-based solvents requiring replacement every 2-5 years due to oxidative degradation.

Scale-up challenges continue to impede widespread adoption. The largest operational carbon capture facility currently processes 1 million tons of CO₂ annually, while meaningful climate impact would require scaling to billions of tons. Engineering challenges in areas such as heat integration, pressure drop management, and equipment corrosion further complicate large-scale implementation.

Economic constraints remain formidable, with current capture costs ranging from $40-120 per ton of CO₂, significantly above carbon pricing in most markets. Without stronger policy incentives or technological breakthroughs, the economic viability of widespread carbon capture deployment remains questionable in many regions.

Pre-combustion capture, while theoretically more efficient, has seen limited commercial deployment due to the substantial capital investment required for integrated gasification combined cycle (IGCC) plants. Only seven commercial-scale facilities worldwide currently employ this technology, despite its potential for higher capture rates of 85-95%.

Oxy-fuel combustion remains largely in the demonstration phase, with only three operational facilities globally. The technology's high oxygen production costs, typically accounting for 60% of the total operational expenses, present a significant barrier to widespread adoption.

The geographical distribution of carbon capture technology development shows clear regional leaders. North America hosts 43% of operational carbon capture facilities, followed by Europe (27%) and Asia (21%), with China rapidly expanding its research and deployment capabilities. This distribution largely correlates with regional climate policies and carbon pricing mechanisms.

Current technical challenges span multiple dimensions. Energy penalties remain the most significant barrier, with state-of-the-art systems requiring 0.7-1.2 GJ of energy per ton of CO₂ captured. This translates to efficiency losses of 20-30% in power generation applications. Material limitations also persist, particularly in sorbent degradation, with most amine-based solvents requiring replacement every 2-5 years due to oxidative degradation.

Scale-up challenges continue to impede widespread adoption. The largest operational carbon capture facility currently processes 1 million tons of CO₂ annually, while meaningful climate impact would require scaling to billions of tons. Engineering challenges in areas such as heat integration, pressure drop management, and equipment corrosion further complicate large-scale implementation.

Economic constraints remain formidable, with current capture costs ranging from $40-120 per ton of CO₂, significantly above carbon pricing in most markets. Without stronger policy incentives or technological breakthroughs, the economic viability of widespread carbon capture deployment remains questionable in many regions.

Current Carbon Capture Implementation Solutions

01 Direct air capture (DAC) technologies

Direct air capture technologies involve systems that extract carbon dioxide directly from the atmosphere. These technologies use various sorbents and processes to capture CO2 from ambient air, offering flexibility in installation locations. DAC systems can achieve varying efficiency levels depending on the sorbent materials used, energy sources, and system design. Recent innovations focus on improving energy efficiency and reducing the cost per ton of CO2 captured.- Direct air capture (DAC) technologies: Direct air capture technologies involve systems that extract carbon dioxide directly from the atmosphere. These technologies use various sorbents and processes to capture CO2 from ambient air, which can then be stored or utilized. DAC systems are being developed with increasing efficiency metrics, including improved energy consumption rates, capture capacity, and operational costs. Recent innovations focus on enhancing sorbent materials and optimizing system designs to increase carbon capture efficiency while reducing energy requirements.

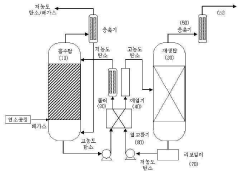

- Post-combustion carbon capture systems: Post-combustion carbon capture technologies focus on removing CO2 from flue gases after fossil fuel combustion. These systems typically employ chemical absorption, adsorption, or membrane separation techniques. Efficiency improvements in these technologies include enhanced solvent formulations with lower regeneration energy requirements, advanced membrane materials with higher selectivity, and optimized process configurations that reduce parasitic energy loads. Recent developments have achieved significant increases in capture rates while decreasing the energy penalty associated with carbon capture operations.

- Biological and nature-based carbon capture methods: Biological carbon capture leverages natural processes such as photosynthesis in plants, algae, and microorganisms to remove CO2 from the atmosphere. These approaches include enhanced forestry practices, algae cultivation systems, and engineered microorganisms designed specifically for carbon fixation. The efficiency of these methods is measured by carbon sequestration rates, land use requirements, and sustainability metrics. Recent innovations focus on optimizing growth conditions, genetic modifications to increase carbon fixation rates, and developing integrated systems that combine biological capture with utilization pathways.

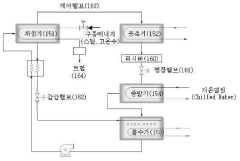

- Carbon capture efficiency monitoring and optimization systems: Advanced monitoring and optimization systems are being developed to enhance the efficiency of carbon capture technologies. These systems employ sensors, data analytics, artificial intelligence, and machine learning algorithms to continuously monitor performance parameters and optimize operational conditions in real-time. By analyzing variables such as temperature, pressure, flow rates, and chemical compositions, these systems can identify inefficiencies and automatically adjust parameters to maximize capture rates while minimizing energy consumption. These technologies enable adaptive control strategies that respond to changing conditions and improve overall system efficiency.

- Novel materials and sorbents for enhanced carbon capture: Research into advanced materials and sorbents is significantly improving carbon capture efficiency. These innovations include metal-organic frameworks (MOFs), zeolites, functionalized polymers, and composite materials specifically designed for CO2 adsorption. These materials offer advantages such as higher selectivity for CO2, increased adsorption capacity, faster kinetics, and improved regeneration characteristics. Recent developments focus on tailoring pore structures, surface chemistry, and material stability to enhance performance under various operating conditions, resulting in substantial efficiency gains and reduced energy requirements for the carbon capture process.

02 Post-combustion carbon capture systems

Post-combustion capture technologies remove CO2 from flue gases after the combustion process in power plants and industrial facilities. These systems typically employ chemical absorption using amine-based solvents or other advanced materials. Efficiency improvements focus on reducing the energy penalty associated with solvent regeneration, optimizing absorption/desorption cycles, and developing novel materials with higher CO2 selectivity and capacity.Expand Specific Solutions03 Biological and nature-based carbon capture methods

Biological carbon capture leverages natural processes such as photosynthesis in plants, algae, and microorganisms to sequester carbon dioxide. These approaches include enhanced forestry practices, algae cultivation systems, and biochar production. The efficiency of biological methods depends on factors like species selection, growing conditions, and management practices. Recent innovations focus on optimizing growth conditions, genetic modifications to increase carbon fixation rates, and developing integrated systems that combine carbon capture with valuable product generation.Expand Specific Solutions04 Monitoring and efficiency measurement systems

Advanced monitoring and measurement technologies are crucial for assessing and improving the efficiency of carbon capture systems. These include sensor networks, data analytics platforms, and simulation tools that provide real-time performance metrics and optimization opportunities. Such systems enable operators to track capture rates, energy consumption, and overall system efficiency, facilitating continuous improvement and validation of carbon reduction claims.Expand Specific Solutions05 Novel materials and process innovations

Research into advanced materials and process innovations aims to significantly improve carbon capture efficiency. These developments include metal-organic frameworks (MOFs), specialized membranes, ionic liquids, and novel sorbents with enhanced CO2 selectivity and capacity. Process innovations focus on reducing energy requirements, improving regeneration cycles, and developing hybrid systems that combine multiple capture approaches. These materials and processes are designed to increase capture efficiency while reducing operational costs and energy consumption.Expand Specific Solutions

Major Industry Players in Carbon Capture Sector

Carbon capture technology is currently in a growth phase, with the market expected to expand significantly due to increasing climate change concerns and regulatory pressures. The global carbon capture market is projected to reach approximately $7-10 billion by 2030, growing at a CAGR of 15-20%. Technologically, the field shows varying maturity levels across different capture methods. Leading players like ExxonMobil Upstream Research and Schlumberger are advancing post-combustion technologies, while companies such as China Petroleum & Chemical Corp. and Huaneng Clean Energy Research Institute are making significant progress in industrial applications. Emerging players like Echeneidae Inc. are developing innovative mobile carbon capture solutions for transportation sectors. Academic institutions including Zhejiang University and Nanyang Technological University are contributing breakthrough research in novel materials and processes, indicating a dynamic competitive landscape with both established energy giants and specialized technology providers.

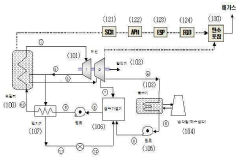

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed the GreenGen IGCC (Integrated Gasification Combined Cycle) with carbon capture technology, representing China's most advanced indigenous carbon capture system. Their approach utilizes a two-stage physical absorption process with proprietary solvents that can achieve CO2 capture rates exceeding 90% while maintaining energy penalties below 20% of plant output. The institute has successfully implemented this technology at the Huaneng Shanghai Shidongkou Power Plant, capturing approximately 120,000 tons of CO2 annually with a capture cost of approximately $40 per ton, significantly lower than global averages. Their research has focused on optimizing absorption-based capture systems specifically for coal-fired power plants, which represent a major emission source in China. The institute has also pioneered integration techniques that allow retrofitting existing power plants with minimal disruption to operations, enabling a phased approach to decarbonization of China's extensive coal power infrastructure.

Strengths: Specifically optimized for coal-fired power plants which remain prevalent in many developing economies; demonstrated cost-effectiveness compared to international benchmarks; proven retrofit capability for existing infrastructure. Weaknesses: Primary focus on coal power limits application in other industrial sectors; technology still faces challenges in further reducing energy penalties; economic viability depends partly on finding utilization pathways for captured CO2.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec (China Petroleum & Chemical Corp.) has developed an innovative carbon capture technology focusing on integrated CCUS (Carbon Capture, Utilization and Storage) systems. Their approach combines pre-combustion, post-combustion, and oxy-fuel combustion technologies tailored to different industrial applications. Sinopec's flagship Qilu-Shengli Oilfield CCUS project captures over 1 million tons of CO2 annually from petrochemical operations, which is then purified to 99% concentration and transported via pipeline for enhanced oil recovery (EOR). The company has also pioneered membrane separation technology that reduces energy consumption by approximately 35% compared to traditional amine scrubbing methods. Their proprietary solvent formulations demonstrate superior CO2 absorption capacity with lower regeneration energy requirements. Sinopec has implemented these technologies across multiple facilities in China, creating a comprehensive carbon capture network that spans from industrial sources to utilization and storage sites.

Strengths: Extensive practical implementation experience; integrated approach covering capture, transport, utilization and storage; proven scalability with million-ton level projects. Weaknesses: Heavy focus on EOR as utilization pathway may limit application in regions without suitable oil fields; technology optimization still ongoing for non-petrochemical industries; high initial capital requirements.

Key Carbon Capture Efficiency Innovations

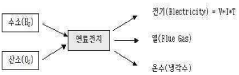

Carbon dioxide capture and storage system using heat pump and fuel cell

PatentInactiveKR1020140023113A

Innovation

- Utilizing an absorption heat pump driven by exhaust heat from a fuel cell power generation system to supply thermal energy to the regeneration tower, reducing the need for extracted steam and maintaining plant efficiency.

Gaseous co 2 capture systems for improving capture performace, and methods of use thereof

PatentWO2023056011A1

Innovation

- The development of gaseous CO2 capture systems that include a plurality of CO2 sources connected through a common capture constraining element, such as a shared CO2 capture liquid or mineralization system, to improve capture performance metrics like efficiency and cost-effectiveness, and utilize protocols like absorption, adsorption, and membrane transport.

Regulatory Framework and Policy Incentives

The regulatory landscape for carbon capture technologies has evolved significantly over the past decade, creating both opportunities and challenges for technology developers and adopters. At the international level, the Paris Agreement has established a framework encouraging nations to implement carbon reduction strategies, with carbon capture technologies playing a crucial role in meeting these commitments. This global momentum has catalyzed the development of national and regional regulatory frameworks specifically addressing carbon capture, utilization, and storage (CCUS).

In the United States, the 45Q tax credit has emerged as a cornerstone policy, offering up to $50 per metric ton of CO2 permanently sequestered and $35 per ton for CO2 used in enhanced oil recovery or other utilization pathways. The 2022 Inflation Reduction Act further expanded these incentives, increasing credit values and lowering capture thresholds, making projects more economically viable across various industrial sectors. Similarly, the European Union has implemented the Innovation Fund, allocating billions of euros to support demonstration projects for innovative low-carbon technologies, including advanced carbon capture systems.

Carbon pricing mechanisms represent another significant policy lever, with over 40 countries now implementing either carbon taxes or emissions trading systems. These mechanisms create economic incentives for emissions reduction while generating revenue that can be reinvested in climate technologies. The EU Emissions Trading System (ETS), for instance, has progressively increased carbon prices, improving the business case for carbon capture investments as conventional emissions become more costly.

Regulatory frameworks are increasingly addressing the full lifecycle of carbon capture projects, from technology deployment to long-term storage liability. Countries like Norway, Canada, and Australia have developed comprehensive regulatory regimes covering site selection, monitoring requirements, and post-closure responsibilities. These frameworks provide crucial certainty for project developers while ensuring environmental safeguards are maintained throughout the carbon capture value chain.

Despite these advances, significant regulatory gaps remain. The cross-border transport of captured CO2 faces complex jurisdictional challenges, particularly for international pipeline networks or shipping arrangements. Additionally, the regulatory treatment of novel utilization pathways—such as CO2-derived building materials or synthetic fuels—remains underdeveloped in many jurisdictions, creating uncertainty for emerging technology applications.

Looking forward, policy harmonization across regions will be essential to facilitate technology transfer and create economies of scale. The development of international standards for measuring, reporting, and verifying carbon capture performance will support both regulatory compliance and market-based incentive mechanisms, ultimately accelerating the efficiency improvements needed for widespread adoption.

In the United States, the 45Q tax credit has emerged as a cornerstone policy, offering up to $50 per metric ton of CO2 permanently sequestered and $35 per ton for CO2 used in enhanced oil recovery or other utilization pathways. The 2022 Inflation Reduction Act further expanded these incentives, increasing credit values and lowering capture thresholds, making projects more economically viable across various industrial sectors. Similarly, the European Union has implemented the Innovation Fund, allocating billions of euros to support demonstration projects for innovative low-carbon technologies, including advanced carbon capture systems.

Carbon pricing mechanisms represent another significant policy lever, with over 40 countries now implementing either carbon taxes or emissions trading systems. These mechanisms create economic incentives for emissions reduction while generating revenue that can be reinvested in climate technologies. The EU Emissions Trading System (ETS), for instance, has progressively increased carbon prices, improving the business case for carbon capture investments as conventional emissions become more costly.

Regulatory frameworks are increasingly addressing the full lifecycle of carbon capture projects, from technology deployment to long-term storage liability. Countries like Norway, Canada, and Australia have developed comprehensive regulatory regimes covering site selection, monitoring requirements, and post-closure responsibilities. These frameworks provide crucial certainty for project developers while ensuring environmental safeguards are maintained throughout the carbon capture value chain.

Despite these advances, significant regulatory gaps remain. The cross-border transport of captured CO2 faces complex jurisdictional challenges, particularly for international pipeline networks or shipping arrangements. Additionally, the regulatory treatment of novel utilization pathways—such as CO2-derived building materials or synthetic fuels—remains underdeveloped in many jurisdictions, creating uncertainty for emerging technology applications.

Looking forward, policy harmonization across regions will be essential to facilitate technology transfer and create economies of scale. The development of international standards for measuring, reporting, and verifying carbon capture performance will support both regulatory compliance and market-based incentive mechanisms, ultimately accelerating the efficiency improvements needed for widespread adoption.

Economic Viability and Cost-Benefit Analysis

The economic viability of carbon capture technologies remains a critical factor in their widespread adoption. Current cost estimates for carbon capture range from $40 to $120 per ton of CO2 captured, depending on the technology and implementation context. This significant cost variance highlights the importance of comprehensive economic analysis when evaluating potential deployments.

Investment requirements for carbon capture projects are substantial, with capital expenditures for large-scale installations often exceeding $500 million. Operating costs add another layer of financial burden, typically representing 3-7% of capital costs annually. These financial demands create significant barriers to entry, particularly for smaller organizations or developing economies.

Cost-benefit analyses reveal that carbon capture technologies become economically viable under specific conditions. Carbon pricing mechanisms exceeding $50-60 per ton create favorable economics for many capture technologies. Additionally, tax incentives like the 45Q tax credit in the United States, which offers up to $50 per ton for sequestered carbon, significantly improve project economics.

The economic equation is further complicated by potential revenue streams from captured carbon. Enhanced oil recovery applications can generate $20-40 per ton of CO2, while emerging markets for carbon utilization in building materials or synthetic fuels offer promising but still developing revenue opportunities. These potential income sources must be factored into comprehensive economic assessments.

Sensitivity analyses demonstrate that energy costs represent the most significant variable affecting economic viability. Technologies requiring less energy input per ton of carbon captured show more favorable economics across various deployment scenarios. This highlights the importance of continued research into energy-efficient capture methods.

Long-term economic projections suggest that carbon capture costs could decrease by 25-40% over the next decade through technological improvements and economies of scale. This cost reduction trajectory is critical for broader implementation without heavy reliance on policy support mechanisms.

Return on investment timelines currently range from 8-15 years for most carbon capture projects, exceeding typical corporate investment thresholds. This extended payback period necessitates innovative financing mechanisms, including public-private partnerships and green bonds, to bridge the economic gap until technology costs decrease further.

Investment requirements for carbon capture projects are substantial, with capital expenditures for large-scale installations often exceeding $500 million. Operating costs add another layer of financial burden, typically representing 3-7% of capital costs annually. These financial demands create significant barriers to entry, particularly for smaller organizations or developing economies.

Cost-benefit analyses reveal that carbon capture technologies become economically viable under specific conditions. Carbon pricing mechanisms exceeding $50-60 per ton create favorable economics for many capture technologies. Additionally, tax incentives like the 45Q tax credit in the United States, which offers up to $50 per ton for sequestered carbon, significantly improve project economics.

The economic equation is further complicated by potential revenue streams from captured carbon. Enhanced oil recovery applications can generate $20-40 per ton of CO2, while emerging markets for carbon utilization in building materials or synthetic fuels offer promising but still developing revenue opportunities. These potential income sources must be factored into comprehensive economic assessments.

Sensitivity analyses demonstrate that energy costs represent the most significant variable affecting economic viability. Technologies requiring less energy input per ton of carbon captured show more favorable economics across various deployment scenarios. This highlights the importance of continued research into energy-efficient capture methods.

Long-term economic projections suggest that carbon capture costs could decrease by 25-40% over the next decade through technological improvements and economies of scale. This cost reduction trajectory is critical for broader implementation without heavy reliance on policy support mechanisms.

Return on investment timelines currently range from 8-15 years for most carbon capture projects, exceeding typical corporate investment thresholds. This extended payback period necessitates innovative financing mechanisms, including public-private partnerships and green bonds, to bridge the economic gap until technology costs decrease further.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!