Carbon Capture Technologies Strategies in the Automotive Field

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive Carbon Capture Background and Objectives

Carbon capture technologies in the automotive sector have evolved significantly over the past decades, transitioning from theoretical concepts to practical applications aimed at reducing the industry's substantial carbon footprint. The automotive sector contributes approximately 15-20% of global CO2 emissions, making it a critical focus area for carbon reduction strategies. Initially, carbon capture efforts in vehicles were limited to improving fuel efficiency and reducing tailpipe emissions through catalytic converters and particulate filters.

The evolution of automotive carbon capture technologies has been accelerated by increasingly stringent global emissions regulations, including the European Union's Euro 7 standards, California's Zero Emission Vehicle (ZEV) program, and various national commitments under the Paris Agreement. These regulatory frameworks have established clear trajectories for emissions reduction, creating both compliance necessities and innovation opportunities within the automotive industry.

Current technological approaches to carbon capture in vehicles can be categorized into three main streams: direct air capture systems integrated into vehicles, exhaust gas recirculation with carbon capture capabilities, and the development of carbon-neutral synthetic fuels. Each approach represents different levels of technological maturity and implementation feasibility, with varying potential for immediate versus long-term impact on emissions reduction.

The primary objective of automotive carbon capture technologies is to achieve significant reduction in net carbon emissions while maintaining or enhancing vehicle performance and user experience. Specifically, the industry aims to develop systems capable of capturing at least 80% of carbon emissions from internal combustion engines, with captured carbon either stored for later processing or immediately converted into less harmful compounds.

Secondary objectives include developing economically viable solutions that add minimal cost to vehicle production, ensuring minimal impact on vehicle weight and space requirements, and creating systems that require little to no additional maintenance from vehicle owners. These practical considerations are essential for widespread adoption and real-world effectiveness of carbon capture technologies in the automotive sector.

Looking forward, the technological roadmap for automotive carbon capture includes near-term goals of prototype demonstration in commercial vehicles by 2025, mid-term goals of limited production implementation by 2030, and long-term goals of industry-wide adoption across multiple vehicle categories by 2040. This timeline aligns with broader industry commitments to achieve carbon neutrality by mid-century.

The evolution of automotive carbon capture technologies has been accelerated by increasingly stringent global emissions regulations, including the European Union's Euro 7 standards, California's Zero Emission Vehicle (ZEV) program, and various national commitments under the Paris Agreement. These regulatory frameworks have established clear trajectories for emissions reduction, creating both compliance necessities and innovation opportunities within the automotive industry.

Current technological approaches to carbon capture in vehicles can be categorized into three main streams: direct air capture systems integrated into vehicles, exhaust gas recirculation with carbon capture capabilities, and the development of carbon-neutral synthetic fuels. Each approach represents different levels of technological maturity and implementation feasibility, with varying potential for immediate versus long-term impact on emissions reduction.

The primary objective of automotive carbon capture technologies is to achieve significant reduction in net carbon emissions while maintaining or enhancing vehicle performance and user experience. Specifically, the industry aims to develop systems capable of capturing at least 80% of carbon emissions from internal combustion engines, with captured carbon either stored for later processing or immediately converted into less harmful compounds.

Secondary objectives include developing economically viable solutions that add minimal cost to vehicle production, ensuring minimal impact on vehicle weight and space requirements, and creating systems that require little to no additional maintenance from vehicle owners. These practical considerations are essential for widespread adoption and real-world effectiveness of carbon capture technologies in the automotive sector.

Looking forward, the technological roadmap for automotive carbon capture includes near-term goals of prototype demonstration in commercial vehicles by 2025, mid-term goals of limited production implementation by 2030, and long-term goals of industry-wide adoption across multiple vehicle categories by 2040. This timeline aligns with broader industry commitments to achieve carbon neutrality by mid-century.

Market Demand Analysis for Vehicle Emission Reduction

The global automotive industry is experiencing unprecedented pressure to reduce carbon emissions due to increasingly stringent environmental regulations worldwide. The European Union's target to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels represents one of the most aggressive regulatory frameworks. Similarly, China has implemented its dual-credit policy system that rewards manufacturers for producing low-emission vehicles, while the United States has reinstated stricter fuel economy standards targeting 55 mpg for passenger cars by 2026.

Market research indicates that consumer awareness regarding environmental issues has significantly increased, with 67% of global consumers now considering a vehicle's environmental impact during purchasing decisions. This shift in consumer preference has created a growing demand segment for low-emission and zero-emission vehicles, expanding beyond early adopters to mainstream consumers.

The commercial vehicle sector also demonstrates substantial demand for emission reduction technologies. Fleet operators face mounting pressure from both regulatory requirements and corporate sustainability goals, creating a significant market for retrofitting existing vehicles with emission reduction systems and transitioning to cleaner propulsion technologies.

Economic factors further drive market demand, as fuel efficiency directly impacts operational costs. The total cost of ownership calculations increasingly favor vehicles with advanced emission reduction technologies despite higher initial purchase prices. Government incentives, including tax benefits, subsidies, and preferential access policies for low-emission vehicles, have created additional market pull factors across different regions.

Industry analysis reveals that the global market for automotive emission control systems was valued at approximately $92 billion in 2022 and is projected to grow at a compound annual growth rate of 8.3% through 2030. Carbon capture technologies specifically represent an emerging segment within this broader market, with particular growth potential in commercial transportation and premium vehicle segments.

The aftermarket for emission reduction technologies presents another significant opportunity, especially for solutions that can be retrofitted to existing vehicle fleets. This segment is particularly important in regions with aging vehicle populations where complete fleet replacement is economically unfeasible.

Market forecasts suggest that as regulatory pressures intensify and technology costs decrease through economies of scale, demand for advanced emission reduction technologies, including carbon capture systems, will accelerate across all vehicle segments. The premium automotive segment is expected to lead adoption, followed by commercial vehicles where operational cost benefits can offset implementation expenses.

Market research indicates that consumer awareness regarding environmental issues has significantly increased, with 67% of global consumers now considering a vehicle's environmental impact during purchasing decisions. This shift in consumer preference has created a growing demand segment for low-emission and zero-emission vehicles, expanding beyond early adopters to mainstream consumers.

The commercial vehicle sector also demonstrates substantial demand for emission reduction technologies. Fleet operators face mounting pressure from both regulatory requirements and corporate sustainability goals, creating a significant market for retrofitting existing vehicles with emission reduction systems and transitioning to cleaner propulsion technologies.

Economic factors further drive market demand, as fuel efficiency directly impacts operational costs. The total cost of ownership calculations increasingly favor vehicles with advanced emission reduction technologies despite higher initial purchase prices. Government incentives, including tax benefits, subsidies, and preferential access policies for low-emission vehicles, have created additional market pull factors across different regions.

Industry analysis reveals that the global market for automotive emission control systems was valued at approximately $92 billion in 2022 and is projected to grow at a compound annual growth rate of 8.3% through 2030. Carbon capture technologies specifically represent an emerging segment within this broader market, with particular growth potential in commercial transportation and premium vehicle segments.

The aftermarket for emission reduction technologies presents another significant opportunity, especially for solutions that can be retrofitted to existing vehicle fleets. This segment is particularly important in regions with aging vehicle populations where complete fleet replacement is economically unfeasible.

Market forecasts suggest that as regulatory pressures intensify and technology costs decrease through economies of scale, demand for advanced emission reduction technologies, including carbon capture systems, will accelerate across all vehicle segments. The premium automotive segment is expected to lead adoption, followed by commercial vehicles where operational cost benefits can offset implementation expenses.

Current Carbon Capture Technologies and Challenges in Automotive

Carbon capture technologies in the automotive sector currently fall into three main categories: direct air capture (DAC), onboard carbon capture systems, and infrastructure-based solutions. DAC technologies extract CO2 directly from ambient air through chemical processes, with companies like Climeworks and Carbon Engineering leading development. However, these systems remain energy-intensive and costly, with current capture costs ranging from $250-600 per ton of CO2, significantly higher than the $50-100 target needed for widespread adoption.

Onboard carbon capture systems represent an emerging approach specifically designed for vehicles. These systems typically utilize specialized filters or absorbent materials integrated into the exhaust system to trap CO2 emissions before they enter the atmosphere. Mercedes-Benz has demonstrated prototype vehicles with onboard capture capabilities, while Toyota and Porsche are exploring similar technologies. The primary challenge lies in developing systems compact enough for vehicle integration while maintaining sufficient capture efficiency.

Weight considerations present a significant obstacle for automotive carbon capture. Current systems add approximately 50-200kg to vehicle weight, negatively impacting fuel efficiency and potentially offsetting carbon reduction benefits. Additionally, the captured carbon requires periodic removal and processing, necessitating new infrastructure development alongside existing fueling networks.

Energy requirements pose another substantial challenge. Most capture technologies demand significant energy input, which can reduce overall vehicle efficiency. For electric vehicles, this translates to reduced range; for combustion engines, it means increased fuel consumption. Research indicates that current systems can increase energy consumption by 10-25%, depending on the capture efficiency targeted.

Scalability and cost barriers remain formidable. Manufacturing carbon capture systems at automotive production scales requires substantial investment in new production facilities and supply chains. Current prototype systems add approximately $3,000-8,000 to vehicle costs, representing a significant price premium that most consumers are unwilling to accept without regulatory incentives or carbon pricing mechanisms.

Regulatory frameworks for automotive carbon capture remain underdeveloped globally. While the European Union has begun exploring standards for measuring and crediting captured carbon in transportation, most regions lack clear policies for incentivizing or mandating such technologies. This regulatory uncertainty hampers investment and standardization efforts necessary for widespread implementation.

Onboard carbon capture systems represent an emerging approach specifically designed for vehicles. These systems typically utilize specialized filters or absorbent materials integrated into the exhaust system to trap CO2 emissions before they enter the atmosphere. Mercedes-Benz has demonstrated prototype vehicles with onboard capture capabilities, while Toyota and Porsche are exploring similar technologies. The primary challenge lies in developing systems compact enough for vehicle integration while maintaining sufficient capture efficiency.

Weight considerations present a significant obstacle for automotive carbon capture. Current systems add approximately 50-200kg to vehicle weight, negatively impacting fuel efficiency and potentially offsetting carbon reduction benefits. Additionally, the captured carbon requires periodic removal and processing, necessitating new infrastructure development alongside existing fueling networks.

Energy requirements pose another substantial challenge. Most capture technologies demand significant energy input, which can reduce overall vehicle efficiency. For electric vehicles, this translates to reduced range; for combustion engines, it means increased fuel consumption. Research indicates that current systems can increase energy consumption by 10-25%, depending on the capture efficiency targeted.

Scalability and cost barriers remain formidable. Manufacturing carbon capture systems at automotive production scales requires substantial investment in new production facilities and supply chains. Current prototype systems add approximately $3,000-8,000 to vehicle costs, representing a significant price premium that most consumers are unwilling to accept without regulatory incentives or carbon pricing mechanisms.

Regulatory frameworks for automotive carbon capture remain underdeveloped globally. While the European Union has begun exploring standards for measuring and crediting captured carbon in transportation, most regions lack clear policies for incentivizing or mandating such technologies. This regulatory uncertainty hampers investment and standardization efforts necessary for widespread implementation.

Existing Carbon Capture Implementation Strategies for Vehicles

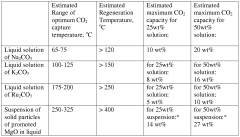

01 Chemical absorption methods for carbon capture

Chemical absorption is a widely used method for capturing carbon dioxide from various sources. This approach involves the use of solvents, typically amine-based compounds, that selectively bind to CO2 molecules. The process generally consists of an absorption phase where CO2 is captured by the solvent and a regeneration phase where the CO2 is released and the solvent is recycled. These systems can be integrated with power plants and industrial facilities to reduce carbon emissions. Advancements in solvent formulations have improved efficiency and reduced the energy requirements of the capture process.- Chemical absorption methods for carbon capture: Chemical absorption is a widely used method for capturing carbon dioxide from various emission sources. This approach involves the use of solvents, typically amine-based compounds, that selectively bind to CO2 molecules. The process generally consists of an absorption phase where CO2 is captured by the solvent and a regeneration phase where the CO2 is released and the solvent is recycled. This technology is particularly effective for high-concentration CO2 streams and can achieve high capture rates, making it suitable for industrial applications.

- Direct air capture technologies: Direct air capture (DAC) technologies are designed to extract carbon dioxide directly from ambient air, regardless of the emission source. These systems typically use specialized sorbents or solutions that can selectively capture CO2 even at the low concentrations found in the atmosphere. After capture, the CO2 can be released through heating or other regeneration processes, then compressed and stored or utilized. DAC technologies are particularly valuable for addressing distributed emissions and potentially achieving negative emissions by removing historical CO2 from the atmosphere.

- Membrane-based carbon capture systems: Membrane-based carbon capture systems utilize selective permeable barriers that allow CO2 molecules to pass through while blocking other gases. These membranes can be made from various materials including polymers, ceramics, or composite materials, each offering different selectivity and permeability characteristics. The driving force for separation is typically a pressure or concentration gradient across the membrane. This technology offers advantages such as lower energy requirements, compact design, and continuous operation without regeneration cycles, making it suitable for both industrial applications and smaller-scale implementations.

- Biological carbon capture methods: Biological carbon capture methods leverage natural biological processes to remove CO2 from the atmosphere or emission sources. These approaches include engineered microalgae systems, enhanced forest management, biochar production, and microbial conversion of CO2 into valuable products. Biological systems can offer cost-effective carbon capture while simultaneously providing additional benefits such as biofuel production, soil improvement, or ecosystem restoration. These methods often require less energy than mechanical approaches and can be integrated into existing agricultural or industrial processes.

- Mineralization and geological storage of captured carbon: Mineralization and geological storage involve the conversion of captured CO2 into stable mineral forms or its injection into suitable geological formations for long-term sequestration. In mineralization, CO2 reacts with metal oxides to form stable carbonate minerals, effectively locking the carbon in solid form indefinitely. Geological storage involves injecting compressed CO2 into deep underground formations such as depleted oil and gas reservoirs, saline aquifers, or unminable coal seams. These approaches offer permanent or very long-term carbon storage solutions, addressing concerns about the durability of carbon removal efforts.

02 Direct air capture technologies

Direct air capture (DAC) technologies are designed to extract carbon dioxide directly from ambient air rather than from point sources like power plant emissions. These systems typically use specialized sorbents or solutions that can selectively capture CO2 even at the low concentrations found in the atmosphere. After capture, the CO2 can be released through heating or other processes, then compressed and stored or utilized. DAC technologies are particularly valuable for addressing distributed emissions sources and potentially achieving negative emissions by removing historical CO2 from the atmosphere.Expand Specific Solutions03 Membrane-based carbon capture systems

Membrane-based carbon capture systems utilize selective permeable barriers that allow CO2 to pass through while blocking other gases. These membranes can be made from various materials including polymers, ceramics, or composite structures with specifically engineered pore sizes and surface properties. The separation occurs due to differences in diffusion rates or solubility of different gases in the membrane material. Membrane systems offer advantages such as continuous operation, compact design, and potentially lower energy requirements compared to some other capture methods. Recent innovations have focused on improving membrane selectivity, permeability, and durability under industrial conditions.Expand Specific Solutions04 Cryogenic carbon capture processes

Cryogenic carbon capture involves cooling gas streams to very low temperatures where CO2 desublimates (transitions directly from gas to solid) and can be physically separated from other gases. This approach can achieve high capture rates and produce high-purity CO2 suitable for storage or utilization. The process typically involves multiple cooling stages and heat exchangers to improve energy efficiency. While cryogenic methods require significant refrigeration energy, they can be particularly effective for high-concentration CO2 streams and can operate without chemical solvents. Recent developments have focused on reducing the energy penalties associated with the extreme cooling requirements.Expand Specific Solutions05 Biological and nature-based carbon capture solutions

Biological and nature-based carbon capture solutions leverage natural processes to remove CO2 from the atmosphere. These approaches include engineered systems using microalgae, bacteria, or enzymes that can fix carbon through photosynthesis or other metabolic pathways. Some technologies enhance natural carbon sinks like forests, wetlands, or ocean systems. Bioreactors can be designed to optimize conditions for biological carbon fixation, while biomimetic systems may incorporate biological principles into synthetic capture mechanisms. These methods often offer co-benefits such as producing valuable biomass or improving ecosystem services alongside carbon sequestration.Expand Specific Solutions

Leading Automotive and Carbon Capture Technology Companies

Carbon capture technologies in the automotive sector are in an early growth phase, with market size expected to expand significantly as regulatory pressures increase. The technology maturity varies across different approaches, with major players demonstrating diverse capabilities. Saudi Aramco and Sinopec are leveraging their energy expertise to develop integrated carbon capture solutions, while automotive manufacturers like Stellantis are exploring vehicle-specific implementations. Research institutions including Dalian University of Technology, Politecnico di Milano, and Georgia Tech are advancing fundamental technologies. Innovative startups such as CocoonCarbon and Echeneidae are developing specialized mobile carbon capture systems specifically for transportation applications. The competitive landscape reflects a blend of established energy companies, automotive manufacturers, academic institutions, and emerging technology providers working to address emissions challenges.

Saudi Arabian Oil Co.

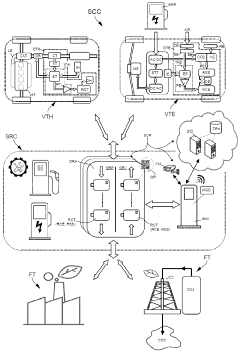

Technical Solution: Saudi Aramco has developed an advanced Mobile Carbon Capture (MCC) technology specifically designed for automotive applications. Their system integrates directly with internal combustion engines to capture CO2 from exhaust gases before emission. The technology employs a two-stage capture process: first using a specialized solvent-based system that operates efficiently at the high temperatures found in vehicle exhaust systems, followed by a compression and storage mechanism that temporarily holds the captured carbon onboard. According to their published research, the system can capture approximately 25-30% of vehicle carbon emissions while adding only about 5-8% to the vehicle's weight. Saudi Aramco has conducted extensive field testing with major automotive manufacturers, demonstrating the technology's durability under various driving conditions and its compatibility with existing vehicle designs. Their solution also includes an infrastructure component for the periodic offloading of captured carbon at service stations, where it can be further processed for permanent storage or utilization. The company has additionally developed integration pathways for hybrid vehicles that optimize the capture system's operation based on driving mode.

Strengths: Relatively high capture efficiency for a mobile system; designed for integration with existing vehicle platforms without major redesign; comprehensive solution including offloading infrastructure. Weaknesses: Additional weight impacts overall fuel efficiency; requires regular access to specialized offloading facilities; limited storage capacity necessitates frequent offloading.

Aramco Services Co.

Technical Solution: Aramco Services has developed Mobile Carbon Capture and Storage (MCCS) technology specifically designed for automotive applications. Their system captures CO2 directly from vehicle exhaust gases using a proprietary chemical absorption process with specialized amine-based solvents that can withstand high temperatures and vibration conditions found in vehicles. The captured CO2 is then compressed and stored in specially designed onboard tanks. Their latest generation system achieves capture rates of up to 40% of vehicle emissions while adding only approximately 7-10% to vehicle weight. Aramco has conducted extensive road tests with major automotive manufacturers, demonstrating the technology's viability in real-world conditions. The company has also developed an infrastructure solution for offloading captured carbon at refueling stations, where it can be further processed for underground storage or utilization in industrial processes. Their technology roadmap includes integration with hydrogen fuel cell vehicles, where carbon capture can help offset emissions from hydrogen production.

Strengths: High capture efficiency compared to other mobile solutions; comprehensive end-to-end system including offloading infrastructure; applicable to conventional internal combustion engines without major redesigns. Weaknesses: Additional weight impacts fuel efficiency; requires regular offloading infrastructure; storage capacity limitations for long-distance driving.

Key Carbon Capture Patents and Innovations for Automotive Applications

?n-board recovery and storage of c02 from motor vehicle exhaust gases

PatentWO2012100165A1

Innovation

- A system for on-board CO2 capture and storage using a treatment zone with a capture agent, heat exchanger, compression zone, and storage zone, leveraging waste heat for regeneration and densification of CO2, which reduces the volume and cost of storage.

System for capturing and collecting the co2 in a number of motor vehicles

PatentWO2024089321A1

Innovation

- A CO2 capture and collection system for a rolling vehicle fleet, comprising on-board devices that capture, process, and store CO2 as a supercritical fluid in compact, removable tanks, which are then replaced at collection stations, along with an inverted fuel cell for producing synthetic fuel from captured CO2 and hydrogen, and a system for managing and monitoring storage tanks and user accounts.

Regulatory Framework and Emission Standards Impact

The automotive industry faces increasingly stringent regulatory frameworks worldwide, with emission standards becoming a primary driver for carbon capture technology adoption. The European Union's Euro 7 standards, expected to be implemented by 2025, will significantly reduce allowable CO2 and NOx emissions, forcing manufacturers to integrate advanced carbon capture solutions. Similarly, the United States EPA has established Corporate Average Fuel Economy (CAFE) standards that progressively lower fleet-wide emission targets, with penalties for non-compliance increasing annually.

China, the world's largest automotive market, has implemented its China VI emission standards, comparable to Euro 6 regulations but with stricter implementation timelines. These regulations have accelerated research and development in carbon capture technologies across the automotive supply chain, with manufacturers allocating substantial budgets to compliance strategies.

The regulatory landscape has created a tiered approach to carbon reduction, with immediate compliance measures focusing on engine efficiency and exhaust treatment, while medium-term strategies explore direct air capture systems integrated into vehicle designs. The Paris Agreement's commitment to limit global warming to well below 2°C has further influenced national policies, with several countries announcing future bans on internal combustion engines, creating clear timelines for industry transformation.

Financial incentives have emerged as powerful regulatory tools, with tax credits for low-emission vehicles in the United States (e.g., the Inflation Reduction Act providing up to $7,500 for qualifying electric vehicles) and similar schemes in the EU and Asia. These incentives have created market advantages for early adopters of carbon capture technologies, influencing consumer behavior and manufacturer priorities.

Regulatory frameworks have also begun addressing lifecycle emissions, with the EU's proposed Carbon Border Adjustment Mechanism potentially affecting automotive supply chains by imposing carbon pricing on imports. This holistic approach to emissions accounting is pushing manufacturers to consider carbon capture not only in vehicle operation but throughout production processes.

The interplay between regulations and technological development has created a feedback loop, where compliance requirements drive innovation, which in turn informs future regulatory standards. Industry stakeholders increasingly participate in regulatory development through technical working groups and standards committees, ensuring that emission targets remain ambitious yet technically achievable within implementation timeframes.

China, the world's largest automotive market, has implemented its China VI emission standards, comparable to Euro 6 regulations but with stricter implementation timelines. These regulations have accelerated research and development in carbon capture technologies across the automotive supply chain, with manufacturers allocating substantial budgets to compliance strategies.

The regulatory landscape has created a tiered approach to carbon reduction, with immediate compliance measures focusing on engine efficiency and exhaust treatment, while medium-term strategies explore direct air capture systems integrated into vehicle designs. The Paris Agreement's commitment to limit global warming to well below 2°C has further influenced national policies, with several countries announcing future bans on internal combustion engines, creating clear timelines for industry transformation.

Financial incentives have emerged as powerful regulatory tools, with tax credits for low-emission vehicles in the United States (e.g., the Inflation Reduction Act providing up to $7,500 for qualifying electric vehicles) and similar schemes in the EU and Asia. These incentives have created market advantages for early adopters of carbon capture technologies, influencing consumer behavior and manufacturer priorities.

Regulatory frameworks have also begun addressing lifecycle emissions, with the EU's proposed Carbon Border Adjustment Mechanism potentially affecting automotive supply chains by imposing carbon pricing on imports. This holistic approach to emissions accounting is pushing manufacturers to consider carbon capture not only in vehicle operation but throughout production processes.

The interplay between regulations and technological development has created a feedback loop, where compliance requirements drive innovation, which in turn informs future regulatory standards. Industry stakeholders increasingly participate in regulatory development through technical working groups and standards committees, ensuring that emission targets remain ambitious yet technically achievable within implementation timeframes.

Economic Viability and Scalability Assessment

The economic viability of carbon capture technologies in the automotive sector hinges on several critical factors that determine both short-term feasibility and long-term sustainability. Current cost analyses indicate that direct air capture (DAC) technologies range from $250-600 per ton of CO2 captured, while point-source carbon capture at vehicle manufacturing facilities averages $58-120 per ton. These costs remain significantly higher than the current carbon market prices, creating a substantial economic barrier to widespread adoption.

Investment requirements for implementing carbon capture systems vary considerably across different automotive manufacturing scales. Large manufacturers face initial capital expenditures of $25-100 million for comprehensive factory-based systems, while smaller operations implementing targeted solutions might invest $5-15 million. The return on investment timeline typically extends beyond 7-10 years under current market conditions, challenging traditional business models that prioritize shorter payback periods.

Scalability presents another critical dimension for assessment. Current carbon capture technologies deployed in automotive applications demonstrate limited capacity, with most systems processing 5,000-50,000 tons of CO2 annually. This represents only 2-15% of a typical automotive manufacturing facility's total emissions, highlighting significant scaling challenges. Technical scalability issues include space requirements for capture equipment, energy intensity of operations, and integration complexities with existing manufacturing processes.

Economic incentives significantly influence viability trajectories. Carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the US offering $50-85 per ton for captured carbon), and regulatory compliance requirements are reshaping the financial equation. Markets with established carbon pricing above $75 per ton show accelerated adoption rates, suggesting a threshold price point for economic viability.

Supply chain considerations further complicate the economic assessment. The specialized materials required for carbon capture systems (particularly advanced sorbents and membranes) face supply constraints that could impede rapid scaling. Additionally, the downstream infrastructure for carbon transport, utilization, and storage remains underdeveloped in many regions, creating potential bottlenecks that increase overall system costs.

Future cost reduction pathways appear promising but uncertain. Technology learning curves suggest potential cost decreases of 12-25% with each doubling of deployed capacity. Material innovations, particularly in sorbent efficiency and durability, could drive capture costs below $100 per ton by 2030 according to industry projections. However, these improvements depend on sustained R&D investment and supportive policy frameworks that may vary significantly across global markets.

Investment requirements for implementing carbon capture systems vary considerably across different automotive manufacturing scales. Large manufacturers face initial capital expenditures of $25-100 million for comprehensive factory-based systems, while smaller operations implementing targeted solutions might invest $5-15 million. The return on investment timeline typically extends beyond 7-10 years under current market conditions, challenging traditional business models that prioritize shorter payback periods.

Scalability presents another critical dimension for assessment. Current carbon capture technologies deployed in automotive applications demonstrate limited capacity, with most systems processing 5,000-50,000 tons of CO2 annually. This represents only 2-15% of a typical automotive manufacturing facility's total emissions, highlighting significant scaling challenges. Technical scalability issues include space requirements for capture equipment, energy intensity of operations, and integration complexities with existing manufacturing processes.

Economic incentives significantly influence viability trajectories. Carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the US offering $50-85 per ton for captured carbon), and regulatory compliance requirements are reshaping the financial equation. Markets with established carbon pricing above $75 per ton show accelerated adoption rates, suggesting a threshold price point for economic viability.

Supply chain considerations further complicate the economic assessment. The specialized materials required for carbon capture systems (particularly advanced sorbents and membranes) face supply constraints that could impede rapid scaling. Additionally, the downstream infrastructure for carbon transport, utilization, and storage remains underdeveloped in many regions, creating potential bottlenecks that increase overall system costs.

Future cost reduction pathways appear promising but uncertain. Technology learning curves suggest potential cost decreases of 12-25% with each doubling of deployed capacity. Material innovations, particularly in sorbent efficiency and durability, could drive capture costs below $100 per ton by 2030 according to industry projections. However, these improvements depend on sustained R&D investment and supportive policy frameworks that may vary significantly across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!