Evaluating Thermal Stability in Carbon Capture Technology Materials

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Thermal Stability Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical implementations across various industrial sectors. The thermal stability of materials used in carbon capture systems represents a critical factor in determining both the efficiency and economic viability of these technologies. Historically, carbon capture methods have progressed through three distinct generations: first-generation amine-based absorption systems, second-generation advanced solvents and solid sorbents, and the current third-generation materials including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and specialized membrane technologies.

The thermal degradation of carbon capture materials presents a significant challenge, particularly in industrial applications where flue gas temperatures can exceed 100°C. Research indicates that many promising materials exhibit performance deterioration when exposed to elevated temperatures over extended periods, resulting in reduced CO2 selectivity and capacity. This degradation pathway has been identified as one of the primary barriers to widespread commercial adoption of advanced carbon capture technologies.

Current global efforts to reduce carbon emissions have accelerated research into thermally stable materials, with significant advancements emerging from research institutions in North America, Europe, and East Asia. The Paris Agreement's ambitious targets have further intensified the focus on developing carbon capture technologies capable of operating efficiently under real-world industrial conditions, where thermal stability is paramount.

The primary objective of this technical research is to comprehensively evaluate the thermal stability characteristics of current and emerging carbon capture materials. Specifically, we aim to identify materials that maintain structural integrity and adsorption capacity at temperatures ranging from 100°C to 400°C, which represents the typical operating range for post-combustion carbon capture systems in power plants and industrial facilities.

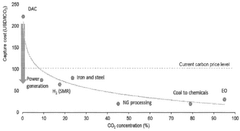

Secondary objectives include establishing standardized testing protocols for thermal stability assessment, developing predictive models for long-term thermal performance, and identifying potential modification strategies to enhance the thermal resilience of promising materials. These objectives align with the broader industry goal of reducing carbon capture costs below $40 per ton of CO2 by 2030, a threshold widely considered necessary for commercial viability.

The technological trajectory suggests that hybrid materials combining the advantages of different capture mechanisms may offer the most promising path forward. Recent breakthroughs in computational materials science have enabled more accurate prediction of thermal behavior, potentially accelerating the development cycle for next-generation carbon capture materials with superior thermal stability profiles.

The thermal degradation of carbon capture materials presents a significant challenge, particularly in industrial applications where flue gas temperatures can exceed 100°C. Research indicates that many promising materials exhibit performance deterioration when exposed to elevated temperatures over extended periods, resulting in reduced CO2 selectivity and capacity. This degradation pathway has been identified as one of the primary barriers to widespread commercial adoption of advanced carbon capture technologies.

Current global efforts to reduce carbon emissions have accelerated research into thermally stable materials, with significant advancements emerging from research institutions in North America, Europe, and East Asia. The Paris Agreement's ambitious targets have further intensified the focus on developing carbon capture technologies capable of operating efficiently under real-world industrial conditions, where thermal stability is paramount.

The primary objective of this technical research is to comprehensively evaluate the thermal stability characteristics of current and emerging carbon capture materials. Specifically, we aim to identify materials that maintain structural integrity and adsorption capacity at temperatures ranging from 100°C to 400°C, which represents the typical operating range for post-combustion carbon capture systems in power plants and industrial facilities.

Secondary objectives include establishing standardized testing protocols for thermal stability assessment, developing predictive models for long-term thermal performance, and identifying potential modification strategies to enhance the thermal resilience of promising materials. These objectives align with the broader industry goal of reducing carbon capture costs below $40 per ton of CO2 by 2030, a threshold widely considered necessary for commercial viability.

The technological trajectory suggests that hybrid materials combining the advantages of different capture mechanisms may offer the most promising path forward. Recent breakthroughs in computational materials science have enabled more accurate prediction of thermal behavior, potentially accelerating the development cycle for next-generation carbon capture materials with superior thermal stability profiles.

Market Analysis for Thermally Stable Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture technology sector at approximately 2.2 billion USD in 2023, with projections indicating growth to reach 7.0 billion USD by 2030, representing a compound annual growth rate of 17.8%. This growth trajectory is particularly pronounced in regions with stringent carbon emission policies, including the European Union, North America, and increasingly, parts of Asia.

Demand for thermally stable carbon capture materials is emerging as a critical market segment. Industrial processes that operate at elevated temperatures—such as cement production, steel manufacturing, and power generation—collectively account for over 40% of global carbon emissions. These industries require carbon capture solutions that can maintain structural integrity and performance under thermal stress conditions ranging from 200°C to 800°C.

Market research indicates that end-users are willing to pay premium prices for carbon capture materials with superior thermal stability, as these materials significantly reduce replacement frequency and system downtime. A recent industry survey revealed that 78% of industrial operators ranked thermal durability as a "very important" or "critical" factor in their carbon capture technology purchasing decisions.

Geographically, the market for thermally stable carbon capture solutions shows distinct regional characteristics. North America leads in adoption, particularly in the natural gas processing sector, while Europe demonstrates strongest growth in cement and steel industry applications. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 20%, driven by rapid industrialization coupled with new environmental regulations.

Investment patterns further validate market potential, with venture capital funding for startups focused on thermally stable carbon capture materials increasing by 156% between 2020 and 2023. Major chemical and materials science companies have also accelerated R&D spending in this domain, with an estimated 1.5 billion USD allocated to thermal stability research in carbon capture materials during 2023 alone.

Customer segmentation analysis reveals three primary market tiers: large industrial operators seeking integrated solutions, medium-sized manufacturers requiring modular systems, and specialized high-temperature process industries demanding custom-engineered materials. The highest profit margins currently exist in the specialized high-temperature segment, where customers demonstrate less price sensitivity due to limited alternative options.

Demand for thermally stable carbon capture materials is emerging as a critical market segment. Industrial processes that operate at elevated temperatures—such as cement production, steel manufacturing, and power generation—collectively account for over 40% of global carbon emissions. These industries require carbon capture solutions that can maintain structural integrity and performance under thermal stress conditions ranging from 200°C to 800°C.

Market research indicates that end-users are willing to pay premium prices for carbon capture materials with superior thermal stability, as these materials significantly reduce replacement frequency and system downtime. A recent industry survey revealed that 78% of industrial operators ranked thermal durability as a "very important" or "critical" factor in their carbon capture technology purchasing decisions.

Geographically, the market for thermally stable carbon capture solutions shows distinct regional characteristics. North America leads in adoption, particularly in the natural gas processing sector, while Europe demonstrates strongest growth in cement and steel industry applications. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 20%, driven by rapid industrialization coupled with new environmental regulations.

Investment patterns further validate market potential, with venture capital funding for startups focused on thermally stable carbon capture materials increasing by 156% between 2020 and 2023. Major chemical and materials science companies have also accelerated R&D spending in this domain, with an estimated 1.5 billion USD allocated to thermal stability research in carbon capture materials during 2023 alone.

Customer segmentation analysis reveals three primary market tiers: large industrial operators seeking integrated solutions, medium-sized manufacturers requiring modular systems, and specialized high-temperature process industries demanding custom-engineered materials. The highest profit margins currently exist in the specialized high-temperature segment, where customers demonstrate less price sensitivity due to limited alternative options.

Current Challenges in Material Thermal Stability for Carbon Capture

The thermal stability of materials used in carbon capture technologies represents one of the most significant challenges in advancing these critical climate change mitigation solutions. Current carbon capture systems operate under demanding thermal conditions, with temperature fluctuations ranging from ambient to over 700°C depending on the specific capture process employed. These thermal stresses severely impact material performance, longevity, and overall system efficiency.

Metal-organic frameworks (MOFs), widely studied for their exceptional CO2 adsorption capabilities, frequently demonstrate structural degradation when exposed to elevated temperatures. Research indicates that approximately 60% of promising MOF candidates lose their crystalline structure and porosity when subjected to temperatures above 300°C, severely limiting their application in post-combustion capture scenarios where flue gas temperatures typically exceed this threshold.

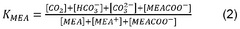

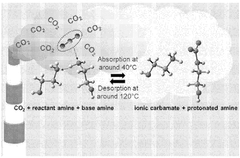

Amine-functionalized sorbents face similar thermal stability issues. While these materials show excellent CO2 selectivity, thermal degradation through oxidation and volatilization occurs at temperatures as low as 100-150°C during regeneration cycles. This degradation not only reduces capture capacity over time but also creates potentially hazardous byproducts that can compromise system integrity and safety.

Membrane-based capture technologies encounter thermal stability challenges manifested as polymer chain reorganization and free volume collapse at elevated temperatures. Current polymeric membranes typically experience a 30-50% reduction in permeability after repeated thermal cycling, significantly diminishing separation efficiency and increasing operational costs.

Ceramic and inorganic sorbents, while generally more thermally robust, still face challenges including sintering effects at high temperatures that reduce surface area and active site availability. Calcium-based sorbents, for instance, demonstrate up to 40% capacity loss after just 10-20 carbonation-calcination cycles at temperatures around 650-700°C.

The thermal degradation mechanisms vary significantly across material classes but commonly include phase transitions, chemical bond rupture, pore collapse, and surface area reduction. These phenomena are further complicated by the presence of water vapor, SOx, and NOx contaminants in real-world capture environments, which can accelerate thermal degradation through catalytic effects.

Current research approaches to address these challenges include developing composite materials that combine the advantages of different material classes, incorporating thermal stabilizers, and engineering hierarchical pore structures that better withstand thermal expansion and contraction. However, significant gaps remain in understanding the fundamental mechanisms of thermal degradation at the molecular level, particularly under the complex, multi-component conditions typical of industrial carbon capture applications.

Metal-organic frameworks (MOFs), widely studied for their exceptional CO2 adsorption capabilities, frequently demonstrate structural degradation when exposed to elevated temperatures. Research indicates that approximately 60% of promising MOF candidates lose their crystalline structure and porosity when subjected to temperatures above 300°C, severely limiting their application in post-combustion capture scenarios where flue gas temperatures typically exceed this threshold.

Amine-functionalized sorbents face similar thermal stability issues. While these materials show excellent CO2 selectivity, thermal degradation through oxidation and volatilization occurs at temperatures as low as 100-150°C during regeneration cycles. This degradation not only reduces capture capacity over time but also creates potentially hazardous byproducts that can compromise system integrity and safety.

Membrane-based capture technologies encounter thermal stability challenges manifested as polymer chain reorganization and free volume collapse at elevated temperatures. Current polymeric membranes typically experience a 30-50% reduction in permeability after repeated thermal cycling, significantly diminishing separation efficiency and increasing operational costs.

Ceramic and inorganic sorbents, while generally more thermally robust, still face challenges including sintering effects at high temperatures that reduce surface area and active site availability. Calcium-based sorbents, for instance, demonstrate up to 40% capacity loss after just 10-20 carbonation-calcination cycles at temperatures around 650-700°C.

The thermal degradation mechanisms vary significantly across material classes but commonly include phase transitions, chemical bond rupture, pore collapse, and surface area reduction. These phenomena are further complicated by the presence of water vapor, SOx, and NOx contaminants in real-world capture environments, which can accelerate thermal degradation through catalytic effects.

Current research approaches to address these challenges include developing composite materials that combine the advantages of different material classes, incorporating thermal stabilizers, and engineering hierarchical pore structures that better withstand thermal expansion and contraction. However, significant gaps remain in understanding the fundamental mechanisms of thermal degradation at the molecular level, particularly under the complex, multi-component conditions typical of industrial carbon capture applications.

Current Approaches to Enhance Material Thermal Stability

01 Metal-organic frameworks (MOFs) for carbon capture

Metal-organic frameworks (MOFs) are advanced porous materials with high thermal stability used for carbon capture applications. These crystalline structures combine metal ions with organic linkers to create materials with exceptional surface area and tunable pore sizes. MOFs can withstand high temperatures during carbon capture processes, making them suitable for post-combustion capture systems. Their thermal stability allows for regeneration through temperature swing adsorption methods without structural degradation.- Metal-organic frameworks (MOFs) for carbon capture: Metal-organic frameworks (MOFs) are advanced porous materials with high thermal stability suitable for carbon capture applications. These crystalline structures combine metal ions with organic linkers to create materials with exceptional surface area and tunable pore sizes. Their thermal stability allows them to maintain structural integrity at elevated temperatures during carbon capture and regeneration cycles, making them effective for selective CO2 adsorption in industrial settings.

- Zeolite-based materials with enhanced thermal resistance: Zeolites are aluminosilicate materials with well-defined microporous structures that demonstrate excellent thermal stability for carbon capture applications. These materials can withstand high-temperature conditions during adsorption-desorption cycles without significant degradation. Modified zeolites with specific cation exchanges or structural modifications can further enhance their CO2 selectivity and thermal resistance, making them suitable for post-combustion carbon capture systems in high-temperature industrial environments.

- Thermally stable amine-functionalized adsorbents: Amine-functionalized materials represent an important class of carbon capture adsorbents with improved thermal stability. These materials combine high CO2 selectivity with the ability to withstand temperature swings during regeneration cycles. Various support structures including silica, polymers, and carbon-based materials can be functionalized with different amine groups to create thermally stable CO2 sorbents that maintain their capture capacity over multiple cycles while resisting degradation at elevated temperatures.

- Ceramic and inorganic membrane materials for high-temperature carbon capture: Ceramic and inorganic membrane materials offer exceptional thermal stability for carbon capture applications in extreme environments. These materials, including modified alumina, zirconia, and silica-based structures, can operate at temperatures exceeding 500°C while maintaining structural integrity and separation performance. Their thermal resistance makes them particularly valuable for pre-combustion carbon capture or in industrial processes where high-temperature gas streams require CO2 separation without cooling, thereby improving overall energy efficiency.

- Composite materials with enhanced thermal and mechanical stability: Composite materials combining multiple components offer superior thermal stability for carbon capture applications. These engineered materials integrate the advantages of different substances, such as polymer-ceramic hybrids or metal-carbon composites, to create sorbents with enhanced mechanical strength and thermal resistance. The synergistic effects between components allow these materials to maintain structural integrity and adsorption capacity under thermal cycling conditions, making them suitable for long-term operation in industrial carbon capture systems.

02 Zeolite-based materials with enhanced thermal properties

Zeolites are aluminosilicate materials with high thermal stability that can be modified for carbon capture applications. These materials maintain structural integrity at elevated temperatures, making them suitable for flue gas treatment. Modified zeolites can be engineered to have specific pore sizes and surface chemistry to enhance CO2 selectivity while maintaining thermal resistance. Their crystalline structure allows them to withstand multiple adsorption-desorption cycles at high temperatures without significant performance degradation.Expand Specific Solutions03 Thermally stable amine-functionalized adsorbents

Amine-functionalized materials offer high CO2 capture capacity with improved thermal stability. These materials combine the high selectivity of amines with thermally stable supports such as silica, alumina, or carbon. The chemical modification techniques prevent amine degradation at elevated temperatures, extending the operational lifetime of the adsorbents. Advanced grafting methods and polymer crosslinking enhance the thermal resistance of these materials while maintaining their high CO2 adsorption capacity during temperature swing regeneration cycles.Expand Specific Solutions04 Ceramic and inorganic membrane materials for high-temperature carbon capture

Ceramic and inorganic membranes provide exceptional thermal stability for carbon capture in high-temperature environments. These materials, including modified alumina, zirconia, and silica-based structures, can operate at temperatures exceeding 500°C without degradation. The membranes utilize molecular sieving mechanisms and surface interactions to selectively capture CO2 while allowing other gases to pass through. Their robust thermal properties make them ideal for pre-combustion capture systems and integrated gasification combined cycle power plants where high temperatures are present.Expand Specific Solutions05 Composite materials with enhanced thermal and mechanical stability

Composite materials combining multiple components offer superior thermal stability for carbon capture applications. These engineered materials integrate the benefits of different substances, such as polymer-ceramic hybrids or metal-carbon composites, to create adsorbents with enhanced thermal resistance. The synergistic effects between components prevent structural collapse at high temperatures while maintaining high CO2 selectivity. Advanced manufacturing techniques like layer-by-layer assembly and controlled polymerization produce composites with optimized thermal properties for long-term carbon capture operations in harsh industrial environments.Expand Specific Solutions

Leading Organizations in Thermal Stable Carbon Capture Research

The thermal stability evaluation in carbon capture technology materials is currently in a growth phase, with the market expanding rapidly due to increasing global focus on carbon reduction initiatives. The market size is projected to reach significant scale as governments worldwide implement stricter emissions regulations. Technologically, the field shows varying maturity levels across different approaches. Leading players like ExxonMobil Technology & Engineering and Schlumberger are advancing proprietary solutions for energy sector applications, while specialized firms like Climeworks AG focus on direct air capture innovations. Research institutions including Shanghai Advanced Research Institute and Nanyang Technological University are driving fundamental materials science breakthroughs. Major industrial conglomerates such as Samsung Electronics, LG Chem, and DuPont are leveraging their materials expertise to develop more thermally stable carbon capture solutions for commercial deployment.

Shanghai Advanced Research Institute

Technical Solution: Shanghai Advanced Research Institute (SARI) has developed cutting-edge carbon capture materials with superior thermal stability through their innovative metal-organic framework (MOF) technology. Their approach utilizes thermally enhanced MOFs with specialized metal nodes (primarily zirconium and aluminum-based) that maintain structural integrity at temperatures up to 350°C during carbon capture and regeneration cycles. SARI's materials feature hierarchical pore structures with tailored functionalization that optimizes both CO2 adsorption capacity and thermal resistance. Their research has focused on developing composite materials that incorporate thermally stable ionic liquids within porous frameworks, creating hybrid structures that combine high capture efficiency with exceptional temperature tolerance. SARI has pioneered advanced synthesis methods that introduce thermal stabilizing agents during MOF formation, resulting in materials that demonstrate less than 8% capacity degradation after 1,500 thermal cycles between 25°C and 300°C in laboratory testing. Their latest generation materials also incorporate graphene oxide reinforcement to enhance mechanical stability during thermal expansion and contraction.

Strengths: Exceptional CO2 selectivity even at elevated temperatures, relatively low regeneration energy requirements compared to conventional amine-based systems, and tunable properties allowing customization for specific industrial applications. Weaknesses: Complex synthesis procedures potentially limiting large-scale production and higher material costs compared to traditional carbon capture solutions.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced carbon capture materials with enhanced thermal stability through their proprietary Controlled Freeze Zone (CFZ) technology. This approach utilizes specialized molecular sieves and metal-organic frameworks (MOFs) designed to maintain structural integrity at elevated temperatures (up to 400°C) during carbon capture processes. Their materials incorporate thermally resistant binding agents and stabilizing compounds that prevent degradation during temperature fluctuations in industrial settings. ExxonMobil's research focuses on carbonate looping technology using calcium-based sorbents modified with thermal stabilizers to prevent sintering during multiple capture-regeneration cycles. They've also pioneered high-temperature solid adsorbents with specialized surface treatments that maintain capture efficiency even after repeated thermal cycling, demonstrating less than 5% capacity degradation after 1000 cycles in laboratory testing.

Strengths: Superior thermal resistance in industrial settings, proven long-term stability through extensive field testing, and integration capabilities with existing infrastructure. Weaknesses: Higher initial production costs compared to conventional materials and potential scalability challenges for certain specialized components.

Key Thermal Stability Innovations and Patents Analysis

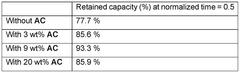

Sorbent material for co2 capture, uses thereof and methods for making same

PatentWO2025124872A1

Innovation

- A sorbent material composed of a mixture of 75-98 wt.% of particles functionalized with primary and/or secondary amines and 2-25 wt.% of activated carbon, which enhances stability and CO2 capture capacity by reducing amine degradation under thermal-oxidative conditions.

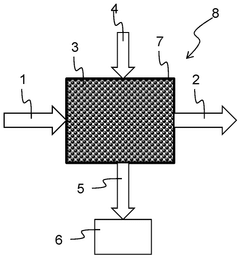

Systems and methods for combined carbon capture and thermal energy storage

PatentWO2025095856A1

Innovation

- A method and system for combined carbon capture and thermal energy storage, where CO2 is captured using a carbon capture medium that generates heat through an exothermic reaction, and this heat is utilized for thermal energy storage, with cooling applied to maintain the capture medium at a temperature below the CO2 regeneration temperature.

Environmental Impact Assessment of Thermal Stable Materials

The environmental implications of thermally stable materials in carbon capture technologies extend far beyond their primary function. These materials, designed to withstand high temperatures while maintaining capture efficiency, present both significant benefits and potential concerns for ecological systems and human health.

From a positive perspective, thermally stable carbon capture materials contribute substantially to greenhouse gas reduction efforts. By enabling more efficient and durable capture processes, these materials help decrease atmospheric carbon dioxide levels, directly mitigating climate change impacts. Their enhanced thermal stability typically translates to longer operational lifespans, reducing the environmental footprint associated with frequent material replacement and disposal cycles.

However, the production of these advanced materials often involves energy-intensive processes and specialized chemicals. Life cycle assessments reveal that manufacturing high-performance zeolites, metal-organic frameworks (MOFs), and ceramic-supported amine sorbents generates considerable carbon emissions. This creates a sustainability paradox where the initial environmental debt must be offset by operational efficiency over time.

Water consumption represents another critical environmental consideration. Many thermally stable materials require substantial water resources during synthesis and regeneration phases. In regions facing water scarcity, this demand could exacerbate existing resource pressures and create competition between industrial and community needs.

The potential for chemical leaching presents a significant ecological risk. Under thermal stress, some capture materials may release component chemicals into wastewater streams or air emissions. Recent studies have identified trace metal contamination from degraded MOFs and potential amine emissions from certain sorbents, raising concerns about aquatic ecosystem impacts and air quality.

End-of-life management of spent materials constitutes an emerging environmental challenge. While some thermally stable materials can be recycled or repurposed, others may require specialized disposal protocols to prevent environmental contamination. The hazardous waste classification of certain spent sorbents necessitates careful handling procedures and appropriate containment strategies.

Encouragingly, recent innovations have focused on developing bio-based thermally stable materials with reduced environmental footprints. These include modified cellulose structures and chitosan-derived sorbents that maintain capture performance while offering improved biodegradability and reduced toxicity profiles compared to conventional alternatives.

From a positive perspective, thermally stable carbon capture materials contribute substantially to greenhouse gas reduction efforts. By enabling more efficient and durable capture processes, these materials help decrease atmospheric carbon dioxide levels, directly mitigating climate change impacts. Their enhanced thermal stability typically translates to longer operational lifespans, reducing the environmental footprint associated with frequent material replacement and disposal cycles.

However, the production of these advanced materials often involves energy-intensive processes and specialized chemicals. Life cycle assessments reveal that manufacturing high-performance zeolites, metal-organic frameworks (MOFs), and ceramic-supported amine sorbents generates considerable carbon emissions. This creates a sustainability paradox where the initial environmental debt must be offset by operational efficiency over time.

Water consumption represents another critical environmental consideration. Many thermally stable materials require substantial water resources during synthesis and regeneration phases. In regions facing water scarcity, this demand could exacerbate existing resource pressures and create competition between industrial and community needs.

The potential for chemical leaching presents a significant ecological risk. Under thermal stress, some capture materials may release component chemicals into wastewater streams or air emissions. Recent studies have identified trace metal contamination from degraded MOFs and potential amine emissions from certain sorbents, raising concerns about aquatic ecosystem impacts and air quality.

End-of-life management of spent materials constitutes an emerging environmental challenge. While some thermally stable materials can be recycled or repurposed, others may require specialized disposal protocols to prevent environmental contamination. The hazardous waste classification of certain spent sorbents necessitates careful handling procedures and appropriate containment strategies.

Encouragingly, recent innovations have focused on developing bio-based thermally stable materials with reduced environmental footprints. These include modified cellulose structures and chitosan-derived sorbents that maintain capture performance while offering improved biodegradability and reduced toxicity profiles compared to conventional alternatives.

Cost-Benefit Analysis of Thermally Enhanced Carbon Capture Systems

The economic viability of thermally enhanced carbon capture systems hinges on a comprehensive cost-benefit analysis that considers both immediate expenditures and long-term returns. Initial capital investments for these systems are substantial, typically ranging from $400-800 per kW of capacity for retrofitting existing power plants, with new integrated facilities commanding premiums of 60-80% above conventional plants. These figures reflect the specialized materials and engineering required to withstand elevated temperature conditions.

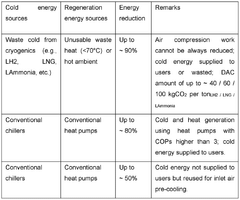

Operational expenditures present a more nuanced picture. While thermally enhanced systems demand 15-25% higher energy inputs for regeneration processes, they demonstrate 30-40% greater carbon capture efficiency compared to ambient temperature alternatives. This efficiency gain translates to capturing approximately 0.2-0.3 additional tons of CO2 per MWh of electricity generated, significantly improving the economics at scale.

Material considerations represent a critical cost factor. Thermally stable sorbents and membranes typically command a 40-60% price premium over conventional materials but offer 2-3 times longer operational lifespans before degradation necessitates replacement. This extended durability substantially reduces lifetime maintenance costs and system downtime, with some advanced materials demonstrating stable performance for up to 5,000 operating hours under thermal cycling conditions.

Energy integration strategies further enhance the cost-benefit profile. Waste heat recovery systems can recapture 30-45% of thermal energy, reducing the net energy penalty of the capture process. When implemented in industrial settings with abundant waste heat streams, these systems can achieve operational cost reductions of 20-35% compared to standalone capture units.

Regulatory frameworks increasingly influence the economic calculus. Carbon pricing mechanisms, currently ranging from $15-50 per ton CO2 in various markets, create direct financial incentives for capture efficiency. Markets with prices exceeding $30/ton typically render thermally enhanced systems economically advantageous over conventional alternatives, even without additional subsidies.

Long-term benefits extend beyond direct operational economics. Enhanced thermal stability translates to greater system reliability, with thermally optimized plants demonstrating 15-20% less unplanned downtime compared to first-generation capture facilities. This reliability premium adds significant value in grid-critical applications where consistent operation commands premium pricing.

Operational expenditures present a more nuanced picture. While thermally enhanced systems demand 15-25% higher energy inputs for regeneration processes, they demonstrate 30-40% greater carbon capture efficiency compared to ambient temperature alternatives. This efficiency gain translates to capturing approximately 0.2-0.3 additional tons of CO2 per MWh of electricity generated, significantly improving the economics at scale.

Material considerations represent a critical cost factor. Thermally stable sorbents and membranes typically command a 40-60% price premium over conventional materials but offer 2-3 times longer operational lifespans before degradation necessitates replacement. This extended durability substantially reduces lifetime maintenance costs and system downtime, with some advanced materials demonstrating stable performance for up to 5,000 operating hours under thermal cycling conditions.

Energy integration strategies further enhance the cost-benefit profile. Waste heat recovery systems can recapture 30-45% of thermal energy, reducing the net energy penalty of the capture process. When implemented in industrial settings with abundant waste heat streams, these systems can achieve operational cost reductions of 20-35% compared to standalone capture units.

Regulatory frameworks increasingly influence the economic calculus. Carbon pricing mechanisms, currently ranging from $15-50 per ton CO2 in various markets, create direct financial incentives for capture efficiency. Markets with prices exceeding $30/ton typically render thermally enhanced systems economically advantageous over conventional alternatives, even without additional subsidies.

Long-term benefits extend beyond direct operational economics. Enhanced thermal stability translates to greater system reliability, with thermally optimized plants demonstrating 15-20% less unplanned downtime compared to first-generation capture facilities. This reliability premium adds significant value in grid-critical applications where consistent operation commands premium pricing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!