Carbon Capture Technologies in Clean Energy Standards

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Evolution and Objectives

Carbon capture technologies have evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industrial settings. The journey began in the 1970s with early experiments in carbon dioxide separation, primarily focused on enhanced oil recovery applications rather than environmental concerns. By the 1990s, as climate change awareness grew, carbon capture research expanded to include post-combustion, pre-combustion, and oxy-fuel combustion approaches, establishing the foundation for modern carbon capture systems.

The early 2000s marked a pivotal shift with the first large-scale carbon capture and storage (CCS) projects, such as the Sleipner project in Norway, which demonstrated the feasibility of storing CO2 in geological formations. This period saw significant advancements in solvent-based capture technologies, particularly amine scrubbing processes that remain industry standards today. The technological evolution continued with membrane-based separation, solid sorbent systems, and chemical looping combustion emerging as promising alternatives to conventional methods.

Recent years have witnessed the development of direct air capture (DAC) technologies, representing a paradigm shift from point-source capture to extracting CO2 directly from ambient air. This innovation expands the potential application scope beyond industrial facilities to address historical emissions. Simultaneously, bioenergy with carbon capture and storage (BECCS) has gained attention as a negative emissions technology, potentially removing more CO2 than it produces throughout its lifecycle.

The primary objective of carbon capture technologies within clean energy standards is to facilitate the transition to a low-carbon economy while acknowledging the continued reliance on fossil fuels in many regions. These technologies aim to reduce greenhouse gas emissions from power generation and industrial processes by 80-90% compared to unabated operations. Additionally, they seek to provide a bridge solution that allows existing infrastructure to operate with significantly reduced environmental impact during the transition to renewable energy sources.

Long-term objectives include reducing the energy penalty associated with carbon capture processes, currently ranging from 20-30% of a power plant's output, to below 10%. Cost reduction represents another critical goal, with targets to decrease capture costs from the current $40-80 per ton of CO2 to under $30 by 2030. The ultimate vision encompasses developing economically viable carbon utilization pathways that transform captured CO2 from waste product to valuable resource, creating circular carbon economies that support both environmental sustainability and economic growth.

The early 2000s marked a pivotal shift with the first large-scale carbon capture and storage (CCS) projects, such as the Sleipner project in Norway, which demonstrated the feasibility of storing CO2 in geological formations. This period saw significant advancements in solvent-based capture technologies, particularly amine scrubbing processes that remain industry standards today. The technological evolution continued with membrane-based separation, solid sorbent systems, and chemical looping combustion emerging as promising alternatives to conventional methods.

Recent years have witnessed the development of direct air capture (DAC) technologies, representing a paradigm shift from point-source capture to extracting CO2 directly from ambient air. This innovation expands the potential application scope beyond industrial facilities to address historical emissions. Simultaneously, bioenergy with carbon capture and storage (BECCS) has gained attention as a negative emissions technology, potentially removing more CO2 than it produces throughout its lifecycle.

The primary objective of carbon capture technologies within clean energy standards is to facilitate the transition to a low-carbon economy while acknowledging the continued reliance on fossil fuels in many regions. These technologies aim to reduce greenhouse gas emissions from power generation and industrial processes by 80-90% compared to unabated operations. Additionally, they seek to provide a bridge solution that allows existing infrastructure to operate with significantly reduced environmental impact during the transition to renewable energy sources.

Long-term objectives include reducing the energy penalty associated with carbon capture processes, currently ranging from 20-30% of a power plant's output, to below 10%. Cost reduction represents another critical goal, with targets to decrease capture costs from the current $40-80 per ton of CO2 to under $30 by 2030. The ultimate vision encompasses developing economically viable carbon utilization pathways that transform captured CO2 from waste product to valuable resource, creating circular carbon economies that support both environmental sustainability and economic growth.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing climate change concerns and stringent emission regulations. Currently valued at approximately $2.1 billion in 2023, the market is projected to reach $7.3 billion by 2030, representing a compound annual growth rate of 19.2%. This expansion is primarily fueled by government initiatives, corporate sustainability commitments, and technological advancements making carbon capture more economically viable.

North America dominates the market with over 40% share, led by the United States where tax incentives like the 45Q credit have stimulated investment. The European market follows closely, propelled by the EU's ambitious climate targets and carbon pricing mechanisms. The Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market segment with projected growth rates exceeding 25% annually through 2030.

By application segment, the power generation sector currently accounts for the largest market share at 35%, followed by industrial processes (28%), natural gas processing (20%), and other applications (17%). Enhanced oil recovery (EOR) remains the primary utilization pathway for captured carbon, though dedicated geological storage is growing rapidly as carbon pricing increases.

The market exhibits a fragmented competitive landscape with both established energy companies and innovative startups. Major players include Exxon Mobil, Shell, Mitsubishi Heavy Industries, and Schlumberger, who collectively hold approximately 45% market share. Emerging companies like Carbon Engineering, Climeworks, and Global Thermostat are disrupting the market with direct air capture technologies, attracting significant venture capital investment totaling over $1.9 billion in 2022 alone.

Customer segments are diversifying beyond traditional energy and industrial sectors. Utilities facing clean energy standards are increasingly investing in carbon capture retrofits for existing fossil fuel plants. Additionally, hard-to-abate industries like cement, steel, and chemicals are emerging as crucial market segments due to limited decarbonization alternatives.

Price sensitivity remains a significant market factor, with current carbon capture costs ranging from $40-120 per ton depending on the source and technology. Market adoption accelerates significantly when costs fall below $50 per ton, which aligns with carbon prices in several jurisdictions. The most substantial market barrier continues to be the absence of comprehensive carbon pricing mechanisms in many regions, creating uncertainty for long-term investments.

North America dominates the market with over 40% share, led by the United States where tax incentives like the 45Q credit have stimulated investment. The European market follows closely, propelled by the EU's ambitious climate targets and carbon pricing mechanisms. The Asia-Pacific region, particularly China and Japan, is emerging as the fastest-growing market segment with projected growth rates exceeding 25% annually through 2030.

By application segment, the power generation sector currently accounts for the largest market share at 35%, followed by industrial processes (28%), natural gas processing (20%), and other applications (17%). Enhanced oil recovery (EOR) remains the primary utilization pathway for captured carbon, though dedicated geological storage is growing rapidly as carbon pricing increases.

The market exhibits a fragmented competitive landscape with both established energy companies and innovative startups. Major players include Exxon Mobil, Shell, Mitsubishi Heavy Industries, and Schlumberger, who collectively hold approximately 45% market share. Emerging companies like Carbon Engineering, Climeworks, and Global Thermostat are disrupting the market with direct air capture technologies, attracting significant venture capital investment totaling over $1.9 billion in 2022 alone.

Customer segments are diversifying beyond traditional energy and industrial sectors. Utilities facing clean energy standards are increasingly investing in carbon capture retrofits for existing fossil fuel plants. Additionally, hard-to-abate industries like cement, steel, and chemicals are emerging as crucial market segments due to limited decarbonization alternatives.

Price sensitivity remains a significant market factor, with current carbon capture costs ranging from $40-120 per ton depending on the source and technology. Market adoption accelerates significantly when costs fall below $50 per ton, which aligns with carbon prices in several jurisdictions. The most substantial market barrier continues to be the absence of comprehensive carbon pricing mechanisms in many regions, creating uncertainty for long-term investments.

Global Carbon Capture Landscape and Barriers

Carbon capture technologies have evolved significantly over the past two decades, with global deployment accelerating as climate change mitigation becomes increasingly urgent. Currently, there are approximately 35 commercial-scale carbon capture facilities operating worldwide, with the capacity to capture about 45 million tonnes of CO2 annually. This represents less than 0.1% of global emissions, highlighting the substantial gap between current implementation and climate goals.

The geographical distribution of carbon capture projects reveals significant concentration in North America and Europe, with emerging growth in Asia, particularly China. The United States leads with the most operational projects, benefiting from the 45Q tax credit and extensive geological storage capacity. The European Union follows closely, driven by its Emissions Trading System and Innovation Fund supporting demonstration projects.

Despite technological advancements, carbon capture faces substantial barriers to widespread adoption. Cost remains the primary obstacle, with current capture costs ranging from $40-120 per tonne of CO2 depending on the source and technology. This economic challenge is compounded by the absence of robust carbon pricing mechanisms in many regions, creating insufficient financial incentives for deployment.

Infrastructure limitations present another significant barrier. The development of CO2 transport networks and storage sites requires substantial investment and faces regulatory uncertainties. Many regions lack comprehensive regulatory frameworks for CO2 storage liability, monitoring requirements, and permitting processes, creating investment hesitation.

Public acceptance issues further complicate deployment, particularly regarding geological storage safety concerns and the perception that carbon capture extends fossil fuel dependence rather than facilitating transition to renewable energy systems. This has led to opposition in several proposed project locations.

Technical challenges persist across the capture chain. For industrial applications, integration with existing facilities often requires significant retrofitting and operational adjustments. Post-combustion capture technologies still struggle with energy penalties, reducing overall system efficiency by 15-30% in power generation applications.

International collaboration efforts have emerged to address these barriers, including the Carbon Sequestration Leadership Forum and the International CCS Knowledge Centre. However, knowledge sharing remains limited by commercial interests and intellectual property concerns, slowing global technology diffusion and standardization efforts.

The current landscape indicates that while carbon capture technology is technically viable, its deployment at climate-relevant scales requires coordinated policy support, substantial investment in infrastructure, and continued innovation to reduce costs and improve performance across diverse applications.

The geographical distribution of carbon capture projects reveals significant concentration in North America and Europe, with emerging growth in Asia, particularly China. The United States leads with the most operational projects, benefiting from the 45Q tax credit and extensive geological storage capacity. The European Union follows closely, driven by its Emissions Trading System and Innovation Fund supporting demonstration projects.

Despite technological advancements, carbon capture faces substantial barriers to widespread adoption. Cost remains the primary obstacle, with current capture costs ranging from $40-120 per tonne of CO2 depending on the source and technology. This economic challenge is compounded by the absence of robust carbon pricing mechanisms in many regions, creating insufficient financial incentives for deployment.

Infrastructure limitations present another significant barrier. The development of CO2 transport networks and storage sites requires substantial investment and faces regulatory uncertainties. Many regions lack comprehensive regulatory frameworks for CO2 storage liability, monitoring requirements, and permitting processes, creating investment hesitation.

Public acceptance issues further complicate deployment, particularly regarding geological storage safety concerns and the perception that carbon capture extends fossil fuel dependence rather than facilitating transition to renewable energy systems. This has led to opposition in several proposed project locations.

Technical challenges persist across the capture chain. For industrial applications, integration with existing facilities often requires significant retrofitting and operational adjustments. Post-combustion capture technologies still struggle with energy penalties, reducing overall system efficiency by 15-30% in power generation applications.

International collaboration efforts have emerged to address these barriers, including the Carbon Sequestration Leadership Forum and the International CCS Knowledge Centre. However, knowledge sharing remains limited by commercial interests and intellectual property concerns, slowing global technology diffusion and standardization efforts.

The current landscape indicates that while carbon capture technology is technically viable, its deployment at climate-relevant scales requires coordinated policy support, substantial investment in infrastructure, and continued innovation to reduce costs and improve performance across diverse applications.

Current Carbon Capture Implementation Approaches

01 Chemical absorption methods for carbon capture

Chemical absorption is a widely used method for carbon capture that involves the use of solvents to absorb CO2 from flue gases. These processes typically use amine-based solvents or other chemical compounds that selectively bind with carbon dioxide. The captured CO2 can then be released through heating or pressure changes, allowing the solvent to be reused. This technology is particularly effective for post-combustion capture from power plants and industrial facilities.- Chemical absorption methods for carbon capture: Chemical absorption is a widely used method for carbon capture that involves the use of solvents to absorb CO2 from flue gases. These processes typically use amine-based solvents or other chemical compounds that selectively bind with CO2. The captured carbon dioxide can then be released through heating or pressure changes, allowing the solvent to be regenerated and reused. This technology is particularly effective for post-combustion capture from power plants and industrial facilities.

- Direct air capture technologies: Direct air capture (DAC) technologies extract CO2 directly from the atmosphere rather than from point sources like power plants. These systems use specialized materials or chemical processes to selectively capture carbon dioxide from ambient air despite its relatively low concentration. Once captured, the CO2 can be permanently stored underground or utilized in various applications. DAC technologies are becoming increasingly important as they can address both current and historical carbon emissions regardless of their source.

- Biological carbon capture systems: Biological carbon capture utilizes natural processes such as photosynthesis to remove CO2 from the atmosphere. These approaches include enhanced forestry management, algae cultivation systems, and engineered microorganisms designed to consume carbon dioxide. Biological systems can be integrated with industrial processes to capture emissions directly or deployed independently to sequester atmospheric carbon. These methods often provide co-benefits such as biomass production, which can be used for energy or materials.

- Mineral carbonation and enhanced weathering: Mineral carbonation involves the reaction of CO2 with metal oxides to form stable carbonate minerals, effectively locking away carbon in solid form. This process mimics natural weathering but accelerates it significantly. Various approaches include using industrial waste materials like slag and fly ash, or naturally occurring minerals such as olivine and serpentine. These technologies can provide permanent carbon storage without the monitoring requirements of geological sequestration, as the resulting carbonates are thermodynamically stable.

- Carbon capture utilization and storage (CCUS) integration: CCUS integration focuses on creating comprehensive systems that not only capture carbon dioxide but also transport, utilize, or permanently store it. These integrated approaches include pipeline networks for CO2 transport, enhanced oil recovery using captured carbon, conversion of CO2 into valuable products like fuels or chemicals, and geological sequestration in depleted oil fields or saline aquifers. By addressing the full carbon lifecycle, these systems aim to create economically viable pathways for large-scale carbon management.

02 Direct air capture (DAC) technologies

Direct air capture technologies extract CO2 directly from the atmosphere rather than from point sources. These systems use various sorbents or solutions that can selectively capture carbon dioxide from ambient air despite its relatively low concentration. After capture, the CO2 can be released in a concentrated form for storage or utilization. DAC technologies are particularly valuable for addressing distributed emissions and potentially achieving negative emissions when combined with permanent storage solutions.Expand Specific Solutions03 Membrane-based carbon capture systems

Membrane-based carbon capture systems utilize selective membranes that allow CO2 to pass through while blocking other gases. These membranes can be made from polymers, ceramics, or composite materials with specific pore sizes and chemical properties designed to maximize CO2 separation efficiency. Membrane technology offers advantages including lower energy requirements, compact design, and continuous operation capability, making it suitable for various industrial applications including natural gas processing and post-combustion capture.Expand Specific Solutions04 Biological carbon capture methods

Biological carbon capture methods leverage natural biological processes to capture and sequester carbon dioxide. These approaches include engineered microalgae systems, enhanced forest management, biochar production, and microbial carbon fixation. Biological systems can capture carbon through photosynthesis or other metabolic processes and potentially offer cost-effective, sustainable solutions with additional environmental benefits. These methods can be deployed in various settings from agricultural lands to industrial facilities.Expand Specific Solutions05 Carbon capture utilization and storage (CCUS) integration

Carbon capture utilization and storage integration focuses on the complete carbon management chain, from capture to transportation, utilization, and permanent storage. These integrated systems connect capture technologies with end uses such as enhanced oil recovery, concrete production, synthetic fuel manufacturing, or geological sequestration. CCUS integration addresses the full lifecycle of captured carbon and creates economic incentives through valuable products or services derived from the captured CO2, potentially improving the financial viability of carbon capture operations.Expand Specific Solutions

Industry Leaders in Carbon Capture Innovation

Carbon capture technologies in clean energy standards are evolving rapidly, with the market currently in a growth phase characterized by increasing investments and expanding applications. The global carbon capture market is projected to reach significant scale as countries implement stricter emissions regulations. Technologically, the field shows varying maturity levels across different capture methods. Leading players like China National Petroleum Corporation and State Grid Corp. of China are developing large-scale infrastructure projects, while research institutions such as Zhejiang University and Dalian University of Technology are advancing fundamental technologies. Companies like Toshiba Energy Systems and 8 Rivers Capital are commercializing innovative capture solutions, while Huaneng Clean Energy Research Institute focuses on integration with existing power generation. This competitive landscape reflects a sector transitioning from research to commercial deployment, with both established energy giants and specialized technology providers competing for market position.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed an integrated carbon capture system specifically designed for coal-fired power plants. Their technology employs a two-stage absorption process using advanced amine-based solvents that can capture up to 90% of CO2 emissions. The institute has implemented a pilot project at the Huaneng Shanghai Shidongkou No. 2 Power Plant, which was China's first carbon capture demonstration project with a capacity of 120,000 tons of CO2 per year[1]. Their approach integrates heat recovery systems to minimize energy penalties associated with carbon capture, reducing the energy consumption to approximately 2.8-3.2 GJ/ton CO2 captured[3]. The institute has also pioneered the development of solid sorbents with high CO2 selectivity and capacity, which operate at lower regeneration temperatures compared to conventional liquid solvents. These innovations have been incorporated into China's national clean energy standards framework as benchmark technologies for carbon capture in thermal power generation[5].

Strengths: Proven technology with operational demonstration projects; lower energy penalty compared to first-generation capture systems; integration with existing power infrastructure. Weaknesses: Still faces challenges in scaling to commercial deployment; regeneration energy requirements remain significant despite improvements; economic viability depends heavily on carbon pricing mechanisms or regulatory frameworks.

China National Petroleum Corporation

Technical Solution: China National Petroleum Corporation (CNPC) has developed a comprehensive carbon capture, utilization, and storage (CCUS) technology suite focused on the energy sector. Their approach centers on geological carbon sequestration combined with enhanced oil recovery (EOR), creating an economically viable pathway for carbon management. CNPC's flagship Jilin Oil Field CCUS project has successfully injected over 1.5 million tons of CO2 since its inception, making it one of China's largest operational CCUS projects[2]. The corporation employs proprietary membrane separation technology that achieves 95% CO2 capture efficiency while reducing energy consumption by approximately 20% compared to conventional amine scrubbing methods[4]. CNPC has also pioneered integration of carbon capture with natural gas processing facilities, where CO2 is separated during natural gas purification and then utilized for EOR operations. This integrated approach has been recognized in China's clean energy standards as a model for carbon-neutral fossil fuel utilization[6]. Their technology roadmap includes development of novel catalytic conversion processes to transform captured CO2 into valuable chemicals and fuels.

Strengths: Integration with existing oil and gas operations provides economic incentives through EOR; extensive geological storage expertise; proven large-scale implementation. Weaknesses: Heavy focus on utilization for enhanced oil recovery may limit net climate benefits; technology primarily applicable to high-concentration CO2 sources; geographical constraints based on suitable geological formations for storage.

Key Patents and Research in Carbon Sequestration

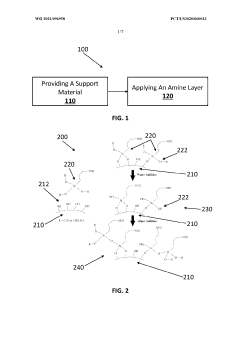

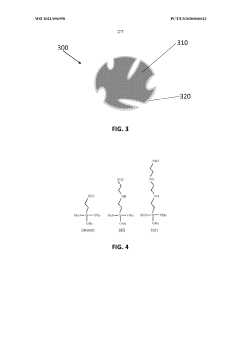

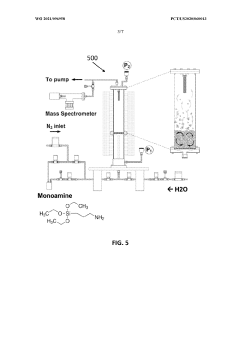

Synthesis process for solid carbon capture materials

PatentWO2021096958A1

Innovation

- The use of molecular layer deposition (MLD) to create amine-functionalized solid CO2 sorbents, which allows for precise angstrom-level thickness control and covalent anchoring of amine layers on a wide range of substrate materials, including nano-powders, enhancing surface area functionalization and maintaining active sites during regeneration without specialized substrates or costly preparation.

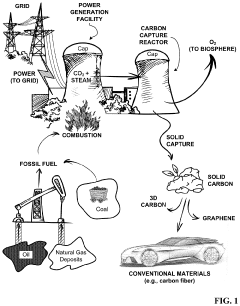

Negative emission, large scale carbon capture for clean fossil fuel power generation

PatentPendingUS20230074143A1

Innovation

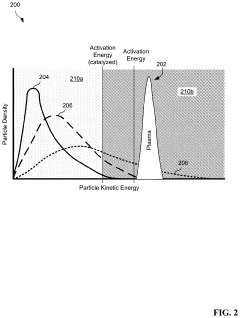

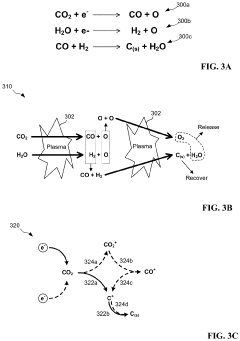

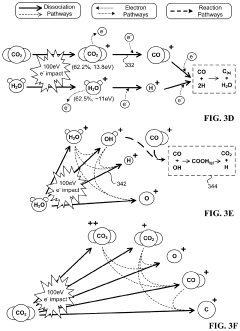

- A high-frequency, atmospheric pressure non-equilibrium plasma processing reactor is used to break down carbon dioxide and other greenhouse gases into benign constituents, allowing for the capture and recombination of oxygen, nitrogen, and hydrogen, while forming solid carbon by-products like graphene, which can be reused industrially.

Policy Frameworks for Carbon Capture Integration

The integration of carbon capture technologies into clean energy standards requires robust policy frameworks that provide clear guidelines, incentives, and regulatory structures. Currently, several nations have implemented varying approaches to carbon capture policy integration, with the United States, European Union, United Kingdom, and Canada leading these efforts. These frameworks typically combine regulatory mandates, financial incentives, and market-based mechanisms to drive adoption.

Regulatory approaches include emissions performance standards that establish maximum allowable CO2 emissions for power plants and industrial facilities. These standards increasingly recognize carbon capture as a compliance pathway, particularly in jurisdictions with ambitious climate targets. For instance, the EU's Industrial Emissions Directive and the US Clean Air Act provide regulatory foundations that can accommodate carbon capture requirements.

Financial incentive structures represent another critical policy component, encompassing tax credits, grants, and preferential loan programs. The US Section 45Q tax credit offers up to $85 per metric ton of CO2 permanently sequestered, while the EU Innovation Fund provides substantial grants for demonstration projects. These financial mechanisms help address the significant capital costs associated with carbon capture implementation.

Market-based instruments, including carbon pricing systems and emissions trading schemes, create economic signals that favor carbon capture deployment. The EU Emissions Trading System (ETS) and similar programs in Canada and California establish a price on carbon emissions, thereby improving the business case for capture technologies. However, current carbon prices in most markets remain insufficient to drive widespread adoption without complementary policies.

Procurement policies and clean energy standards increasingly incorporate carbon capture provisions. Several jurisdictions now allow carbon capture-equipped facilities to qualify for clean energy credits or participate in clean energy portfolio standards. This approach recognizes the potential role of carbon capture in achieving grid reliability while meeting decarbonization objectives.

Infrastructure development policies represent an emerging focus area, with governments establishing frameworks for CO2 transport and storage networks. The European CO2 transport infrastructure initiative and similar programs aim to create shared infrastructure that reduces costs for individual capture projects. These efforts acknowledge that widespread carbon capture deployment requires coordinated infrastructure planning beyond facility-level investments.

Cross-border cooperation frameworks are also developing, with international agreements addressing carbon accounting, technology transfer, and shared infrastructure. The London Protocol amendments regarding CO2 transport for geological storage exemplify progress in establishing international governance structures for carbon capture activities.

Regulatory approaches include emissions performance standards that establish maximum allowable CO2 emissions for power plants and industrial facilities. These standards increasingly recognize carbon capture as a compliance pathway, particularly in jurisdictions with ambitious climate targets. For instance, the EU's Industrial Emissions Directive and the US Clean Air Act provide regulatory foundations that can accommodate carbon capture requirements.

Financial incentive structures represent another critical policy component, encompassing tax credits, grants, and preferential loan programs. The US Section 45Q tax credit offers up to $85 per metric ton of CO2 permanently sequestered, while the EU Innovation Fund provides substantial grants for demonstration projects. These financial mechanisms help address the significant capital costs associated with carbon capture implementation.

Market-based instruments, including carbon pricing systems and emissions trading schemes, create economic signals that favor carbon capture deployment. The EU Emissions Trading System (ETS) and similar programs in Canada and California establish a price on carbon emissions, thereby improving the business case for capture technologies. However, current carbon prices in most markets remain insufficient to drive widespread adoption without complementary policies.

Procurement policies and clean energy standards increasingly incorporate carbon capture provisions. Several jurisdictions now allow carbon capture-equipped facilities to qualify for clean energy credits or participate in clean energy portfolio standards. This approach recognizes the potential role of carbon capture in achieving grid reliability while meeting decarbonization objectives.

Infrastructure development policies represent an emerging focus area, with governments establishing frameworks for CO2 transport and storage networks. The European CO2 transport infrastructure initiative and similar programs aim to create shared infrastructure that reduces costs for individual capture projects. These efforts acknowledge that widespread carbon capture deployment requires coordinated infrastructure planning beyond facility-level investments.

Cross-border cooperation frameworks are also developing, with international agreements addressing carbon accounting, technology transfer, and shared infrastructure. The London Protocol amendments regarding CO2 transport for geological storage exemplify progress in establishing international governance structures for carbon capture activities.

Economic Viability of Carbon Capture Technologies

The economic viability of carbon capture technologies remains a critical factor in their widespread adoption within clean energy standards. Current cost estimates for carbon capture and storage (CCS) range from $40 to $120 per ton of CO2 captured, depending on the technology type and implementation scale. These costs have decreased by approximately 30% over the past decade, yet remain significantly higher than many carbon pricing mechanisms globally.

Capital expenditure represents the most substantial barrier, with initial investment costs for retrofitting existing power plants typically ranging between $400-$900 million for a standard 500MW facility. This translates to increased electricity costs of $20-$50 per MWh, creating challenges for market competitiveness without substantial policy support.

Operational expenses present additional economic hurdles, with energy penalties ranging from 15% to 30% of total plant output. This "parasitic load" significantly impacts overall plant efficiency and requires additional fuel consumption to maintain the same energy output, further affecting the economic equation.

The economic landscape varies considerably across different carbon capture approaches. Post-combustion capture technologies, while more mature, generally incur higher operational costs due to energy-intensive solvent regeneration processes. Pre-combustion and oxy-fuel technologies potentially offer better economics at scale but face higher technological risks and capital requirements.

Revenue streams remain limited and uncertain, heavily dependent on policy frameworks. Carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the US offering $50-$85 per ton), and regulatory compliance value constitute the primary economic incentives. However, these mechanisms often fall short of covering the full implementation costs.

Market analysis indicates that without significant policy support, carbon capture technologies become economically viable only when carbon prices exceed $75-$100 per ton consistently. Current global carbon prices average only $25-$35 per ton in most markets, creating a substantial viability gap.

The economic outlook is gradually improving through technological learning curves, with second and third-generation capture technologies promising 30-50% cost reductions. Additionally, emerging business models incorporating CO2 utilization pathways (CCUS) potentially offer supplementary revenue streams through enhanced oil recovery, building materials production, and chemical manufacturing applications.

Capital expenditure represents the most substantial barrier, with initial investment costs for retrofitting existing power plants typically ranging between $400-$900 million for a standard 500MW facility. This translates to increased electricity costs of $20-$50 per MWh, creating challenges for market competitiveness without substantial policy support.

Operational expenses present additional economic hurdles, with energy penalties ranging from 15% to 30% of total plant output. This "parasitic load" significantly impacts overall plant efficiency and requires additional fuel consumption to maintain the same energy output, further affecting the economic equation.

The economic landscape varies considerably across different carbon capture approaches. Post-combustion capture technologies, while more mature, generally incur higher operational costs due to energy-intensive solvent regeneration processes. Pre-combustion and oxy-fuel technologies potentially offer better economics at scale but face higher technological risks and capital requirements.

Revenue streams remain limited and uncertain, heavily dependent on policy frameworks. Carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the US offering $50-$85 per ton), and regulatory compliance value constitute the primary economic incentives. However, these mechanisms often fall short of covering the full implementation costs.

Market analysis indicates that without significant policy support, carbon capture technologies become economically viable only when carbon prices exceed $75-$100 per ton consistently. Current global carbon prices average only $25-$35 per ton in most markets, creating a substantial viability gap.

The economic outlook is gradually improving through technological learning curves, with second and third-generation capture technologies promising 30-50% cost reductions. Additionally, emerging business models incorporating CO2 utilization pathways (CCUS) potentially offer supplementary revenue streams through enhanced oil recovery, building materials production, and chemical manufacturing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!