What Are the Key Drivers of Carbon Capture Technology Evolution

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Evolution Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, driven by the growing recognition of climate change as a global challenge. The journey began in the 1970s with initial experiments in capturing carbon dioxide from industrial processes, primarily for enhanced oil recovery applications. Since then, the technology has progressed through various developmental phases, each marked by incremental improvements in efficiency, cost-effectiveness, and scalability.

The evolution of carbon capture technologies follows a trajectory influenced by scientific breakthroughs, policy frameworks, and market dynamics. Early systems focused on post-combustion capture from power plants, while more recent innovations have expanded to include pre-combustion, oxy-fuel combustion, and direct air capture methodologies. This diversification represents a response to the complex nature of carbon emissions across different sectors and the recognition that no single approach can address all emission sources.

Current technological trends point toward more integrated systems that combine capture with utilization and storage (CCUS), creating potential value streams from captured carbon. Simultaneously, research is advancing toward more energy-efficient capture processes, novel materials for absorption and adsorption, and biomimetic approaches inspired by natural carbon cycles. These developments aim to overcome the historical challenges of high energy penalties and operational costs associated with carbon capture.

The primary objective of carbon capture technology evolution is to develop economically viable solutions that can be deployed at scale to significantly reduce greenhouse gas emissions. This includes achieving capture costs below $50 per ton of CO2, reducing energy requirements to less than 1.5 GJ per ton of CO2 captured, and designing systems compatible with both existing infrastructure (retrofits) and new facilities (integrated designs).

Secondary objectives include enhancing the versatility of capture technologies to address diverse emission sources, from large point sources like power plants and industrial facilities to distributed sources and ambient air. Additionally, there is growing emphasis on developing technologies that can be deployed in various geographical and economic contexts, including emerging economies where emissions are rising rapidly.

The technological evolution is increasingly guided by the urgency of climate targets established under international agreements such as the Paris Accord, which necessitates not only incremental improvements but transformative innovations that can accelerate deployment and impact. This has catalyzed interest in negative emission technologies and approaches that can achieve carbon-negative outcomes, particularly in hard-to-abate sectors where direct emission reductions remain challenging.

The evolution of carbon capture technologies follows a trajectory influenced by scientific breakthroughs, policy frameworks, and market dynamics. Early systems focused on post-combustion capture from power plants, while more recent innovations have expanded to include pre-combustion, oxy-fuel combustion, and direct air capture methodologies. This diversification represents a response to the complex nature of carbon emissions across different sectors and the recognition that no single approach can address all emission sources.

Current technological trends point toward more integrated systems that combine capture with utilization and storage (CCUS), creating potential value streams from captured carbon. Simultaneously, research is advancing toward more energy-efficient capture processes, novel materials for absorption and adsorption, and biomimetic approaches inspired by natural carbon cycles. These developments aim to overcome the historical challenges of high energy penalties and operational costs associated with carbon capture.

The primary objective of carbon capture technology evolution is to develop economically viable solutions that can be deployed at scale to significantly reduce greenhouse gas emissions. This includes achieving capture costs below $50 per ton of CO2, reducing energy requirements to less than 1.5 GJ per ton of CO2 captured, and designing systems compatible with both existing infrastructure (retrofits) and new facilities (integrated designs).

Secondary objectives include enhancing the versatility of capture technologies to address diverse emission sources, from large point sources like power plants and industrial facilities to distributed sources and ambient air. Additionally, there is growing emphasis on developing technologies that can be deployed in various geographical and economic contexts, including emerging economies where emissions are rising rapidly.

The technological evolution is increasingly guided by the urgency of climate targets established under international agreements such as the Paris Accord, which necessitates not only incremental improvements but transformative innovations that can accelerate deployment and impact. This has catalyzed interest in negative emission technologies and approaches that can achieve carbon-negative outcomes, particularly in hard-to-abate sectors where direct emission reductions remain challenging.

Market Demand Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven primarily by increasing environmental concerns and regulatory pressures. Current market projections indicate the carbon capture, utilization, and storage (CCUS) market will reach approximately $7 billion by 2030, with a compound annual growth rate exceeding 15% from 2023 to 2030. This growth trajectory reflects the urgent need for decarbonization solutions across multiple industries.

Industrial sectors represent the largest demand segment for carbon capture technologies, particularly power generation, cement manufacturing, steel production, and chemical processing. These heavy industries contribute nearly 40% of global carbon emissions and face mounting pressure to reduce their carbon footprint while maintaining production capacity. The power generation sector alone accounts for roughly one-third of the current carbon capture market demand.

Geographically, North America and Europe lead in carbon capture implementation, with Asia-Pacific showing the fastest growth rate. China's recent climate commitments have significantly expanded the potential market in the region, with projected investments in carbon capture exceeding $2 billion by 2025. The Middle East is emerging as another significant market, leveraging carbon capture for enhanced oil recovery operations.

Policy frameworks and carbon pricing mechanisms are critical market demand catalysts. Regions with established carbon markets or carbon taxes demonstrate substantially higher adoption rates of carbon capture technologies. The European Union's Emissions Trading System and similar mechanisms in Canada and parts of the United States have created economic incentives that directly translate to market demand.

Corporate sustainability commitments represent another substantial market driver. Over 300 major global corporations have made net-zero pledges, creating a private sector demand for carbon capture solutions independent of regulatory requirements. This trend is particularly evident in consumer-facing industries where brand reputation increasingly depends on demonstrated climate action.

Emerging business models, including Carbon Capture as a Service (CCaaS), are expanding market accessibility by reducing capital expenditure barriers for potential adopters. This service-based approach is expected to increase the addressable market by making carbon capture solutions viable for medium-sized enterprises previously excluded by cost considerations.

The voluntary carbon offset market provides additional demand momentum, with carbon removal credits from engineered solutions commanding premium prices compared to traditional offsets. This price differential is creating financial incentives for direct air capture and other negative emissions technologies, with market analysts projecting the voluntary market for engineered carbon removal to reach $1 billion by 2025.

Industrial sectors represent the largest demand segment for carbon capture technologies, particularly power generation, cement manufacturing, steel production, and chemical processing. These heavy industries contribute nearly 40% of global carbon emissions and face mounting pressure to reduce their carbon footprint while maintaining production capacity. The power generation sector alone accounts for roughly one-third of the current carbon capture market demand.

Geographically, North America and Europe lead in carbon capture implementation, with Asia-Pacific showing the fastest growth rate. China's recent climate commitments have significantly expanded the potential market in the region, with projected investments in carbon capture exceeding $2 billion by 2025. The Middle East is emerging as another significant market, leveraging carbon capture for enhanced oil recovery operations.

Policy frameworks and carbon pricing mechanisms are critical market demand catalysts. Regions with established carbon markets or carbon taxes demonstrate substantially higher adoption rates of carbon capture technologies. The European Union's Emissions Trading System and similar mechanisms in Canada and parts of the United States have created economic incentives that directly translate to market demand.

Corporate sustainability commitments represent another substantial market driver. Over 300 major global corporations have made net-zero pledges, creating a private sector demand for carbon capture solutions independent of regulatory requirements. This trend is particularly evident in consumer-facing industries where brand reputation increasingly depends on demonstrated climate action.

Emerging business models, including Carbon Capture as a Service (CCaaS), are expanding market accessibility by reducing capital expenditure barriers for potential adopters. This service-based approach is expected to increase the addressable market by making carbon capture solutions viable for medium-sized enterprises previously excluded by cost considerations.

The voluntary carbon offset market provides additional demand momentum, with carbon removal credits from engineered solutions commanding premium prices compared to traditional offsets. This price differential is creating financial incentives for direct air capture and other negative emissions technologies, with market analysts projecting the voluntary market for engineered carbon removal to reach $1 billion by 2025.

Current Carbon Capture Technologies and Challenges

Carbon capture technologies have evolved significantly over the past decades, with three primary approaches currently dominating the field: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. Post-combustion technology, the most mature and widely deployed method, involves separating CO2 from flue gases after fossil fuel combustion using chemical solvents like monoethanolamine (MEA). While relatively straightforward to retrofit to existing facilities, this approach suffers from high energy penalties, typically requiring 20-30% of a power plant's energy output for the capture process.

Pre-combustion capture converts fuel into syngas before combustion and removes CO2 before the combustion process. This method achieves higher CO2 concentration streams (15-60%) compared to post-combustion (3-15%), making separation more efficient. However, it requires significant modifications to existing plants and is primarily suitable for new installations, limiting widespread adoption despite its theoretical efficiency advantages.

Oxy-fuel combustion uses pure oxygen instead of air for combustion, resulting in exhaust gases composed primarily of CO2 and water vapor, from which CO2 can be easily separated. While this approach simplifies separation, the energy-intensive air separation process to produce pure oxygen creates substantial efficiency penalties.

Direct air capture (DAC), an emerging technology that extracts CO2 directly from ambient air, represents a promising frontier but faces enormous challenges due to the extremely dilute concentration of CO2 in the atmosphere (approximately 420 ppm). Current DAC technologies require substantial energy inputs and face prohibitive costs ranging from $250-600 per ton of CO2 captured, compared to $40-100 for point-source capture methods.

The fundamental technical challenges across all carbon capture technologies include energy efficiency, cost reduction, and scalability. The energy penalty remains a critical barrier, with current technologies requiring 25-40% additional energy for the capture process. Material limitations also present significant obstacles, as existing solvents and sorbents suffer from degradation, corrosion issues, and limited CO2 selectivity in complex gas mixtures.

Infrastructure constraints further complicate deployment, with transportation and storage of captured CO2 requiring extensive pipeline networks and suitable geological formations. The absence of comprehensive carbon pricing mechanisms and regulatory frameworks in many regions creates economic uncertainty that hampers investment and technological advancement.

Emerging research focuses on novel materials like metal-organic frameworks (MOFs), advanced membranes, and enzyme-based systems that promise higher efficiency and lower energy requirements. However, bridging the gap between laboratory success and industrial-scale implementation remains a significant challenge for the next generation of carbon capture technologies.

Pre-combustion capture converts fuel into syngas before combustion and removes CO2 before the combustion process. This method achieves higher CO2 concentration streams (15-60%) compared to post-combustion (3-15%), making separation more efficient. However, it requires significant modifications to existing plants and is primarily suitable for new installations, limiting widespread adoption despite its theoretical efficiency advantages.

Oxy-fuel combustion uses pure oxygen instead of air for combustion, resulting in exhaust gases composed primarily of CO2 and water vapor, from which CO2 can be easily separated. While this approach simplifies separation, the energy-intensive air separation process to produce pure oxygen creates substantial efficiency penalties.

Direct air capture (DAC), an emerging technology that extracts CO2 directly from ambient air, represents a promising frontier but faces enormous challenges due to the extremely dilute concentration of CO2 in the atmosphere (approximately 420 ppm). Current DAC technologies require substantial energy inputs and face prohibitive costs ranging from $250-600 per ton of CO2 captured, compared to $40-100 for point-source capture methods.

The fundamental technical challenges across all carbon capture technologies include energy efficiency, cost reduction, and scalability. The energy penalty remains a critical barrier, with current technologies requiring 25-40% additional energy for the capture process. Material limitations also present significant obstacles, as existing solvents and sorbents suffer from degradation, corrosion issues, and limited CO2 selectivity in complex gas mixtures.

Infrastructure constraints further complicate deployment, with transportation and storage of captured CO2 requiring extensive pipeline networks and suitable geological formations. The absence of comprehensive carbon pricing mechanisms and regulatory frameworks in many regions creates economic uncertainty that hampers investment and technological advancement.

Emerging research focuses on novel materials like metal-organic frameworks (MOFs), advanced membranes, and enzyme-based systems that promise higher efficiency and lower energy requirements. However, bridging the gap between laboratory success and industrial-scale implementation remains a significant challenge for the next generation of carbon capture technologies.

Mainstream Carbon Capture Implementation Approaches

01 Chemical absorption methods for carbon capture

Chemical absorption is a widely used method for carbon capture that involves the use of solvents to absorb CO2 from flue gases. These processes typically use amine-based solvents or other chemical compounds that selectively bind with CO2. The captured carbon dioxide can then be released through heating or pressure changes, allowing the solvent to be regenerated and reused. This technology is particularly effective for post-combustion carbon capture in industrial facilities and power plants.- Direct Air Capture (DAC) Systems: Direct Air Capture systems are designed to extract carbon dioxide directly from the atmosphere. These technologies typically use sorbent materials or chemical solutions that selectively bind with CO2 molecules in ambient air. After capture, the CO2 can be released through heating or pressure changes, then compressed and stored or utilized. DAC systems can be deployed in various locations regardless of emission sources, making them versatile tools for carbon removal.

- Post-combustion Carbon Capture: Post-combustion capture technologies focus on removing CO2 from flue gases after fossil fuel combustion. These systems typically employ chemical absorption using amine-based solvents, membrane separation, or adsorption processes. The technology can be retrofitted to existing power plants and industrial facilities, making it a practical solution for reducing emissions from established infrastructure without requiring complete redesign of combustion processes.

- Carbon Utilization and Conversion: Carbon utilization technologies convert captured CO2 into valuable products rather than simply storing it. These processes transform carbon dioxide into fuels, chemicals, building materials, or other commercial products. Methods include catalytic conversion, electrochemical reduction, mineralization, and biological conversion using microorganisms. This approach creates economic incentives for carbon capture by generating marketable products while reducing net carbon emissions.

- Biological Carbon Sequestration: Biological carbon sequestration leverages natural processes to capture and store carbon dioxide. These approaches include enhanced forestry management, algae cultivation systems, biochar production, and soil carbon enhancement techniques. Biological methods often provide co-benefits such as improved soil health, increased biodiversity, and enhanced ecosystem services while sequestering carbon at relatively low costs compared to some engineered solutions.

- Carbon Storage and Monitoring Systems: Carbon storage technologies focus on the secure, long-term containment of captured CO2. These include geological storage in depleted oil and gas reservoirs, deep saline formations, or unminable coal seams. Advanced monitoring systems using sensors, imaging technologies, and data analytics ensure the integrity of storage sites and prevent leakage. These technologies are critical for verifying the permanence of carbon removal and ensuring environmental safety of storage operations.

02 Direct air capture (DAC) technologies

Direct air capture technologies are designed to extract carbon dioxide directly from ambient air rather than from point sources like industrial emissions. These systems typically use specialized sorbents or membranes that can selectively capture CO2 even at the low concentrations found in the atmosphere. DAC technologies can be deployed anywhere and are not limited to industrial sites, making them versatile tools for carbon removal. The captured CO2 can then be permanently stored or utilized in various applications.Expand Specific Solutions03 Carbon capture utilization and storage (CCUS) systems

CCUS systems integrate the capture of carbon dioxide with its subsequent utilization or permanent storage. These comprehensive systems include technologies for capturing CO2, transporting it to utilization or storage sites, and either converting it into valuable products or sequestering it underground. Applications include enhanced oil recovery, conversion to fuels or chemicals, and geological storage in depleted oil fields or saline aquifers. CCUS represents a holistic approach to managing carbon emissions while potentially creating economic value.Expand Specific Solutions04 Biological carbon capture methods

Biological carbon capture leverages natural processes such as photosynthesis to remove CO2 from the atmosphere. These methods include engineered algae systems, enhanced forestry practices, and specialized microorganisms designed to accelerate carbon sequestration. Bioreactors containing algae or cyanobacteria can efficiently capture carbon dioxide while producing valuable biomass. These biological approaches often have lower energy requirements than mechanical or chemical methods and can provide additional environmental benefits such as habitat creation or soil improvement.Expand Specific Solutions05 Novel materials and adsorption technologies

Advanced materials are being developed specifically for carbon capture applications, including metal-organic frameworks (MOFs), zeolites, and specialized polymer membranes. These materials offer high selectivity and capacity for CO2 adsorption while requiring less energy for regeneration compared to traditional solvents. Pressure swing adsorption and temperature swing adsorption techniques utilize these materials to efficiently separate carbon dioxide from gas mixtures. The development of these novel materials represents a significant advancement in making carbon capture more energy-efficient and cost-effective.Expand Specific Solutions

Leading Organizations in Carbon Capture Industry

Carbon capture technology evolution is currently in a growth phase, with the market expected to expand significantly due to increasing climate change concerns. The global carbon capture market is projected to reach $7-10 billion by 2030, growing at a CAGR of approximately 15%. Technologically, the field is advancing from first-generation post-combustion capture to more innovative approaches. Leading players include energy giants like Sinopec and CHN Energy Investment Group, who are leveraging their industrial infrastructure, alongside specialized firms like AirCapture LLC and Daphne Technology developing breakthrough solutions. Academic institutions such as Columbia University, Zhejiang University, and Korea Advanced Institute of Science & Technology are driving fundamental research, while collaborations between industry and academia are accelerating commercialization pathways for emerging carbon capture technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive carbon capture technology solutions focusing on post-combustion capture using advanced amine-based solvents. Their integrated CCUS (Carbon Capture, Utilization and Storage) approach combines capture facilities with enhanced oil recovery (EOR) applications. Sinopec's Qilu-Shengli CCUS project, one of China's largest, captures approximately 1 million tons of CO2 annually from petrochemical operations and injects it into oil fields to increase production while achieving permanent storage. The company has also pioneered membrane separation technology and solid adsorbents specifically designed for high-pressure, high-concentration CO2 streams from industrial processes. Sinopec's research focuses on reducing energy penalties associated with carbon capture, with their latest solvent formulations requiring 25-30% less energy for regeneration compared to conventional MEA solutions.

Strengths: Extensive industrial implementation experience; integration with existing petroleum infrastructure; proven large-scale deployment capabilities; strong R&D capacity for solvent optimization. Weaknesses: Technologies primarily focused on high-concentration CO2 sources; relatively high capital costs; technology solutions heavily tied to EOR applications which may limit applicability in regions without suitable oil fields.

Infinium Technology LLC

Technical Solution: Infinium Technology LLC has pioneered an integrated carbon capture and conversion system focused on transforming industrial CO2 emissions into carbon-neutral electrofuels. Their proprietary technology combines advanced carbon capture with electrochemical conversion processes to produce drop-in replacement fuels and chemical feedstocks. The capture component utilizes a specialized ionic liquid absorbent that selectively binds CO2 with approximately 25% lower energy requirements for regeneration compared to conventional amine systems. What distinguishes Infinium's approach is their direct integration of capture with conversion - the captured CO2 is fed into their electrochemical conversion units where it combines with green hydrogen (produced via renewable-powered electrolysis) to create synthetic fuels including eFuel (synthetic gasoline), eSAF (sustainable aviation fuel), and eDiesel. Their system achieves conversion efficiencies of 70-80% from electricity to liquid fuel, significantly higher than alternative power-to-liquid pathways. Infinium has deployed commercial-scale demonstration projects capturing 10,000+ tons of CO2 annually and converting it to usable fuels, with plans to scale to megaton capacity within the next 5 years.

Strengths: Integrated capture-to-products approach; production of high-value drop-in replacement fuels; ability to utilize intermittent renewable energy; modular and scalable design; creates economic value from captured carbon. Weaknesses: Higher overall system complexity; requires significant renewable electricity for conversion process; economics heavily dependent on electricity prices and fuel market values; technology still scaling to achieve full commercial deployment; requires hydrogen production infrastructure.

Critical Patents and Innovations in Carbon Capture

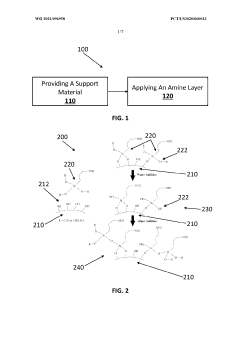

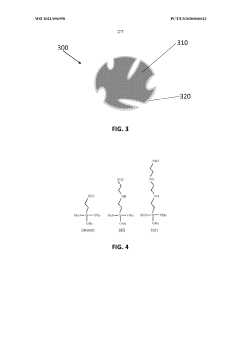

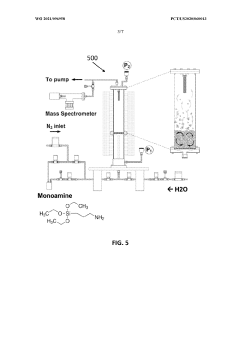

Synthesis process for solid carbon capture materials

PatentWO2021096958A1

Innovation

- The use of molecular layer deposition (MLD) to create amine-functionalized solid CO2 sorbents, which allows for precise angstrom-level thickness control and covalent anchoring of amine layers on a wide range of substrate materials, including nano-powders, enhancing surface area functionalization and maintaining active sites during regeneration without specialized substrates or costly preparation.

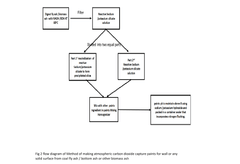

Method of making atmospheric carbon dioxide capture paints for wall or any solid surface from coal fly ash / bottom ash or other biomass ash

PatentPendingIN202321036002A

Innovation

- Development of paints from coal fly ash or biomass ash containing reactive sodium/potassium silicate that react with atmospheric CO2 at normal temperatures and pressures, reducing energy consumption and waste, using a process involving heating ash with sodium/potassium hydroxide, filtration, and mixing with additives to form a paint that captures CO2 through a thermodynamically favorable reaction.

Policy and Regulatory Framework for Carbon Capture

The policy and regulatory landscape has emerged as a critical driver in the evolution of carbon capture technologies. Governments worldwide have implemented various mechanisms to incentivize carbon capture deployment, with carbon pricing being among the most influential. Carbon taxes and cap-and-trade systems create economic incentives for industries to reduce emissions, thereby stimulating investment in carbon capture solutions. The European Union Emissions Trading System (EU ETS) represents one of the most established carbon markets, while similar mechanisms are expanding globally.

Tax incentives and direct subsidies form another crucial component of the regulatory framework. The United States' 45Q tax credit, which provides up to $50 per metric ton of CO2 stored geologically, has significantly accelerated carbon capture projects across the country. Similarly, Canada's carbon tax rebate program and the UK's Contracts for Difference scheme have created favorable conditions for technology development and implementation.

Mandatory emission reduction targets established through international agreements have further propelled carbon capture innovation. The Paris Agreement's nationally determined contributions (NDCs) have prompted countries to develop comprehensive climate strategies, many of which include carbon capture as a key component. These targets create long-term market certainty that encourages sustained research and development investments.

Regulatory frameworks for carbon transport and storage infrastructure represent another critical policy area. Countries like Norway and the UK have established comprehensive legal frameworks addressing liability, monitoring requirements, and permitting processes for CO2 storage sites. These regulations reduce investment uncertainty and facilitate project development by clarifying operational parameters and risk allocation.

Cross-border cooperation mechanisms have emerged as essential elements in scaling carbon capture deployment. The EU's Innovation Fund and similar multinational initiatives provide funding for demonstration projects and knowledge sharing platforms. These collaborative approaches help overcome the significant capital requirements and technical challenges associated with early-stage carbon capture technologies.

Standards and certification systems for carbon removal and storage verification are increasingly important as the market matures. Organizations like the International Organization for Standardization (ISO) are developing frameworks to ensure captured carbon is permanently sequestered, creating trust in offset markets and enabling premium pricing for verified carbon removal. These standards are essential for the development of robust carbon markets that can channel private investment into technology development.

Tax incentives and direct subsidies form another crucial component of the regulatory framework. The United States' 45Q tax credit, which provides up to $50 per metric ton of CO2 stored geologically, has significantly accelerated carbon capture projects across the country. Similarly, Canada's carbon tax rebate program and the UK's Contracts for Difference scheme have created favorable conditions for technology development and implementation.

Mandatory emission reduction targets established through international agreements have further propelled carbon capture innovation. The Paris Agreement's nationally determined contributions (NDCs) have prompted countries to develop comprehensive climate strategies, many of which include carbon capture as a key component. These targets create long-term market certainty that encourages sustained research and development investments.

Regulatory frameworks for carbon transport and storage infrastructure represent another critical policy area. Countries like Norway and the UK have established comprehensive legal frameworks addressing liability, monitoring requirements, and permitting processes for CO2 storage sites. These regulations reduce investment uncertainty and facilitate project development by clarifying operational parameters and risk allocation.

Cross-border cooperation mechanisms have emerged as essential elements in scaling carbon capture deployment. The EU's Innovation Fund and similar multinational initiatives provide funding for demonstration projects and knowledge sharing platforms. These collaborative approaches help overcome the significant capital requirements and technical challenges associated with early-stage carbon capture technologies.

Standards and certification systems for carbon removal and storage verification are increasingly important as the market matures. Organizations like the International Organization for Standardization (ISO) are developing frameworks to ensure captured carbon is permanently sequestered, creating trust in offset markets and enabling premium pricing for verified carbon removal. These standards are essential for the development of robust carbon markets that can channel private investment into technology development.

Economic Viability and Cost Reduction Strategies

Economic viability remains the most significant barrier to widespread adoption of carbon capture technologies. Current capture costs range from $40-120 per ton of CO2 depending on the source and technology employed, making many implementations financially unfeasible without substantial subsidies or carbon pricing mechanisms. The high capital expenditure (CAPEX) for installation and significant operational expenditure (OPEX) for energy consumption create challenging economic hurdles.

Cost reduction strategies are emerging across multiple fronts. Materials innovation represents a critical pathway, with research focused on developing more efficient sorbents and membranes that can capture CO2 with lower energy penalties. Advanced amines, metal-organic frameworks (MOFs), and enzyme-based systems show particular promise for reducing regeneration energy requirements by 30-40% compared to conventional technologies.

Process optimization through heat integration, pressure swing adsorption improvements, and more efficient solvent regeneration cycles has demonstrated potential cost reductions of 15-25%. These engineering advances, while incremental, provide near-term opportunities for making carbon capture more economically viable across various industrial applications.

Scale economies represent another crucial driver, with modeling suggesting that doubling capture capacity can reduce unit costs by approximately 10-15%. This has spurred interest in hub-and-cluster approaches where multiple industrial facilities share capture and transport infrastructure, distributing fixed costs across larger CO2 volumes.

Policy mechanisms increasingly influence economic viability. Carbon pricing, tax credits like the U.S. 45Q, and regulatory frameworks in the EU and Canada have begun shifting the financial equation. The U.S. Inflation Reduction Act's enhancement of the 45Q tax credit to $85/ton for stored CO2 has particularly accelerated project development by improving return-on-investment calculations.

Innovative business models are emerging to address remaining economic barriers. These include carbon capture-as-a-service offerings, CO2 utilization partnerships that create revenue streams from captured carbon, and risk-sharing arrangements between technology providers and industrial partners. These approaches help overcome the significant upfront investment requirements that have historically limited deployment.

The learning curve effect is becoming increasingly apparent as more projects reach commercial scale. Data from operational facilities indicates cost reductions of approximately 5-8% with each doubling of global installed capacity, suggesting that accelerated deployment itself becomes a driver of improved economic viability.

Cost reduction strategies are emerging across multiple fronts. Materials innovation represents a critical pathway, with research focused on developing more efficient sorbents and membranes that can capture CO2 with lower energy penalties. Advanced amines, metal-organic frameworks (MOFs), and enzyme-based systems show particular promise for reducing regeneration energy requirements by 30-40% compared to conventional technologies.

Process optimization through heat integration, pressure swing adsorption improvements, and more efficient solvent regeneration cycles has demonstrated potential cost reductions of 15-25%. These engineering advances, while incremental, provide near-term opportunities for making carbon capture more economically viable across various industrial applications.

Scale economies represent another crucial driver, with modeling suggesting that doubling capture capacity can reduce unit costs by approximately 10-15%. This has spurred interest in hub-and-cluster approaches where multiple industrial facilities share capture and transport infrastructure, distributing fixed costs across larger CO2 volumes.

Policy mechanisms increasingly influence economic viability. Carbon pricing, tax credits like the U.S. 45Q, and regulatory frameworks in the EU and Canada have begun shifting the financial equation. The U.S. Inflation Reduction Act's enhancement of the 45Q tax credit to $85/ton for stored CO2 has particularly accelerated project development by improving return-on-investment calculations.

Innovative business models are emerging to address remaining economic barriers. These include carbon capture-as-a-service offerings, CO2 utilization partnerships that create revenue streams from captured carbon, and risk-sharing arrangements between technology providers and industrial partners. These approaches help overcome the significant upfront investment requirements that have historically limited deployment.

The learning curve effect is becoming increasingly apparent as more projects reach commercial scale. Data from operational facilities indicates cost reductions of approximately 5-8% with each doubling of global installed capacity, suggesting that accelerated deployment itself becomes a driver of improved economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!