Comparative Analysis of Thermal Management in Carbon Capture Tech

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Thermal Management Background and Objectives

Carbon capture technologies have evolved significantly over the past three decades, transitioning from theoretical concepts to commercial implementations across various industrial sectors. The thermal management aspects of these technologies represent a critical component that directly impacts their efficiency, operational costs, and environmental footprint. Historically, carbon capture systems have been characterized by high energy penalties, with thermal management challenges accounting for approximately 70-80% of the total energy consumption in conventional amine-based capture systems.

The evolution of thermal management in carbon capture can be traced through three distinct phases. The first phase (1990-2005) focused primarily on basic absorption processes with limited thermal optimization. The second phase (2005-2015) saw the introduction of heat integration techniques and advanced solvent formulations designed to reduce regeneration energy requirements. The current phase (2015-present) is characterized by innovative approaches including membrane-assisted absorption, non-aqueous solvents, and advanced process configurations that fundamentally alter the thermal dynamics of capture systems.

Current technological trajectories indicate a convergence toward hybrid systems that combine multiple capture mechanisms to optimize thermal performance across varying operational conditions. The integration of waste heat recovery, phase-change materials for thermal energy storage, and advanced heat exchanger designs represents key areas of development that are reshaping the thermal efficiency landscape of carbon capture technologies.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of thermal management strategies across the major carbon capture pathways: post-combustion, pre-combustion, and oxy-fuel combustion technologies. This analysis aims to identify the most promising thermal management innovations that can significantly reduce the energy penalty associated with carbon capture while maintaining or improving capture efficiency.

Secondary objectives include quantifying the relationship between thermal management approaches and overall system performance metrics, evaluating the scalability of emerging thermal management solutions, and assessing their compatibility with existing industrial infrastructure. Additionally, this research seeks to establish standardized metrics for comparing thermal performance across diverse capture technologies, enabling more accurate techno-economic assessments and informing strategic R&D investments in the field.

The findings from this comparative analysis will provide critical insights for technology developers, policy makers, and industrial stakeholders seeking to accelerate the deployment of economically viable carbon capture solutions as part of broader decarbonization strategies.

The evolution of thermal management in carbon capture can be traced through three distinct phases. The first phase (1990-2005) focused primarily on basic absorption processes with limited thermal optimization. The second phase (2005-2015) saw the introduction of heat integration techniques and advanced solvent formulations designed to reduce regeneration energy requirements. The current phase (2015-present) is characterized by innovative approaches including membrane-assisted absorption, non-aqueous solvents, and advanced process configurations that fundamentally alter the thermal dynamics of capture systems.

Current technological trajectories indicate a convergence toward hybrid systems that combine multiple capture mechanisms to optimize thermal performance across varying operational conditions. The integration of waste heat recovery, phase-change materials for thermal energy storage, and advanced heat exchanger designs represents key areas of development that are reshaping the thermal efficiency landscape of carbon capture technologies.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of thermal management strategies across the major carbon capture pathways: post-combustion, pre-combustion, and oxy-fuel combustion technologies. This analysis aims to identify the most promising thermal management innovations that can significantly reduce the energy penalty associated with carbon capture while maintaining or improving capture efficiency.

Secondary objectives include quantifying the relationship between thermal management approaches and overall system performance metrics, evaluating the scalability of emerging thermal management solutions, and assessing their compatibility with existing industrial infrastructure. Additionally, this research seeks to establish standardized metrics for comparing thermal performance across diverse capture technologies, enabling more accurate techno-economic assessments and informing strategic R&D investments in the field.

The findings from this comparative analysis will provide critical insights for technology developers, policy makers, and industrial stakeholders seeking to accelerate the deployment of economically viable carbon capture solutions as part of broader decarbonization strategies.

Market Demand Analysis for Efficient Carbon Capture Solutions

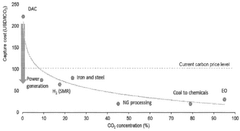

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and stringent regulatory frameworks aimed at reducing greenhouse gas emissions. Current market projections indicate that the carbon capture, utilization, and storage (CCUS) market is expected to reach $7.0 billion by 2030, with a compound annual growth rate of approximately 13.8% from 2023. This growth trajectory underscores the escalating demand for efficient carbon capture solutions across various industrial sectors.

Energy-intensive industries, particularly power generation, cement production, steel manufacturing, and chemical processing, represent the primary market segments for carbon capture technologies. These sectors collectively contribute to over 70% of global industrial CO2 emissions, creating substantial demand for thermal management solutions that can enhance capture efficiency while minimizing energy penalties.

Market research reveals a growing preference for technologies that address the thermal management challenges inherent in carbon capture processes. Post-combustion capture methods, which currently dominate the market with approximately 65% share, face significant energy penalties due to the heat required for solvent regeneration. This has created a specific market demand for advanced thermal integration strategies that can reduce the energy consumption by 20-30% compared to conventional approaches.

Regional analysis indicates varying market dynamics, with North America and Europe leading in technology adoption due to favorable policy environments and carbon pricing mechanisms. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 15% annually, driven by rapid industrialization coupled with increasing environmental commitments.

Customer requirements are evolving toward solutions that offer not only effective carbon capture but also optimized thermal performance. End-users increasingly prioritize technologies that demonstrate lower parasitic energy loads, improved heat recovery systems, and enhanced thermal integration with existing industrial processes. Market surveys indicate that approximately 85% of potential adopters consider energy efficiency and thermal management capabilities as critical decision factors when evaluating carbon capture solutions.

The market also shows growing interest in modular and scalable systems that can be retrofitted to existing facilities with minimal disruption. This trend is particularly evident in the industrial sector, where space constraints and operational continuity are significant considerations. Solutions offering compact heat exchangers and advanced thermal storage capabilities are experiencing demand growth rates approximately 1.5 times higher than conventional systems.

Emerging market opportunities exist in developing integrated energy systems that combine carbon capture with waste heat utilization, potentially creating additional value streams through cogeneration or district heating applications. This integration potential is increasingly recognized as a key market differentiator, with pilot projects demonstrating up to 40% improvement in overall system economics through effective thermal management strategies.

Energy-intensive industries, particularly power generation, cement production, steel manufacturing, and chemical processing, represent the primary market segments for carbon capture technologies. These sectors collectively contribute to over 70% of global industrial CO2 emissions, creating substantial demand for thermal management solutions that can enhance capture efficiency while minimizing energy penalties.

Market research reveals a growing preference for technologies that address the thermal management challenges inherent in carbon capture processes. Post-combustion capture methods, which currently dominate the market with approximately 65% share, face significant energy penalties due to the heat required for solvent regeneration. This has created a specific market demand for advanced thermal integration strategies that can reduce the energy consumption by 20-30% compared to conventional approaches.

Regional analysis indicates varying market dynamics, with North America and Europe leading in technology adoption due to favorable policy environments and carbon pricing mechanisms. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 15% annually, driven by rapid industrialization coupled with increasing environmental commitments.

Customer requirements are evolving toward solutions that offer not only effective carbon capture but also optimized thermal performance. End-users increasingly prioritize technologies that demonstrate lower parasitic energy loads, improved heat recovery systems, and enhanced thermal integration with existing industrial processes. Market surveys indicate that approximately 85% of potential adopters consider energy efficiency and thermal management capabilities as critical decision factors when evaluating carbon capture solutions.

The market also shows growing interest in modular and scalable systems that can be retrofitted to existing facilities with minimal disruption. This trend is particularly evident in the industrial sector, where space constraints and operational continuity are significant considerations. Solutions offering compact heat exchangers and advanced thermal storage capabilities are experiencing demand growth rates approximately 1.5 times higher than conventional systems.

Emerging market opportunities exist in developing integrated energy systems that combine carbon capture with waste heat utilization, potentially creating additional value streams through cogeneration or district heating applications. This integration potential is increasingly recognized as a key market differentiator, with pilot projects demonstrating up to 40% improvement in overall system economics through effective thermal management strategies.

Current Thermal Management Challenges in Carbon Capture

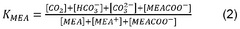

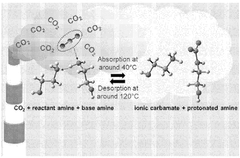

Carbon capture technologies face significant thermal management challenges that directly impact their efficiency, operational costs, and environmental footprint. The primary challenge stems from the substantial energy requirements for solvent regeneration in post-combustion capture systems, which typically consume 70-80% of the total energy demand. This regeneration process requires temperatures between 100-150°C for conventional amine-based systems, creating a substantial thermal load that must be managed effectively.

Heat integration represents another critical challenge, as carbon capture units must be thermally integrated with existing power plants or industrial facilities. The temperature mismatch between flue gas streams (typically 40-60°C) and optimal absorption conditions often necessitates additional cooling systems, further complicating thermal management strategies and reducing overall system efficiency.

Temperature control during absorption processes presents unique difficulties, as most chemical solvents exhibit temperature-dependent absorption capacities. Exothermic absorption reactions generate heat that must be removed to maintain optimal capture efficiency, requiring sophisticated cooling systems that add complexity and cost to capture installations. This delicate balance between temperature and capture performance remains a significant engineering challenge.

Material degradation accelerated by thermal cycling constitutes another major concern. Conventional amine solvents undergo thermal degradation at regeneration temperatures, forming heat-stable salts and reducing capture capacity over time. This degradation not only increases operational costs through solvent replacement but also creates potential environmental hazards from degradation byproducts.

Energy penalties associated with thermal management directly impact the commercial viability of carbon capture technologies. Current estimates suggest that implementing carbon capture in power plants reduces net efficiency by 7-12 percentage points, primarily due to thermal energy requirements. This substantial energy penalty translates to higher electricity costs and reduced competitiveness compared to unabated power generation.

Scaling issues present additional thermal management complications. Heat exchanger fouling from particulate matter in flue gas streams reduces heat transfer efficiency over time, while uneven temperature distribution in large-scale absorber columns can create performance inconsistencies and operational challenges. These scaling issues become increasingly problematic as capture technologies move from demonstration to commercial deployment.

Emerging technologies like solid sorbents and membrane systems face their own thermal challenges, including heat management during pressure-temperature swing cycles and temperature-dependent selectivity issues. These newer approaches require innovative thermal management solutions that differ substantially from those developed for conventional solvent-based systems.

Heat integration represents another critical challenge, as carbon capture units must be thermally integrated with existing power plants or industrial facilities. The temperature mismatch between flue gas streams (typically 40-60°C) and optimal absorption conditions often necessitates additional cooling systems, further complicating thermal management strategies and reducing overall system efficiency.

Temperature control during absorption processes presents unique difficulties, as most chemical solvents exhibit temperature-dependent absorption capacities. Exothermic absorption reactions generate heat that must be removed to maintain optimal capture efficiency, requiring sophisticated cooling systems that add complexity and cost to capture installations. This delicate balance between temperature and capture performance remains a significant engineering challenge.

Material degradation accelerated by thermal cycling constitutes another major concern. Conventional amine solvents undergo thermal degradation at regeneration temperatures, forming heat-stable salts and reducing capture capacity over time. This degradation not only increases operational costs through solvent replacement but also creates potential environmental hazards from degradation byproducts.

Energy penalties associated with thermal management directly impact the commercial viability of carbon capture technologies. Current estimates suggest that implementing carbon capture in power plants reduces net efficiency by 7-12 percentage points, primarily due to thermal energy requirements. This substantial energy penalty translates to higher electricity costs and reduced competitiveness compared to unabated power generation.

Scaling issues present additional thermal management complications. Heat exchanger fouling from particulate matter in flue gas streams reduces heat transfer efficiency over time, while uneven temperature distribution in large-scale absorber columns can create performance inconsistencies and operational challenges. These scaling issues become increasingly problematic as capture technologies move from demonstration to commercial deployment.

Emerging technologies like solid sorbents and membrane systems face their own thermal challenges, including heat management during pressure-temperature swing cycles and temperature-dependent selectivity issues. These newer approaches require innovative thermal management solutions that differ substantially from those developed for conventional solvent-based systems.

Existing Thermal Management Technologies for Carbon Capture

01 Heat management systems for carbon capture processes

Thermal management systems designed specifically for carbon capture processes help optimize energy efficiency. These systems include heat exchangers, thermal recovery units, and temperature control mechanisms that manage the heat generated during carbon capture operations. By effectively managing thermal energy, these systems can reduce the overall energy consumption of carbon capture facilities while maintaining operational efficiency.- Heat management systems for carbon capture processes: Thermal management systems designed specifically for carbon capture processes help optimize energy efficiency. These systems include heat exchangers, thermal recovery units, and temperature control mechanisms that manage the heat generated during carbon capture operations. By effectively managing thermal energy, these systems can reduce the overall energy consumption of carbon capture facilities while maintaining operational efficiency.

- Cooling technologies for carbon capture equipment: Specialized cooling technologies are essential for maintaining optimal operating temperatures in carbon capture equipment. These include advanced cooling systems that prevent overheating of critical components, liquid cooling circuits, and temperature regulation mechanisms. Effective cooling solutions help extend equipment lifespan, improve capture efficiency, and prevent thermal-related failures in carbon capture installations.

- Waste heat recovery in carbon capture systems: Waste heat recovery technologies capture and repurpose thermal energy generated during carbon capture processes. These systems integrate heat exchangers, thermal storage solutions, and energy conversion mechanisms to utilize waste heat for other processes or to generate electricity. By recovering waste heat, these technologies improve the overall energy efficiency of carbon capture operations and reduce operational costs.

- Thermal integration with industrial processes: Carbon capture systems can be thermally integrated with existing industrial processes to optimize energy usage. This integration involves connecting the thermal management systems of carbon capture units with industrial heat networks, allowing for efficient heat exchange between processes. Such integration reduces the net energy penalty of carbon capture while providing thermal management benefits to both the capture system and the industrial process.

- Advanced materials for thermal efficiency in carbon capture: Novel materials with enhanced thermal properties are being developed for carbon capture applications. These materials include thermally conductive composites, heat-resistant alloys, and advanced insulation materials that improve heat transfer, thermal stability, and energy efficiency. By incorporating these materials into carbon capture equipment, thermal management challenges can be addressed more effectively, leading to improved performance and reduced energy requirements.

02 Cooling technologies for carbon capture equipment

Specialized cooling technologies are essential for maintaining optimal operating temperatures in carbon capture equipment. These include advanced cooling systems that prevent overheating of critical components, liquid cooling circuits, and temperature regulation mechanisms. Effective cooling ensures the longevity of equipment, prevents thermal degradation of capture materials, and maintains capture efficiency under various operational conditions.Expand Specific Solutions03 Waste heat recovery in carbon capture systems

Waste heat recovery technologies capture and repurpose thermal energy generated during carbon capture processes. These systems integrate heat exchangers, thermal storage solutions, and energy conversion technologies to utilize waste heat for other processes within the facility. By recovering waste heat, these technologies improve the overall energy efficiency of carbon capture operations and reduce operational costs.Expand Specific Solutions04 Thermal integration with industrial processes

Carbon capture systems can be thermally integrated with existing industrial processes to optimize energy usage. This integration involves designing capture systems that can utilize excess heat from industrial operations or provide heating/cooling to other processes. Such thermal integration reduces the net energy penalty associated with carbon capture and creates synergies between carbon capture and other industrial operations.Expand Specific Solutions05 Temperature-responsive capture materials and methods

Advanced materials and methods that respond to temperature changes can enhance carbon capture efficiency. These include temperature-swing adsorption techniques, thermally responsive sorbents, and materials with temperature-dependent capture properties. By leveraging the relationship between temperature and capture efficiency, these technologies can optimize the carbon capture process while minimizing energy requirements for regeneration and operation.Expand Specific Solutions

Key Industry Players in Carbon Capture Thermal Solutions

The thermal management landscape in carbon capture technologies is evolving rapidly, currently transitioning from early commercialization to growth phase with a projected market size exceeding $7 billion by 2030. Research institutions like Huaneng Clean Energy Research Institute, Korea Research Institute of Chemical Technology, and universities (Southeast University, Melbourne, Nanyang Technological) are driving fundamental innovations, while industrial players demonstrate varying technical maturity. Energy corporations (Huaneng Group, GE, Schlumberger) focus on integration with existing power infrastructure, while specialized firms like Airrane and C-Tech develop membrane-based solutions. Equipment manufacturers (Hitachi, Toshiba, Mitsubishi) are advancing thermal efficiency improvements, creating a competitive ecosystem balancing academic research with industrial implementation across different technological approaches.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed an integrated thermal management system for their carbon capture facilities that utilizes waste heat recovery and optimization. Their approach incorporates a multi-stage heat integration framework that captures and repurposes thermal energy from various points in the carbon capture process. The system employs advanced heat exchangers and thermal storage solutions to minimize energy penalties associated with solvent regeneration, which typically accounts for 60-70% of the total energy consumption in post-combustion capture systems. Their proprietary thermal management control system dynamically adjusts operating parameters based on real-time plant conditions, achieving up to 30% reduction in regeneration energy requirements compared to conventional systems. The institute has implemented this technology at several pilot plants, demonstrating consistent performance improvements across different capture technologies including amine-based and advanced solid sorbent systems.

Strengths: Significant reduction in energy penalty through advanced heat integration; proven implementation at commercial scale; adaptability to various carbon capture technologies. Weaknesses: Higher initial capital investment; requires sophisticated control systems and expertise for optimal operation; performance may vary with fluctuating plant loads.

Korea Research Institute of Chemical Technology

Technical Solution: Korea Research Institute of Chemical Technology (KRICT) has pioneered a novel thermal management approach for carbon capture that focuses on advanced material solutions and process intensification. Their technology utilizes specially engineered heat transfer fluids with enhanced thermal conductivity and heat capacity, allowing for more efficient temperature control during both absorption and desorption processes. KRICT's system incorporates microstructured heat exchangers that provide significantly higher surface area-to-volume ratios than conventional designs, enabling more compact equipment footprints while maintaining thermal efficiency. Their research has demonstrated that these specialized heat exchangers can reduce the temperature gradient across absorption columns by up to 40%, resulting in more uniform solvent performance and reduced degradation rates. Additionally, KRICT has developed phase-change materials specifically designed for carbon capture applications that can store and release thermal energy at precise temperature ranges, helping to buffer thermal fluctuations and reduce peak energy demands during the regeneration cycle.

Strengths: Innovative materials science approach; significant reduction in equipment size and footprint; excellent thermal stability and control. Weaknesses: Higher material costs; potential scaling challenges for very large installations; requires specialized manufacturing capabilities for advanced heat exchanger designs.

Critical Patents and Innovations in Carbon Capture Heat Control

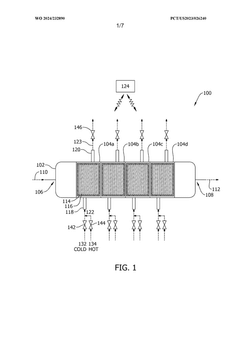

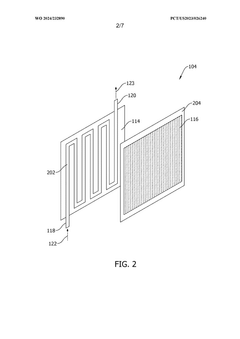

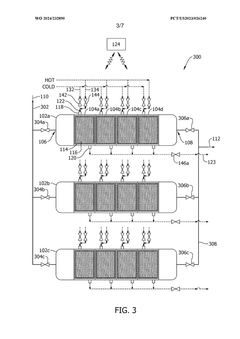

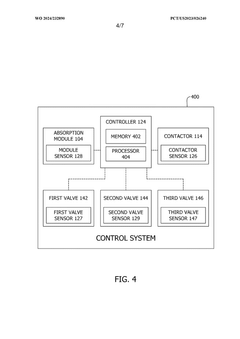

Systems and methods for optimizing carbon dioxide capture using temperature management

PatentWO2024232890A1

Innovation

- A capture system utilizing a contactor with a regulating fluid stream comprising a cold and hot stream, managed by a controller to modulate the temperature of adsorption modules, allowing for indirect heating and cooling to optimize carbon dioxide adsorption and desorption efficiency.

Systems and methods for combined carbon capture and thermal energy storage

PatentWO2025095856A1

Innovation

- A method and system for combined carbon capture and thermal energy storage, where CO2 is captured using a carbon capture medium that generates heat through an exothermic reaction, and this heat is utilized for thermal energy storage, with cooling applied to maintain the capture medium at a temperature below the CO2 regeneration temperature.

Environmental Impact Assessment of Thermal Management Methods

The environmental implications of thermal management systems in carbon capture technologies extend far beyond operational efficiency, representing a critical factor in the overall sustainability assessment of these solutions. Different thermal management approaches can significantly vary in their environmental footprints, necessitating comprehensive evaluation.

Water consumption presents a primary environmental concern, particularly in post-combustion capture systems that typically employ water-intensive cooling methods. Regions facing water scarcity must carefully consider this impact, as conventional wet cooling towers can consume 2-3 gallons of water per kilowatt-hour of electricity generated when integrated with carbon capture systems. Alternative dry cooling technologies, while reducing water usage by up to 90%, often incur energy penalties that may indirectly increase carbon emissions.

Air pollution profiles differ substantially across thermal management solutions. Traditional cooling systems may contribute to localized air quality issues through particulate matter and potential refrigerant leakage. Advanced membrane-based cooling technologies demonstrate significantly reduced air pollutant emissions, with recent field tests showing reductions of up to 75% in volatile organic compound releases compared to conventional alternatives.

Land use requirements represent another crucial environmental dimension. Geothermal heat exchange systems for carbon capture facilities typically require extensive underground infrastructure, potentially disrupting local ecosystems during installation. However, their long-term land footprint is minimal compared to large cooling towers or air-cooled condensers that permanently alter landscapes and potentially impact wildlife habitats.

Waste heat utilization efficiency varies dramatically between thermal management approaches. Integrated systems that capture and repurpose waste heat for district heating or industrial processes can transform what would be environmental pollution into valuable energy resources. Recent implementations in Northern European carbon capture facilities demonstrate that up to 60% of waste heat can be effectively recovered and utilized, substantially improving the overall environmental profile.

Life cycle assessment studies reveal that advanced thermal management systems incorporating phase-change materials and thermally conductive nanofluids can reduce the embodied carbon of carbon capture operations by 15-25% compared to conventional cooling approaches. However, these materials may introduce new environmental challenges related to nanoparticle production and end-of-life disposal considerations that require further investigation.

The environmental resilience of different thermal management solutions also varies significantly under changing climate conditions, with passive cooling systems demonstrating greater adaptability to rising ambient temperatures compared to conventional mechanical cooling approaches.

Water consumption presents a primary environmental concern, particularly in post-combustion capture systems that typically employ water-intensive cooling methods. Regions facing water scarcity must carefully consider this impact, as conventional wet cooling towers can consume 2-3 gallons of water per kilowatt-hour of electricity generated when integrated with carbon capture systems. Alternative dry cooling technologies, while reducing water usage by up to 90%, often incur energy penalties that may indirectly increase carbon emissions.

Air pollution profiles differ substantially across thermal management solutions. Traditional cooling systems may contribute to localized air quality issues through particulate matter and potential refrigerant leakage. Advanced membrane-based cooling technologies demonstrate significantly reduced air pollutant emissions, with recent field tests showing reductions of up to 75% in volatile organic compound releases compared to conventional alternatives.

Land use requirements represent another crucial environmental dimension. Geothermal heat exchange systems for carbon capture facilities typically require extensive underground infrastructure, potentially disrupting local ecosystems during installation. However, their long-term land footprint is minimal compared to large cooling towers or air-cooled condensers that permanently alter landscapes and potentially impact wildlife habitats.

Waste heat utilization efficiency varies dramatically between thermal management approaches. Integrated systems that capture and repurpose waste heat for district heating or industrial processes can transform what would be environmental pollution into valuable energy resources. Recent implementations in Northern European carbon capture facilities demonstrate that up to 60% of waste heat can be effectively recovered and utilized, substantially improving the overall environmental profile.

Life cycle assessment studies reveal that advanced thermal management systems incorporating phase-change materials and thermally conductive nanofluids can reduce the embodied carbon of carbon capture operations by 15-25% compared to conventional cooling approaches. However, these materials may introduce new environmental challenges related to nanoparticle production and end-of-life disposal considerations that require further investigation.

The environmental resilience of different thermal management solutions also varies significantly under changing climate conditions, with passive cooling systems demonstrating greater adaptability to rising ambient temperatures compared to conventional mechanical cooling approaches.

Energy Integration Strategies for Carbon Capture Systems

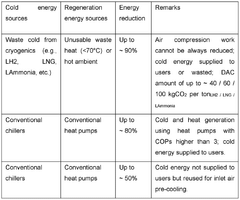

Energy integration represents a critical dimension in optimizing carbon capture systems, particularly when addressing thermal management challenges. The integration of heat recovery networks within carbon capture processes can significantly reduce the overall energy penalty, which typically ranges from 20-30% in conventional systems. Process integration techniques such as pinch analysis and exergy optimization have demonstrated potential energy savings of 15-25% in post-combustion capture facilities.

Advanced heat exchanger networks play a pivotal role in energy integration strategies. Shell-and-tube configurations remain prevalent in industrial applications, while compact plate heat exchangers offer enhanced efficiency in space-constrained environments. Recent innovations in printed circuit heat exchangers have shown promising results for high-pressure CO2 applications, achieving thermal effectiveness exceeding 90% while minimizing pressure drop.

Waste heat recovery systems represent another crucial energy integration pathway. Low-grade heat from flue gas streams and compression intercooling can be repurposed to provide thermal energy for solvent regeneration. Studies indicate that implementing multi-level heat recovery can reduce reboiler duty by 10-15% in amine-based capture systems, translating to substantial operational cost savings.

Cogeneration and polygeneration strategies further enhance energy integration by coupling carbon capture with power generation and other value-added processes. Combined heat and power (CHP) systems integrated with carbon capture have demonstrated overall system efficiencies of 65-75%, compared to 55-60% for conventional arrangements. These integrated energy systems can simultaneously address carbon capture requirements while producing electricity, steam, and potentially other products like hydrogen or synthetic fuels.

Process intensification techniques, including dividing wall columns and reactive distillation, represent emerging approaches to energy integration. These technologies combine multiple unit operations into single equipment, reducing capital costs while improving energy efficiency. Membrane-assisted solvent regeneration has shown potential to decrease regeneration energy requirements by up to 20% compared to conventional thermal regeneration methods.

The selection of optimal energy integration strategies must consider site-specific factors including available utility systems, spatial constraints, and operational flexibility requirements. Techno-economic analyses suggest that comprehensive energy integration can reduce the cost of CO2 avoided by $10-15 per tonne, significantly improving the economic viability of carbon capture implementation across various industrial sectors.

Advanced heat exchanger networks play a pivotal role in energy integration strategies. Shell-and-tube configurations remain prevalent in industrial applications, while compact plate heat exchangers offer enhanced efficiency in space-constrained environments. Recent innovations in printed circuit heat exchangers have shown promising results for high-pressure CO2 applications, achieving thermal effectiveness exceeding 90% while minimizing pressure drop.

Waste heat recovery systems represent another crucial energy integration pathway. Low-grade heat from flue gas streams and compression intercooling can be repurposed to provide thermal energy for solvent regeneration. Studies indicate that implementing multi-level heat recovery can reduce reboiler duty by 10-15% in amine-based capture systems, translating to substantial operational cost savings.

Cogeneration and polygeneration strategies further enhance energy integration by coupling carbon capture with power generation and other value-added processes. Combined heat and power (CHP) systems integrated with carbon capture have demonstrated overall system efficiencies of 65-75%, compared to 55-60% for conventional arrangements. These integrated energy systems can simultaneously address carbon capture requirements while producing electricity, steam, and potentially other products like hydrogen or synthetic fuels.

Process intensification techniques, including dividing wall columns and reactive distillation, represent emerging approaches to energy integration. These technologies combine multiple unit operations into single equipment, reducing capital costs while improving energy efficiency. Membrane-assisted solvent regeneration has shown potential to decrease regeneration energy requirements by up to 20% compared to conventional thermal regeneration methods.

The selection of optimal energy integration strategies must consider site-specific factors including available utility systems, spatial constraints, and operational flexibility requirements. Techno-economic analyses suggest that comprehensive energy integration can reduce the cost of CO2 avoided by $10-15 per tonne, significantly improving the economic viability of carbon capture implementation across various industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!