Case Benchmark: Direct Lithium Extraction in High-Salinity Brines

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, particularly in the context of high-salinity brines. The traditional lithium extraction methods, primarily evaporation ponds, have been utilized since the 1950s, requiring extensive land use, significant water consumption, and lengthy processing times of 18-24 months. These limitations have driven the development of more efficient extraction technologies over the past two decades.

The evolution of DLE technologies has accelerated significantly since 2010, with major breakthroughs in selective adsorption materials, membrane technologies, and electrochemical processes. This technological progression has been fueled by the exponential growth in lithium demand, primarily driven by the electric vehicle revolution and renewable energy storage requirements, creating a pressing need for more sustainable and efficient extraction methods.

High-salinity brines present unique challenges and opportunities for lithium extraction. These brines, found in locations such as the Lithium Triangle in South America, the Salton Sea in California, and various geothermal reservoirs globally, contain lithium concentrations ranging from 200 to 7,000 mg/L. The complex chemical composition of these brines, with high concentrations of competing ions like sodium, magnesium, and calcium, has historically complicated efficient lithium recovery.

The primary objective of modern DLE technology development is to achieve selective lithium extraction from high-salinity brines with recovery rates exceeding 90%, while minimizing water consumption, reducing environmental footprint, and accelerating production timelines. Additional technical goals include developing processes that can operate effectively across varying brine chemistries, withstand harsh operating conditions, and maintain performance over thousands of cycles.

Recent technological innovations have focused on addressing the specific challenges of high-salinity environments, including ion selectivity in the presence of competing species, material stability in corrosive conditions, and energy efficiency of separation processes. The development trajectory suggests a convergence toward hybrid systems that combine multiple extraction principles to maximize efficiency and selectivity.

The global transition toward sustainable energy systems has elevated the strategic importance of lithium resources, catalyzing unprecedented investment in DLE research and development. This has accelerated the technology readiness levels of various DLE approaches, with several pilot plants now demonstrating commercial viability in high-salinity environments, signaling a potential paradigm shift in how lithium is sourced for the global battery supply chain.

The evolution of DLE technologies has accelerated significantly since 2010, with major breakthroughs in selective adsorption materials, membrane technologies, and electrochemical processes. This technological progression has been fueled by the exponential growth in lithium demand, primarily driven by the electric vehicle revolution and renewable energy storage requirements, creating a pressing need for more sustainable and efficient extraction methods.

High-salinity brines present unique challenges and opportunities for lithium extraction. These brines, found in locations such as the Lithium Triangle in South America, the Salton Sea in California, and various geothermal reservoirs globally, contain lithium concentrations ranging from 200 to 7,000 mg/L. The complex chemical composition of these brines, with high concentrations of competing ions like sodium, magnesium, and calcium, has historically complicated efficient lithium recovery.

The primary objective of modern DLE technology development is to achieve selective lithium extraction from high-salinity brines with recovery rates exceeding 90%, while minimizing water consumption, reducing environmental footprint, and accelerating production timelines. Additional technical goals include developing processes that can operate effectively across varying brine chemistries, withstand harsh operating conditions, and maintain performance over thousands of cycles.

Recent technological innovations have focused on addressing the specific challenges of high-salinity environments, including ion selectivity in the presence of competing species, material stability in corrosive conditions, and energy efficiency of separation processes. The development trajectory suggests a convergence toward hybrid systems that combine multiple extraction principles to maximize efficiency and selectivity.

The global transition toward sustainable energy systems has elevated the strategic importance of lithium resources, catalyzing unprecedented investment in DLE research and development. This has accelerated the technology readiness levels of various DLE approaches, with several pilot plants now demonstrating commercial viability in high-salinity environments, signaling a potential paradigm shift in how lithium is sourced for the global battery supply chain.

Market Analysis for Lithium Extraction Solutions

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. The market value for lithium extraction solutions reached approximately $4.3 billion in 2022 and is projected to grow at a CAGR of 12.8% through 2030, potentially reaching $11.2 billion by the end of the decade.

Direct Lithium Extraction (DLE) technologies specifically targeting high-salinity brines represent a particularly promising segment within this market. Traditional evaporation pond methods, while still dominant with about 61% market share, are gradually losing ground to more efficient DLE solutions, which currently hold roughly 26% of the market and are expanding rapidly.

The demand for lithium is expected to triple by 2025 compared to 2021 levels, with high-grade lithium compounds for battery production commanding premium prices. This surge is creating significant market pull for innovative extraction technologies that can process previously uneconomical high-salinity brine resources, which contain approximately 58% of global lithium reserves but have remained largely untapped due to technical limitations.

Regional analysis reveals that the Asia-Pacific region dominates lithium consumption (47% of global demand), while Latin America leads in production capacity from brine resources. North America is emerging as a critical growth market, with investments in DLE technologies increasing by 215% between 2020 and 2022, reflecting the strategic importance of securing domestic lithium supply chains.

Customer segmentation shows three primary market groups: major battery manufacturers seeking stable, high-volume supply; mining companies looking to optimize existing operations or develop new resources; and emerging cleantech companies focused on environmentally sustainable extraction methods. The latter segment is growing at 18.3% annually, outpacing the overall market.

Price sensitivity varies significantly across these segments, with battery manufacturers willing to pay 15-20% premiums for consistent high-purity lithium compounds (99.5%+ purity), while mining operators prioritize technologies with lower CAPEX requirements and faster deployment timelines.

Market barriers include high initial investment costs for DLE facilities, technical challenges in managing complex brine chemistries, and regulatory uncertainties regarding water usage and environmental impacts. Despite these challenges, the market opportunity for high-salinity brine extraction solutions remains substantial, with first-movers potentially capturing significant market share in this rapidly evolving landscape.

Direct Lithium Extraction (DLE) technologies specifically targeting high-salinity brines represent a particularly promising segment within this market. Traditional evaporation pond methods, while still dominant with about 61% market share, are gradually losing ground to more efficient DLE solutions, which currently hold roughly 26% of the market and are expanding rapidly.

The demand for lithium is expected to triple by 2025 compared to 2021 levels, with high-grade lithium compounds for battery production commanding premium prices. This surge is creating significant market pull for innovative extraction technologies that can process previously uneconomical high-salinity brine resources, which contain approximately 58% of global lithium reserves but have remained largely untapped due to technical limitations.

Regional analysis reveals that the Asia-Pacific region dominates lithium consumption (47% of global demand), while Latin America leads in production capacity from brine resources. North America is emerging as a critical growth market, with investments in DLE technologies increasing by 215% between 2020 and 2022, reflecting the strategic importance of securing domestic lithium supply chains.

Customer segmentation shows three primary market groups: major battery manufacturers seeking stable, high-volume supply; mining companies looking to optimize existing operations or develop new resources; and emerging cleantech companies focused on environmentally sustainable extraction methods. The latter segment is growing at 18.3% annually, outpacing the overall market.

Price sensitivity varies significantly across these segments, with battery manufacturers willing to pay 15-20% premiums for consistent high-purity lithium compounds (99.5%+ purity), while mining operators prioritize technologies with lower CAPEX requirements and faster deployment timelines.

Market barriers include high initial investment costs for DLE facilities, technical challenges in managing complex brine chemistries, and regulatory uncertainties regarding water usage and environmental impacts. Despite these challenges, the market opportunity for high-salinity brine extraction solutions remains substantial, with first-movers potentially capturing significant market share in this rapidly evolving landscape.

Global DLE Technology Status and Challenges

Direct Lithium Extraction (DLE) technology has gained significant momentum globally as a more sustainable alternative to traditional evaporation ponds for lithium recovery. Currently, DLE technologies are being developed and tested across various regions with high lithium brine resources, including the United States, Chile, Argentina, Bolivia, China, and Australia. These technologies aim to address the limitations of conventional extraction methods by offering faster processing times, reduced water consumption, and higher recovery rates.

The global landscape of DLE technology development shows varying levels of maturity. In North America, several companies have reached pilot or demonstration scale operations, with some approaching commercial deployment. South American countries, which hold approximately 58% of the world's lithium resources in the "Lithium Triangle," are increasingly exploring DLE as an alternative to traditional evaporation methods that consume vast amounts of water in already water-stressed regions.

Despite promising advancements, DLE technologies face significant challenges when applied to high-salinity brines. The primary technical hurdle is selectivity - the ability to extract lithium ions while rejecting other abundant ions such as sodium, potassium, magnesium, and calcium. High-salinity environments exacerbate this challenge, as the concentration of competing ions can be orders of magnitude higher than lithium, leading to reduced efficiency and increased operational costs.

Another critical challenge is the durability of extraction materials in harsh brine environments. Ion exchange resins, adsorbents, and membranes used in DLE processes often suffer from degradation when exposed to high-salinity conditions over extended periods, resulting in decreased performance and increased replacement frequency. This degradation significantly impacts the economic viability of DLE operations in high-salinity settings.

Energy consumption represents another substantial challenge. Many DLE technologies require significant energy inputs for processes such as pumping, heating, or electrochemical operations. In high-salinity brines, these energy requirements can increase due to the need for additional pre-treatment steps or more intensive separation processes to achieve acceptable lithium purity levels.

Water management also presents a complex challenge. While DLE generally uses less water than evaporation ponds, the treatment and disposal of process water containing high concentrations of rejected salts remain problematic, particularly in environmentally sensitive or water-scarce regions.

Geographically, DLE technology development shows interesting patterns. North American and European companies lead in innovation and patent filings, while Chinese entities are rapidly advancing in both technology development and implementation. South American countries, despite hosting the largest lithium brine resources, have been slower to adopt DLE technologies, partly due to established investments in conventional extraction infrastructure.

The global landscape of DLE technology development shows varying levels of maturity. In North America, several companies have reached pilot or demonstration scale operations, with some approaching commercial deployment. South American countries, which hold approximately 58% of the world's lithium resources in the "Lithium Triangle," are increasingly exploring DLE as an alternative to traditional evaporation methods that consume vast amounts of water in already water-stressed regions.

Despite promising advancements, DLE technologies face significant challenges when applied to high-salinity brines. The primary technical hurdle is selectivity - the ability to extract lithium ions while rejecting other abundant ions such as sodium, potassium, magnesium, and calcium. High-salinity environments exacerbate this challenge, as the concentration of competing ions can be orders of magnitude higher than lithium, leading to reduced efficiency and increased operational costs.

Another critical challenge is the durability of extraction materials in harsh brine environments. Ion exchange resins, adsorbents, and membranes used in DLE processes often suffer from degradation when exposed to high-salinity conditions over extended periods, resulting in decreased performance and increased replacement frequency. This degradation significantly impacts the economic viability of DLE operations in high-salinity settings.

Energy consumption represents another substantial challenge. Many DLE technologies require significant energy inputs for processes such as pumping, heating, or electrochemical operations. In high-salinity brines, these energy requirements can increase due to the need for additional pre-treatment steps or more intensive separation processes to achieve acceptable lithium purity levels.

Water management also presents a complex challenge. While DLE generally uses less water than evaporation ponds, the treatment and disposal of process water containing high concentrations of rejected salts remain problematic, particularly in environmentally sensitive or water-scarce regions.

Geographically, DLE technology development shows interesting patterns. North American and European companies lead in innovation and patent filings, while Chinese entities are rapidly advancing in both technology development and implementation. South American countries, despite hosting the largest lithium brine resources, have been slower to adopt DLE technologies, partly due to established investments in conventional extraction infrastructure.

Current DLE Solutions for High-Salinity Brines

01 Adsorption-based DLE technologies for improved extraction efficiency

Adsorption-based Direct Lithium Extraction technologies utilize specialized adsorbents that selectively capture lithium ions from brine solutions. These materials can significantly improve extraction efficiency compared to traditional evaporation methods. The process typically involves passing lithium-containing brines through columns packed with lithium-selective adsorbents, followed by desorption steps to recover concentrated lithium solutions. This approach reduces processing time and increases lithium recovery rates while minimizing water consumption.- Adsorption-based DLE technologies: Adsorption-based Direct Lithium Extraction (DLE) technologies utilize specialized adsorbent materials to selectively capture lithium ions from brine solutions. These materials, such as lithium ion sieves, inorganic ion exchangers, and functionalized polymers, can significantly improve extraction efficiency compared to traditional evaporation methods. The process typically involves passing lithium-containing brine through columns packed with these adsorbents, followed by desorption steps to recover concentrated lithium solutions. This approach reduces water consumption and processing time while achieving higher lithium recovery rates.

- Membrane and electrochemical DLE systems: Membrane and electrochemical Direct Lithium Extraction systems employ selective membranes and electrical potential differences to separate lithium from other ions in brine solutions. These technologies include electrodialysis, capacitive deionization, and electrochemical cells with lithium-selective membranes. By applying electrical current, lithium ions can be selectively transported across membranes, resulting in concentrated lithium streams. These approaches offer advantages in terms of continuous operation, reduced chemical consumption, and the ability to process brines with varying compositions, ultimately enhancing extraction efficiency.

- Solvent extraction and chemical precipitation methods: Solvent extraction and chemical precipitation methods for Direct Lithium Extraction involve the use of specific chemical reagents to selectively separate lithium from brine solutions. These techniques utilize specialized extractants, complexing agents, or precipitating compounds that preferentially interact with lithium ions. The process typically includes mixing the brine with the extraction medium, followed by phase separation and stripping steps to recover concentrated lithium. These methods can achieve high extraction efficiency and selectivity, particularly for brines with challenging compositions or high impurity levels.

- Process optimization and efficiency enhancement techniques: Various process optimization techniques have been developed to enhance the efficiency of Direct Lithium Extraction operations. These include multi-stage extraction processes, regeneration protocols for adsorbent materials, flow rate optimization, temperature control, and pH adjustment. Advanced process control systems and real-time monitoring enable dynamic adjustments to extraction parameters based on feed composition variations. Additionally, hybrid approaches combining different extraction technologies can overcome limitations of individual methods, resulting in higher overall lithium recovery rates and improved economic performance.

- Novel materials and sustainable DLE approaches: Innovative materials and sustainable approaches are being developed to improve Direct Lithium Extraction efficiency while reducing environmental impact. These include bio-inspired adsorbents, metal-organic frameworks, nanostructured materials, and green chemistry approaches. Such materials offer enhanced selectivity, capacity, and regeneration properties. Sustainable DLE methods focus on minimizing water usage, reducing chemical consumption, utilizing renewable energy sources, and enabling zero liquid discharge operations. These advancements address both technical efficiency and environmental considerations in lithium extraction from various sources including geothermal brines and oil field waters.

02 Ion exchange membrane systems for selective lithium extraction

Ion exchange membrane systems employ specialized membranes that allow for selective transport of lithium ions while excluding competing ions. These systems can achieve high extraction efficiency by creating concentration gradients that drive lithium ions across membranes. The technology enables continuous processing of brines with reduced chemical consumption and environmental impact. Advanced membrane configurations and materials have been developed to enhance selectivity for lithium over other monovalent ions, resulting in higher purity lithium products and improved overall extraction efficiency.Expand Specific Solutions03 Electrochemical methods for enhanced lithium recovery

Electrochemical approaches to Direct Lithium Extraction utilize electrical potential differences to selectively extract lithium ions from brines. These methods can achieve high extraction efficiency through precise control of electrochemical parameters. The technology includes electrochemical cells with specialized electrodes that capture lithium ions when voltage is applied and release them during regeneration cycles. This approach offers advantages in terms of energy efficiency, processing speed, and the ability to handle brines with varying lithium concentrations, resulting in improved overall extraction performance.Expand Specific Solutions04 Solvent extraction techniques for lithium concentration

Solvent extraction techniques for lithium recovery involve the use of specialized organic solvents or ionic liquids that selectively bind to lithium ions. These methods can achieve high extraction efficiency by transferring lithium from aqueous brines to an organic phase, followed by back-extraction into a concentrated lithium solution. The process allows for effective separation of lithium from competing ions such as sodium, potassium, and magnesium. Recent innovations in solvent chemistry have improved selectivity and reduced solvent losses, enhancing the economic viability and extraction efficiency of these systems.Expand Specific Solutions05 Process optimization and integration for maximizing DLE efficiency

Optimizing Direct Lithium Extraction processes involves integrating multiple technologies and fine-tuning operational parameters to maximize extraction efficiency. This includes developing hybrid systems that combine different extraction mechanisms, optimizing pre-treatment steps to remove impurities, and implementing advanced process control strategies. Innovations in this area focus on reducing energy consumption, minimizing reagent use, and maximizing lithium recovery rates. Integrated approaches that consider the entire extraction process from brine sourcing to final product purification have demonstrated significant improvements in overall extraction efficiency and economic performance.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) in high-salinity brines represents an emerging competitive landscape currently transitioning from early development to commercial scaling. The market is experiencing rapid growth, projected to reach significant scale as global lithium demand increases for battery applications. Technologically, the field shows varying maturity levels across different approaches, with companies like EnergySource Minerals, Sunresin New Materials, and Energy Exploration Technologies (EnergyX) leading innovation in adsorption and membrane technologies. Established players such as Albemarle are integrating DLE into their operations, while research institutions including The University of Manchester and Beijing University of Chemical Technology are advancing fundamental science. The competitive dynamics are intensifying as extraction efficiency in high-salinity environments becomes a critical differentiator for commercial viability.

Sunresin New Materials Co., Ltd.

Technical Solution: Sunresin has developed a comprehensive DLE solution based on their proprietary lithium-selective adsorption resins specifically engineered for high-salinity brines. Their technology utilizes advanced macroporous adsorption materials with specially designed functional groups that demonstrate exceptional lithium selectivity even in brines with TDS exceeding 200,000 mg/L. The process employs a fixed-bed adsorption system with multiple columns operating in sequence to ensure continuous processing while maximizing lithium recovery. Sunresin's technology incorporates an optimized elution and regeneration process that minimizes chemical consumption while producing concentrated lithium solutions suitable for downstream processing. Their system has been implemented at commercial scale in multiple Chinese salt lakes, demonstrating lithium recovery rates of 80-85% in high-salinity environments while achieving concentration factors of 50-100x from initial brine to lithium-rich eluate. The technology can process brines with challenging chemistries, including those with high magnesium/lithium ratios (>70:1) that are problematic for conventional extraction methods.

Strengths: Proven commercial implementation at scale; high selectivity for lithium in complex brine environments; resin longevity exceeding 3-5 years in field conditions; modular design allowing for capacity expansion. Weaknesses: Requires careful management of resin fouling in certain brine compositions; higher initial capital investment compared to traditional methods; process optimization needed for each specific brine source.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has pioneered LiTAS™ (Lithium Ion Transport and Separation), a membrane-based DLE technology specifically engineered for high-salinity brines. Their approach utilizes metal-organic framework (MOF) membranes with nanoporous structures that allow for highly selective lithium ion transport while effectively blocking larger competing ions. The system operates under low-energy conditions and can process brines with salinity levels up to 250,000 mg/L TDS. EnergyX's technology employs a continuous flow process where brine passes through multiple membrane modules, concentrating lithium ions while minimizing water consumption. The process achieves concentration factors of 100-200x from initial brine to lithium-rich solution, enabling direct production of lithium compounds without extensive post-processing. Their pilot plants have demonstrated lithium recovery rates of approximately 85-90% in high-salinity environments while reducing water usage by over 90% compared to traditional evaporation methods.

Strengths: Minimal chemical consumption; continuous operation capability; high selectivity for lithium even in magnesium-rich brines; significantly reduced environmental footprint. Weaknesses: Membrane fouling in certain high-impurity brines requires additional pre-treatment; higher initial capital costs compared to conventional methods; technology still scaling to commercial deployment.

Critical Patents and Technical Innovations in DLE

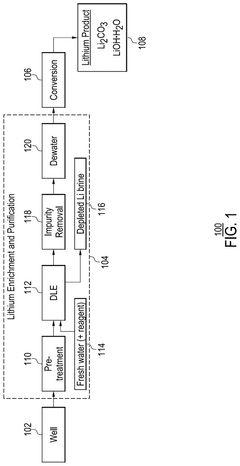

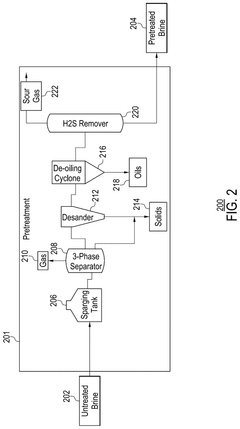

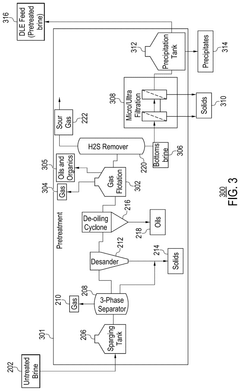

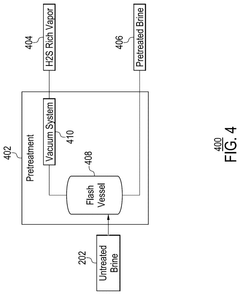

Method and apparatus for producing treated brine composition with reduced hydrogen sulfide

PatentPendingUS20250263812A1

Innovation

- A pretreatment process using a three-phase separator, stripper, and vacuum system to reduce hydrogen sulfide and organic impurities in brines, followed by direct lithium extraction (DLE) to produce a treated brine composition suitable for efficient lithium recovery.

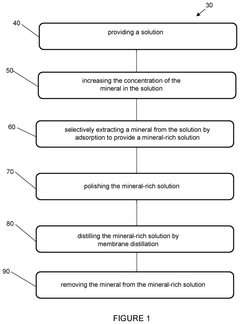

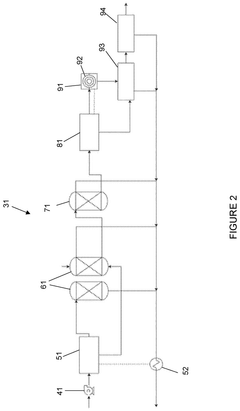

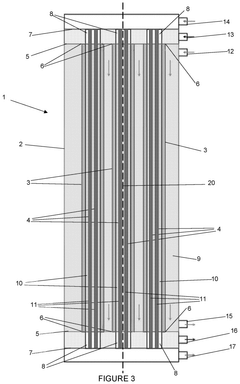

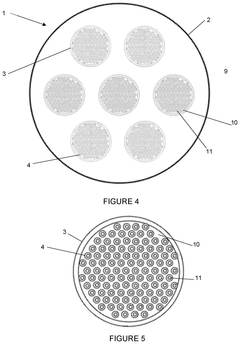

Method and Apparatus for Mineral Extraction

PatentPendingUS20250153104A1

Innovation

- A method and apparatus for mineral extraction using membrane distillation, which involves selectively extracting lithium from a brine solution by adsorption, followed by concentration through membrane distillation, and finally removing the lithium through crystallization.

Environmental Impact Assessment of DLE Methods

The environmental impact of Direct Lithium Extraction (DLE) methods in high-salinity brines represents a critical consideration for sustainable lithium production. Traditional lithium extraction methods, particularly evaporation ponds, have significant environmental footprints including extensive land use, high water consumption, and potential contamination of surrounding ecosystems. DLE technologies offer promising alternatives with potentially reduced environmental impacts.

Water usage metrics reveal substantial differences between conventional and DLE approaches. While evaporation ponds consume approximately 500-2,000 gallons of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE methods can reduce this to 50-300 gallons per kilogram. This 80-90% reduction in water consumption is particularly significant in arid regions where lithium brine resources are often located, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia.

Land disturbance assessments demonstrate that DLE facilities require significantly smaller physical footprints compared to evaporation ponds. A typical evaporation pond operation may occupy 2,000-3,500 hectares, while comparable DLE facilities require only 50-100 hectares for equivalent production capacity. This reduced land use minimizes habitat disruption and preserves natural landscapes.

Chemical usage and waste generation vary considerably across different DLE technologies. Ion exchange methods typically utilize regeneration chemicals that must be properly managed, while adsorption-based approaches may require periodic replacement of adsorbent materials. Membrane-based systems generally produce concentrated brine streams that require appropriate disposal or further processing. Comprehensive life cycle assessments indicate that most DLE methods generate 30-60% less chemical waste than conventional processes.

Carbon footprint analyses reveal that energy requirements for DLE operations exceed those of passive evaporation systems. However, when considering the entire production chain, DLE's accelerated extraction timeframe (hours versus months) and higher recovery rates (80-90% versus 40-50%) may offset these energy demands. Integration with renewable energy sources can further mitigate these impacts, with several pilot projects demonstrating successful solar-powered DLE operations.

Groundwater and ecosystem protection represents another advantage of DLE systems. By operating in closed-loop configurations, these technologies minimize the risk of brine leakage and groundwater contamination. Furthermore, the ability to reinject processed brine helps maintain subsurface pressure and prevents land subsidence, a growing concern in regions with extensive brine extraction.

Water usage metrics reveal substantial differences between conventional and DLE approaches. While evaporation ponds consume approximately 500-2,000 gallons of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE methods can reduce this to 50-300 gallons per kilogram. This 80-90% reduction in water consumption is particularly significant in arid regions where lithium brine resources are often located, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia.

Land disturbance assessments demonstrate that DLE facilities require significantly smaller physical footprints compared to evaporation ponds. A typical evaporation pond operation may occupy 2,000-3,500 hectares, while comparable DLE facilities require only 50-100 hectares for equivalent production capacity. This reduced land use minimizes habitat disruption and preserves natural landscapes.

Chemical usage and waste generation vary considerably across different DLE technologies. Ion exchange methods typically utilize regeneration chemicals that must be properly managed, while adsorption-based approaches may require periodic replacement of adsorbent materials. Membrane-based systems generally produce concentrated brine streams that require appropriate disposal or further processing. Comprehensive life cycle assessments indicate that most DLE methods generate 30-60% less chemical waste than conventional processes.

Carbon footprint analyses reveal that energy requirements for DLE operations exceed those of passive evaporation systems. However, when considering the entire production chain, DLE's accelerated extraction timeframe (hours versus months) and higher recovery rates (80-90% versus 40-50%) may offset these energy demands. Integration with renewable energy sources can further mitigate these impacts, with several pilot projects demonstrating successful solar-powered DLE operations.

Groundwater and ecosystem protection represents another advantage of DLE systems. By operating in closed-loop configurations, these technologies minimize the risk of brine leakage and groundwater contamination. Furthermore, the ability to reinject processed brine helps maintain subsurface pressure and prevents land subsidence, a growing concern in regions with extensive brine extraction.

Economic Feasibility of DLE Implementation

The economic feasibility of Direct Lithium Extraction (DLE) in high-salinity brines represents a critical factor in determining its commercial viability and potential for widespread adoption. Current economic analyses indicate that DLE technologies can achieve production costs ranging from $3,000 to $7,000 per ton of lithium carbonate equivalent (LCE), compared to traditional evaporation pond methods which typically cost between $2,500 and $5,000 per ton. This cost differential has been narrowing as DLE technologies mature and achieve economies of scale.

Capital expenditure (CAPEX) requirements for DLE facilities vary significantly based on technology type, brine chemistry, and production capacity. Initial investments typically range from $15,000 to $30,000 per annual ton of LCE capacity, with adsorption-based systems generally requiring lower upfront investment than membrane or solvent extraction systems. However, these higher initial costs must be evaluated against the substantially reduced land requirements and accelerated time-to-market that DLE offers.

Operational expenditure (OPEX) considerations reveal both advantages and challenges for DLE implementation in high-salinity environments. Energy consumption represents a significant cost factor, with most DLE processes requiring between 2,000 and 4,000 kWh per ton of LCE produced. Chemical reagent costs for regeneration cycles and water treatment add approximately $500-$1,000 per ton to operational expenses, though these costs can be higher in extremely high-salinity brines due to increased fouling and scaling issues.

Return on investment (ROI) projections for DLE projects in high-salinity brines indicate potential payback periods of 3-5 years at current lithium market prices, assuming production capacities above 10,000 tons per year. Sensitivity analyses suggest that DLE economics remain favorable even with lithium price fluctuations down to approximately $10,000 per ton, providing a reasonable buffer against market volatility.

Environmental compliance costs represent an increasingly important economic consideration. While DLE typically requires higher energy inputs than traditional methods, the reduced environmental footprint and water consumption translate to lower environmental mitigation expenses and potentially valuable ESG (Environmental, Social, and Governance) credentials that may command premium pricing in certain markets.

Scaling considerations reveal that DLE economics improve significantly with increased production capacity, with optimal economic efficiency typically achieved at production scales above 20,000 tons of LCE annually. This suggests that larger operations will likely be the first to achieve economic viability in high-salinity environments, though modular approaches are being developed to address smaller brine resources.

Capital expenditure (CAPEX) requirements for DLE facilities vary significantly based on technology type, brine chemistry, and production capacity. Initial investments typically range from $15,000 to $30,000 per annual ton of LCE capacity, with adsorption-based systems generally requiring lower upfront investment than membrane or solvent extraction systems. However, these higher initial costs must be evaluated against the substantially reduced land requirements and accelerated time-to-market that DLE offers.

Operational expenditure (OPEX) considerations reveal both advantages and challenges for DLE implementation in high-salinity environments. Energy consumption represents a significant cost factor, with most DLE processes requiring between 2,000 and 4,000 kWh per ton of LCE produced. Chemical reagent costs for regeneration cycles and water treatment add approximately $500-$1,000 per ton to operational expenses, though these costs can be higher in extremely high-salinity brines due to increased fouling and scaling issues.

Return on investment (ROI) projections for DLE projects in high-salinity brines indicate potential payback periods of 3-5 years at current lithium market prices, assuming production capacities above 10,000 tons per year. Sensitivity analyses suggest that DLE economics remain favorable even with lithium price fluctuations down to approximately $10,000 per ton, providing a reasonable buffer against market volatility.

Environmental compliance costs represent an increasingly important economic consideration. While DLE typically requires higher energy inputs than traditional methods, the reduced environmental footprint and water consumption translate to lower environmental mitigation expenses and potentially valuable ESG (Environmental, Social, and Governance) credentials that may command premium pricing in certain markets.

Scaling considerations reveal that DLE economics improve significantly with increased production capacity, with optimal economic efficiency typically achieved at production scales above 20,000 tons of LCE annually. This suggests that larger operations will likely be the first to achieve economic viability in high-salinity environments, though modular approaches are being developed to address smaller brine resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!