Case Study: Direct Lithium Extraction with Organic Solvents

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, evolving significantly since its conceptual development in the 1970s. Traditional lithium extraction methods primarily relied on solar evaporation of brine resources or hard-rock mining, both characterized by extensive land use, high water consumption, and lengthy production timelines. The growing demand for lithium, driven by the rapid expansion of electric vehicle markets and energy storage systems, has accelerated the need for more efficient and environmentally sustainable extraction technologies.

The use of organic solvents in DLE represents a significant technological advancement in this field. This approach leverages the selective chemical properties of certain organic compounds to preferentially bind with lithium ions, enabling their separation from other elements present in brine solutions. The evolution of this technology has been marked by continuous improvements in solvent chemistry, process efficiency, and scalability considerations.

The primary objective of organic solvent-based DLE technology is to establish a more sustainable, economically viable, and rapid method for lithium extraction that can address the exponential growth in global lithium demand. Specific technical goals include achieving higher lithium recovery rates (exceeding 90%), reducing processing time from months to days, minimizing environmental footprint, and developing processes adaptable to various brine chemistries worldwide.

Recent technological milestones include the development of novel solvent formulations with enhanced selectivity for lithium over competing ions such as sodium, potassium, magnesium, and calcium. These advancements have been complemented by innovations in process engineering, including continuous flow systems, improved phase separation techniques, and more efficient solvent regeneration methods.

The technology trend is moving toward integrated systems that combine organic solvent extraction with other purification steps to produce battery-grade lithium compounds directly. This integration aims to reduce capital expenditure and operational costs while increasing production flexibility and responsiveness to market demands.

Future technological trajectories for organic solvent-based DLE include the development of bio-derived or environmentally benign solvents, process intensification through advanced reactor designs, and the incorporation of digital technologies for real-time optimization. Additionally, research is focusing on extending the application of these techniques to unconventional lithium sources, including geothermal brines, oilfield produced waters, and recycled battery materials.

The use of organic solvents in DLE represents a significant technological advancement in this field. This approach leverages the selective chemical properties of certain organic compounds to preferentially bind with lithium ions, enabling their separation from other elements present in brine solutions. The evolution of this technology has been marked by continuous improvements in solvent chemistry, process efficiency, and scalability considerations.

The primary objective of organic solvent-based DLE technology is to establish a more sustainable, economically viable, and rapid method for lithium extraction that can address the exponential growth in global lithium demand. Specific technical goals include achieving higher lithium recovery rates (exceeding 90%), reducing processing time from months to days, minimizing environmental footprint, and developing processes adaptable to various brine chemistries worldwide.

Recent technological milestones include the development of novel solvent formulations with enhanced selectivity for lithium over competing ions such as sodium, potassium, magnesium, and calcium. These advancements have been complemented by innovations in process engineering, including continuous flow systems, improved phase separation techniques, and more efficient solvent regeneration methods.

The technology trend is moving toward integrated systems that combine organic solvent extraction with other purification steps to produce battery-grade lithium compounds directly. This integration aims to reduce capital expenditure and operational costs while increasing production flexibility and responsiveness to market demands.

Future technological trajectories for organic solvent-based DLE include the development of bio-derived or environmentally benign solvents, process intensification through advanced reactor designs, and the incorporation of digital technologies for real-time optimization. Additionally, research is focusing on extending the application of these techniques to unconventional lithium sources, including geothermal brines, oilfield produced waters, and recycled battery materials.

Lithium Market Demand Analysis

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the global lithium market at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-14% through 2030, potentially reaching $18-20 billion by the end of the decade.

Demand for lithium has seen a dramatic surge, with consumption volumes increasing from around 280,000 metric tons of lithium carbonate equivalent (LCE) in 2020 to over 500,000 metric tons in 2022. Industry forecasts suggest this figure could triple by 2030, reaching 1.5 million metric tons annually as battery production scales globally.

The EV sector remains the primary demand driver, accounting for approximately 74% of lithium consumption. This dominance is expected to intensify as major automotive markets including China, Europe, and North America accelerate their transition away from internal combustion engines. Battery manufacturers are expanding production capacity at unprecedented rates, with global gigafactory capacity expected to increase fivefold by 2030.

Energy storage systems represent the second largest and fastest-growing application segment, currently accounting for about 15% of lithium demand. As renewable energy integration accelerates worldwide, grid-scale storage requirements are projected to grow at 25-30% annually through 2030, further intensifying lithium demand pressures.

Regional analysis reveals China dominates current lithium processing capabilities, handling over 60% of global refining despite controlling only about 13% of raw lithium resources. Australia leads extraction operations, producing approximately 52% of global supply, while the "Lithium Triangle" of Chile, Argentina, and Bolivia collectively holds over 58% of known global reserves.

Supply constraints remain a critical market concern. Current extraction methods are predominantly concentrated on hard rock mining (spodumene) and traditional brine evaporation, both facing significant scaling limitations. This supply-demand imbalance has driven lithium carbonate prices to historic highs, reaching peaks of $80,000 per ton in late 2022, representing a sevenfold increase from 2020 levels.

Direct Lithium Extraction (DLE) technologies, particularly those utilizing organic solvents, represent a potential solution to this supply bottleneck. Market analysts estimate that successful commercialization of efficient DLE methods could increase global production capacity by 30-40% within five years while potentially reducing extraction costs by 20-25% compared to conventional methods.

Demand for lithium has seen a dramatic surge, with consumption volumes increasing from around 280,000 metric tons of lithium carbonate equivalent (LCE) in 2020 to over 500,000 metric tons in 2022. Industry forecasts suggest this figure could triple by 2030, reaching 1.5 million metric tons annually as battery production scales globally.

The EV sector remains the primary demand driver, accounting for approximately 74% of lithium consumption. This dominance is expected to intensify as major automotive markets including China, Europe, and North America accelerate their transition away from internal combustion engines. Battery manufacturers are expanding production capacity at unprecedented rates, with global gigafactory capacity expected to increase fivefold by 2030.

Energy storage systems represent the second largest and fastest-growing application segment, currently accounting for about 15% of lithium demand. As renewable energy integration accelerates worldwide, grid-scale storage requirements are projected to grow at 25-30% annually through 2030, further intensifying lithium demand pressures.

Regional analysis reveals China dominates current lithium processing capabilities, handling over 60% of global refining despite controlling only about 13% of raw lithium resources. Australia leads extraction operations, producing approximately 52% of global supply, while the "Lithium Triangle" of Chile, Argentina, and Bolivia collectively holds over 58% of known global reserves.

Supply constraints remain a critical market concern. Current extraction methods are predominantly concentrated on hard rock mining (spodumene) and traditional brine evaporation, both facing significant scaling limitations. This supply-demand imbalance has driven lithium carbonate prices to historic highs, reaching peaks of $80,000 per ton in late 2022, representing a sevenfold increase from 2020 levels.

Direct Lithium Extraction (DLE) technologies, particularly those utilizing organic solvents, represent a potential solution to this supply bottleneck. Market analysts estimate that successful commercialization of efficient DLE methods could increase global production capacity by 30-40% within five years while potentially reducing extraction costs by 20-25% compared to conventional methods.

Organic Solvent DLE: Current Status and Challenges

Direct Lithium Extraction (DLE) using organic solvents represents a promising alternative to traditional lithium extraction methods. Currently, the technology has advanced beyond laboratory-scale experiments to pilot plant demonstrations, with several companies actively developing proprietary solvent systems. These systems typically employ specialized organic compounds designed to selectively bind with lithium ions in brine solutions, enabling separation from other elements like sodium, magnesium, and calcium.

The current technical landscape shows varying degrees of maturity across different organic solvent approaches. Solvent extraction systems using crown ethers and β-diketones have demonstrated lithium recovery rates of 80-95% in controlled environments, significantly higher than traditional evaporation pond methods. However, commercial-scale implementation remains limited, with most projects still in demonstration phases rather than full commercial deployment.

Despite promising results, organic solvent DLE faces several critical challenges. Solvent stability represents a primary concern, as many organic compounds degrade when exposed to the harsh conditions of geothermal brines or oil field waters, which often contain high temperatures, extreme pH levels, and various contaminants. Current data indicates solvent degradation rates of 2-5% per cycle in some systems, necessitating regular replacement and increasing operational costs.

Selectivity issues persist as another significant challenge. While some solvents show excellent lithium selectivity in laboratory conditions, performance decreases in real-world brines with complex compositions. Typical lithium/sodium selectivity ratios range from 10:1 to 50:1, but these ratios often diminish in the presence of competing ions, particularly magnesium, which can reduce extraction efficiency by 15-30%.

Environmental concerns also present substantial obstacles. Many organic solvents used in DLE processes are potentially toxic or environmentally persistent. Solvent losses to the environment, even at minimal levels (typically 0.1-0.5% per cycle), raise questions about long-term sustainability and regulatory compliance. Water usage, while lower than evaporation ponds, remains significant at 10-15 cubic meters per ton of lithium carbonate equivalent produced.

Economic viability presents perhaps the most immediate challenge. Current cost estimates for organic solvent DLE range from $5,000-$9,000 per ton of lithium carbonate equivalent, compared to $2,500-$3,500 for traditional methods in established operations. This cost differential primarily stems from higher capital expenditures for specialized equipment, ongoing solvent replacement costs, and energy requirements for solvent regeneration processes.

Technical scalability remains unproven at industrial levels. While laboratory and pilot demonstrations have shown promising results with processing capacities of 20-100 cubic meters of brine per day, scaling to commercial requirements of 1,000+ cubic meters daily introduces significant engineering challenges related to solvent management, mass transfer efficiency, and process control.

The current technical landscape shows varying degrees of maturity across different organic solvent approaches. Solvent extraction systems using crown ethers and β-diketones have demonstrated lithium recovery rates of 80-95% in controlled environments, significantly higher than traditional evaporation pond methods. However, commercial-scale implementation remains limited, with most projects still in demonstration phases rather than full commercial deployment.

Despite promising results, organic solvent DLE faces several critical challenges. Solvent stability represents a primary concern, as many organic compounds degrade when exposed to the harsh conditions of geothermal brines or oil field waters, which often contain high temperatures, extreme pH levels, and various contaminants. Current data indicates solvent degradation rates of 2-5% per cycle in some systems, necessitating regular replacement and increasing operational costs.

Selectivity issues persist as another significant challenge. While some solvents show excellent lithium selectivity in laboratory conditions, performance decreases in real-world brines with complex compositions. Typical lithium/sodium selectivity ratios range from 10:1 to 50:1, but these ratios often diminish in the presence of competing ions, particularly magnesium, which can reduce extraction efficiency by 15-30%.

Environmental concerns also present substantial obstacles. Many organic solvents used in DLE processes are potentially toxic or environmentally persistent. Solvent losses to the environment, even at minimal levels (typically 0.1-0.5% per cycle), raise questions about long-term sustainability and regulatory compliance. Water usage, while lower than evaporation ponds, remains significant at 10-15 cubic meters per ton of lithium carbonate equivalent produced.

Economic viability presents perhaps the most immediate challenge. Current cost estimates for organic solvent DLE range from $5,000-$9,000 per ton of lithium carbonate equivalent, compared to $2,500-$3,500 for traditional methods in established operations. This cost differential primarily stems from higher capital expenditures for specialized equipment, ongoing solvent replacement costs, and energy requirements for solvent regeneration processes.

Technical scalability remains unproven at industrial levels. While laboratory and pilot demonstrations have shown promising results with processing capacities of 20-100 cubic meters of brine per day, scaling to commercial requirements of 1,000+ cubic meters daily introduces significant engineering challenges related to solvent management, mass transfer efficiency, and process control.

Current Organic Solvent-Based DLE Solutions

01 Organic solvent-based extraction systems

Various organic solvents can be used for direct lithium extraction from brines and other sources. These systems typically involve selective solvents that can complex with lithium ions while leaving other ions in solution. The extraction process often includes mixing the lithium-containing solution with the organic solvent, followed by separation and recovery steps. These methods can achieve high selectivity for lithium over competing ions such as sodium, potassium, and magnesium.- Solvent extraction methods for lithium recovery: Various organic solvents can be used for direct lithium extraction from brines and other sources. These methods typically involve selective extraction of lithium ions from aqueous solutions into an organic phase. The process often utilizes specific extractants that form complexes with lithium ions, allowing for their separation from other elements present in the solution. This approach offers advantages in terms of selectivity and efficiency compared to traditional evaporation methods.

- Specialized organic extractants for lithium: Certain organic compounds have been developed specifically for lithium extraction. These include crown ethers, phosphorus-based extractants, and other specialized molecules designed to selectively bind with lithium ions. The chemical structure of these extractants enables them to form stable complexes with lithium while minimizing interactions with competing ions such as sodium, potassium, and magnesium, which are commonly found alongside lithium in natural brines and other sources.

- Continuous flow extraction systems: Continuous flow systems for direct lithium extraction utilize organic solvents in a dynamic process rather than batch operations. These systems often employ counter-current extraction techniques where the organic solvent and lithium-containing solution flow in opposite directions through specialized equipment. This approach maximizes contact between the phases and improves extraction efficiency. The continuous nature of these processes allows for higher throughput and potentially lower operating costs compared to traditional batch extraction methods.

- Recovery and recycling of organic solvents: Methods for recovering and recycling organic solvents used in lithium extraction processes are critical for economic and environmental sustainability. These techniques typically involve stripping lithium from the loaded organic phase using back-extraction into an aqueous solution, followed by regeneration of the organic solvent for reuse. Advanced processes may incorporate membrane separation, distillation, or adsorption steps to purify the recycled solvent and remove degradation products that could reduce extraction efficiency in subsequent cycles.

- Environmental considerations in solvent-based extraction: Environmental aspects of using organic solvents for lithium extraction include minimizing solvent losses, reducing energy consumption, and preventing contamination of water resources. Newer approaches focus on developing greener solvents with lower toxicity and environmental impact. Some processes incorporate biodegradable solvents or ionic liquids as alternatives to traditional petroleum-based organic solvents. Additionally, closed-loop systems are designed to contain solvents and prevent their release into the environment while maximizing resource efficiency.

02 Solvent extraction with complexing agents

Complexing agents or extractants can be added to organic solvents to enhance lithium selectivity and extraction efficiency. These agents form coordination complexes with lithium ions, facilitating their transfer from the aqueous phase to the organic phase. Common complexing agents include crown ethers, phosphoric acid derivatives, and specialized chelating compounds. The extraction process typically involves multiple stages to improve recovery rates and purity of the extracted lithium.Expand Specific Solutions03 Continuous flow extraction processes

Continuous flow systems for direct lithium extraction using organic solvents allow for more efficient industrial-scale operations compared to batch processes. These systems typically involve counter-current extraction columns or mixer-settler arrangements where the lithium-containing solution flows in the opposite direction to the organic solvent. This approach maximizes contact time and extraction efficiency while enabling continuous production of lithium compounds. The process can be optimized for different feed compositions and desired product specifications.Expand Specific Solutions04 Recovery and regeneration of organic solvents

Methods for recovering and regenerating organic solvents used in direct lithium extraction are essential for economic and environmental sustainability. These techniques typically involve stripping the lithium from the loaded organic phase using acid or base solutions, followed by solvent purification steps. Regeneration processes may include washing, filtration, distillation, or adsorption treatments to remove impurities and degradation products. Efficient solvent recovery systems can significantly reduce operational costs and environmental impact.Expand Specific Solutions05 Novel solvent formulations for enhanced selectivity

Innovative organic solvent formulations have been developed to enhance lithium selectivity and extraction efficiency. These formulations may include mixtures of different solvents, additives to improve phase separation, and specialized modifiers to enhance lithium affinity. Some approaches involve functionalized ionic liquids, deep eutectic solvents, or designer extractants specifically tailored for lithium. These novel formulations can overcome challenges related to co-extraction of interfering ions, slow kinetics, or poor phase separation encountered with conventional solvents.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) with organic solvents is emerging as a transformative technology in the lithium market, currently transitioning from early commercialization to growth phase. The global lithium extraction market is projected to reach $5.88 billion by 2028, driven by surging demand for electric vehicles and energy storage systems. Technology maturity varies significantly among key players: Lilac Solutions and EnergyX lead with advanced ion-exchange and membrane technologies, while established energy companies like Schlumberger and Baker Hughes are leveraging their extraction expertise to enter this space. Academic institutions (Chinese Academy of Sciences, University of Manchester) are developing next-generation extraction methods, while specialized firms like Watercycle Technologies and Pure Lithium are focusing on sustainable extraction processes with reduced environmental footprint. The competitive landscape is characterized by rapid innovation and strategic partnerships across the value chain.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion-exchange technology platform for lithium extraction from brine resources. Their proprietary ceramic ion-exchange beads selectively absorb lithium while rejecting contaminants. The process involves flowing brine through modules containing these beads, which capture lithium ions. The loaded beads are then washed with an acid solution to produce a concentrated lithium solution. This solution undergoes further processing to create battery-grade lithium products. The technology operates as a continuous process with rapid lithium absorption kinetics, enabling high recovery rates (>90%) in hours rather than months required by traditional evaporation ponds. Lilac's system is modular and scalable, allowing for deployment across various brine resources with different chemistries and concentrations.

Strengths: High selectivity for lithium over competing ions; rapid extraction rates; modular design allowing scalability; significantly reduced water footprint compared to evaporation ponds; applicable to low-concentration brines. Weaknesses: Requires periodic replacement of ion-exchange media; energy requirements for regeneration process; potential challenges with certain complex brine chemistries.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has pioneered LiTAS™ (Lithium Ionic Transmission and Separation), a direct lithium extraction technology utilizing mixed matrix membranes (MMMs) and organic solvents. Their approach combines membrane technology with solvent extraction principles to selectively separate lithium from brine solutions. The process employs proprietary metal-organic framework (MOF) materials embedded in polymer membranes that allow lithium ions to pass through while blocking larger ions. This is complemented by an organic solvent system that further enhances selectivity. The technology operates at ambient temperatures and pressures, requiring minimal pre-treatment of brines. EnergyX claims their process can recover over 90% of available lithium in hours, compared to the 40% recovery over 18 months using traditional evaporation methods. The system is designed to be modular and scalable, with a significantly reduced environmental footprint.

Strengths: High lithium recovery rates; energy-efficient operation; minimal water consumption; adaptable to various brine chemistries; reduced land footprint. Weaknesses: Relatively new technology with limited large-scale deployment history; potential membrane fouling issues in certain brine conditions; organic solvent management and recovery challenges.

Critical Patents and Technical Literature Review

Lithium extraction

PatentWO2024126601A1

Innovation

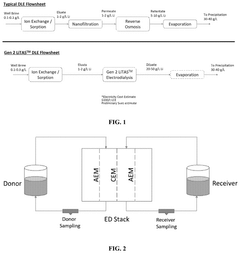

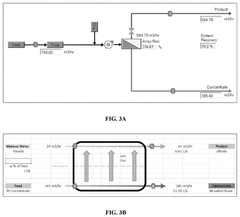

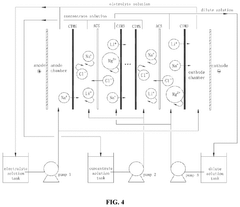

- Replacing hydrochloric acid with organic acids like oxalic or citric acid in the release step, allowing direct reaction with a non-lithium metal hydroxide to produce lithium hydroxide without intermediate lithium carbonate formation, using a lithium-selective ion exchange process with hollow fiber membranes for efficient extraction and release.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment

The environmental impact of Direct Lithium Extraction (DLE) using organic solvents represents a critical consideration in the broader adoption of this technology. Traditional lithium extraction methods, particularly evaporative processes, have significant environmental footprints including extensive water consumption, land use disruption, and chemical pollution. DLE with organic solvents offers potential improvements but introduces its own environmental challenges.

Water usage in organic solvent-based DLE systems is substantially reduced compared to evaporation ponds, with some systems reporting 50-70% less water consumption. This represents a significant advantage in water-stressed regions where lithium deposits are often located. However, the quality of water returned to the environment after processing requires careful monitoring for potential contamination from residual solvents.

Land disturbance is another environmental factor where organic solvent DLE shows advantages. The physical footprint of these systems is approximately 10-20 times smaller than traditional evaporation pond operations, reducing habitat disruption and preserving natural landscapes. This smaller footprint also minimizes the impact on local biodiversity and ecosystem services.

Chemical pollution risks present the most significant environmental concern with organic solvent DLE. The potential for solvent leakage, emissions, or improper disposal poses risks to soil, groundwater, and air quality. Recent studies indicate that certain solvents used in DLE can persist in the environment and may bioaccumulate in organisms. Comprehensive containment systems and rigorous monitoring protocols are essential to mitigate these risks.

Carbon footprint assessments of organic solvent DLE systems show mixed results. While the process itself may be more energy-intensive than passive evaporation, the overall lifecycle emissions can be lower when considering the reduced transportation needs and processing efficiency. Recent life cycle analyses suggest that advanced organic solvent DLE systems can achieve 30-40% lower greenhouse gas emissions compared to traditional methods.

Waste management presents another environmental challenge. Spent solvents and extraction media require proper disposal or regeneration. Emerging circular economy approaches are being developed to regenerate and reuse solvents, potentially reducing waste streams by up to 80% compared to single-use systems.

Regulatory frameworks for environmental protection are still evolving to address the specific challenges of organic solvent DLE. Leading jurisdictions have begun implementing specialized permitting requirements that include solvent management plans, groundwater monitoring, and emergency response protocols for potential chemical releases.

Water usage in organic solvent-based DLE systems is substantially reduced compared to evaporation ponds, with some systems reporting 50-70% less water consumption. This represents a significant advantage in water-stressed regions where lithium deposits are often located. However, the quality of water returned to the environment after processing requires careful monitoring for potential contamination from residual solvents.

Land disturbance is another environmental factor where organic solvent DLE shows advantages. The physical footprint of these systems is approximately 10-20 times smaller than traditional evaporation pond operations, reducing habitat disruption and preserving natural landscapes. This smaller footprint also minimizes the impact on local biodiversity and ecosystem services.

Chemical pollution risks present the most significant environmental concern with organic solvent DLE. The potential for solvent leakage, emissions, or improper disposal poses risks to soil, groundwater, and air quality. Recent studies indicate that certain solvents used in DLE can persist in the environment and may bioaccumulate in organisms. Comprehensive containment systems and rigorous monitoring protocols are essential to mitigate these risks.

Carbon footprint assessments of organic solvent DLE systems show mixed results. While the process itself may be more energy-intensive than passive evaporation, the overall lifecycle emissions can be lower when considering the reduced transportation needs and processing efficiency. Recent life cycle analyses suggest that advanced organic solvent DLE systems can achieve 30-40% lower greenhouse gas emissions compared to traditional methods.

Waste management presents another environmental challenge. Spent solvents and extraction media require proper disposal or regeneration. Emerging circular economy approaches are being developed to regenerate and reuse solvents, potentially reducing waste streams by up to 80% compared to single-use systems.

Regulatory frameworks for environmental protection are still evolving to address the specific challenges of organic solvent DLE. Leading jurisdictions have begun implementing specialized permitting requirements that include solvent management plans, groundwater monitoring, and emergency response protocols for potential chemical releases.

Scalability and Economic Feasibility

The scalability of Direct Lithium Extraction (DLE) using organic solvents represents a critical factor in determining its commercial viability. Current laboratory-scale demonstrations have shown promising results, with extraction efficiencies exceeding 90% under optimal conditions. However, the transition to industrial-scale operations presents significant challenges that must be addressed.

From an economic perspective, the capital expenditure (CAPEX) for establishing organic solvent-based DLE facilities is estimated at $15,000-$20,000 per ton of annual lithium carbonate equivalent (LCE) production capacity. This compares favorably with traditional evaporation pond methods ($18,000-$25,000 per ton) but remains higher than some competing DLE technologies utilizing ion exchange materials ($12,000-$18,000 per ton).

Operational expenditure (OPEX) considerations reveal both advantages and limitations. The organic solvent approach demonstrates lower water consumption (approximately 15-20 cubic meters per ton of LCE) compared to evaporation ponds (50-70 cubic meters). However, solvent loss through degradation and entrainment represents a recurring cost, estimated at 0.5-2% of total solvent volume per cycle, necessitating regular replenishment.

Energy requirements constitute another significant economic factor. Solvent regeneration processes typically demand 5-8 kWh per kilogram of lithium extracted, with additional energy needed for pumping and separation operations. This energy intensity directly impacts operational costs and carbon footprint, potentially affecting market positioning as battery manufacturers increasingly prioritize sustainably sourced materials.

Scale-up considerations must address several technical hurdles. Mixing efficiency and mass transfer limitations become more pronounced at larger scales, potentially reducing extraction kinetics and overall efficiency. Engineering solutions such as advanced reactor designs and optimized flow patterns can mitigate these issues but add complexity and cost to system design.

The economic feasibility is further influenced by market dynamics. With lithium carbonate prices fluctuating between $15,000-$80,000 per ton in recent years, project viability remains sensitive to market conditions. Financial modeling indicates that organic solvent DLE operations require lithium prices above $25,000 per ton to maintain attractive returns on investment, assuming current technology parameters.

Recovery rates during scale-up typically decrease by 5-10% compared to laboratory conditions, affecting overall economics. However, continuous process improvements and optimization efforts are gradually narrowing this performance gap, enhancing the commercial prospects of organic solvent-based DLE technologies.

From an economic perspective, the capital expenditure (CAPEX) for establishing organic solvent-based DLE facilities is estimated at $15,000-$20,000 per ton of annual lithium carbonate equivalent (LCE) production capacity. This compares favorably with traditional evaporation pond methods ($18,000-$25,000 per ton) but remains higher than some competing DLE technologies utilizing ion exchange materials ($12,000-$18,000 per ton).

Operational expenditure (OPEX) considerations reveal both advantages and limitations. The organic solvent approach demonstrates lower water consumption (approximately 15-20 cubic meters per ton of LCE) compared to evaporation ponds (50-70 cubic meters). However, solvent loss through degradation and entrainment represents a recurring cost, estimated at 0.5-2% of total solvent volume per cycle, necessitating regular replenishment.

Energy requirements constitute another significant economic factor. Solvent regeneration processes typically demand 5-8 kWh per kilogram of lithium extracted, with additional energy needed for pumping and separation operations. This energy intensity directly impacts operational costs and carbon footprint, potentially affecting market positioning as battery manufacturers increasingly prioritize sustainably sourced materials.

Scale-up considerations must address several technical hurdles. Mixing efficiency and mass transfer limitations become more pronounced at larger scales, potentially reducing extraction kinetics and overall efficiency. Engineering solutions such as advanced reactor designs and optimized flow patterns can mitigate these issues but add complexity and cost to system design.

The economic feasibility is further influenced by market dynamics. With lithium carbonate prices fluctuating between $15,000-$80,000 per ton in recent years, project viability remains sensitive to market conditions. Financial modeling indicates that organic solvent DLE operations require lithium prices above $25,000 per ton to maintain attractive returns on investment, assuming current technology parameters.

Recovery rates during scale-up typically decrease by 5-10% compared to laboratory conditions, affecting overall economics. However, continuous process improvements and optimization efforts are gradually narrowing this performance gap, enhancing the commercial prospects of organic solvent-based DLE technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!