Diesel Particulate Filter vs Exhaust Gas Recirculation

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Control Technologies Background and Objectives

Emission control technologies have evolved significantly over the past several decades in response to increasingly stringent environmental regulations and growing concerns about air quality and public health. The journey began in the 1970s with the introduction of basic catalytic converters, progressing through various technological innovations to address the complex challenge of reducing harmful emissions from internal combustion engines, particularly diesel engines which present unique challenges due to their operating characteristics.

The diesel engine, while offering superior fuel efficiency and durability compared to gasoline engines, produces higher levels of particulate matter (PM) and nitrogen oxides (NOx) - pollutants that contribute significantly to air pollution and associated health problems. This has driven the development of specialized emission control technologies, with Diesel Particulate Filters (DPF) and Exhaust Gas Recirculation (EGR) emerging as two principal approaches.

DPF technology, first commercially implemented in the early 2000s, focuses on capturing particulate matter from exhaust gases through physical filtration. The technology has undergone continuous refinement, with modern systems achieving filtration efficiencies exceeding 95%. The evolution of DPF systems has been characterized by improvements in filter materials, regeneration strategies, and integration with other emission control components.

Concurrently, EGR technology has evolved as a method primarily targeting NOx reduction by recirculating a portion of exhaust gases back into the engine's intake system, thereby lowering combustion temperatures. EGR systems have progressed from simple mechanical designs to sophisticated electronically controlled systems that optimize recirculation rates based on engine operating conditions.

The technological trajectory for both DPF and EGR has been heavily influenced by regulatory frameworks such as the European emission standards (Euro I-VI), US EPA regulations, and similar standards in other regions. Each regulatory milestone has pushed the boundaries of these technologies, driving innovation and performance improvements.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of DPF and EGR technologies, examining their respective principles of operation, effectiveness in emission reduction, impact on engine performance, durability, maintenance requirements, and cost implications. Additionally, the report aims to identify the synergies between these technologies when implemented together, as is common in modern diesel engines.

Furthermore, this analysis seeks to anticipate future developments in emission control technologies, considering emerging trends such as electrification, alternative fuels, and potential regulatory changes. By understanding the strengths, limitations, and complementary aspects of DPF and EGR technologies, this report will provide valuable insights for strategic decision-making in technology development and implementation.

The diesel engine, while offering superior fuel efficiency and durability compared to gasoline engines, produces higher levels of particulate matter (PM) and nitrogen oxides (NOx) - pollutants that contribute significantly to air pollution and associated health problems. This has driven the development of specialized emission control technologies, with Diesel Particulate Filters (DPF) and Exhaust Gas Recirculation (EGR) emerging as two principal approaches.

DPF technology, first commercially implemented in the early 2000s, focuses on capturing particulate matter from exhaust gases through physical filtration. The technology has undergone continuous refinement, with modern systems achieving filtration efficiencies exceeding 95%. The evolution of DPF systems has been characterized by improvements in filter materials, regeneration strategies, and integration with other emission control components.

Concurrently, EGR technology has evolved as a method primarily targeting NOx reduction by recirculating a portion of exhaust gases back into the engine's intake system, thereby lowering combustion temperatures. EGR systems have progressed from simple mechanical designs to sophisticated electronically controlled systems that optimize recirculation rates based on engine operating conditions.

The technological trajectory for both DPF and EGR has been heavily influenced by regulatory frameworks such as the European emission standards (Euro I-VI), US EPA regulations, and similar standards in other regions. Each regulatory milestone has pushed the boundaries of these technologies, driving innovation and performance improvements.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of DPF and EGR technologies, examining their respective principles of operation, effectiveness in emission reduction, impact on engine performance, durability, maintenance requirements, and cost implications. Additionally, the report aims to identify the synergies between these technologies when implemented together, as is common in modern diesel engines.

Furthermore, this analysis seeks to anticipate future developments in emission control technologies, considering emerging trends such as electrification, alternative fuels, and potential regulatory changes. By understanding the strengths, limitations, and complementary aspects of DPF and EGR technologies, this report will provide valuable insights for strategic decision-making in technology development and implementation.

Market Demand Analysis for DPF and EGR Systems

The global market for emission control technologies in diesel engines has witnessed substantial growth over the past decade, driven primarily by increasingly stringent emission regulations across major automotive markets. The combined market value for DPF and EGR systems reached approximately $12.5 billion in 2022, with projections indicating growth to $18.7 billion by 2028, representing a compound annual growth rate of 7.2%.

Demand for DPF systems has shown particularly strong momentum in passenger vehicle segments, where particulate matter reduction requirements are most stringent. Europe leads this market segment with implementation rates exceeding 95% in new diesel vehicles, followed by North America at 87% and rapidly growing adoption in Asian markets, particularly China and India where implementation has reached 65% and 48% respectively.

EGR systems demonstrate more balanced demand across both light-duty and heavy-duty applications, with the commercial vehicle sector representing the largest market share at 58%. This technology's market penetration varies significantly by region, with mature markets showing near-universal adoption while emerging markets display more gradual implementation curves aligned with their respective regulatory timelines.

Industry analysis reveals distinct market dynamics between original equipment manufacturer (OEM) installations and aftermarket segments. The OEM market accounts for approximately 78% of total revenue, while the aftermarket segment, though smaller, is growing at a faster rate of 9.3% annually as older vehicles are retrofitted to meet newer emission standards.

Regional market distribution shows Europe commanding 38% of global demand, followed by North America (29%), Asia-Pacific (26%), and rest of world (7%). However, the highest growth rates are observed in developing economies, particularly in the Asia-Pacific region where industrialization and vehicle population growth coincide with tightening emission standards.

Customer preference analysis indicates shifting priorities among end-users, with fleet operators increasingly valuing total cost of ownership metrics over initial acquisition costs. This trend favors technologies offering optimal balance between emission reduction efficiency and operational parameters such as fuel economy and maintenance intervals.

Market forecasts suggest continued strong demand growth through 2030, with particular acceleration in hybrid systems that combine multiple emission control technologies. The commercial vehicle segment is expected to represent the fastest-growing application area, driven by regulatory focus on reducing emissions from transportation and logistics operations.

Demand for DPF systems has shown particularly strong momentum in passenger vehicle segments, where particulate matter reduction requirements are most stringent. Europe leads this market segment with implementation rates exceeding 95% in new diesel vehicles, followed by North America at 87% and rapidly growing adoption in Asian markets, particularly China and India where implementation has reached 65% and 48% respectively.

EGR systems demonstrate more balanced demand across both light-duty and heavy-duty applications, with the commercial vehicle sector representing the largest market share at 58%. This technology's market penetration varies significantly by region, with mature markets showing near-universal adoption while emerging markets display more gradual implementation curves aligned with their respective regulatory timelines.

Industry analysis reveals distinct market dynamics between original equipment manufacturer (OEM) installations and aftermarket segments. The OEM market accounts for approximately 78% of total revenue, while the aftermarket segment, though smaller, is growing at a faster rate of 9.3% annually as older vehicles are retrofitted to meet newer emission standards.

Regional market distribution shows Europe commanding 38% of global demand, followed by North America (29%), Asia-Pacific (26%), and rest of world (7%). However, the highest growth rates are observed in developing economies, particularly in the Asia-Pacific region where industrialization and vehicle population growth coincide with tightening emission standards.

Customer preference analysis indicates shifting priorities among end-users, with fleet operators increasingly valuing total cost of ownership metrics over initial acquisition costs. This trend favors technologies offering optimal balance between emission reduction efficiency and operational parameters such as fuel economy and maintenance intervals.

Market forecasts suggest continued strong demand growth through 2030, with particular acceleration in hybrid systems that combine multiple emission control technologies. The commercial vehicle segment is expected to represent the fastest-growing application area, driven by regulatory focus on reducing emissions from transportation and logistics operations.

Current Technical Challenges in Emission Reduction

Despite significant advancements in emission control technologies, both Diesel Particulate Filter (DPF) and Exhaust Gas Recirculation (EGR) systems face substantial technical challenges that limit their effectiveness and widespread adoption. These challenges represent critical barriers to achieving increasingly stringent global emission standards.

DPF systems encounter several persistent technical issues. Regeneration management remains problematic, as the balance between passive and active regeneration cycles significantly impacts fuel economy and system durability. The thermal management during regeneration presents risks of uncontrolled exothermic reactions that can damage filter substrates and reduce service life. Additionally, ash accumulation from lubricating oil additives gradually reduces filter capacity and increases backpressure, necessitating periodic maintenance.

Material limitations also constrain DPF performance. Current ceramic substrates face durability challenges under extreme thermal cycling conditions, while more advanced materials like silicon carbide significantly increase system costs. The trade-off between filtration efficiency and backpressure continues to challenge engineers, as higher filtration rates inevitably increase engine load and fuel consumption.

For EGR systems, precise control under varying operating conditions represents a fundamental challenge. The optimal EGR rate varies significantly across engine load profiles, requiring sophisticated control algorithms and sensors that can accurately respond to transient conditions. Cooled EGR systems struggle with condensation issues that accelerate corrosion and deposit formation in intake systems.

EGR's inherent reduction of oxygen concentration negatively impacts combustion efficiency and power output, creating an unavoidable performance penalty. This trade-off becomes particularly problematic for high-load applications where both power demands and emission control requirements are stringent. Furthermore, EGR systems increase particulate matter formation, often necessitating their combination with particulate filters in modern applications.

Both technologies face integration challenges with other emission control systems. The interaction between DPF, EGR, selective catalytic reduction (SCR), and diesel oxidation catalysts creates complex system dynamics that complicate control strategies and increase system complexity. This integration challenge extends to onboard diagnostics requirements, where regulatory compliance demands accurate monitoring of multiple interrelated systems.

Cost considerations remain significant for both technologies. DPF systems require expensive catalyst materials and complex regeneration management systems, while EGR systems demand precise control components and durable cooling systems. These costs become particularly prohibitive for smaller engines and applications in cost-sensitive markets, limiting global adoption despite environmental benefits.

DPF systems encounter several persistent technical issues. Regeneration management remains problematic, as the balance between passive and active regeneration cycles significantly impacts fuel economy and system durability. The thermal management during regeneration presents risks of uncontrolled exothermic reactions that can damage filter substrates and reduce service life. Additionally, ash accumulation from lubricating oil additives gradually reduces filter capacity and increases backpressure, necessitating periodic maintenance.

Material limitations also constrain DPF performance. Current ceramic substrates face durability challenges under extreme thermal cycling conditions, while more advanced materials like silicon carbide significantly increase system costs. The trade-off between filtration efficiency and backpressure continues to challenge engineers, as higher filtration rates inevitably increase engine load and fuel consumption.

For EGR systems, precise control under varying operating conditions represents a fundamental challenge. The optimal EGR rate varies significantly across engine load profiles, requiring sophisticated control algorithms and sensors that can accurately respond to transient conditions. Cooled EGR systems struggle with condensation issues that accelerate corrosion and deposit formation in intake systems.

EGR's inherent reduction of oxygen concentration negatively impacts combustion efficiency and power output, creating an unavoidable performance penalty. This trade-off becomes particularly problematic for high-load applications where both power demands and emission control requirements are stringent. Furthermore, EGR systems increase particulate matter formation, often necessitating their combination with particulate filters in modern applications.

Both technologies face integration challenges with other emission control systems. The interaction between DPF, EGR, selective catalytic reduction (SCR), and diesel oxidation catalysts creates complex system dynamics that complicate control strategies and increase system complexity. This integration challenge extends to onboard diagnostics requirements, where regulatory compliance demands accurate monitoring of multiple interrelated systems.

Cost considerations remain significant for both technologies. DPF systems require expensive catalyst materials and complex regeneration management systems, while EGR systems demand precise control components and durable cooling systems. These costs become particularly prohibitive for smaller engines and applications in cost-sensitive markets, limiting global adoption despite environmental benefits.

Technical Comparison of DPF and EGR Solutions

01 DPF regeneration strategies

Various methods are employed to regenerate diesel particulate filters by burning off accumulated soot. These include active regeneration using fuel injection or heating elements, passive regeneration through catalytic coatings, and combined approaches. Advanced control systems monitor filter loading and trigger regeneration at optimal times to maintain engine performance while ensuring effective particulate removal.- DPF Regeneration Techniques: Various methods are employed to regenerate diesel particulate filters by burning off accumulated soot. These include active regeneration using fuel injection or heating elements, passive regeneration through catalytic coatings, and combined approaches. Advanced control systems monitor filter loading and trigger regeneration at optimal times to maintain engine performance while ensuring effective particulate removal.

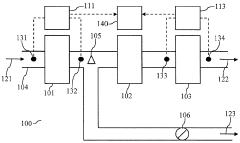

- EGR System Configurations and Control: Exhaust gas recirculation systems are designed with various configurations to effectively reduce NOx emissions. These include high-pressure EGR, low-pressure EGR, and dual-loop systems. Advanced control strategies adjust EGR rates based on engine operating conditions, load demands, and emission requirements. Electronic control units optimize the EGR valve position to maintain the ideal balance between emissions reduction and engine performance.

- Integration of DPF and EGR Systems: The integration of diesel particulate filters with exhaust gas recirculation systems presents both challenges and opportunities for emission control. Combined systems must address potential conflicts between EGR's need for exhaust gas and DPF's regeneration requirements. Advanced control algorithms coordinate these systems to optimize both NOx reduction and particulate matter capture while maintaining engine performance and fuel efficiency.

- Cooling and Thermal Management: Thermal management is critical for both DPF and EGR systems. EGR coolers reduce the temperature of recirculated exhaust gas to improve volumetric efficiency and further reduce NOx formation. For DPFs, temperature control is essential during regeneration to prevent damage while ensuring complete soot oxidation. Integrated cooling systems help maintain optimal operating temperatures across various engine conditions.

- Sensor Technology and Diagnostic Systems: Advanced sensor technologies monitor the performance and condition of both DPF and EGR systems. Pressure differential sensors detect DPF loading levels, while mass flow sensors, temperature sensors, and NOx sensors provide data for EGR control. Onboard diagnostic systems use this sensor data to detect malfunctions, predict maintenance needs, and optimize system performance while ensuring compliance with emission regulations.

02 EGR system configurations and control

Exhaust gas recirculation systems are designed with various configurations to optimize NOx reduction. These include high-pressure EGR, low-pressure EGR, and dual-loop systems. Advanced control strategies adjust EGR rates based on engine operating conditions, load demands, and temperature parameters to balance emissions reduction with engine performance and fuel efficiency.Expand Specific Solutions03 Integration of DPF and EGR systems

The integration of diesel particulate filters with exhaust gas recirculation systems presents both challenges and opportunities. Coordinated control strategies are implemented to manage the interactions between these systems, addressing issues such as EGR fouling from particulates and the impact of recirculated exhaust on DPF performance. Integrated approaches optimize both NOx and particulate matter reduction while maintaining engine efficiency.Expand Specific Solutions04 Thermal management for emission control systems

Effective thermal management is crucial for both DPF and EGR systems. Various approaches include exhaust heat recovery systems, cooling technologies for recirculated exhaust gas, and temperature control strategies during DPF regeneration. These thermal management solutions help maintain optimal operating temperatures for emission control components while minimizing negative impacts on engine performance and fuel consumption.Expand Specific Solutions05 Sensor technologies and diagnostic systems

Advanced sensor technologies and diagnostic systems are employed to monitor the performance and condition of DPF and EGR components. These include pressure differential sensors for DPF loading, temperature sensors, NOx sensors, and particulate matter sensors. Sophisticated diagnostic algorithms detect system malfunctions, predict maintenance needs, and ensure regulatory compliance by continuously monitoring emission control system performance.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The Diesel Particulate Filter (DPF) and Exhaust Gas Recirculation (EGR) technologies market is in a mature growth phase, with an estimated global value exceeding $12 billion. Major automotive and engine manufacturers including Ford, GM, Nissan, Volvo, and Hyundai have developed sophisticated implementations of both technologies to meet increasingly stringent emission regulations. Technical maturity varies between regions, with European and Japanese companies like Bosch, Mitsubishi Heavy Industries, and Toyota Industries leading in innovation, while Chinese manufacturers such as Weichai Power and Wuxi Longsheng Technology are rapidly advancing their capabilities. The competitive landscape features traditional OEMs competing with specialized component suppliers like Infineum International, with recent technological focus shifting toward integration with hybrid and electric powertrain systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive emissions control strategy that evaluates the effectiveness of both DPF and EGR technologies across different vehicle platforms. Their approach includes a cooled EGR system with precise electronic control that can reduce NOx emissions by up to 45% in their diesel engines. For particulate matter control, GM employs advanced DPF systems with active regeneration capabilities that use post-injection fuel strategies to maintain filter efficiency. GM's research has demonstrated that combining optimized EGR rates with catalyzed DPF systems can achieve both Euro 6 and EPA Tier 3 emissions standards while maintaining performance. Their comparative analysis shows that while EGR is more effective for NOx reduction, their latest DPF technology achieves over 98% particulate matter filtration efficiency with reduced backpressure penalties. GM has also pioneered closed-loop control systems that continuously adjust EGR rates based on real-time emissions monitoring.

Strengths: Extensive real-world testing across diverse vehicle platforms; strong integration with powertrain control systems; balanced approach to meeting global emissions standards. Weaknesses: Higher system complexity increases potential failure points; regeneration strategies can impact fuel economy; requires sophisticated calibration for different driving conditions.

Weichai Power

Technical Solution: Weichai Power has developed innovative approaches to both DPF and EGR technologies tailored for heavy-duty applications. Their high-efficiency DPF system utilizes silicon carbide substrates with asymmetric channel designs that increase filtration area while reducing backpressure by approximately 20% compared to conventional designs. Weichai's comparative analysis demonstrates that their advanced DPF technology achieves over 95% particulate matter reduction while their EGR systems can reduce NOx emissions by up to 40%. For EGR applications, Weichai has developed high-durability coolers with special coatings that resist fouling in high-soot environments, extending service intervals by up to 30%. Their research shows that optimized EGR temperature control can significantly improve the NOx-PM trade-off that traditionally challenges diesel engine designers. Weichai has also pioneered model-based control strategies that dynamically adjust EGR rates based on real-time combustion analysis.

Strengths: Technologies specifically optimized for heavy-duty applications; cost-effective solutions suitable for emerging markets; robust designs with extended durability in harsh operating conditions. Weaknesses: Less integration with advanced aftertreatment systems compared to some competitors; higher regeneration frequency requirements in certain applications; limited experience with ultra-low emission standards.

Core Patents and Innovations in Emission Control

Robust EGR control for counteracting exhaust back-pressure fluctuation attributable to soot accumulation in a diesel particulate filter

PatentInactiveEP1831532A2

Innovation

- A processor-based engine control system processes data to correct EGR volumetric efficiency and develop flow control data, accounting for soot accumulation in the DPF, thereby adjusting the recirculation of exhaust gas to maintain optimal engine operation.

monitoring of the particle filter of an exhaust gas recirculation device

PatentInactiveDE102014201325A1

Innovation

- A control unit determines the pressure drop across the EGR filter using existing pressure sensors that also measure the DPF and EGR valve, allowing for cost-effective monitoring of EGR filter contamination and enabling reliable control and regulation of exhaust gas recirculation.

Environmental Impact Assessment

The environmental impact of diesel engine emissions control technologies represents a critical consideration in their comparative evaluation. DPF and EGR technologies demonstrate significantly different environmental footprints across their lifecycle and operational phases.

DPF systems demonstrate remarkable efficiency in particulate matter (PM) reduction, typically capturing 85-95% of diesel soot particles, including the most hazardous fine particles (PM2.5) that pose serious respiratory health risks. This substantial reduction in particulate emissions directly correlates with improved air quality in urban environments and reduced public health impacts. However, DPF systems generally increase fuel consumption by 1-3% due to increased back pressure, resulting in higher CO2 emissions that contribute to climate change.

EGR technology primarily targets nitrogen oxide (NOx) emissions, achieving reduction rates of 40-60% through combustion temperature control. This significant decrease in NOx emissions helps mitigate ground-level ozone formation and acid rain. EGR systems typically operate with lower energy requirements than DPF systems but may increase particulate matter emissions by 10-15% as a trade-off effect, creating a complex environmental balance.

From a lifecycle perspective, DPF systems require periodic regeneration processes that temporarily increase fuel consumption and emissions. Additionally, the manufacturing of DPF systems involves energy-intensive production of ceramic substrates and precious metal catalysts, contributing to their environmental footprint. The disposal of spent DPF units presents challenges due to accumulated heavy metals and other contaminants requiring specialized handling.

EGR systems generally demonstrate lower manufacturing environmental impacts due to simpler construction and fewer precious metals. However, they may reduce engine durability, potentially shortening vehicle lifespan and increasing resource consumption through more frequent engine rebuilds or replacements.

When implemented together in modern diesel engines, these technologies create synergistic effects that optimize overall emissions reduction. Combined systems can achieve up to 98% reduction in particulate matter and 85% reduction in NOx emissions compared to uncontrolled engines, representing significant environmental benefits despite the increased system complexity.

Regional environmental regulations increasingly favor combined approaches, with Euro 6 and EPA Tier 3 standards effectively requiring both technologies to meet stringent emissions limits. This regulatory landscape continues to drive technological improvements that further reduce the environmental impact of both systems while minimizing their operational penalties.

DPF systems demonstrate remarkable efficiency in particulate matter (PM) reduction, typically capturing 85-95% of diesel soot particles, including the most hazardous fine particles (PM2.5) that pose serious respiratory health risks. This substantial reduction in particulate emissions directly correlates with improved air quality in urban environments and reduced public health impacts. However, DPF systems generally increase fuel consumption by 1-3% due to increased back pressure, resulting in higher CO2 emissions that contribute to climate change.

EGR technology primarily targets nitrogen oxide (NOx) emissions, achieving reduction rates of 40-60% through combustion temperature control. This significant decrease in NOx emissions helps mitigate ground-level ozone formation and acid rain. EGR systems typically operate with lower energy requirements than DPF systems but may increase particulate matter emissions by 10-15% as a trade-off effect, creating a complex environmental balance.

From a lifecycle perspective, DPF systems require periodic regeneration processes that temporarily increase fuel consumption and emissions. Additionally, the manufacturing of DPF systems involves energy-intensive production of ceramic substrates and precious metal catalysts, contributing to their environmental footprint. The disposal of spent DPF units presents challenges due to accumulated heavy metals and other contaminants requiring specialized handling.

EGR systems generally demonstrate lower manufacturing environmental impacts due to simpler construction and fewer precious metals. However, they may reduce engine durability, potentially shortening vehicle lifespan and increasing resource consumption through more frequent engine rebuilds or replacements.

When implemented together in modern diesel engines, these technologies create synergistic effects that optimize overall emissions reduction. Combined systems can achieve up to 98% reduction in particulate matter and 85% reduction in NOx emissions compared to uncontrolled engines, representing significant environmental benefits despite the increased system complexity.

Regional environmental regulations increasingly favor combined approaches, with Euro 6 and EPA Tier 3 standards effectively requiring both technologies to meet stringent emissions limits. This regulatory landscape continues to drive technological improvements that further reduce the environmental impact of both systems while minimizing their operational penalties.

Regulatory Compliance Framework

The regulatory landscape governing diesel engine emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented globally. Both Diesel Particulate Filter (DPF) and Exhaust Gas Recirculation (EGR) technologies have emerged as critical solutions for meeting these regulatory requirements, though they address different aspects of emissions control.

In the European Union, the Euro standards (currently Euro 6) set specific limits for particulate matter (PM) and nitrogen oxides (NOx), effectively mandating the use of DPF technology to capture particulate emissions. Similarly, the United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established comprehensive frameworks through the Clean Air Act and subsequent amendments that necessitate advanced emission control technologies.

The regulatory timeline reveals an accelerating pace of compliance requirements. The EPA's Tier 4 Final standards for off-road diesel engines and the on-road heavy-duty engine standards have progressively reduced allowable PM and NOx levels by over 90% compared to previous decades. These regulations have directly influenced the technological development and market adoption of both DPF and EGR systems.

Japan, China, and India have also implemented their own regulatory frameworks modeled after European or American standards, creating a global compliance ecosystem that manufacturers must navigate. The International Maritime Organization (IMO) has extended similar requirements to marine applications, broadening the scope of these technologies beyond traditional automotive and industrial applications.

Compliance testing protocols have become increasingly sophisticated, with real-world driving emissions (RDE) tests supplementing laboratory-based evaluations. This shift has exposed the performance gap between controlled testing environments and actual operating conditions, particularly for NOx emissions control where EGR systems play a crucial role.

Non-compliance penalties have escalated dramatically, as evidenced by multi-billion dollar settlements in recent diesel emissions scandals. These financial consequences, coupled with potential market exclusion, have elevated regulatory compliance from a technical consideration to a fundamental business imperative.

Looking forward, upcoming regulatory changes signal even more stringent requirements. The Euro 7 standards under development and similar initiatives worldwide will likely necessitate integrated emission control strategies combining both DPF and EGR technologies, alongside other solutions such as selective catalytic reduction (SCR) systems.

The regulatory framework thus serves not only as a compliance challenge but also as an innovation driver, pushing manufacturers to develop more efficient, durable, and effective emission control technologies that balance environmental protection with operational performance.

In the European Union, the Euro standards (currently Euro 6) set specific limits for particulate matter (PM) and nitrogen oxides (NOx), effectively mandating the use of DPF technology to capture particulate emissions. Similarly, the United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established comprehensive frameworks through the Clean Air Act and subsequent amendments that necessitate advanced emission control technologies.

The regulatory timeline reveals an accelerating pace of compliance requirements. The EPA's Tier 4 Final standards for off-road diesel engines and the on-road heavy-duty engine standards have progressively reduced allowable PM and NOx levels by over 90% compared to previous decades. These regulations have directly influenced the technological development and market adoption of both DPF and EGR systems.

Japan, China, and India have also implemented their own regulatory frameworks modeled after European or American standards, creating a global compliance ecosystem that manufacturers must navigate. The International Maritime Organization (IMO) has extended similar requirements to marine applications, broadening the scope of these technologies beyond traditional automotive and industrial applications.

Compliance testing protocols have become increasingly sophisticated, with real-world driving emissions (RDE) tests supplementing laboratory-based evaluations. This shift has exposed the performance gap between controlled testing environments and actual operating conditions, particularly for NOx emissions control where EGR systems play a crucial role.

Non-compliance penalties have escalated dramatically, as evidenced by multi-billion dollar settlements in recent diesel emissions scandals. These financial consequences, coupled with potential market exclusion, have elevated regulatory compliance from a technical consideration to a fundamental business imperative.

Looking forward, upcoming regulatory changes signal even more stringent requirements. The Euro 7 standards under development and similar initiatives worldwide will likely necessitate integrated emission control strategies combining both DPF and EGR technologies, alongside other solutions such as selective catalytic reduction (SCR) systems.

The regulatory framework thus serves not only as a compliance challenge but also as an innovation driver, pushing manufacturers to develop more efficient, durable, and effective emission control technologies that balance environmental protection with operational performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!