Designing Diesel Particulate Filter for Enhanced CO2 Capture

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF CO2 Capture Technology Background and Objectives

Diesel Particulate Filters (DPFs) have evolved significantly since their introduction in the 1980s as emission control devices for diesel engines. Initially designed to capture particulate matter and soot from diesel exhaust, these filters have undergone substantial technological advancement over the past four decades. The evolution has been primarily driven by increasingly stringent emission regulations worldwide, particularly in Europe, North America, and Asia, which have progressively lowered the permissible levels of particulate emissions from diesel engines.

The technological trajectory of DPFs has seen a shift from simple mechanical filtration systems to sophisticated catalytic converters integrated with advanced sensing and regeneration mechanisms. Traditional DPFs focus exclusively on particulate matter reduction, with no consideration for greenhouse gas emissions such as CO2. This represents a significant gap in current emission control strategies, as diesel engines remain major contributors to global CO2 emissions.

Recent climate change imperatives and carbon neutrality goals have created a pressing need to address CO2 emissions across all sectors, including transportation and industrial applications where diesel engines are prevalent. This has prompted research into dual-function filtration systems that can simultaneously address particulate matter and CO2 emissions, representing a paradigm shift in emission control technology.

The primary objective of enhanced DPF technology for CO2 capture is to develop a next-generation filtration system that maintains excellent particulate matter removal efficiency while incorporating novel materials and structures capable of adsorbing or converting CO2 from exhaust gases. This approach aims to leverage the existing DPF infrastructure in millions of diesel vehicles and industrial applications worldwide, providing a cost-effective pathway to reducing greenhouse gas emissions without requiring complete powertrain replacement.

Technical goals include developing filter materials with high CO2 adsorption capacity at typical diesel exhaust temperatures (150-400°C), ensuring durability through multiple regeneration cycles, minimizing back-pressure increases that could affect engine performance, and creating systems that can effectively manage the captured CO2 through either onboard storage or conversion processes.

The evolution trend points toward multi-functional filter systems that integrate traditional ceramic or silicon carbide substrates with novel CO2-capturing materials such as metal-organic frameworks (MOFs), zeolites, or amine-functionalized sorbents. These hybrid systems represent a convergence of particulate filtration technology with carbon capture chemistry, potentially offering a transitional technology as the world moves toward zero-emission transportation solutions.

Success in this technological endeavor would provide a critical bridge technology that extends the environmental viability of existing diesel infrastructure while more comprehensive electrification and alternative fuel solutions continue to develop and scale globally.

The technological trajectory of DPFs has seen a shift from simple mechanical filtration systems to sophisticated catalytic converters integrated with advanced sensing and regeneration mechanisms. Traditional DPFs focus exclusively on particulate matter reduction, with no consideration for greenhouse gas emissions such as CO2. This represents a significant gap in current emission control strategies, as diesel engines remain major contributors to global CO2 emissions.

Recent climate change imperatives and carbon neutrality goals have created a pressing need to address CO2 emissions across all sectors, including transportation and industrial applications where diesel engines are prevalent. This has prompted research into dual-function filtration systems that can simultaneously address particulate matter and CO2 emissions, representing a paradigm shift in emission control technology.

The primary objective of enhanced DPF technology for CO2 capture is to develop a next-generation filtration system that maintains excellent particulate matter removal efficiency while incorporating novel materials and structures capable of adsorbing or converting CO2 from exhaust gases. This approach aims to leverage the existing DPF infrastructure in millions of diesel vehicles and industrial applications worldwide, providing a cost-effective pathway to reducing greenhouse gas emissions without requiring complete powertrain replacement.

Technical goals include developing filter materials with high CO2 adsorption capacity at typical diesel exhaust temperatures (150-400°C), ensuring durability through multiple regeneration cycles, minimizing back-pressure increases that could affect engine performance, and creating systems that can effectively manage the captured CO2 through either onboard storage or conversion processes.

The evolution trend points toward multi-functional filter systems that integrate traditional ceramic or silicon carbide substrates with novel CO2-capturing materials such as metal-organic frameworks (MOFs), zeolites, or amine-functionalized sorbents. These hybrid systems represent a convergence of particulate filtration technology with carbon capture chemistry, potentially offering a transitional technology as the world moves toward zero-emission transportation solutions.

Success in this technological endeavor would provide a critical bridge technology that extends the environmental viability of existing diesel infrastructure while more comprehensive electrification and alternative fuel solutions continue to develop and scale globally.

Market Demand Analysis for Enhanced CO2 Capture Systems

The global market for enhanced CO2 capture systems has witnessed significant growth in recent years, driven by increasing environmental regulations and corporate sustainability initiatives. The diesel particulate filter (DPF) market, traditionally focused on reducing particulate matter emissions, is now evolving to address carbon dioxide capture capabilities, creating a new market segment with substantial growth potential.

Current market analysis indicates that the global carbon capture and storage market was valued at approximately $7.1 billion in 2021 and is projected to reach $15.3 billion by 2030, growing at a CAGR of 9.2%. Within this broader market, enhanced DPF systems for CO2 capture represent an emerging niche with accelerating demand, particularly in regions with stringent emission regulations.

The transportation sector accounts for nearly 24% of global CO2 emissions, with diesel engines contributing significantly to this figure. This creates a substantial addressable market for enhanced DPF technologies that can capture CO2 in addition to particulate matter. Fleet operators, particularly in commercial transportation, logistics, and public transit, are showing increased interest in these dual-function filtration systems as they face mounting pressure to reduce their carbon footprint.

Regional market analysis reveals varying levels of demand. Europe leads adoption due to its ambitious climate targets and regulatory framework, including the European Green Deal and Euro 7 emission standards. North America follows with growing interest, particularly as the Biden administration strengthens climate policies. The Asia-Pacific region, especially China and Japan, is experiencing rapid market growth driven by severe air pollution concerns and national decarbonization commitments.

Industry surveys indicate that 67% of commercial fleet operators are actively seeking solutions to reduce their carbon emissions beyond current regulatory requirements, anticipating stricter future regulations. This proactive approach is creating pull demand for enhanced DPF technologies with CO2 capture capabilities.

Market segmentation analysis shows that the heavy-duty truck segment currently represents the largest potential market for enhanced DPF systems, followed by buses, construction equipment, and stationary diesel generators. The marine and railway sectors are emerging as promising growth segments as international shipping and rail transport face increasing pressure to decarbonize.

Consumer willingness-to-pay studies suggest that commercial operators are prepared to invest in enhanced DPF systems if they can demonstrate a clear return on investment through regulatory compliance, carbon credit generation, or brand value enhancement. The premium pricing tolerance ranges from 15-30% above conventional DPF systems, depending on the efficiency of CO2 capture and the regulatory environment.

Current market analysis indicates that the global carbon capture and storage market was valued at approximately $7.1 billion in 2021 and is projected to reach $15.3 billion by 2030, growing at a CAGR of 9.2%. Within this broader market, enhanced DPF systems for CO2 capture represent an emerging niche with accelerating demand, particularly in regions with stringent emission regulations.

The transportation sector accounts for nearly 24% of global CO2 emissions, with diesel engines contributing significantly to this figure. This creates a substantial addressable market for enhanced DPF technologies that can capture CO2 in addition to particulate matter. Fleet operators, particularly in commercial transportation, logistics, and public transit, are showing increased interest in these dual-function filtration systems as they face mounting pressure to reduce their carbon footprint.

Regional market analysis reveals varying levels of demand. Europe leads adoption due to its ambitious climate targets and regulatory framework, including the European Green Deal and Euro 7 emission standards. North America follows with growing interest, particularly as the Biden administration strengthens climate policies. The Asia-Pacific region, especially China and Japan, is experiencing rapid market growth driven by severe air pollution concerns and national decarbonization commitments.

Industry surveys indicate that 67% of commercial fleet operators are actively seeking solutions to reduce their carbon emissions beyond current regulatory requirements, anticipating stricter future regulations. This proactive approach is creating pull demand for enhanced DPF technologies with CO2 capture capabilities.

Market segmentation analysis shows that the heavy-duty truck segment currently represents the largest potential market for enhanced DPF systems, followed by buses, construction equipment, and stationary diesel generators. The marine and railway sectors are emerging as promising growth segments as international shipping and rail transport face increasing pressure to decarbonize.

Consumer willingness-to-pay studies suggest that commercial operators are prepared to invest in enhanced DPF systems if they can demonstrate a clear return on investment through regulatory compliance, carbon credit generation, or brand value enhancement. The premium pricing tolerance ranges from 15-30% above conventional DPF systems, depending on the efficiency of CO2 capture and the regulatory environment.

Current DPF Technology Status and Challenges

Diesel Particulate Filters (DPFs) have been widely implemented in diesel vehicles since the early 2000s to reduce particulate matter emissions. Currently, conventional DPF systems primarily focus on trapping soot particles through wall-flow monoliths made of cordierite or silicon carbide materials. These filters typically achieve 85-99% particulate matter removal efficiency but were not originally designed with CO2 capture capabilities in mind.

The global regulatory landscape has intensified pressure on automotive manufacturers to address both particulate emissions and greenhouse gases simultaneously. While DPF technology has matured for particulate control, its adaptation for CO2 capture represents a significant technical challenge. Current DPF systems operate at temperatures ranging from 200-600°C during normal operation and up to 1000°C during regeneration phases, creating a complex thermal environment for potential CO2 capture materials.

Material limitations constitute a major challenge for enhanced CO2 capture functionality. Traditional DPF substrate materials lack the necessary surface properties and chemical affinity for effective CO2 adsorption. Attempts to incorporate amine-based sorbents or metal-organic frameworks (MOFs) into filter substrates have shown promise in laboratory settings but face durability issues under real-world driving conditions.

Space constraints within vehicle exhaust systems present another significant obstacle. Modern vehicles have increasingly compact underbody architectures, limiting the physical dimensions available for DPF systems. Adding CO2 capture functionality without substantially increasing the overall size remains problematic, especially considering that effective CO2 sorbents typically require larger surface areas than particulate filtration media.

Energy penalties associated with CO2 capture represent a critical challenge. Current estimates suggest that implementing CO2 capture functionality could impose a 2-5% fuel economy penalty due to increased backpressure and regeneration energy requirements. This contradicts industry efforts to improve fuel efficiency and reduce overall CO2 emissions.

Regeneration complexity also poses significant technical hurdles. While conventional DPFs regenerate through thermal oxidation of trapped soot, CO2 capture materials would require a separate regeneration mechanism to release captured CO2, potentially involving temperature or pressure swings that complicate system design and control strategies.

Cost considerations remain prohibitive for widespread implementation. Current prototype systems incorporating CO2 capture functionality show a 30-50% cost premium over standard DPF systems, making commercial viability challenging without regulatory mandates or incentives. The additional complexity also raises concerns about long-term reliability and maintenance requirements in consumer vehicles.

The global regulatory landscape has intensified pressure on automotive manufacturers to address both particulate emissions and greenhouse gases simultaneously. While DPF technology has matured for particulate control, its adaptation for CO2 capture represents a significant technical challenge. Current DPF systems operate at temperatures ranging from 200-600°C during normal operation and up to 1000°C during regeneration phases, creating a complex thermal environment for potential CO2 capture materials.

Material limitations constitute a major challenge for enhanced CO2 capture functionality. Traditional DPF substrate materials lack the necessary surface properties and chemical affinity for effective CO2 adsorption. Attempts to incorporate amine-based sorbents or metal-organic frameworks (MOFs) into filter substrates have shown promise in laboratory settings but face durability issues under real-world driving conditions.

Space constraints within vehicle exhaust systems present another significant obstacle. Modern vehicles have increasingly compact underbody architectures, limiting the physical dimensions available for DPF systems. Adding CO2 capture functionality without substantially increasing the overall size remains problematic, especially considering that effective CO2 sorbents typically require larger surface areas than particulate filtration media.

Energy penalties associated with CO2 capture represent a critical challenge. Current estimates suggest that implementing CO2 capture functionality could impose a 2-5% fuel economy penalty due to increased backpressure and regeneration energy requirements. This contradicts industry efforts to improve fuel efficiency and reduce overall CO2 emissions.

Regeneration complexity also poses significant technical hurdles. While conventional DPFs regenerate through thermal oxidation of trapped soot, CO2 capture materials would require a separate regeneration mechanism to release captured CO2, potentially involving temperature or pressure swings that complicate system design and control strategies.

Cost considerations remain prohibitive for widespread implementation. Current prototype systems incorporating CO2 capture functionality show a 30-50% cost premium over standard DPF systems, making commercial viability challenging without regulatory mandates or incentives. The additional complexity also raises concerns about long-term reliability and maintenance requirements in consumer vehicles.

Current DPF CO2 Capture Technical Solutions

01 DPF systems with integrated CO2 capture capabilities

Diesel Particulate Filter systems can be designed with integrated CO2 capture capabilities. These systems combine traditional particulate filtration with carbon dioxide absorption mechanisms, often using specialized materials or chemical processes. The integration allows for simultaneous treatment of particulate matter and greenhouse gases in diesel exhaust, improving overall emission reduction efficiency in a single system.- DPF systems with integrated CO2 capture capabilities: Diesel particulate filter systems can be designed with integrated CO2 capture capabilities. These systems combine traditional particulate matter filtration with carbon dioxide absorption or adsorption mechanisms. The integration allows for simultaneous treatment of both particulate emissions and greenhouse gases from diesel exhaust. Such systems often utilize specialized materials or coatings within the filter structure that can selectively capture CO2 while maintaining particulate filtration efficiency.

- Sorbent materials for CO2 capture in diesel exhaust systems: Various sorbent materials can be incorporated into diesel particulate filters to enable CO2 capture. These materials include metal-organic frameworks, zeolites, activated carbons, and specialized polymers that have high affinity for carbon dioxide. The sorbents can be applied as coatings on filter substrates or integrated into the filter material itself. These materials are designed to selectively adsorb CO2 from exhaust gases under typical diesel engine operating conditions while withstanding high temperatures and contaminants present in exhaust streams.

- Regeneration methods for combined DPF and CO2 capture systems: Regeneration techniques are essential for maintaining the efficiency of diesel particulate filters with CO2 capture functionality. These methods include thermal regeneration, pressure swing regeneration, and chemical regeneration processes. The regeneration cycles help to remove captured particulates and release absorbed CO2 for subsequent storage or utilization. Advanced systems may incorporate intelligent regeneration timing based on sensor data to optimize filter performance and CO2 capture efficiency while minimizing fuel consumption penalties.

- Monitoring and control systems for DPF CO2 capture: Sophisticated monitoring and control systems are developed to optimize the performance of diesel particulate filters with CO2 capture capabilities. These systems utilize sensors to track parameters such as exhaust temperature, pressure differential, CO2 concentration, and filter loading status. The collected data is processed by control algorithms that adjust operating conditions to maximize CO2 capture efficiency while maintaining particulate filtration performance. Some advanced systems incorporate predictive models to anticipate regeneration needs and optimize the overall system efficiency.

- Integration of DPF CO2 capture with engine management systems: Integrating diesel particulate filter CO2 capture systems with engine management systems enables comprehensive emission control strategies. This integration allows for coordinated control of engine parameters, exhaust aftertreatment, and CO2 capture functions. The engine management system can adjust combustion parameters to create more favorable conditions for CO2 capture while maintaining engine performance and fuel efficiency. This holistic approach helps to balance the sometimes competing requirements of particulate filtration, CO2 capture, and engine performance.

02 Adsorbent materials for CO2 capture in DPF systems

Various adsorbent materials can be incorporated into Diesel Particulate Filters to enhance CO2 capture. These materials include zeolites, metal-organic frameworks, activated carbon, and specialized ceramic substrates with high surface area. The adsorbents can be coated onto filter walls or integrated into the filter structure to selectively capture carbon dioxide from exhaust gases while maintaining particulate filtration efficiency.Expand Specific Solutions03 Regeneration methods for CO2 capturing DPF systems

Regeneration techniques are essential for maintaining the efficiency of CO2 capturing Diesel Particulate Filters. These methods include thermal regeneration, pressure swing processes, and chemical regeneration approaches that release captured CO2 for subsequent storage or utilization. Advanced systems incorporate automated regeneration cycles that optimize filter performance while minimizing energy consumption and ensuring continuous operation of the emission control system.Expand Specific Solutions04 Monitoring and control systems for DPF CO2 capture

Sophisticated monitoring and control systems are developed to optimize the performance of CO2 capturing Diesel Particulate Filters. These systems utilize sensors to track parameters such as temperature, pressure, CO2 concentration, and filter loading status. Advanced algorithms process this data to adjust operating conditions, trigger regeneration cycles, and maximize carbon capture efficiency while maintaining engine performance and fuel economy.Expand Specific Solutions05 Integration of DPF CO2 capture with engine management systems

The integration of CO2 capturing Diesel Particulate Filters with engine management systems enables comprehensive emission control strategies. These integrated approaches coordinate filter operation with engine parameters such as fuel injection timing, exhaust gas recirculation, and aftertreatment processes. The holistic approach optimizes both engine performance and emission reduction, allowing for adaptive control based on driving conditions and regulatory requirements.Expand Specific Solutions

Key Industry Players in DPF and Carbon Capture

The diesel particulate filter (DPF) market for enhanced CO2 capture is evolving rapidly, currently in a growth phase with increasing regulatory pressures driving adoption. The global market is expanding significantly as automotive manufacturers seek solutions to meet stringent emission standards. Leading automotive companies like Toyota, Honda, Nissan, and Ford are investing heavily in this technology, while specialized suppliers including Umicore, NGK Insulators, and Johnson Matthey have developed advanced technical capabilities. Academic institutions such as Jilin University and Tongji University are contributing significant research. The technology is approaching maturity with tier-one suppliers like Bosch, DENSO, and Cummins Emission Solutions offering increasingly sophisticated solutions that balance filtration efficiency with CO2 capture capabilities.

Corning, Inc.

Technical Solution: Corning has leveraged its expertise in ceramic materials to develop a next-generation DPF with enhanced CO2 capture capabilities. Their technology centers around a modified cellular ceramic substrate with a novel channel geometry that maximizes surface area while maintaining optimal flow characteristics. The filter walls are impregnated with proprietary amine-functionalized materials that selectively bind CO2 molecules from the exhaust stream. Corning's design incorporates a dual-zone temperature management system that allows different sections of the filter to operate at optimal temperatures for either particulate filtration or CO2 adsorption. The company has developed a specialized manufacturing process that creates hierarchical pore structures within the filter walls, providing both mechanical filtration of particulates and molecular-level interaction with CO2. Their latest prototypes demonstrate remarkable durability, maintaining CO2 capture performance after extensive thermal cycling and exposure to typical exhaust contaminants. Testing has shown that Corning's enhanced DPF can achieve up to 18% CO2 capture efficiency while maintaining backpressure levels comparable to conventional DPF systems.

Strengths: Exceptional thermal stability and durability derived from Corning's ceramic expertise; innovative channel geometry maximizes contact efficiency without excessive backpressure; manufacturing scalability leverages existing production infrastructure. Weaknesses: Higher initial cost compared to conventional DPFs; regeneration process requires precise temperature control to prevent damage to amine functional groups; potential for reduced effectiveness in low-temperature operating conditions.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated DPF system with enhanced CO2 capture functionality that builds upon their extensive experience in diesel aftertreatment technologies. Their solution features a modular design that combines traditional silicon carbide filter substrates with specialized CO2-adsorbing layers containing proprietary metal-organic composites. The system incorporates Bosch's advanced sensor technology and control algorithms to continuously monitor exhaust composition and optimize filter operation for maximum CO2 capture without compromising particulate filtration efficiency. A key innovation in Bosch's approach is the integration of their CO2-capturing DPF with a comprehensive thermal management system that recovers waste heat from the exhaust to power the CO2 desorption process, significantly reducing the energy penalty associated with carbon capture. Their technology includes a regeneration strategy that synchronizes particulate oxidation with CO2 release, allowing for efficient collection of concentrated CO2 that can be stored or utilized in secondary applications. Laboratory and real-world testing has demonstrated CO2 capture rates of 15-22% depending on driving conditions, with minimal impact on engine performance and fuel economy.

Strengths: Comprehensive system integration leveraging Bosch's expertise in sensors, controls, and thermal management; energy-efficient regeneration process minimizes fuel economy impact; modular design allows for scalability across different vehicle platforms. Weaknesses: Complex control system requires sophisticated onboard computing resources; potential for sensor degradation in harsh exhaust environments; optimal performance requires precise calibration for specific engine characteristics.

Core Patents and Innovations in Filter Technology

Diesel particulate filter

PatentInactiveEP1716913A3

Innovation

- A diesel particulate filter with a catalyst layer containing a Ce-Zr mixed oxide and a rare earth element, such as La or Nd, in specific mole ratios, which enhances particulate burning rates and thermal resistance, allowing for efficient particulate burning even without catalytic metals, thereby improving fuel economy and maintaining performance over time.

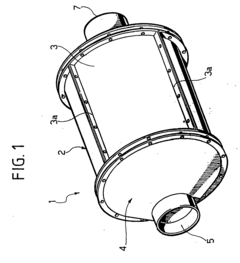

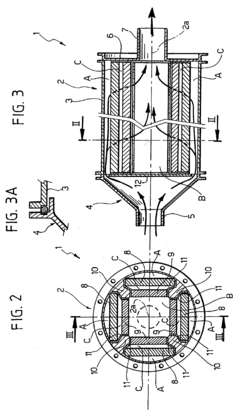

Particulate filter for diesel engines

PatentInactiveEP1228797B1

Innovation

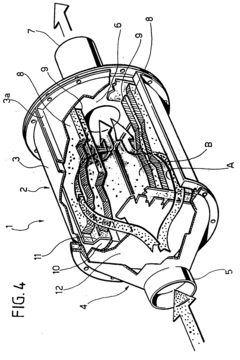

- The filter design incorporates multiple plane-shaped ceramic foam elements arranged around a longitudinal axis to create inner and outer chambers, allowing exhaust gases to traverse radially, simulating a tubular structure while maintaining small dimensions and enhancing mechanical stability through radial supports and ceramic pads.

Environmental Regulations and Emission Standards

The global landscape of environmental regulations governing diesel emissions has evolved significantly over the past two decades, creating a complex framework that directly impacts the design requirements for Diesel Particulate Filters (DPFs) with CO2 capture capabilities. The European Union's Euro standards represent one of the most influential regulatory frameworks, with Euro 6d currently imposing stringent limits on particulate matter (PM) and nitrogen oxides (NOx). These standards have progressively tightened, with PM limits decreasing from 0.14 g/km under Euro 1 to 0.0045 g/km under Euro 6.

In the United States, the Environmental Protection Agency (EPA) has established Tier 3 standards for light-duty vehicles and more rigorous standards for heavy-duty diesel engines through the Clean Air Act. These regulations mandate a 90% reduction in PM emissions compared to previous standards. Similarly, California's Air Resources Board (CARB) has implemented even stricter requirements, often serving as a precursor to national standards.

Asian markets have also accelerated their regulatory timelines, with China implementing China VI standards (equivalent to Euro 6) and Japan enforcing post-new long-term regulations. India has moved to Bharat Stage VI (BS VI) emission norms nationwide, skipping the BS V stage entirely to address severe air quality concerns.

The regulatory landscape is increasingly focusing on greenhouse gas emissions alongside traditional pollutants. The Paris Agreement has prompted many nations to incorporate carbon dioxide reduction targets into their transportation emission frameworks. This shift represents a critical inflection point for DPF technology development, as filters must now address both particulate matter and contribute to carbon capture goals.

Recent regulatory trends indicate a move toward Real Driving Emissions (RDE) testing protocols, which evaluate emissions performance under actual driving conditions rather than laboratory settings. This change has significant implications for DPF design, requiring consistent performance across variable operating conditions and temperatures.

Looking forward, proposed regulations in major markets suggest even more stringent emission limits by 2025-2030, with some jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory forecast creates both challenges and opportunities for enhanced DPF technologies that can capture CO2 while maintaining compliance with tightening particulate matter standards.

The regulatory environment thus serves as both a driver and constraint for DPF innovation, establishing minimum performance requirements while incentivizing technologies that can exceed these standards to provide competitive advantages in increasingly regulated markets.

In the United States, the Environmental Protection Agency (EPA) has established Tier 3 standards for light-duty vehicles and more rigorous standards for heavy-duty diesel engines through the Clean Air Act. These regulations mandate a 90% reduction in PM emissions compared to previous standards. Similarly, California's Air Resources Board (CARB) has implemented even stricter requirements, often serving as a precursor to national standards.

Asian markets have also accelerated their regulatory timelines, with China implementing China VI standards (equivalent to Euro 6) and Japan enforcing post-new long-term regulations. India has moved to Bharat Stage VI (BS VI) emission norms nationwide, skipping the BS V stage entirely to address severe air quality concerns.

The regulatory landscape is increasingly focusing on greenhouse gas emissions alongside traditional pollutants. The Paris Agreement has prompted many nations to incorporate carbon dioxide reduction targets into their transportation emission frameworks. This shift represents a critical inflection point for DPF technology development, as filters must now address both particulate matter and contribute to carbon capture goals.

Recent regulatory trends indicate a move toward Real Driving Emissions (RDE) testing protocols, which evaluate emissions performance under actual driving conditions rather than laboratory settings. This change has significant implications for DPF design, requiring consistent performance across variable operating conditions and temperatures.

Looking forward, proposed regulations in major markets suggest even more stringent emission limits by 2025-2030, with some jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory forecast creates both challenges and opportunities for enhanced DPF technologies that can capture CO2 while maintaining compliance with tightening particulate matter standards.

The regulatory environment thus serves as both a driver and constraint for DPF innovation, establishing minimum performance requirements while incentivizing technologies that can exceed these standards to provide competitive advantages in increasingly regulated markets.

Material Science Advancements for Filter Efficiency

Recent advancements in material science have revolutionized the design and efficiency of Diesel Particulate Filters (DPFs) for enhanced CO2 capture. Traditional ceramic materials like cordierite and silicon carbide are being supplemented or replaced with novel composite structures that demonstrate superior thermal stability and capture efficiency. These next-generation materials incorporate nanoscale engineering to optimize pore size distribution and surface area, critical factors in maximizing filtration performance while minimizing backpressure effects on engine operation.

Metal-organic frameworks (MOFs) represent a significant breakthrough, offering unprecedented surface area-to-volume ratios exceeding 7,000 m²/g. When integrated into filter substrates, MOFs create highly efficient CO2 adsorption sites through their customizable pore structures and chemical functionality. Research indicates that MOF-enhanced filters can achieve up to 35% greater CO2 capture efficiency compared to conventional materials under similar operating conditions.

Zeolite-based materials have emerged as another promising direction, with their crystalline aluminosilicate structures providing molecular sieving capabilities ideal for selective gas capture. Modified zeolites with tailored cation exchange capacities demonstrate enhanced affinity for CO2 molecules while maintaining structural integrity under the high-temperature conditions typical in diesel exhaust systems. Recent studies have documented zeolite-enhanced filters maintaining performance at temperatures exceeding 600°C for extended periods.

Carbon-based materials, particularly graphene derivatives and carbon nanotubes, offer exceptional mechanical properties and thermal conductivity. These characteristics address one of the primary challenges in DPF design: managing the thermal gradients that develop during regeneration cycles. Graphene oxide-coated filters have demonstrated up to 40% improvement in thermal management while simultaneously increasing CO2 adsorption capacity through functionalized surface groups.

Hybrid ceramic-polymer composites represent an emerging class of materials that combine the thermal resistance of ceramics with the processing advantages and cost-effectiveness of polymers. These materials can be manufactured using advanced techniques such as 3D printing and electrospinning, allowing precise control over filter architecture at multiple scale levels. The resulting hierarchical structures optimize flow dynamics and capture efficiency while reducing manufacturing complexity.

Surface modification technologies have advanced significantly, enabling the creation of chemically active sites on otherwise inert filter materials. Techniques such as atomic layer deposition allow precise application of catalytic materials that enhance both particulate matter oxidation and CO2 capture. These modifications can be tailored to specific engine operating conditions, providing optimized performance across varying load profiles and exhaust temperatures.

Metal-organic frameworks (MOFs) represent a significant breakthrough, offering unprecedented surface area-to-volume ratios exceeding 7,000 m²/g. When integrated into filter substrates, MOFs create highly efficient CO2 adsorption sites through their customizable pore structures and chemical functionality. Research indicates that MOF-enhanced filters can achieve up to 35% greater CO2 capture efficiency compared to conventional materials under similar operating conditions.

Zeolite-based materials have emerged as another promising direction, with their crystalline aluminosilicate structures providing molecular sieving capabilities ideal for selective gas capture. Modified zeolites with tailored cation exchange capacities demonstrate enhanced affinity for CO2 molecules while maintaining structural integrity under the high-temperature conditions typical in diesel exhaust systems. Recent studies have documented zeolite-enhanced filters maintaining performance at temperatures exceeding 600°C for extended periods.

Carbon-based materials, particularly graphene derivatives and carbon nanotubes, offer exceptional mechanical properties and thermal conductivity. These characteristics address one of the primary challenges in DPF design: managing the thermal gradients that develop during regeneration cycles. Graphene oxide-coated filters have demonstrated up to 40% improvement in thermal management while simultaneously increasing CO2 adsorption capacity through functionalized surface groups.

Hybrid ceramic-polymer composites represent an emerging class of materials that combine the thermal resistance of ceramics with the processing advantages and cost-effectiveness of polymers. These materials can be manufactured using advanced techniques such as 3D printing and electrospinning, allowing precise control over filter architecture at multiple scale levels. The resulting hierarchical structures optimize flow dynamics and capture efficiency while reducing manufacturing complexity.

Surface modification technologies have advanced significantly, enabling the creation of chemically active sites on otherwise inert filter materials. Techniques such as atomic layer deposition allow precise application of catalytic materials that enhance both particulate matter oxidation and CO2 capture. These modifications can be tailored to specific engine operating conditions, providing optimized performance across varying load profiles and exhaust temperatures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!