How to Develop Diesel Particulate Filter Noise Suppression

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Noise Suppression Background and Objectives

Diesel Particulate Filters (DPFs) have become an integral component in modern diesel engine exhaust systems since their widespread adoption in the early 2000s. Initially developed to meet increasingly stringent emission regulations, particularly Euro 4 standards in Europe and Tier 2 Bin 5 in the United States, these filtration systems effectively capture and eliminate particulate matter (PM) from diesel exhaust gases, reducing harmful emissions by over 90%.

The evolution of DPF technology has progressed through several generations, from early passive systems to more sophisticated active regeneration mechanisms. However, as these systems have become more complex and efficient at emissions reduction, they have introduced new challenges, particularly in the realm of noise generation and acoustic performance.

DPF-related noise issues emerged as a significant concern around 2010, when automotive manufacturers and consumers began reporting unusual acoustic phenomena during specific operating conditions. These noise manifestations typically present as low-frequency drone, high-pitched whistling, or resonant humming during regeneration cycles or specific engine load conditions.

The primary objective of DPF noise suppression technology development is to maintain the excellent filtration efficiency and emissions reduction capabilities while eliminating or significantly reducing the acoustic side effects. This requires a multidisciplinary approach combining fluid dynamics, acoustic engineering, materials science, and mechanical design principles.

Current industry benchmarks suggest that successful DPF noise suppression should achieve at least a 10dB reduction in problematic frequency ranges without compromising back pressure specifications or filtration efficiency. Additionally, solutions must maintain durability across the vehicle's operational lifetime, typically 150,000+ miles or 10+ years of service.

The technological trajectory indicates a shift from reactive noise treatment (adding insulation or acoustic shields) toward proactive design solutions that address noise generation at its source. This includes innovations in substrate geometry, flow path optimization, and advanced regeneration control strategies that minimize acoustic excitation.

Recent regulatory developments, particularly Euro 7 and upcoming EPA standards, have further complicated the technical landscape by requiring even more efficient filtration while maintaining acceptable noise levels. This creates a challenging engineering balance between emissions performance, acoustic comfort, and system durability.

The ultimate goal of this technical research is to develop comprehensive design guidelines and technological solutions that enable next-generation DPF systems to operate with optimal filtration efficiency while maintaining acoustic transparency across all operating conditions and throughout the entire service life of the vehicle.

The evolution of DPF technology has progressed through several generations, from early passive systems to more sophisticated active regeneration mechanisms. However, as these systems have become more complex and efficient at emissions reduction, they have introduced new challenges, particularly in the realm of noise generation and acoustic performance.

DPF-related noise issues emerged as a significant concern around 2010, when automotive manufacturers and consumers began reporting unusual acoustic phenomena during specific operating conditions. These noise manifestations typically present as low-frequency drone, high-pitched whistling, or resonant humming during regeneration cycles or specific engine load conditions.

The primary objective of DPF noise suppression technology development is to maintain the excellent filtration efficiency and emissions reduction capabilities while eliminating or significantly reducing the acoustic side effects. This requires a multidisciplinary approach combining fluid dynamics, acoustic engineering, materials science, and mechanical design principles.

Current industry benchmarks suggest that successful DPF noise suppression should achieve at least a 10dB reduction in problematic frequency ranges without compromising back pressure specifications or filtration efficiency. Additionally, solutions must maintain durability across the vehicle's operational lifetime, typically 150,000+ miles or 10+ years of service.

The technological trajectory indicates a shift from reactive noise treatment (adding insulation or acoustic shields) toward proactive design solutions that address noise generation at its source. This includes innovations in substrate geometry, flow path optimization, and advanced regeneration control strategies that minimize acoustic excitation.

Recent regulatory developments, particularly Euro 7 and upcoming EPA standards, have further complicated the technical landscape by requiring even more efficient filtration while maintaining acceptable noise levels. This creates a challenging engineering balance between emissions performance, acoustic comfort, and system durability.

The ultimate goal of this technical research is to develop comprehensive design guidelines and technological solutions that enable next-generation DPF systems to operate with optimal filtration efficiency while maintaining acoustic transparency across all operating conditions and throughout the entire service life of the vehicle.

Market Demand Analysis for Quieter Diesel Systems

The global market for diesel particulate filter (DPF) noise suppression technologies is experiencing significant growth driven by increasingly stringent emission regulations and consumer demand for quieter vehicle operation. Current market analysis indicates that the automotive sector represents the largest segment for DPF noise suppression solutions, with commercial vehicles and off-road equipment following closely behind.

Recent surveys among fleet operators reveal that noise reduction has become a critical purchasing factor, with over 80% of commercial fleet managers citing noise levels as an important consideration when acquiring new diesel vehicles. This represents a substantial shift from previous decades when performance and fuel efficiency were the predominant concerns.

The European market currently leads demand for quieter diesel systems, largely due to the EU's strict noise emission standards for vehicles operating in urban environments. North America follows as the second-largest market, with rapid growth observed in the Asia-Pacific region, particularly in China, Japan, and South Korea, where urbanization has intensified concerns about noise pollution.

Market segmentation analysis shows distinct customer preferences across different applications. In the passenger vehicle segment, consumers prioritize cabin comfort and are willing to pay premium prices for vehicles with reduced noise profiles. The commercial transportation sector emphasizes compliance with noise regulations that restrict delivery times in residential areas, creating demand for quieter systems that enable extended operational hours.

Economic analysis of the market reveals that the global DPF noise suppression technology sector is valued at several billion dollars annually, with projected compound annual growth rates between 5-7% through 2028. This growth is primarily driven by regulatory pressures rather than voluntary adoption, suggesting that manufacturers who develop cost-effective noise suppression solutions will gain significant competitive advantage.

Industry reports indicate a growing trend toward integrated noise reduction solutions that address multiple sources of diesel system noise simultaneously, rather than focusing solely on DPF-related noise. This holistic approach is creating new market opportunities for system suppliers who can provide comprehensive acoustic management solutions.

Customer willingness-to-pay studies demonstrate that noise reduction features command different premium levels across market segments, with luxury vehicle manufacturers able to command the highest premiums for quieter diesel systems, while commercial vehicle operators show more price sensitivity but increasing recognition of the operational benefits of reduced noise.

Recent surveys among fleet operators reveal that noise reduction has become a critical purchasing factor, with over 80% of commercial fleet managers citing noise levels as an important consideration when acquiring new diesel vehicles. This represents a substantial shift from previous decades when performance and fuel efficiency were the predominant concerns.

The European market currently leads demand for quieter diesel systems, largely due to the EU's strict noise emission standards for vehicles operating in urban environments. North America follows as the second-largest market, with rapid growth observed in the Asia-Pacific region, particularly in China, Japan, and South Korea, where urbanization has intensified concerns about noise pollution.

Market segmentation analysis shows distinct customer preferences across different applications. In the passenger vehicle segment, consumers prioritize cabin comfort and are willing to pay premium prices for vehicles with reduced noise profiles. The commercial transportation sector emphasizes compliance with noise regulations that restrict delivery times in residential areas, creating demand for quieter systems that enable extended operational hours.

Economic analysis of the market reveals that the global DPF noise suppression technology sector is valued at several billion dollars annually, with projected compound annual growth rates between 5-7% through 2028. This growth is primarily driven by regulatory pressures rather than voluntary adoption, suggesting that manufacturers who develop cost-effective noise suppression solutions will gain significant competitive advantage.

Industry reports indicate a growing trend toward integrated noise reduction solutions that address multiple sources of diesel system noise simultaneously, rather than focusing solely on DPF-related noise. This holistic approach is creating new market opportunities for system suppliers who can provide comprehensive acoustic management solutions.

Customer willingness-to-pay studies demonstrate that noise reduction features command different premium levels across market segments, with luxury vehicle manufacturers able to command the highest premiums for quieter diesel systems, while commercial vehicle operators show more price sensitivity but increasing recognition of the operational benefits of reduced noise.

Current DPF Noise Challenges and Technical Limitations

Diesel Particulate Filters (DPFs) have become standard components in modern diesel engines to meet increasingly stringent emission regulations. However, these systems introduce complex acoustic challenges that significantly impact vehicle noise, vibration, and harshness (NVH) performance. Current DPF noise issues primarily manifest as regeneration noise, resonance phenomena, and pressure-induced vibrations that propagate through the exhaust system.

The regeneration process, essential for DPF functionality, creates substantial acoustic challenges. During active regeneration, the rapid temperature changes and combustion of accumulated particulate matter generate pressure pulses that excite resonant frequencies within the filter substrate. These acoustic events typically occur in the 500-2000 Hz range, which unfortunately coincides with frequencies particularly noticeable to human hearing, resulting in customer complaints about unexpected noise during vehicle operation.

Flow-induced noise represents another significant limitation in current DPF technology. The honeycomb structure of the filter substrate, while necessary for particulate capture, creates complex flow patterns that generate turbulence. This turbulence produces broadband noise that varies with engine load and speed, making it difficult to implement consistent noise suppression strategies across the entire operating range of the vehicle.

Material constraints further complicate DPF noise management. Current ceramic substrates offer excellent filtration properties but possess poor acoustic damping characteristics. The high-temperature operating environment (regularly exceeding 600°C during regeneration) severely limits material selection for noise-dampening components, as most conventional acoustic materials would degrade rapidly under such conditions.

Packaging limitations present additional challenges. The increasingly crowded underbody architecture of modern vehicles restricts the physical space available for acoustic treatment solutions. Engineers face the difficult task of implementing effective noise suppression measures within extremely confined spaces, often competing with other critical components for available volume.

Integration with existing exhaust system components creates further complications. The acoustic impedance mismatch between the DPF and other exhaust components (catalytic converters, mufflers, tailpipes) can create reflection points for sound waves, establishing standing wave patterns that amplify certain frequencies. Current design approaches struggle to address these system-level acoustic interactions effectively.

Computational modeling limitations also hinder progress in this field. While Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) have advanced significantly, accurately predicting the acoustic behavior of DPF systems remains challenging due to the complex interaction between thermodynamics, fluid dynamics, and structural vibration. This modeling gap makes it difficult to optimize designs without extensive physical prototyping and testing.

The regeneration process, essential for DPF functionality, creates substantial acoustic challenges. During active regeneration, the rapid temperature changes and combustion of accumulated particulate matter generate pressure pulses that excite resonant frequencies within the filter substrate. These acoustic events typically occur in the 500-2000 Hz range, which unfortunately coincides with frequencies particularly noticeable to human hearing, resulting in customer complaints about unexpected noise during vehicle operation.

Flow-induced noise represents another significant limitation in current DPF technology. The honeycomb structure of the filter substrate, while necessary for particulate capture, creates complex flow patterns that generate turbulence. This turbulence produces broadband noise that varies with engine load and speed, making it difficult to implement consistent noise suppression strategies across the entire operating range of the vehicle.

Material constraints further complicate DPF noise management. Current ceramic substrates offer excellent filtration properties but possess poor acoustic damping characteristics. The high-temperature operating environment (regularly exceeding 600°C during regeneration) severely limits material selection for noise-dampening components, as most conventional acoustic materials would degrade rapidly under such conditions.

Packaging limitations present additional challenges. The increasingly crowded underbody architecture of modern vehicles restricts the physical space available for acoustic treatment solutions. Engineers face the difficult task of implementing effective noise suppression measures within extremely confined spaces, often competing with other critical components for available volume.

Integration with existing exhaust system components creates further complications. The acoustic impedance mismatch between the DPF and other exhaust components (catalytic converters, mufflers, tailpipes) can create reflection points for sound waves, establishing standing wave patterns that amplify certain frequencies. Current design approaches struggle to address these system-level acoustic interactions effectively.

Computational modeling limitations also hinder progress in this field. While Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) have advanced significantly, accurately predicting the acoustic behavior of DPF systems remains challenging due to the complex interaction between thermodynamics, fluid dynamics, and structural vibration. This modeling gap makes it difficult to optimize designs without extensive physical prototyping and testing.

Current Noise Suppression Solutions for DPF Systems

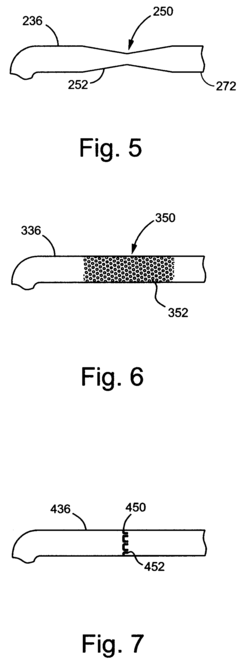

01 Noise reduction through filter design and structure

The design and structure of diesel particulate filters can be optimized to reduce noise. This includes using specific materials, geometrical configurations, and internal structures that minimize acoustic resonance and vibration. Modifications to the filter walls, channels, and overall shape can significantly impact noise generation during operation and regeneration processes.- Noise reduction through filter design and structure: Specific designs and structures of diesel particulate filters can help reduce noise. This includes optimizing the filter's internal geometry, using multiple chambers or compartments, and incorporating sound-absorbing materials. The design can be tailored to target specific frequency ranges that cause the most noticeable noise during operation or regeneration phases.

- Acoustic monitoring and diagnostic systems: Systems that monitor acoustic signatures of diesel particulate filters can help diagnose filter conditions and identify abnormal noise patterns. These systems use sensors to detect changes in sound characteristics that might indicate clogging, damage, or inefficient operation. By analyzing acoustic data, these systems can trigger maintenance before noise issues become severe or help optimize filter operation to minimize noise.

- Regeneration process noise management: The regeneration process, where accumulated particulates are burned off, can be a significant source of noise in diesel particulate filters. Techniques to manage this noise include controlling the timing and rate of regeneration, optimizing temperature profiles during regeneration, and implementing staged regeneration approaches. Advanced control algorithms can balance effective particulate removal with noise reduction during this critical maintenance phase.

- Flow path optimization for noise reduction: Optimizing the exhaust gas flow path through the diesel particulate filter can significantly reduce noise generation. This includes designing baffles, flow distributors, and channel configurations that minimize turbulence and pressure fluctuations. Some designs incorporate expansion chambers or resonators that target specific noise frequencies, while others focus on creating more laminar flow patterns to reduce overall acoustic emissions.

- Integration with exhaust system components for noise attenuation: Integrating diesel particulate filters with other exhaust system components can provide comprehensive noise attenuation. This approach considers the entire exhaust path as a noise management system, combining the filter with mufflers, resonators, and acoustic insulation. Some designs position the filter strategically within the exhaust system to take advantage of natural noise cancellation effects or incorporate additional silencing elements specifically designed to work with the filter's acoustic characteristics.

02 Acoustic dampening systems and mufflers

Specialized acoustic dampening systems and mufflers can be integrated with diesel particulate filters to reduce noise. These systems may include resonators, sound-absorbing materials, and acoustic chambers designed to attenuate specific frequencies associated with DPF operation. The placement and design of these components relative to the filter can significantly reduce noise transmission to the vehicle exterior.Expand Specific Solutions03 Monitoring and control systems for noise management

Advanced monitoring and control systems can be implemented to manage noise from diesel particulate filters. These systems use sensors to detect pressure, temperature, and acoustic conditions, allowing for real-time adjustments to filter operation. Control algorithms can modify regeneration timing, exhaust flow, and other parameters to minimize noise during critical operating conditions.Expand Specific Solutions04 Regeneration process optimization for noise reduction

The regeneration process of diesel particulate filters can be optimized to reduce noise. This involves controlling the timing, duration, and temperature of regeneration events to minimize acoustic emissions. Strategies include gradual heating, staged regeneration, and adaptive control based on operating conditions to prevent sudden thermal expansions that cause noise.Expand Specific Solutions05 Filter substrate and coating technologies

Advanced substrate materials and coating technologies can be applied to diesel particulate filters to reduce noise. These include specialized ceramic compositions, metallic substrates, and catalytic coatings that improve filtration efficiency while minimizing acoustic resonance. The physical properties of these materials can be engineered to dampen vibrations and reduce noise generation during operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DPF Technology

The diesel particulate filter (DPF) noise suppression technology market is currently in a growth phase, driven by increasingly stringent emissions regulations worldwide. The market size is expanding steadily, estimated at approximately $2-3 billion globally, with projected annual growth of 5-7%. Technologically, the field is moderately mature but continues to evolve, with major automotive manufacturers like Ford, GM, Hyundai, Nissan, and Volvo leading development alongside specialized component suppliers such as Donaldson, Corning, and IBIDEN. These companies are advancing solutions through various approaches including acoustic design optimization, resonator integration, and electronic control systems. Research institutions like Hunan University and Harbin Engineering University are contributing fundamental research, while tier-one suppliers like Bosch and BASF are developing integrated systems that combine filtration efficiency with noise reduction capabilities.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Diesel Particulate Filter (DPF) noise suppression system that integrates multiple technologies to address both acoustic and structural aspects of DPF-related noise. Their solution incorporates a multi-layer acoustic insulation system with specialized heat-resistant materials that can withstand temperatures up to 800°C while providing effective sound dampening. Ford's approach includes strategically placed resonators in the exhaust system that are specifically tuned to counteract the dominant frequencies generated during DPF regeneration cycles. Additionally, they've implemented an adaptive control algorithm that modifies engine parameters during regeneration to minimize pressure fluctuations that cause noise. Ford's system also features a dual-path exhaust design with variable valve technology that can redirect exhaust flow to optimize both noise suppression and backpressure management. Their comprehensive solution addresses noise across the entire frequency spectrum, with particular attention to the 500-2000 Hz range that is most perceptible to human hearing.

Strengths: Ford's integrated approach addresses multiple noise sources simultaneously, providing comprehensive noise reduction across various operating conditions. Their adaptive control system can respond to changing conditions in real-time. Weaknesses: The complex multi-component system increases manufacturing costs and adds weight to the vehicle, potentially affecting fuel economy. The system requires sophisticated electronic controls and sensors that add complexity to maintenance.

Corning, Inc.

Technical Solution: Corning has developed an innovative material science approach to DPF noise suppression that focuses on the filter substrate itself. Their proprietary DuraTrap® AC filter technology incorporates an advanced cellular ceramic structure with optimized wall porosity and channel geometry specifically designed to minimize acoustic resonance while maintaining high filtration efficiency. The ceramic substrate features asymmetric cell structures that disrupt sound wave propagation patterns, effectively diffusing acoustic energy across a wider frequency range. Corning's filters incorporate a gradient density design where the porosity of the filter walls varies throughout the structure, creating acoustic impedance mismatches that reduce sound transmission. Additionally, they've developed a specialized coating technology that adds a viscoelastic layer to the filter channels, providing further damping of acoustic vibrations. This coating maintains its damping properties even at the high temperatures experienced during regeneration cycles (up to 600°C). Corning's approach also includes an innovative filter mounting system with elastomeric isolators that decouple the DPF from the exhaust system structure, preventing the transmission of structure-borne noise to the vehicle body.

Strengths: Corning's material-based approach addresses noise at the source without requiring complex electronic controls or additional components. Their solution maintains excellent filtration performance while reducing noise. Weaknesses: The specialized materials and manufacturing processes increase the initial cost of the DPF. The acoustic performance may degrade over time as soot accumulates in specific patterns within the filter.

Key Patents and Innovations in DPF Acoustic Engineering

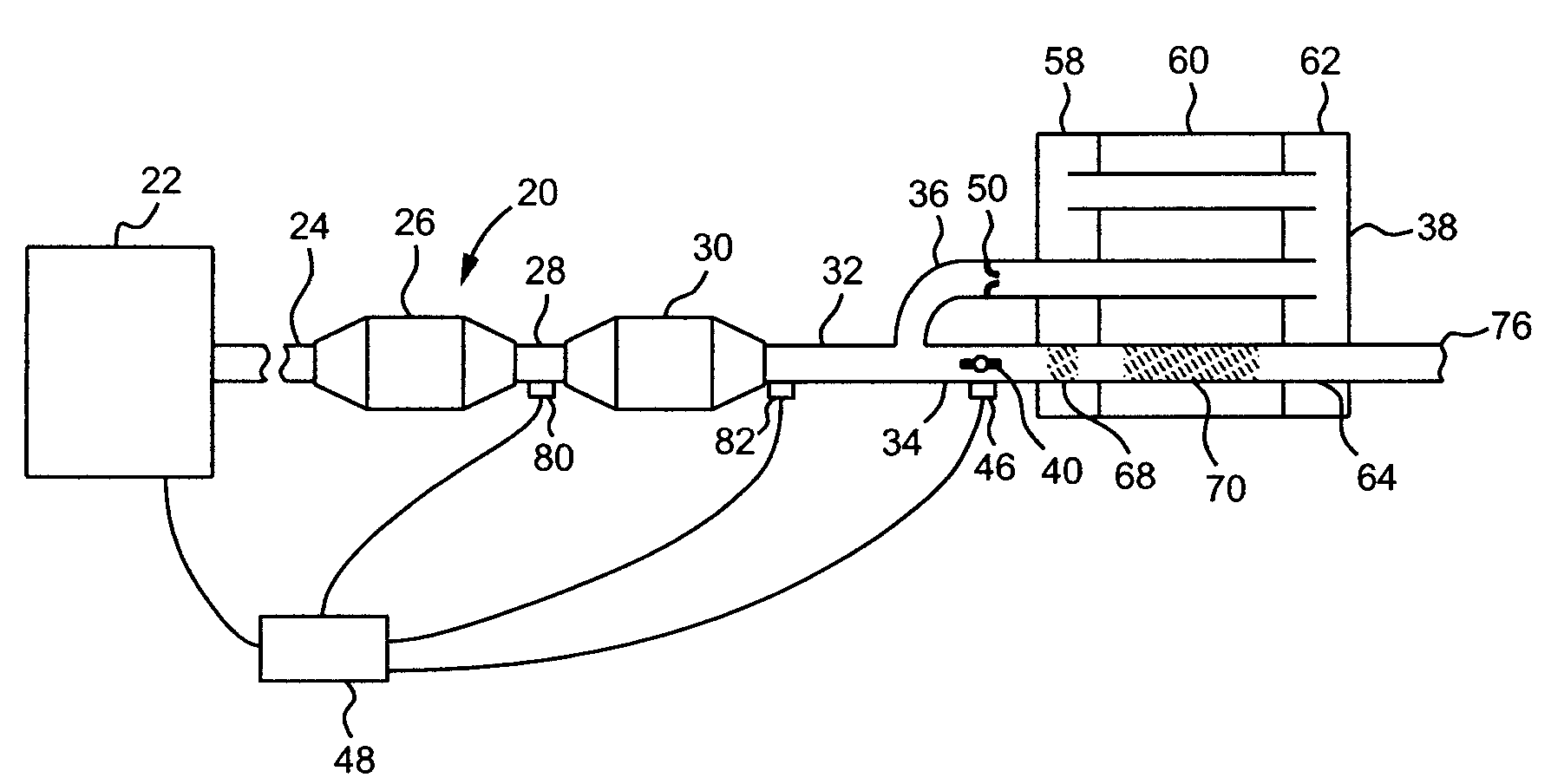

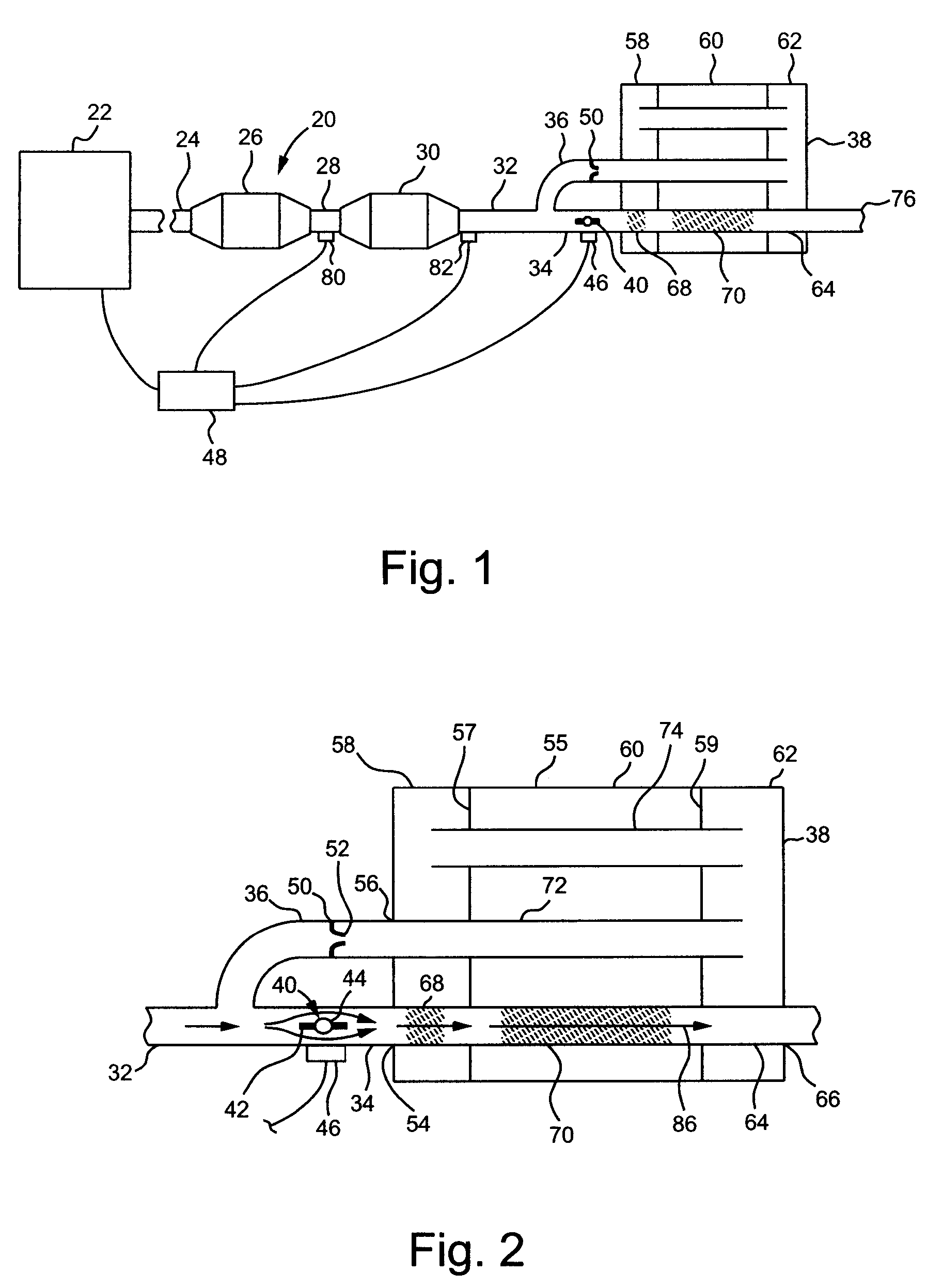

Diesel exhaust system variable backpressure muffler

PatentInactiveUS7337609B2

Innovation

- An exhaust system with a diesel particulate filter and a particulate filter backpressure valve that redirects exhaust flow through a restricted path in the muffler, creating backpressure to induce regeneration without additional heaters or excessive fuel, while minimizing noise and backpressure during normal operation.

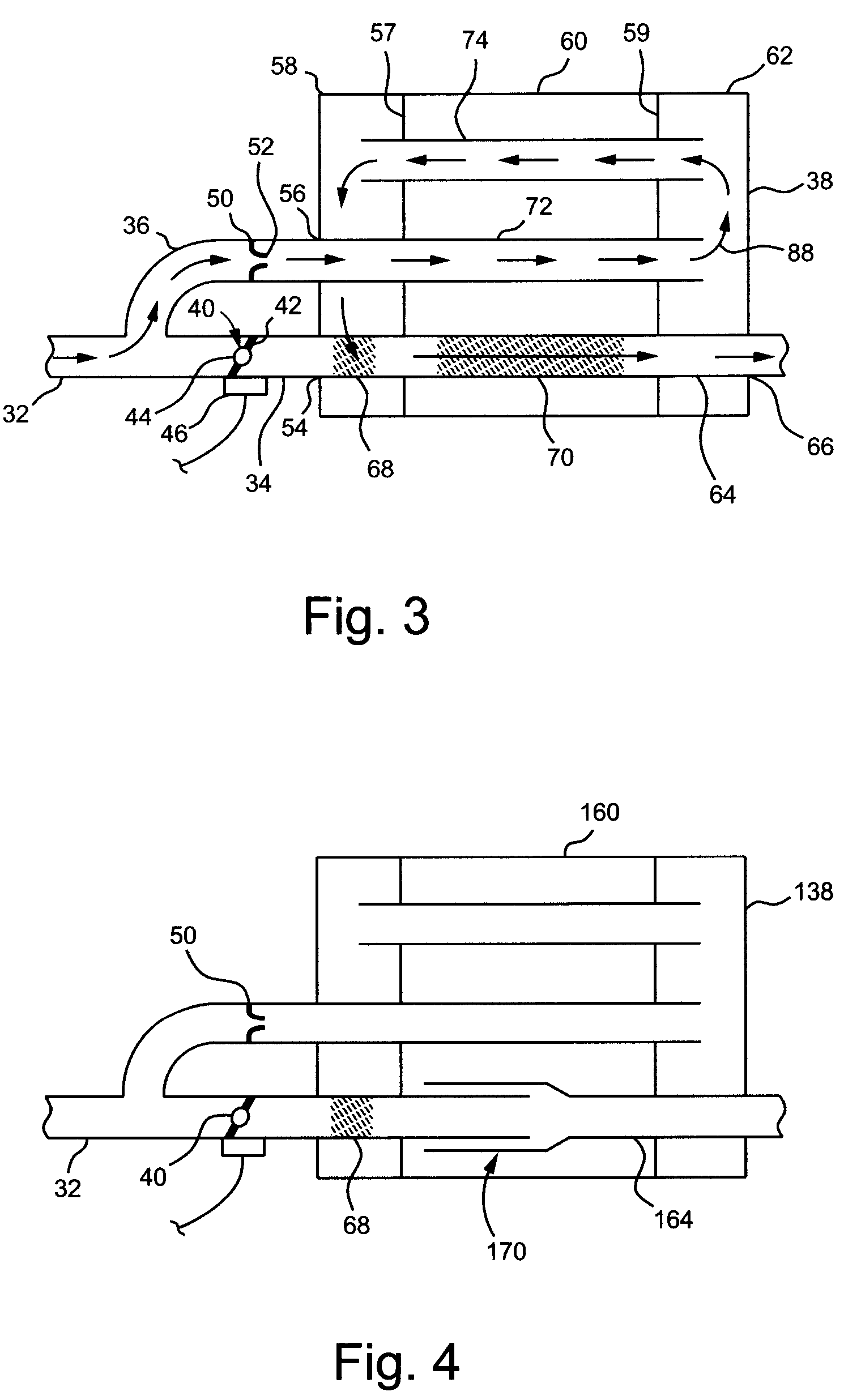

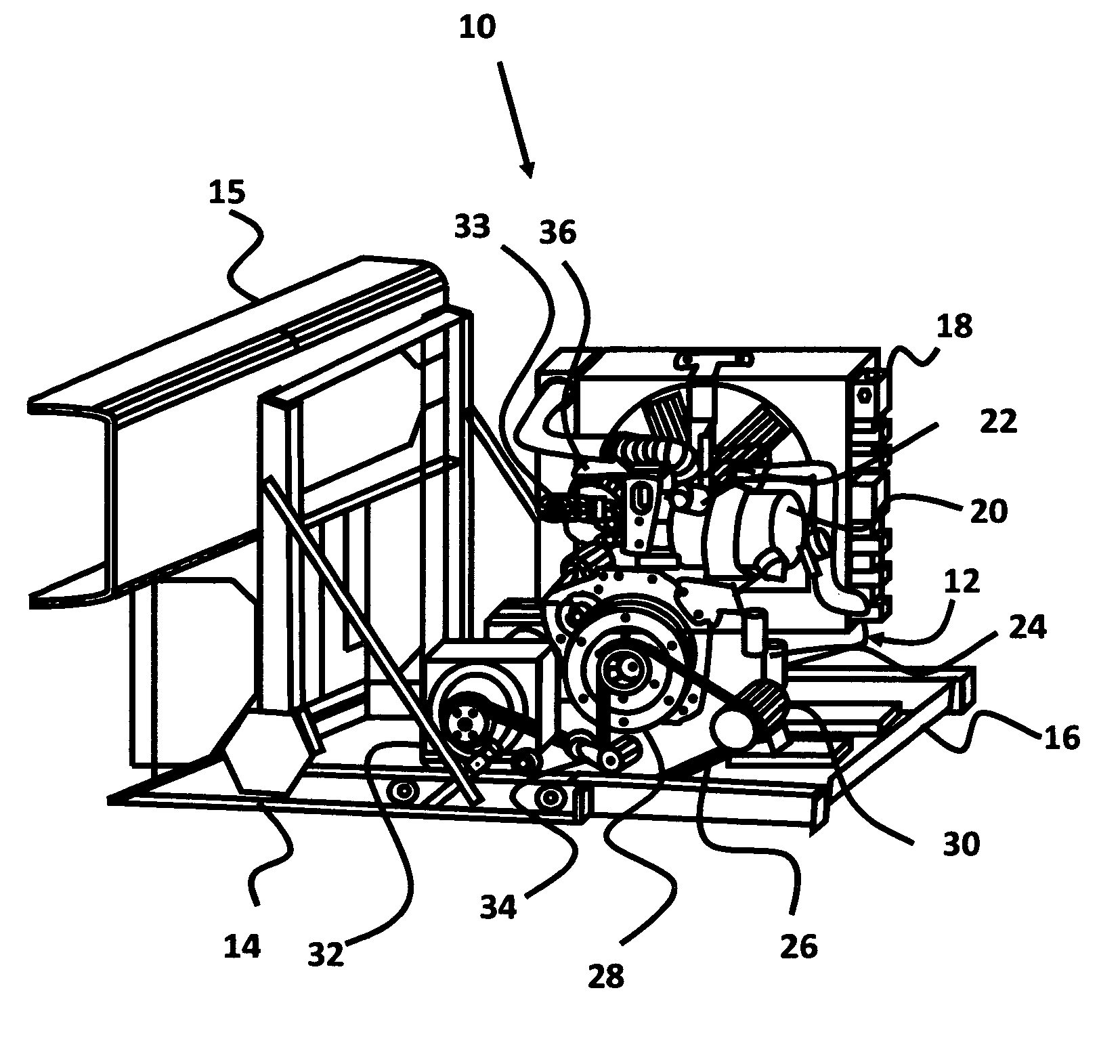

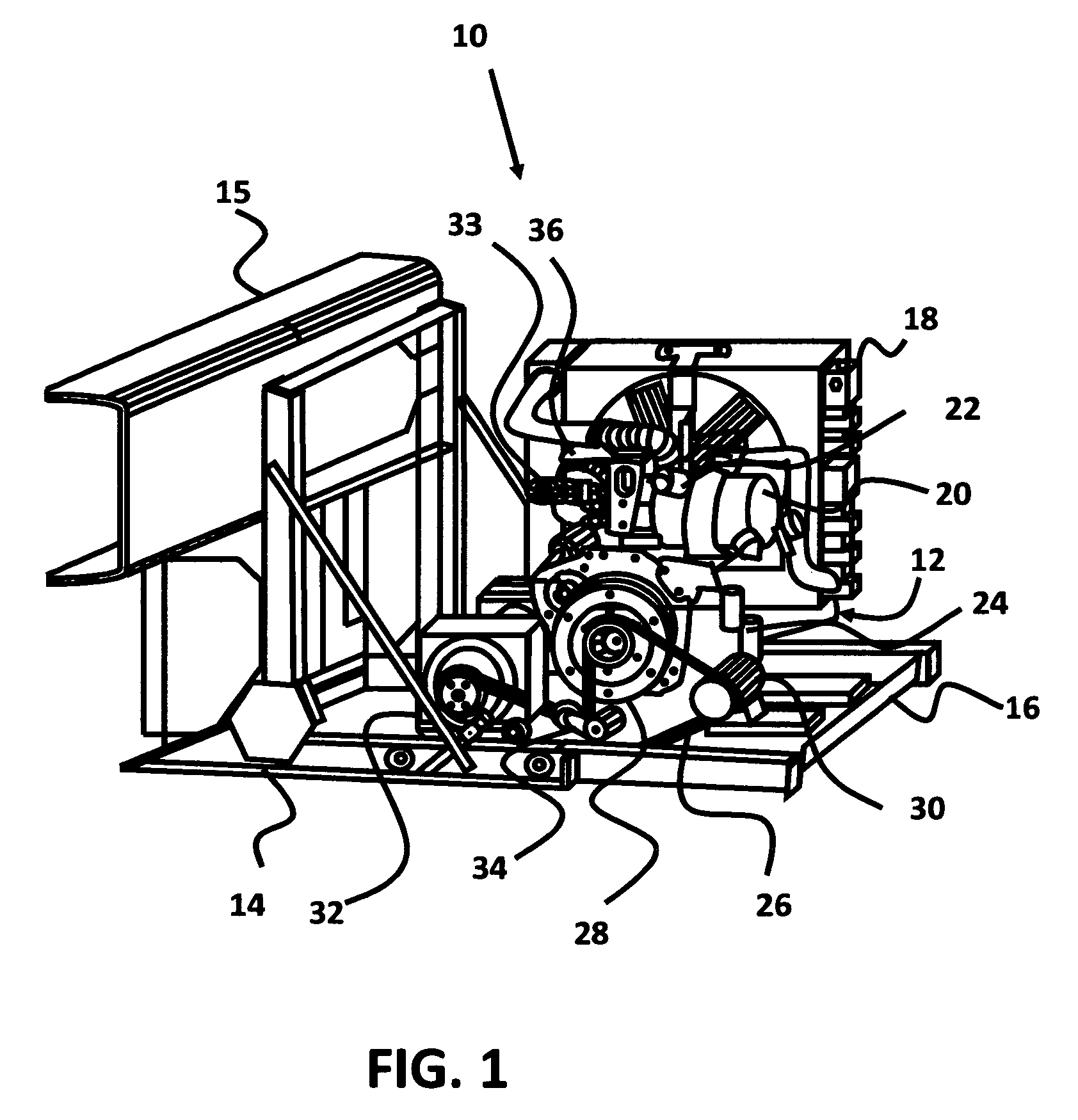

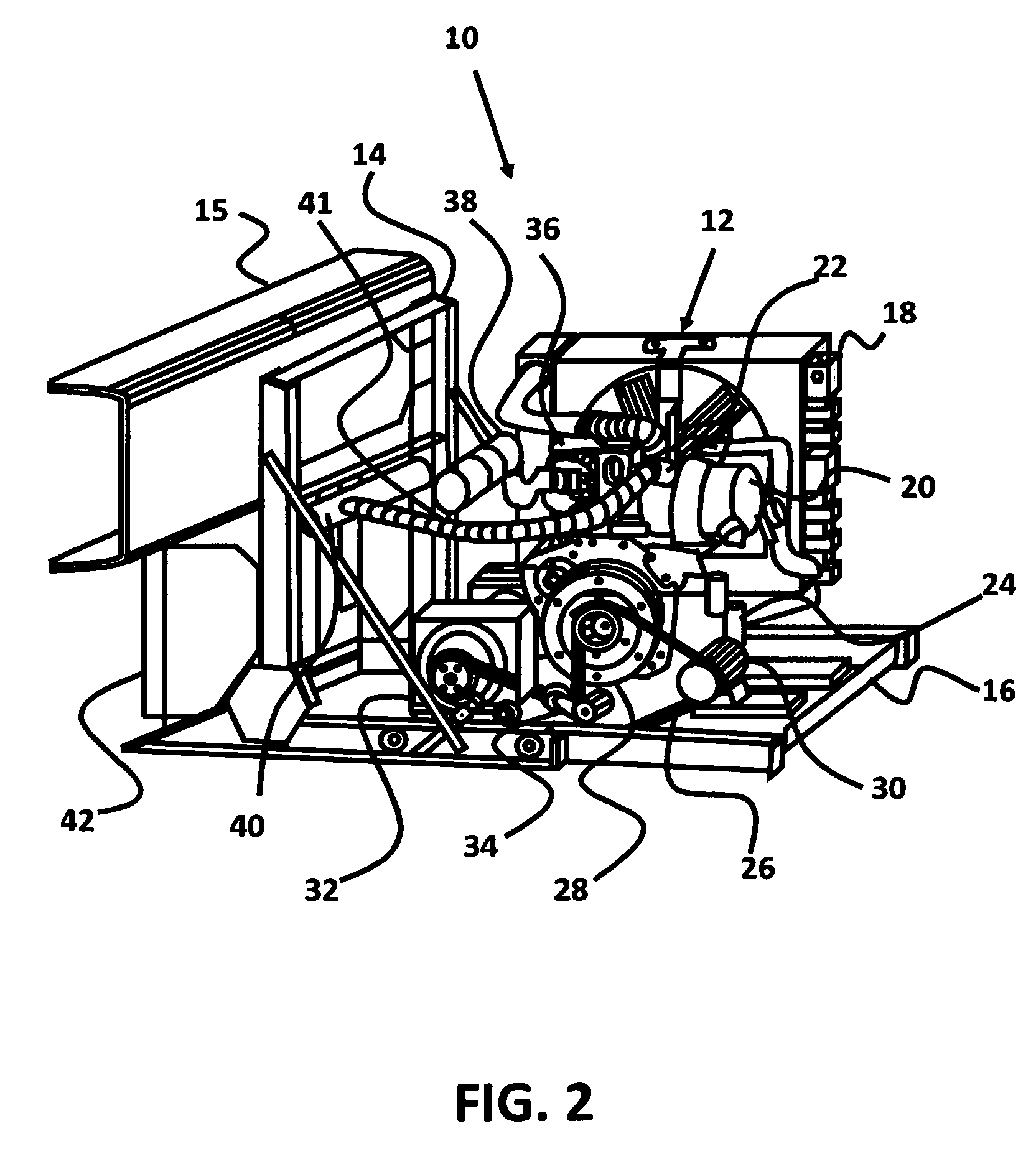

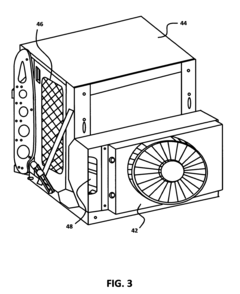

Diesel particulate filter system for auxiliary power units

PatentInactiveUS7849680B2

Innovation

- A small form factor active/passive DPF system integrated with an exhaust backpressure sensor, heating element, Diesel Oxidation Catalyst, and electronic control unit, which enables real-time regeneration and combines noise reduction components like air intake silencers and mufflers to minimize vibrations and noise while maintaining efficient particulate matter filtration.

Environmental Regulations Impact on DPF Design

Environmental regulations worldwide have become increasingly stringent regarding diesel engine emissions, directly influencing the design and functionality of Diesel Particulate Filters (DPFs). The European Union's Euro standards, particularly Euro 6 and the upcoming Euro 7, have progressively reduced permissible particulate matter emissions to near-zero levels, necessitating more efficient DPF systems. Similarly, the United States EPA Tier 4 Final and California Air Resources Board (CARB) regulations have established comparable stringent standards.

These regulatory frameworks have fundamentally altered DPF design priorities, with manufacturers now required to balance filtration efficiency with acoustic performance. The increased back pressure created by more efficient filtration media directly contributes to noise generation, creating a technical contradiction that engineers must resolve. Regulations now often include specific noise emission limits alongside particulate matter restrictions, compelling integrated design approaches.

The regulatory landscape has also accelerated innovation in DPF materials and structures. Traditional cordierite filters are increasingly being supplemented or replaced by silicon carbide and aluminum titanate variants that offer superior thermal properties and potentially better acoustic characteristics. The regulatory requirement for on-board diagnostics (OBD) systems to monitor DPF performance has further complicated design considerations, as these systems must accurately detect filter conditions without generating false positives from normal acoustic variations.

Geographic regulatory differences present additional challenges for global manufacturers. While European regulations emphasize both particulate reduction and noise control, North American standards have historically focused more heavily on emissions reduction. Asian markets, particularly China with its China VI standards, are rapidly adopting stringent requirements combining both approaches. This regulatory divergence necessitates either market-specific DPF designs or more complex universal systems capable of meeting all global requirements.

The regulatory timeline for implementation has also shaped DPF noise suppression development. Phased implementation of standards has created technology development windows, with manufacturers typically focusing first on meeting particulate matter limits before optimizing acoustic performance. This sequential approach has sometimes resulted in first-generation compliance systems with suboptimal noise characteristics, followed by refined designs as technology matures.

Future regulatory trends indicate continued tightening of both emissions and noise standards, with increasing focus on real-world driving emissions (RDE) testing rather than laboratory cycles. This shift will likely demand DPF systems with consistent acoustic performance across a wider range of operating conditions, further challenging engineers to develop advanced noise suppression solutions that maintain compliance under all circumstances.

These regulatory frameworks have fundamentally altered DPF design priorities, with manufacturers now required to balance filtration efficiency with acoustic performance. The increased back pressure created by more efficient filtration media directly contributes to noise generation, creating a technical contradiction that engineers must resolve. Regulations now often include specific noise emission limits alongside particulate matter restrictions, compelling integrated design approaches.

The regulatory landscape has also accelerated innovation in DPF materials and structures. Traditional cordierite filters are increasingly being supplemented or replaced by silicon carbide and aluminum titanate variants that offer superior thermal properties and potentially better acoustic characteristics. The regulatory requirement for on-board diagnostics (OBD) systems to monitor DPF performance has further complicated design considerations, as these systems must accurately detect filter conditions without generating false positives from normal acoustic variations.

Geographic regulatory differences present additional challenges for global manufacturers. While European regulations emphasize both particulate reduction and noise control, North American standards have historically focused more heavily on emissions reduction. Asian markets, particularly China with its China VI standards, are rapidly adopting stringent requirements combining both approaches. This regulatory divergence necessitates either market-specific DPF designs or more complex universal systems capable of meeting all global requirements.

The regulatory timeline for implementation has also shaped DPF noise suppression development. Phased implementation of standards has created technology development windows, with manufacturers typically focusing first on meeting particulate matter limits before optimizing acoustic performance. This sequential approach has sometimes resulted in first-generation compliance systems with suboptimal noise characteristics, followed by refined designs as technology matures.

Future regulatory trends indicate continued tightening of both emissions and noise standards, with increasing focus on real-world driving emissions (RDE) testing rather than laboratory cycles. This shift will likely demand DPF systems with consistent acoustic performance across a wider range of operating conditions, further challenging engineers to develop advanced noise suppression solutions that maintain compliance under all circumstances.

Cost-Benefit Analysis of Advanced Noise Suppression Technologies

The implementation of advanced noise suppression technologies for Diesel Particulate Filters (DPFs) requires careful evaluation of economic implications. When analyzing the cost-benefit ratio, initial investment costs for research, development, and implementation must be weighed against long-term operational benefits and market advantages.

Manufacturing costs for advanced acoustic materials and resonator systems typically range from $50-200 per unit, depending on complexity and scale of production. However, these costs tend to decrease by 15-25% within 3-5 years as manufacturing processes mature and economies of scale take effect. Integration costs add approximately 10-15% to the base component expenses, particularly when retrofitting existing DPF systems rather than incorporating noise suppression during initial design phases.

Operational benefits manifest in multiple dimensions. Extended DPF lifespan resulting from optimized backpressure management can reduce replacement frequency by 20-30%, translating to savings of $500-1,500 per vehicle over its operational lifetime. Reduced maintenance requirements further contribute to operational cost reductions of approximately 8-12% annually.

Customer satisfaction metrics indicate willingness to pay premiums of 5-8% for quieter diesel vehicles, particularly in commercial and passenger segments where noise pollution is a significant concern. This translates to potential revenue increases of $300-700 per vehicle in premium market segments.

Regulatory compliance benefits must also factor into the analysis. As noise emission standards become increasingly stringent across global markets, early adoption of advanced suppression technologies can prevent costly retrofitting requirements and potential market access restrictions. The avoided costs of regulatory penalties and market exclusion can exceed $1,000 per non-compliant vehicle in strict regulatory environments.

Return on investment calculations indicate that most advanced noise suppression technologies achieve break-even within 2-3 years for fleet operators and 3-4 years for individual vehicle owners. Net present value analysis typically shows positive returns when calculated over a 7-year operational period, with internal rates of return ranging from 12-18% depending on application context and regional factors.

Sensitivity analysis reveals that the cost-benefit ratio is most heavily influenced by production scale, regulatory environment stringency, and fuel price fluctuations. As production volumes increase beyond 10,000 units annually, unit costs typically decrease by 30-40%, significantly improving the value proposition for both manufacturers and end-users.

Manufacturing costs for advanced acoustic materials and resonator systems typically range from $50-200 per unit, depending on complexity and scale of production. However, these costs tend to decrease by 15-25% within 3-5 years as manufacturing processes mature and economies of scale take effect. Integration costs add approximately 10-15% to the base component expenses, particularly when retrofitting existing DPF systems rather than incorporating noise suppression during initial design phases.

Operational benefits manifest in multiple dimensions. Extended DPF lifespan resulting from optimized backpressure management can reduce replacement frequency by 20-30%, translating to savings of $500-1,500 per vehicle over its operational lifetime. Reduced maintenance requirements further contribute to operational cost reductions of approximately 8-12% annually.

Customer satisfaction metrics indicate willingness to pay premiums of 5-8% for quieter diesel vehicles, particularly in commercial and passenger segments where noise pollution is a significant concern. This translates to potential revenue increases of $300-700 per vehicle in premium market segments.

Regulatory compliance benefits must also factor into the analysis. As noise emission standards become increasingly stringent across global markets, early adoption of advanced suppression technologies can prevent costly retrofitting requirements and potential market access restrictions. The avoided costs of regulatory penalties and market exclusion can exceed $1,000 per non-compliant vehicle in strict regulatory environments.

Return on investment calculations indicate that most advanced noise suppression technologies achieve break-even within 2-3 years for fleet operators and 3-4 years for individual vehicle owners. Net present value analysis typically shows positive returns when calculated over a 7-year operational period, with internal rates of return ranging from 12-18% depending on application context and regional factors.

Sensitivity analysis reveals that the cost-benefit ratio is most heavily influenced by production scale, regulatory environment stringency, and fuel price fluctuations. As production volumes increase beyond 10,000 units annually, unit costs typically decrease by 30-40%, significantly improving the value proposition for both manufacturers and end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!