Diesel Particulate Filter in Cold Climates vs Performance

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emissions regulations worldwide, particularly targeting particulate matter (PM) emissions from diesel engines. The technology has evolved significantly over the past four decades, transitioning from experimental systems to standard equipment on virtually all modern diesel vehicles. This evolution has been driven by progressive tightening of emissions standards, including Euro 6, US EPA Tier 3, and China 6 regulations, which have established increasingly lower PM limits.

The fundamental principle of DPF operation involves trapping soot particles from exhaust gases in a ceramic honeycomb structure, typically made of cordierite or silicon carbide. As these filters accumulate particulate matter, they require periodic regeneration—a process where trapped soot is oxidized at high temperatures to restore filter capacity. This regeneration process represents one of the most significant technical challenges in DPF technology, particularly in cold climate conditions.

Cold climate operation presents unique challenges for DPF systems. Low ambient temperatures inhibit the natural regeneration process by preventing exhaust gases from reaching the temperatures necessary for soot oxidation (typically 550-650°C). This temperature threshold is difficult to achieve during short trips or idle operations in cold environments, leading to increased soot accumulation and potential filter clogging. The technical evolution in this domain has focused on developing more efficient regeneration strategies that can function effectively across diverse operating conditions.

Current technological trends in DPF development are moving toward integrated systems that balance emissions control with performance optimization. Advanced thermal management systems, improved catalyst formulations, and sophisticated electronic control units are being developed to address the cold climate challenges. The industry is also exploring alternative regeneration methods, including electrical heating elements and fuel-borne catalysts, which can lower the temperature threshold required for effective regeneration.

The primary technical objectives for next-generation DPF systems include: reducing regeneration frequency while maintaining filtration efficiency; minimizing the performance impact on engine operation, particularly in terms of fuel economy and power output; developing more robust systems capable of reliable operation in extreme temperature conditions; and creating intelligent predictive systems that can optimize regeneration timing based on driving patterns and environmental conditions.

As emissions regulations continue to tighten globally, DPF technology must evolve to meet these standards without compromising vehicle performance or reliability, particularly in challenging operating environments like cold climates. This balance between environmental compliance and operational performance represents the central technical challenge driving innovation in this field.

The fundamental principle of DPF operation involves trapping soot particles from exhaust gases in a ceramic honeycomb structure, typically made of cordierite or silicon carbide. As these filters accumulate particulate matter, they require periodic regeneration—a process where trapped soot is oxidized at high temperatures to restore filter capacity. This regeneration process represents one of the most significant technical challenges in DPF technology, particularly in cold climate conditions.

Cold climate operation presents unique challenges for DPF systems. Low ambient temperatures inhibit the natural regeneration process by preventing exhaust gases from reaching the temperatures necessary for soot oxidation (typically 550-650°C). This temperature threshold is difficult to achieve during short trips or idle operations in cold environments, leading to increased soot accumulation and potential filter clogging. The technical evolution in this domain has focused on developing more efficient regeneration strategies that can function effectively across diverse operating conditions.

Current technological trends in DPF development are moving toward integrated systems that balance emissions control with performance optimization. Advanced thermal management systems, improved catalyst formulations, and sophisticated electronic control units are being developed to address the cold climate challenges. The industry is also exploring alternative regeneration methods, including electrical heating elements and fuel-borne catalysts, which can lower the temperature threshold required for effective regeneration.

The primary technical objectives for next-generation DPF systems include: reducing regeneration frequency while maintaining filtration efficiency; minimizing the performance impact on engine operation, particularly in terms of fuel economy and power output; developing more robust systems capable of reliable operation in extreme temperature conditions; and creating intelligent predictive systems that can optimize regeneration timing based on driving patterns and environmental conditions.

As emissions regulations continue to tighten globally, DPF technology must evolve to meet these standards without compromising vehicle performance or reliability, particularly in challenging operating environments like cold climates. This balance between environmental compliance and operational performance represents the central technical challenge driving innovation in this field.

Market Analysis for Cold Climate DPF Solutions

The global market for Diesel Particulate Filter (DPF) solutions specifically designed for cold climates is experiencing significant growth, driven by increasingly stringent emission regulations and the continued reliance on diesel engines in regions with harsh winter conditions. North America, Northern Europe, and parts of Asia with extreme cold weather represent the primary markets for these specialized filtration systems, collectively accounting for approximately 60% of the global cold climate DPF market.

The market size for cold climate DPF solutions reached $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2028. This growth trajectory is primarily fueled by the implementation of Euro 7 standards in Europe and similar regulatory frameworks in other regions that mandate lower particulate matter emissions even under challenging operating conditions.

Commercial vehicles operating in cold regions constitute the largest customer segment, representing nearly 45% of market demand. Fleet operators in these regions face significant operational challenges, including increased maintenance costs and vehicle downtime due to DPF-related issues in sub-zero temperatures. Market research indicates that fleet managers are willing to pay a premium of 15-20% for DPF solutions that demonstrate reliable performance in temperatures below -20°C.

The aftermarket segment for cold-optimized DPF replacements and retrofits is growing particularly fast at 7.3% annually, outpacing the OEM installation market. This trend reflects the urgent need for existing vehicle fleets to adapt to both regulatory requirements and operational challenges in cold environments.

From a geographical perspective, Canada, Scandinavia, and Russia represent the most mature markets for cold climate DPF solutions, with market penetration rates exceeding 70% among new diesel vehicle sales. Emerging markets include mountainous regions in Central Asia and high-altitude areas in South America, where extreme temperature variations create similar challenges for diesel emission systems.

Customer pain points consistently identified in market surveys include frequent regeneration failures in sub-zero temperatures, increased fuel consumption due to incomplete combustion, and shortened filter lifespan when operating in cold conditions. These challenges translate to tangible economic impacts, with fleet operators in cold regions reporting 30% higher DPF-related maintenance costs compared to temperate climate operations.

The market shows strong demand for integrated solutions that combine advanced thermal management, predictive maintenance capabilities, and materials engineered specifically for thermal cycling resilience. Premium pricing is sustainable for products that can demonstrate measurable improvements in cold-start emissions compliance and reduced regeneration frequency in low-temperature environments.

The market size for cold climate DPF solutions reached $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2028. This growth trajectory is primarily fueled by the implementation of Euro 7 standards in Europe and similar regulatory frameworks in other regions that mandate lower particulate matter emissions even under challenging operating conditions.

Commercial vehicles operating in cold regions constitute the largest customer segment, representing nearly 45% of market demand. Fleet operators in these regions face significant operational challenges, including increased maintenance costs and vehicle downtime due to DPF-related issues in sub-zero temperatures. Market research indicates that fleet managers are willing to pay a premium of 15-20% for DPF solutions that demonstrate reliable performance in temperatures below -20°C.

The aftermarket segment for cold-optimized DPF replacements and retrofits is growing particularly fast at 7.3% annually, outpacing the OEM installation market. This trend reflects the urgent need for existing vehicle fleets to adapt to both regulatory requirements and operational challenges in cold environments.

From a geographical perspective, Canada, Scandinavia, and Russia represent the most mature markets for cold climate DPF solutions, with market penetration rates exceeding 70% among new diesel vehicle sales. Emerging markets include mountainous regions in Central Asia and high-altitude areas in South America, where extreme temperature variations create similar challenges for diesel emission systems.

Customer pain points consistently identified in market surveys include frequent regeneration failures in sub-zero temperatures, increased fuel consumption due to incomplete combustion, and shortened filter lifespan when operating in cold conditions. These challenges translate to tangible economic impacts, with fleet operators in cold regions reporting 30% higher DPF-related maintenance costs compared to temperate climate operations.

The market shows strong demand for integrated solutions that combine advanced thermal management, predictive maintenance capabilities, and materials engineered specifically for thermal cycling resilience. Premium pricing is sustainable for products that can demonstrate measurable improvements in cold-start emissions compliance and reduced regeneration frequency in low-temperature environments.

Current Challenges of DPF in Low Temperatures

Diesel Particulate Filters (DPFs) face significant operational challenges in cold climate conditions that substantially impact their performance and efficiency. When ambient temperatures drop below optimal operating ranges, typically under 200°C, DPF systems struggle to achieve the necessary temperatures for effective regeneration processes. This temperature threshold is critical as it enables the oxidation of accumulated particulate matter within the filter.

In low-temperature environments, diesel engines require longer warm-up periods, resulting in extended periods of incomplete combustion. This produces higher volumes of particulate matter and unburned hydrocarbons that rapidly accumulate within the DPF structure. The accelerated accumulation creates excessive backpressure in the exhaust system, leading to increased fuel consumption and reduced engine power output.

The regeneration process—essential for DPF functionality—becomes particularly problematic in cold conditions. Passive regeneration, which relies on normal exhaust temperatures to oxidize trapped particles, becomes virtually ineffective as exhaust gases rarely reach the required temperature threshold. Active regeneration systems must compensate by injecting additional fuel to artificially raise exhaust temperatures, resulting in significant fuel economy penalties that can reach 5-10% in severe cold conditions.

Cold-start emissions present another major challenge, as DPF systems operate with minimal efficiency during the initial engine warm-up phase. Studies indicate that up to 80% of particulate emissions in cold climates occur during the first few minutes of operation before the system reaches operational temperature. This creates a critical gap in emissions control precisely when pollution levels are highest.

Material durability issues also emerge in cold climate operations. Thermal cycling—the repeated heating and cooling of the filter substrate—creates mechanical stress that can lead to microcracking and eventual filter failure. The ceramic materials commonly used in DPF construction exhibit reduced thermal shock resistance at extremely low temperatures, accelerating structural degradation.

Condensation within the filter presents additional complications, as water vapor in exhaust gases can freeze within the filter channels during shutdown periods. Upon restart, this ice can block exhaust flow paths and potentially damage the filter substrate when rapidly heated. Some advanced systems incorporate heating elements to prevent freezing, but these add complexity, cost, and electrical load to the vehicle.

Fleet operators in cold regions report DPF-related issues as a primary maintenance concern, with replacement frequencies up to three times higher than in moderate climates. This represents a significant operational cost burden and reliability challenge for commercial transportation in northern regions, where DPF failures can lead to vehicle downtime during critical winter operations.

In low-temperature environments, diesel engines require longer warm-up periods, resulting in extended periods of incomplete combustion. This produces higher volumes of particulate matter and unburned hydrocarbons that rapidly accumulate within the DPF structure. The accelerated accumulation creates excessive backpressure in the exhaust system, leading to increased fuel consumption and reduced engine power output.

The regeneration process—essential for DPF functionality—becomes particularly problematic in cold conditions. Passive regeneration, which relies on normal exhaust temperatures to oxidize trapped particles, becomes virtually ineffective as exhaust gases rarely reach the required temperature threshold. Active regeneration systems must compensate by injecting additional fuel to artificially raise exhaust temperatures, resulting in significant fuel economy penalties that can reach 5-10% in severe cold conditions.

Cold-start emissions present another major challenge, as DPF systems operate with minimal efficiency during the initial engine warm-up phase. Studies indicate that up to 80% of particulate emissions in cold climates occur during the first few minutes of operation before the system reaches operational temperature. This creates a critical gap in emissions control precisely when pollution levels are highest.

Material durability issues also emerge in cold climate operations. Thermal cycling—the repeated heating and cooling of the filter substrate—creates mechanical stress that can lead to microcracking and eventual filter failure. The ceramic materials commonly used in DPF construction exhibit reduced thermal shock resistance at extremely low temperatures, accelerating structural degradation.

Condensation within the filter presents additional complications, as water vapor in exhaust gases can freeze within the filter channels during shutdown periods. Upon restart, this ice can block exhaust flow paths and potentially damage the filter substrate when rapidly heated. Some advanced systems incorporate heating elements to prevent freezing, but these add complexity, cost, and electrical load to the vehicle.

Fleet operators in cold regions report DPF-related issues as a primary maintenance concern, with replacement frequencies up to three times higher than in moderate climates. This represents a significant operational cost burden and reliability challenge for commercial transportation in northern regions, where DPF failures can lead to vehicle downtime during critical winter operations.

Existing Cold-Start DPF Solutions

01 DPF Regeneration Strategies

Various regeneration strategies are employed to maintain diesel particulate filter performance by removing accumulated soot. These include active regeneration using fuel injection or heating elements, passive regeneration utilizing catalytic coatings, and combined approaches. Advanced control systems monitor soot load and trigger regeneration at optimal times to ensure efficient operation while minimizing fuel consumption and preventing filter damage from excessive temperatures.- DPF Regeneration Techniques: Various methods for regenerating diesel particulate filters to maintain optimal performance. These include active regeneration using fuel injection or heating elements, passive regeneration through catalytic coatings, and combined approaches. Effective regeneration prevents filter clogging, reduces backpressure, and extends filter lifespan while ensuring continuous particulate matter capture efficiency.

- Filter Material and Structure Optimization: Advanced materials and structural designs for diesel particulate filters that enhance filtration efficiency and durability. This includes ceramic substrates with optimized porosity, wall-flow designs, metal fiber filters, and composite materials. The structure of the filter channels, cell density, and wall thickness are engineered to balance filtration efficiency with acceptable backpressure levels.

- Sensor Integration and Monitoring Systems: Integration of sensors and monitoring systems to evaluate DPF performance in real-time. These systems measure parameters such as differential pressure, temperature, particulate matter load, and exhaust gas composition. The data collected enables predictive maintenance, optimized regeneration timing, and ensures compliance with emission standards through continuous monitoring of filter efficiency.

- Catalytic Coatings and Additives: Application of catalytic coatings and fuel additives to enhance DPF performance. These include precious metal catalysts, base metal oxides, and rare earth compounds that lower the soot combustion temperature and promote passive regeneration. Fuel-borne catalysts and additives can also be used to improve regeneration efficiency and reduce the frequency of active regeneration events.

- System Integration and Control Strategies: Comprehensive control strategies and system integration approaches for optimizing DPF performance within the overall exhaust aftertreatment system. This includes coordination with other components such as selective catalytic reduction (SCR) systems, exhaust gas recirculation (EGR), and engine management systems. Advanced algorithms adjust operating parameters based on driving conditions, filter load, and emission requirements to maximize efficiency and durability.

02 Filter Material and Structure Optimization

The performance of diesel particulate filters is significantly influenced by their material composition and structural design. Advanced ceramic materials, metal substrates, and composite structures are used to enhance filtration efficiency while minimizing backpressure. Innovations include wall-flow filters with optimized porosity, channel designs that increase surface area, and multi-layer structures that improve particulate capture while maintaining durability under high-temperature conditions.Expand Specific Solutions03 Catalytic Coating Technologies

Catalytic coatings applied to diesel particulate filters enhance performance by lowering soot oxidation temperatures and promoting passive regeneration. These coatings typically contain precious metals like platinum and palladium, or base metal oxides that facilitate the conversion of particulate matter at lower temperatures. Advanced formulations may include washcoat technologies that improve catalyst dispersion and stability, resulting in more efficient filtration and extended filter life.Expand Specific Solutions04 Sensor Integration and Monitoring Systems

Modern DPF systems incorporate sophisticated sensors and monitoring technologies to optimize performance. Pressure differential sensors track filter loading, while temperature sensors monitor regeneration conditions. Advanced systems may include particulate matter sensors that directly measure emissions. These monitoring systems enable real-time diagnostics, predictive maintenance, and adaptive control strategies that balance filtration efficiency with fuel economy and system durability.Expand Specific Solutions05 System Integration and Exhaust Aftertreatment

DPF performance is optimized through integration with other exhaust aftertreatment components. Combined systems may include selective catalytic reduction (SCR), diesel oxidation catalysts (DOC), and exhaust gas recirculation (EGR). These integrated approaches enable comprehensive emission control while managing system backpressure and thermal management. Advanced control strategies coordinate the operation of multiple components to meet stringent emission standards while maintaining engine performance and fuel efficiency.Expand Specific Solutions

Key Manufacturers and Industry Competition

The Diesel Particulate Filter (DPF) market in cold climates is currently in a growth phase, with increasing regulatory pressure driving adoption despite performance challenges. The market is expected to reach approximately $15-20 billion by 2025, with a CAGR of 8-10%. Major automotive manufacturers like GM, Ford, Toyota, and Hyundai are leading innovation, while specialized component suppliers such as Bosch, Cummins, and Corning provide critical filtration technologies. Technical maturity varies significantly across solutions, with companies like Delphi Technology and Vitesco Technologies focusing on electronic control systems to optimize DPF performance in cold conditions, while others like Evonik and Lubrizol develop advanced materials and additives to reduce regeneration temperatures. The industry is moving toward integrated systems that balance emissions compliance with performance requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated DPF system specifically engineered to address the challenges of cold climate operation while maintaining optimal performance. Their approach centers on a "Thermal Gradient Optimization" strategy that strategically manages heat distribution throughout the exhaust system. Toyota's DPF utilizes a proprietary cordierite substrate with asymmetric channel design that creates turbulent exhaust flow patterns, enhancing particulate capture efficiency while minimizing backpressure increases that can hamper cold-weather performance. The system incorporates a multi-stage regeneration protocol that adapts to ambient temperature conditions, utilizing a combination of fuel post-injection and intake throttling to achieve optimal regeneration temperatures even in sub-zero environments. Toyota's latest innovation includes a predictive regeneration management system that uses GPS and weather data to anticipate driving conditions and proactively adjust regeneration parameters, reducing the risk of incomplete regeneration cycles in cold climates by approximately 35% compared to conventional systems.

Strengths: Exceptional balance between filtration efficiency and flow resistance; highly adaptive control system that responds effectively to varying climate conditions; excellent integration with Toyota's overall powertrain management. Weaknesses: System optimization is somewhat vehicle-specific, limiting universal application; requires more frequent regeneration cycles in extremely cold conditions; higher initial manufacturing complexity.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Diesel Particulate Filter (DPF) systems specifically designed for cold climate operation. Their technology employs a multi-stage regeneration strategy that includes both passive and active regeneration methods. In cold conditions, Bosch's system utilizes intelligent thermal management with pre-turbo DPF placement to maximize exhaust gas temperature and promote more efficient passive regeneration. The system incorporates predictive algorithms that analyze driving patterns, ambient temperature, and soot load to optimize regeneration timing. Bosch's latest DPF technology features electrically heated catalysts that can rapidly reach operating temperatures even in sub-zero conditions, reducing the cold-start emissions by up to 40% compared to conventional systems. Their DPF substrates are coated with advanced catalytic materials that lower the regeneration temperature threshold, making the system more effective in cold environments while maintaining performance standards.

Strengths: Superior thermal management system allows for efficient operation even in extremely cold conditions; integrated sensors provide real-time monitoring and adaptive control; proven reliability in diverse climate conditions. Weaknesses: Higher system complexity increases manufacturing costs; requires more sophisticated engine control units; slightly increased fuel consumption during active regeneration cycles in cold weather.

Critical Patents in Cold Climate DPF Technology

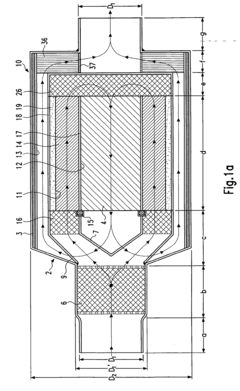

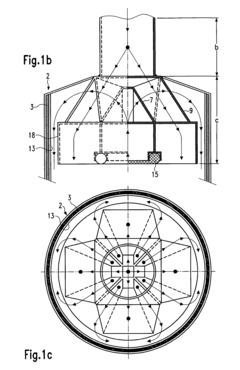

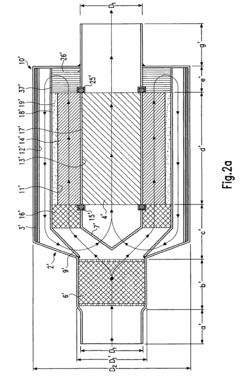

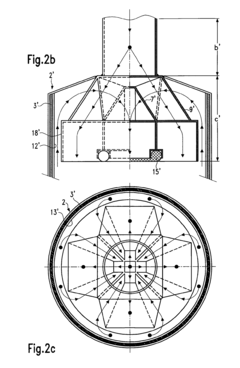

Particulate filter arrangement

PatentActiveEP1801372A1

Innovation

- A compact particle filter arrangement with a 'folded' exhaust gas flow path featuring multiple sections that maximize residence time and temperature, including catalytic converters to enhance heat dissipation and filtration efficiency, ensuring the filter reaches high temperatures quickly to prevent clogging.

Environmental Regulations Impact on DPF Development

Environmental regulations have been the primary driving force behind the development and widespread adoption of Diesel Particulate Filters (DPFs) globally. Since the early 2000s, increasingly stringent emission standards such as Euro 6 in Europe, Tier 3 in the United States, and China 6 have mandated substantial reductions in particulate matter (PM) emissions from diesel engines, effectively necessitating DPF technology.

These regulations have evolved significantly over time, with each iteration demanding more efficient filtration capabilities. The European Union's progression from Euro 1 to Euro 6d has seen particulate matter emission limits decrease by over 97% since 1992. Similarly, the EPA's standards have tightened considerably, with the 2007 Heavy-Duty Highway Rule reducing PM emissions by 90% compared to previous requirements.

Cold climate regions present unique regulatory challenges for DPF systems. Scandinavian countries, Canada, and northern regions of the United States have implemented specialized provisions within their emission frameworks to address the performance issues that arise in sub-zero temperatures. These provisions often include extended regeneration cycles and modified performance parameters specifically designed for cold weather operation.

The regulatory landscape has also begun addressing the trade-off between emissions control and fuel efficiency. Recent amendments to global standards acknowledge the potential fuel economy penalties associated with DPF operation in cold climates, with some regulations now incorporating temperature-dependent compliance pathways that provide limited flexibility during extreme cold conditions.

Looking forward, upcoming regulatory frameworks are increasingly focusing on real-world emissions performance rather than laboratory testing alone. The introduction of Real Driving Emissions (RDE) testing in Europe and similar initiatives globally are forcing manufacturers to ensure DPF systems perform effectively across all operating conditions, including cold climates, rather than being optimized solely for standardized test cycles.

The economic impact of these regulations has been substantial, with manufacturers investing billions in research and development to meet compliance requirements while maintaining acceptable vehicle performance. The regulatory pressure has accelerated innovation in thermal management systems, advanced filter materials, and intelligent regeneration strategies specifically designed to address cold climate challenges.

Interestingly, regional variations in regulatory approaches have led to different technological solutions. While European regulations have emphasized NOx reduction alongside particulate control, North American standards have historically focused more heavily on particulate emissions, resulting in different DPF system optimizations across markets.

These regulations have evolved significantly over time, with each iteration demanding more efficient filtration capabilities. The European Union's progression from Euro 1 to Euro 6d has seen particulate matter emission limits decrease by over 97% since 1992. Similarly, the EPA's standards have tightened considerably, with the 2007 Heavy-Duty Highway Rule reducing PM emissions by 90% compared to previous requirements.

Cold climate regions present unique regulatory challenges for DPF systems. Scandinavian countries, Canada, and northern regions of the United States have implemented specialized provisions within their emission frameworks to address the performance issues that arise in sub-zero temperatures. These provisions often include extended regeneration cycles and modified performance parameters specifically designed for cold weather operation.

The regulatory landscape has also begun addressing the trade-off between emissions control and fuel efficiency. Recent amendments to global standards acknowledge the potential fuel economy penalties associated with DPF operation in cold climates, with some regulations now incorporating temperature-dependent compliance pathways that provide limited flexibility during extreme cold conditions.

Looking forward, upcoming regulatory frameworks are increasingly focusing on real-world emissions performance rather than laboratory testing alone. The introduction of Real Driving Emissions (RDE) testing in Europe and similar initiatives globally are forcing manufacturers to ensure DPF systems perform effectively across all operating conditions, including cold climates, rather than being optimized solely for standardized test cycles.

The economic impact of these regulations has been substantial, with manufacturers investing billions in research and development to meet compliance requirements while maintaining acceptable vehicle performance. The regulatory pressure has accelerated innovation in thermal management systems, advanced filter materials, and intelligent regeneration strategies specifically designed to address cold climate challenges.

Interestingly, regional variations in regulatory approaches have led to different technological solutions. While European regulations have emphasized NOx reduction alongside particulate control, North American standards have historically focused more heavily on particulate emissions, resulting in different DPF system optimizations across markets.

Fuel Economy Trade-offs in Cold Climate DPF Operation

Operating diesel particulate filters (DPFs) in cold climates presents significant challenges for fuel economy. When ambient temperatures drop below freezing, diesel engines require longer warm-up periods, during which incomplete combustion produces more particulate matter. This increased soot load necessitates more frequent DPF regeneration cycles, directly impacting fuel consumption.

Studies indicate that vehicles operating in sub-zero temperatures can experience a 5-8% decrease in fuel economy solely due to DPF-related factors. The regeneration process, which burns accumulated soot at temperatures exceeding 600°C, consumes additional fuel specifically for this cleaning function. In cold climates, these regeneration events occur approximately 30-40% more frequently than in moderate temperature environments.

Engine control units typically inject additional fuel post-combustion to raise exhaust temperatures during active regeneration. This extra fuel does not contribute to vehicle propulsion, representing a direct efficiency loss. Quantitative analysis shows that each regeneration event can consume between 0.5-2 liters of additional diesel fuel, depending on vehicle size and DPF condition.

Cold-start conditions further exacerbate these trade-offs. When engines start in sub-zero temperatures, the exhaust system remains cold for extended periods, allowing more particulates to accumulate in the DPF before the system reaches optimal operating temperature. This "cold accumulation" requires more aggressive regeneration strategies later in the drive cycle.

Fleet data from northern regions demonstrates that winter operation can reduce overall fuel economy by 12-15% compared to summer operation, with approximately one-third of this reduction attributable to DPF-related factors. Commercial fleets operating in Arctic regions report even more dramatic impacts, with some heavy-duty applications seeing up to 20% seasonal variation in fuel efficiency.

Advanced thermal management strategies show promise in mitigating these effects. Technologies such as electric heating elements for DPF pre-warming, exhaust flow diverters, and advanced insulation materials can reduce the fuel economy penalty by 2-4%. However, these solutions add cost and complexity to the exhaust aftertreatment system.

The balance between emissions compliance and fuel economy becomes particularly challenging in cold climates. Manufacturers must carefully calibrate regeneration strategies to maintain regulatory compliance while minimizing the fuel economy impact. This calibration often represents a compromise, as optimizing for one parameter typically comes at the expense of the other.

Studies indicate that vehicles operating in sub-zero temperatures can experience a 5-8% decrease in fuel economy solely due to DPF-related factors. The regeneration process, which burns accumulated soot at temperatures exceeding 600°C, consumes additional fuel specifically for this cleaning function. In cold climates, these regeneration events occur approximately 30-40% more frequently than in moderate temperature environments.

Engine control units typically inject additional fuel post-combustion to raise exhaust temperatures during active regeneration. This extra fuel does not contribute to vehicle propulsion, representing a direct efficiency loss. Quantitative analysis shows that each regeneration event can consume between 0.5-2 liters of additional diesel fuel, depending on vehicle size and DPF condition.

Cold-start conditions further exacerbate these trade-offs. When engines start in sub-zero temperatures, the exhaust system remains cold for extended periods, allowing more particulates to accumulate in the DPF before the system reaches optimal operating temperature. This "cold accumulation" requires more aggressive regeneration strategies later in the drive cycle.

Fleet data from northern regions demonstrates that winter operation can reduce overall fuel economy by 12-15% compared to summer operation, with approximately one-third of this reduction attributable to DPF-related factors. Commercial fleets operating in Arctic regions report even more dramatic impacts, with some heavy-duty applications seeing up to 20% seasonal variation in fuel efficiency.

Advanced thermal management strategies show promise in mitigating these effects. Technologies such as electric heating elements for DPF pre-warming, exhaust flow diverters, and advanced insulation materials can reduce the fuel economy penalty by 2-4%. However, these solutions add cost and complexity to the exhaust aftertreatment system.

The balance between emissions compliance and fuel economy becomes particularly challenging in cold climates. Manufacturers must carefully calibrate regeneration strategies to maintain regulatory compliance while minimizing the fuel economy impact. This calibration often represents a compromise, as optimizing for one parameter typically comes at the expense of the other.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!