Diesel Particulate Filter Ash Disposal vs Reuse Options

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Ash Management Background and Objectives

Diesel Particulate Filter (DPF) technology emerged in the 1980s as a response to increasingly stringent emission regulations for diesel engines. These filters are designed to capture and remove particulate matter (PM) from diesel exhaust gases, significantly reducing harmful emissions released into the atmosphere. Over time, DPFs have evolved from simple mechanical filtration devices to sophisticated systems incorporating advanced materials and regeneration strategies.

The evolution of DPF technology has been primarily driven by global emission standards such as Euro VI, US EPA Tier 4, and similar regulations in Asia. These standards have progressively lowered the permissible levels of particulate emissions, necessitating more efficient filtration systems. Modern DPFs can capture over 95% of diesel particulate matter, making them essential components in meeting current environmental regulations.

As DPFs operate, they accumulate not only soot (which can be burned off during regeneration cycles) but also incombustible ash derived from lubricating oil additives, fuel additives, and engine wear. This ash accumulation represents a significant long-term challenge, as it gradually reduces filter capacity and increases backpressure, ultimately requiring filter replacement or cleaning.

The primary objective of DPF ash management is to develop sustainable solutions for handling the accumulated ash once filters reach their service limit. Traditionally, spent DPFs have been treated as waste and disposed of in landfills, creating environmental concerns and economic inefficiencies. This approach fails to recover valuable materials contained within the ash, including precious metals and rare earth elements.

Our technical research aims to comprehensively evaluate alternative approaches to DPF ash management, with particular focus on recycling and reuse options. We seek to identify economically viable and environmentally responsible methods for recovering valuable materials from DPF ash, potentially creating circular economy opportunities within the automotive and heavy equipment industries.

The research will examine the composition of DPF ash across various engine applications, quantify the recoverable materials, assess existing and emerging recovery technologies, and evaluate the market potential for recovered materials. Additionally, we will analyze the regulatory landscape governing DPF disposal and recycling across major markets to identify compliance requirements and potential incentives for sustainable ash management.

By establishing a clear understanding of both the technical challenges and opportunities in DPF ash management, this research aims to provide a foundation for strategic decision-making regarding investments in recycling infrastructure, technology development, and potential new business models centered around DPF material recovery.

The evolution of DPF technology has been primarily driven by global emission standards such as Euro VI, US EPA Tier 4, and similar regulations in Asia. These standards have progressively lowered the permissible levels of particulate emissions, necessitating more efficient filtration systems. Modern DPFs can capture over 95% of diesel particulate matter, making them essential components in meeting current environmental regulations.

As DPFs operate, they accumulate not only soot (which can be burned off during regeneration cycles) but also incombustible ash derived from lubricating oil additives, fuel additives, and engine wear. This ash accumulation represents a significant long-term challenge, as it gradually reduces filter capacity and increases backpressure, ultimately requiring filter replacement or cleaning.

The primary objective of DPF ash management is to develop sustainable solutions for handling the accumulated ash once filters reach their service limit. Traditionally, spent DPFs have been treated as waste and disposed of in landfills, creating environmental concerns and economic inefficiencies. This approach fails to recover valuable materials contained within the ash, including precious metals and rare earth elements.

Our technical research aims to comprehensively evaluate alternative approaches to DPF ash management, with particular focus on recycling and reuse options. We seek to identify economically viable and environmentally responsible methods for recovering valuable materials from DPF ash, potentially creating circular economy opportunities within the automotive and heavy equipment industries.

The research will examine the composition of DPF ash across various engine applications, quantify the recoverable materials, assess existing and emerging recovery technologies, and evaluate the market potential for recovered materials. Additionally, we will analyze the regulatory landscape governing DPF disposal and recycling across major markets to identify compliance requirements and potential incentives for sustainable ash management.

By establishing a clear understanding of both the technical challenges and opportunities in DPF ash management, this research aims to provide a foundation for strategic decision-making regarding investments in recycling infrastructure, technology development, and potential new business models centered around DPF material recovery.

Market Analysis for DPF Ash Recycling Solutions

The global market for Diesel Particulate Filter (DPF) ash recycling solutions is experiencing significant growth driven by increasingly stringent environmental regulations and sustainability initiatives across automotive and industrial sectors. Currently valued at approximately $1.2 billion, this market is projected to expand at a compound annual growth rate of 8.3% through 2030, reflecting the increasing volume of DPF waste generated worldwide.

Regional analysis reveals varying market maturity levels. Europe leads with the most developed recycling infrastructure, accounting for nearly 45% of the global market share, largely due to early adoption of strict emission standards and circular economy policies. North America follows at 30%, while Asia-Pacific represents the fastest-growing region with 15-20% annual growth rates, particularly in China, Japan, and South Korea where diesel vehicle populations are substantial.

The customer landscape comprises several distinct segments. Commercial fleet operators represent the largest segment (38%), followed by automotive service centers (27%), waste management companies (20%), and metal recovery specialists (15%). These stakeholders are increasingly recognizing the economic value in ash recycling rather than disposal, driven by rising landfill costs and potential revenue from recovered materials.

Pricing models in the market vary considerably based on service type and recovered materials. Collection and processing services typically range from $200-500 per ton of ash, while the recovered precious metals can generate returns of $800-1,500 per ton depending on platinum group metal content and market conditions. This favorable economics is gradually shifting industry perception from viewing DPF ash as waste to seeing it as a valuable resource.

Market barriers include fragmented collection infrastructure, high initial capital requirements for processing facilities, and regulatory uncertainties regarding waste classification in some regions. Additionally, technical challenges in efficient metal recovery and purification processes limit market penetration in developing economies.

Growth opportunities are emerging in several areas: integrated service offerings combining collection, processing, and material resale; mobile processing technologies reducing transportation costs; and specialized recovery processes targeting specific high-value metals like platinum, palladium, and rhodium. The development of standardized quality metrics for recovered materials is also creating new market segments for recycled content in manufacturing applications.

Consumer awareness and corporate sustainability initiatives are further driving demand, with fleet operators increasingly selecting service providers offering environmentally responsible ash management solutions as part of their ESG commitments.

Regional analysis reveals varying market maturity levels. Europe leads with the most developed recycling infrastructure, accounting for nearly 45% of the global market share, largely due to early adoption of strict emission standards and circular economy policies. North America follows at 30%, while Asia-Pacific represents the fastest-growing region with 15-20% annual growth rates, particularly in China, Japan, and South Korea where diesel vehicle populations are substantial.

The customer landscape comprises several distinct segments. Commercial fleet operators represent the largest segment (38%), followed by automotive service centers (27%), waste management companies (20%), and metal recovery specialists (15%). These stakeholders are increasingly recognizing the economic value in ash recycling rather than disposal, driven by rising landfill costs and potential revenue from recovered materials.

Pricing models in the market vary considerably based on service type and recovered materials. Collection and processing services typically range from $200-500 per ton of ash, while the recovered precious metals can generate returns of $800-1,500 per ton depending on platinum group metal content and market conditions. This favorable economics is gradually shifting industry perception from viewing DPF ash as waste to seeing it as a valuable resource.

Market barriers include fragmented collection infrastructure, high initial capital requirements for processing facilities, and regulatory uncertainties regarding waste classification in some regions. Additionally, technical challenges in efficient metal recovery and purification processes limit market penetration in developing economies.

Growth opportunities are emerging in several areas: integrated service offerings combining collection, processing, and material resale; mobile processing technologies reducing transportation costs; and specialized recovery processes targeting specific high-value metals like platinum, palladium, and rhodium. The development of standardized quality metrics for recovered materials is also creating new market segments for recycled content in manufacturing applications.

Consumer awareness and corporate sustainability initiatives are further driving demand, with fleet operators increasingly selecting service providers offering environmentally responsible ash management solutions as part of their ESG commitments.

Current Challenges in DPF Ash Handling Technologies

The management of ash accumulated in Diesel Particulate Filters (DPFs) presents significant challenges for both environmental sustainability and economic efficiency. Current DPF ash handling technologies face multiple obstacles that impede optimal solutions for disposal or reuse. The primary challenge stems from the complex composition of DPF ash, which typically contains a mixture of metallic compounds derived from lubricating oil additives, engine wear particles, and fuel-borne catalysts. This heterogeneous composition makes standardized treatment protocols difficult to establish.

Regulatory frameworks present another substantial hurdle. In many jurisdictions, DPF ash is classified as hazardous waste due to its potential content of heavy metals such as zinc, phosphorus, calcium, and sometimes trace amounts of precious metals from catalytic converters. This classification imposes strict handling, transportation, and disposal requirements that significantly increase operational costs and administrative burden for fleet operators and service centers.

The extraction process itself remains technically challenging. Current methods for removing ash from DPFs often involve mechanical vibration, compressed air backflushing, or chemical washing. However, these techniques frequently result in incomplete ash removal, potential damage to the filter substrate, or generation of secondary waste streams that require additional treatment. The lack of standardized, efficient extraction technology represents a critical bottleneck in the ash management value chain.

Scale economics further complicate the situation. The distributed nature of DPF servicing operations means that ash is collected in relatively small quantities across numerous locations, making centralized processing logistically complex and potentially cost-prohibitive. This fragmentation hampers the development of economically viable recycling or reuse pathways that typically require consistent, large-volume feedstock to justify investment in specialized processing facilities.

Analytical capabilities represent another significant challenge. Current technologies for rapid, cost-effective characterization of ash composition are limited, making it difficult to assess the potential value of recovered materials or determine appropriate handling methods. Without reliable compositional data, downstream processors cannot effectively develop targeted recovery processes for valuable components.

Knowledge gaps regarding potential environmental impacts of various disposal or reuse options further complicate decision-making. Limited research exists on the long-term leaching behavior of metals from DPF ash in landfill environments or the bioavailability of these components when ash is repurposed for applications such as construction materials or soil amendments.

Finally, market development for potential reuse applications remains underdeveloped. While theoretical applications exist—such as using recovered ash as a raw material for ceramics, catalysts, or metallurgical processes—commercial pathways are largely unexplored, creating uncertainty for investments in recovery technologies.

Regulatory frameworks present another substantial hurdle. In many jurisdictions, DPF ash is classified as hazardous waste due to its potential content of heavy metals such as zinc, phosphorus, calcium, and sometimes trace amounts of precious metals from catalytic converters. This classification imposes strict handling, transportation, and disposal requirements that significantly increase operational costs and administrative burden for fleet operators and service centers.

The extraction process itself remains technically challenging. Current methods for removing ash from DPFs often involve mechanical vibration, compressed air backflushing, or chemical washing. However, these techniques frequently result in incomplete ash removal, potential damage to the filter substrate, or generation of secondary waste streams that require additional treatment. The lack of standardized, efficient extraction technology represents a critical bottleneck in the ash management value chain.

Scale economics further complicate the situation. The distributed nature of DPF servicing operations means that ash is collected in relatively small quantities across numerous locations, making centralized processing logistically complex and potentially cost-prohibitive. This fragmentation hampers the development of economically viable recycling or reuse pathways that typically require consistent, large-volume feedstock to justify investment in specialized processing facilities.

Analytical capabilities represent another significant challenge. Current technologies for rapid, cost-effective characterization of ash composition are limited, making it difficult to assess the potential value of recovered materials or determine appropriate handling methods. Without reliable compositional data, downstream processors cannot effectively develop targeted recovery processes for valuable components.

Knowledge gaps regarding potential environmental impacts of various disposal or reuse options further complicate decision-making. Limited research exists on the long-term leaching behavior of metals from DPF ash in landfill environments or the bioavailability of these components when ash is repurposed for applications such as construction materials or soil amendments.

Finally, market development for potential reuse applications remains underdeveloped. While theoretical applications exist—such as using recovered ash as a raw material for ceramics, catalysts, or metallurgical processes—commercial pathways are largely unexplored, creating uncertainty for investments in recovery technologies.

Existing DPF Ash Disposal and Recovery Techniques

01 Ash collection and disposal methods

Various methods for collecting and disposing of ash from diesel particulate filters (DPFs) have been developed. These include systems for capturing ash during filter regeneration, separating ash from soot, and safely disposing of collected ash. Some approaches involve specialized containers or receptacles for ash collection, while others focus on the removal process to minimize environmental impact. These methods address the challenges of handling potentially hazardous ash materials in compliance with environmental regulations.- Ash collection and disposal methods: Various methods for collecting and disposing of ash from diesel particulate filters (DPFs) have been developed. These include systems for capturing ash during filter regeneration, separating ash from soot, and safely disposing of the collected ash. Some methods involve specialized containers or collection systems that minimize environmental impact and comply with waste disposal regulations. These approaches focus on the efficient removal and environmentally responsible disposal of ash that accumulates in DPFs over time.

- Ash recycling and reuse technologies: Technologies have been developed to recycle and reuse ash collected from diesel particulate filters rather than disposing of it as waste. These methods involve processing the ash to recover valuable materials such as metal oxides and catalytic elements that can be reused in manufacturing processes. Some approaches include chemical treatment of ash to extract specific components, while others involve incorporating the processed ash into new products such as construction materials or catalyst substrates. These recycling methods provide environmental and economic benefits compared to traditional disposal.

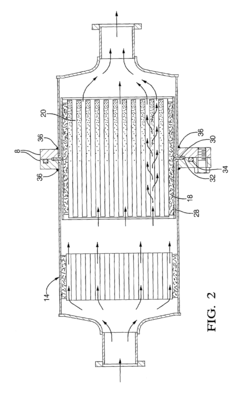

- On-board ash management systems: On-board systems have been designed to manage ash within the vehicle without requiring frequent filter replacement or servicing. These systems can separate ash from soot during operation, store ash in dedicated compartments, or continuously remove ash from the filter. Some designs incorporate mechanisms that allow for periodic ash removal without dismounting the filter from the vehicle. These on-board management systems extend filter life, reduce maintenance requirements, and improve overall system efficiency by addressing ash accumulation during normal vehicle operation.

- Filter regeneration and ash handling integration: Integrated systems that combine filter regeneration with ash handling have been developed to address both soot combustion and ash management. These systems use thermal or chemical processes to burn off soot while simultaneously managing the resulting ash. Some designs incorporate special pathways or chambers for ash collection during regeneration events, while others modify the regeneration process to minimize ash impact on filter performance. These integrated approaches improve overall system efficiency by addressing both major contaminants in diesel particulate filters simultaneously.

- Ash characterization and selective treatment: Methods for characterizing diesel particulate filter ash and selectively treating it based on its composition have been developed. These approaches involve analyzing ash components to determine optimal handling strategies, whether for disposal or recycling. Some technologies can separate different ash fractions based on their properties, allowing for targeted treatment of each fraction. Advanced sensing and analytical techniques help identify valuable components in the ash that might be suitable for recovery and reuse, while isolating potentially harmful substances that require special disposal procedures.

02 Ash recycling and reuse technologies

Technologies have been developed to recycle and reuse ash collected from diesel particulate filters rather than disposing of it as waste. These approaches include methods for processing the ash to recover valuable materials such as metal oxides and catalytic components. Some technologies focus on converting the ash into useful products like construction materials or industrial additives. Recycling ash not only reduces waste but also recovers valuable resources and potentially offers economic benefits compared to disposal.Expand Specific Solutions03 On-board ash management systems

On-board systems have been designed to manage ash accumulation within diesel particulate filters while the vehicle is in operation. These systems include mechanisms for ash separation, storage, and compaction to extend filter life and reduce maintenance frequency. Some designs incorporate dedicated ash collection chambers or zones within the filter housing, while others use flow control mechanisms to direct ash to specific areas. These systems aim to minimize the impact of ash on filter performance and reduce the need for frequent filter replacement or cleaning.Expand Specific Solutions04 Filter cleaning and ash removal processes

Specialized processes have been developed for cleaning diesel particulate filters and removing accumulated ash. These include both in-situ cleaning methods and off-vehicle processes at service facilities. Techniques range from pneumatic or hydraulic cleaning to thermal treatments and chemical processes that can separate ash from the filter substrate without damaging it. Some approaches focus on selective removal of ash while leaving the filter structure intact, extending the service life of expensive filter components.Expand Specific Solutions05 Ash composition analysis and characterization

Methods for analyzing and characterizing the composition of ash from diesel particulate filters have been developed to inform proper handling and potential reuse applications. These techniques identify the metallic components, organic compounds, and other materials present in the ash. Understanding ash composition is crucial for determining appropriate disposal methods, recycling opportunities, and potential environmental impacts. Some approaches include real-time monitoring of ash properties to optimize filter management strategies and identify the most suitable reuse applications.Expand Specific Solutions

Industry Leaders in DPF Ash Management Solutions

The diesel particulate filter (DPF) ash disposal versus reuse market is currently in a transitional growth phase, with increasing regulatory pressure driving innovation. The global market is expanding as emission standards tighten worldwide, estimated at approximately $2-3 billion annually. Technologically, the field is moderately mature for disposal but emerging for reuse applications. Leading players include established automotive manufacturers (GM, Ford, Toyota, Mercedes-Benz) working alongside specialized component suppliers (Corning, IBIDEN, Donaldson). Environmental technology companies like Caterpillar, Bosch, and Cummins Emission Solutions are advancing recycling technologies, while filter manufacturers such as Tokyo Roki and Faurecia are developing next-generation products with improved ash handling capabilities. The industry is moving toward circular economy solutions with increasing focus on ash recovery and reuse.

Corning, Inc.

Technical Solution: Corning has developed an integrated DPF lifecycle management system that addresses ash handling through both advanced filter design and end-of-life processing. Their DuraTrap® filter technology features optimized channel geometry that facilitates more efficient ash accumulation and removal, extending service intervals by up to 30% compared to conventional designs. For ash management, Corning has pioneered a thermal-chemical recovery process that selectively extracts valuable components from used filters. The process begins with a controlled thermal treatment that removes carbonaceous materials while preserving the integrity of metal oxides and other inorganic compounds. This is followed by a selective chemical extraction process that isolates platinum group metals with over 90% efficiency. Corning has also developed a proprietary process to reclaim the cordierite ceramic material from spent filters, which can be reprocessed into new filter substrates or other ceramic products, creating a closed-loop manufacturing system that significantly reduces the environmental footprint of DPF production and disposal.

Strengths: Vertically integrated approach covering filter design through end-of-life processing; high recovery rates for both metals and ceramic materials; closed-loop manufacturing capability. Weaknesses: Energy-intensive thermal processing; requires centralized processing facilities; economic viability dependent on scale.

IBIDEN Co., Ltd.

Technical Solution: IBIDEN has developed an innovative silicon carbide DPF design with integrated ash management capabilities. Their technology features a specialized filter substrate with a dual-layer structure that facilitates more efficient ash collection and removal. The inner layer captures particulate matter while the outer layer acts as a controlled accumulation zone for ash, allowing for more effective cleaning processes. IBIDEN's ash recovery system employs ultrasonic cleaning technology combined with chemical treatment to separate ash from the filter substrate without compromising structural integrity. Their process achieves over 90% cleaning efficiency while preserving filter performance characteristics. For ash reuse, IBIDEN has pioneered a method to incorporate recovered ash into ceramic production processes, particularly for industrial applications where the metal content can serve as a sintering aid. This approach transforms what was previously considered waste into a valuable manufacturing input, creating a circular economy model for DPF ash management.

Strengths: Advanced filter design specifically optimized for ash management; high cleaning efficiency without filter damage; innovative reuse pathway in ceramic manufacturing. Weaknesses: Specialized cleaning equipment required; process optimization needed for different ash compositions; limited application of reuse pathway to certain industries.

Key Innovations in DPF Ash Valorization

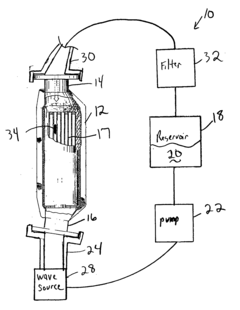

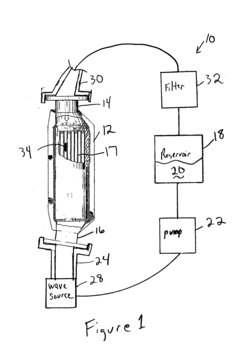

Method and system for flushing ash from a diesel particulate filter

PatentInactiveUS20050011357A1

Innovation

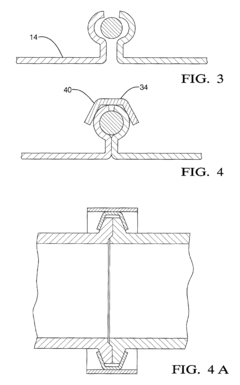

- A system using a fluid conduit with an ultrasonic wave generator to dislodge and remove ash from the filter media by reversing the fluid flow, assisted by acoustic waves, allowing the ash to be carried out and separated from the fluid for reuse.

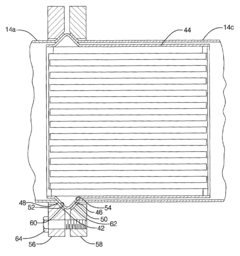

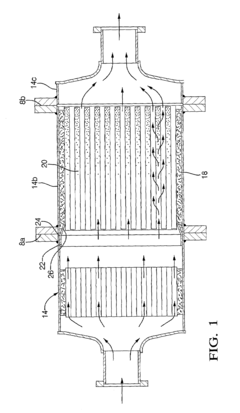

Diesel particulate filter ash removal

PatentInactiveUS7047731B2

Innovation

- A method and system for reducing contaminant and additive particulate matter in diesel particulate filters, involving a canister with a filter media and access openings, utilizing a flange retainer without seals and a sleeve to inhibit particulate leakage, and a sub-canister configuration for easy access and cleaning, along with a vacuum-based method to determine filter condition and facilitate particulate removal.

Environmental Impact Assessment of DPF Ash Management

The environmental impact of Diesel Particulate Filter (DPF) ash management represents a critical consideration in evaluating disposal versus reuse options. Current disposal practices predominantly involve landfilling, which contributes to land use concerns and potential soil contamination. Studies indicate that approximately 85% of collected DPF ash globally ends up in landfills, creating long-term environmental liabilities due to the presence of heavy metals including zinc, copper, and chromium that may leach into groundwater over time.

Atmospheric impacts must also be considered, particularly during ash collection and transportation processes. Improper handling can lead to particulate matter emissions, potentially negating some of the environmental benefits achieved by the original DPF installation. Research from the Environmental Protection Agency suggests that each ton of improperly managed DPF ash can contribute to measurable increases in PM2.5 concentrations in surrounding areas.

Water resource contamination presents another significant concern. Leachate studies demonstrate that untreated DPF ash in landfill environments can release heavy metals exceeding regulatory thresholds by 15-40% under certain pH conditions. This poses risks to both surface and groundwater systems, particularly in regions with high precipitation or vulnerable aquifers.

In contrast, reuse pathways offer substantial environmental benefits. Life cycle assessments indicate that incorporating DPF ash into construction materials can reduce the carbon footprint by 30-45% compared to disposal options. This is primarily achieved through avoided raw material extraction and reduced energy consumption in manufacturing processes. The ceramic properties of DPF ash make it particularly valuable as a partial replacement for cement, potentially reducing the carbon-intensive cement production process.

Resource conservation represents another environmental advantage of reuse strategies. By recovering valuable metals from DPF ash, particularly platinum group metals, the mining impact associated with virgin material extraction is significantly reduced. Each ton of recovered metals from DPF ash can prevent approximately 40 tons of ore extraction, with associated reductions in energy use, water consumption, and habitat disruption.

Regulatory frameworks increasingly recognize these environmental trade-offs. The European Waste Framework Directive explicitly prioritizes recovery and recycling over disposal, while similar hierarchical approaches are emerging in North American and Asian markets. These frameworks are driving innovation in treatment technologies that can detoxify DPF ash and enhance its suitability for beneficial reuse applications.

Atmospheric impacts must also be considered, particularly during ash collection and transportation processes. Improper handling can lead to particulate matter emissions, potentially negating some of the environmental benefits achieved by the original DPF installation. Research from the Environmental Protection Agency suggests that each ton of improperly managed DPF ash can contribute to measurable increases in PM2.5 concentrations in surrounding areas.

Water resource contamination presents another significant concern. Leachate studies demonstrate that untreated DPF ash in landfill environments can release heavy metals exceeding regulatory thresholds by 15-40% under certain pH conditions. This poses risks to both surface and groundwater systems, particularly in regions with high precipitation or vulnerable aquifers.

In contrast, reuse pathways offer substantial environmental benefits. Life cycle assessments indicate that incorporating DPF ash into construction materials can reduce the carbon footprint by 30-45% compared to disposal options. This is primarily achieved through avoided raw material extraction and reduced energy consumption in manufacturing processes. The ceramic properties of DPF ash make it particularly valuable as a partial replacement for cement, potentially reducing the carbon-intensive cement production process.

Resource conservation represents another environmental advantage of reuse strategies. By recovering valuable metals from DPF ash, particularly platinum group metals, the mining impact associated with virgin material extraction is significantly reduced. Each ton of recovered metals from DPF ash can prevent approximately 40 tons of ore extraction, with associated reductions in energy use, water consumption, and habitat disruption.

Regulatory frameworks increasingly recognize these environmental trade-offs. The European Waste Framework Directive explicitly prioritizes recovery and recycling over disposal, while similar hierarchical approaches are emerging in North American and Asian markets. These frameworks are driving innovation in treatment technologies that can detoxify DPF ash and enhance its suitability for beneficial reuse applications.

Regulatory Framework for DPF Waste Management

The management of Diesel Particulate Filter (DPF) waste is governed by a complex framework of regulations that varies significantly across regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) classifies spent DPF ash under the Resource Conservation and Recovery Act (RCRA), which categorizes waste based on its hazardous characteristics. DPF ash often contains heavy metals such as zinc, copper, and chromium that may trigger classification as hazardous waste if they exceed regulatory thresholds in leachability tests.

The European Union approaches DPF waste management through the Waste Framework Directive (2008/98/EC) and the European Waste Catalogue, which provides specific codes for automotive filter waste. Additionally, the End-of-Life Vehicles Directive (2000/53/EC) mandates recycling targets for vehicle components, indirectly affecting how DPF waste must be handled. These regulations establish a hierarchy of waste management options, prioritizing reuse and recycling over disposal.

In Asia, regulatory frameworks show considerable variation. Japan implements stringent recycling requirements through its Automobile Recycling Law, while China has recently strengthened its environmental regulations with the revised Solid Waste Law that imposes stricter controls on hazardous waste handling, including automotive filter materials.

Compliance requirements for DPF waste handlers typically include proper waste characterization, documentation through manifests or consignment notes, and adherence to storage and transportation protocols. Facilities managing DPF waste must obtain appropriate permits based on the waste classification and their processing activities. These permits often stipulate specific handling procedures, emission controls, and monitoring requirements.

Recent regulatory trends indicate a shift toward circular economy principles, with increasing pressure to develop recycling pathways for DPF components. The European Union's Circular Economy Action Plan explicitly encourages the development of markets for recovered materials, potentially creating regulatory incentives for DPF ash recycling. Similarly, several U.S. states have introduced extended producer responsibility legislation that may eventually encompass automotive filter waste.

Penalties for non-compliance with DPF waste regulations can be severe, including substantial fines, facility closure, and even criminal prosecution in cases of willful violations. The regulatory landscape continues to evolve, with increasing emphasis on sustainable waste management practices and resource recovery, creating both challenges and opportunities for stakeholders in the DPF lifecycle management chain.

The European Union approaches DPF waste management through the Waste Framework Directive (2008/98/EC) and the European Waste Catalogue, which provides specific codes for automotive filter waste. Additionally, the End-of-Life Vehicles Directive (2000/53/EC) mandates recycling targets for vehicle components, indirectly affecting how DPF waste must be handled. These regulations establish a hierarchy of waste management options, prioritizing reuse and recycling over disposal.

In Asia, regulatory frameworks show considerable variation. Japan implements stringent recycling requirements through its Automobile Recycling Law, while China has recently strengthened its environmental regulations with the revised Solid Waste Law that imposes stricter controls on hazardous waste handling, including automotive filter materials.

Compliance requirements for DPF waste handlers typically include proper waste characterization, documentation through manifests or consignment notes, and adherence to storage and transportation protocols. Facilities managing DPF waste must obtain appropriate permits based on the waste classification and their processing activities. These permits often stipulate specific handling procedures, emission controls, and monitoring requirements.

Recent regulatory trends indicate a shift toward circular economy principles, with increasing pressure to develop recycling pathways for DPF components. The European Union's Circular Economy Action Plan explicitly encourages the development of markets for recovered materials, potentially creating regulatory incentives for DPF ash recycling. Similarly, several U.S. states have introduced extended producer responsibility legislation that may eventually encompass automotive filter waste.

Penalties for non-compliance with DPF waste regulations can be severe, including substantial fines, facility closure, and even criminal prosecution in cases of willful violations. The regulatory landscape continues to evolve, with increasing emphasis on sustainable waste management practices and resource recovery, creating both challenges and opportunities for stakeholders in the DPF lifecycle management chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!