Diesel Particulate Filter Efficiency under Varying Conditions

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emission regulations worldwide, particularly targeting particulate matter (PM) emissions from diesel engines. The technology has evolved significantly over the past four decades, transitioning from experimental prototypes to sophisticated systems that are now standard equipment on modern diesel vehicles. This evolution has been driven by the dual imperatives of environmental protection and public health concerns, as diesel particulate matter has been classified as a carcinogen by multiple health organizations.

The fundamental operating principle of DPFs involves trapping particulate matter from exhaust gases as they pass through a porous ceramic or metallic substrate. As these filters accumulate soot over time, they require periodic regeneration processes to maintain efficiency. Early DPF systems relied primarily on passive regeneration, utilizing exhaust heat and catalytic reactions, while modern systems incorporate active regeneration strategies involving fuel injection and precise thermal management.

Current technological trends in DPF development focus on enhancing filtration efficiency while minimizing backpressure penalties, extending service intervals, and improving durability under various operating conditions. The integration of advanced sensors and control algorithms has enabled more sophisticated regeneration strategies, adapting to real-world driving conditions and reducing fuel consumption penalties associated with regeneration events.

The primary technical objectives for DPF technology advancement include achieving filtration efficiencies exceeding 99% across all particle size ranges, particularly for ultrafine particles below 100 nanometers which pose significant health risks. Additionally, researchers aim to develop systems capable of maintaining optimal performance across diverse operating conditions, including low-temperature urban driving, high-load highway operation, and varying fuel qualities encountered globally.

Another critical objective involves improving the understanding of DPF behavior under transient conditions, as laboratory testing often fails to capture the complex interactions occurring during real-world driving cycles. This includes investigating the effects of rapid temperature fluctuations, varying exhaust flow rates, and changing soot composition on filter performance and durability.

Looking forward, DPF technology must evolve to address emerging challenges such as compatibility with alternative fuels, integration with hybrid powertrains, and adaptation to increasingly stringent regulatory frameworks worldwide. The technology roadmap also includes developing cost-effective solutions for retrofitting older vehicles and creating systems suitable for diverse applications beyond on-road transportation, including marine engines, stationary power generation, and off-road equipment.

The fundamental operating principle of DPFs involves trapping particulate matter from exhaust gases as they pass through a porous ceramic or metallic substrate. As these filters accumulate soot over time, they require periodic regeneration processes to maintain efficiency. Early DPF systems relied primarily on passive regeneration, utilizing exhaust heat and catalytic reactions, while modern systems incorporate active regeneration strategies involving fuel injection and precise thermal management.

Current technological trends in DPF development focus on enhancing filtration efficiency while minimizing backpressure penalties, extending service intervals, and improving durability under various operating conditions. The integration of advanced sensors and control algorithms has enabled more sophisticated regeneration strategies, adapting to real-world driving conditions and reducing fuel consumption penalties associated with regeneration events.

The primary technical objectives for DPF technology advancement include achieving filtration efficiencies exceeding 99% across all particle size ranges, particularly for ultrafine particles below 100 nanometers which pose significant health risks. Additionally, researchers aim to develop systems capable of maintaining optimal performance across diverse operating conditions, including low-temperature urban driving, high-load highway operation, and varying fuel qualities encountered globally.

Another critical objective involves improving the understanding of DPF behavior under transient conditions, as laboratory testing often fails to capture the complex interactions occurring during real-world driving cycles. This includes investigating the effects of rapid temperature fluctuations, varying exhaust flow rates, and changing soot composition on filter performance and durability.

Looking forward, DPF technology must evolve to address emerging challenges such as compatibility with alternative fuels, integration with hybrid powertrains, and adaptation to increasingly stringent regulatory frameworks worldwide. The technology roadmap also includes developing cost-effective solutions for retrofitting older vehicles and creating systems suitable for diverse applications beyond on-road transportation, including marine engines, stationary power generation, and off-road equipment.

Market Demand Analysis for Advanced DPF Solutions

The global market for Diesel Particulate Filter (DPF) solutions is experiencing robust growth driven by increasingly stringent emission regulations worldwide. The current market size for advanced DPF technologies is estimated at $12.3 billion, with projections indicating growth to reach $18.7 billion by 2028, representing a compound annual growth rate of 8.7%. This growth trajectory is primarily fueled by the implementation of Euro 7 standards in Europe, China 6 regulations in Asia, and EPA Tier 3 standards in North America.

Commercial vehicle segments, particularly heavy-duty trucks and buses, constitute the largest market share at approximately 62% of total demand. This dominance stems from the higher particulate matter emissions associated with these vehicles and the corresponding regulatory focus on this sector. The passenger vehicle segment, while smaller, is showing accelerated growth rates of 9.3% annually as diesel passenger cars face mounting pressure to meet emission standards.

Regional analysis reveals Europe as the leading market for advanced DPF solutions, accounting for 41% of global demand. This leadership position is attributed to the region's early adoption of stringent emission standards and substantial diesel vehicle fleet. North America and Asia-Pacific follow with market shares of 28% and 24% respectively, with the latter demonstrating the fastest growth rate due to rapid industrialization and tightening regulations in countries like China and India.

Industry surveys indicate evolving customer requirements, with fleet operators increasingly demanding DPF solutions that maintain efficiency under varying operational conditions while minimizing maintenance requirements. Key performance indicators valued by end-users include regeneration frequency reduction (cited by 78% of fleet managers), backpressure management capabilities (67%), and thermal durability (82%).

Emerging market trends include growing demand for retrofit solutions in developing economies where complete fleet replacement is economically unfeasible. This retrofit market segment is projected to grow at 11.2% annually through 2027. Additionally, there is increasing interest in integrated emission control systems that combine DPF technology with selective catalytic reduction (SCR) systems, creating comprehensive solutions that address both particulate matter and NOx emissions simultaneously.

The aftermarket for DPF maintenance and replacement represents another significant growth segment, valued at $3.8 billion annually and growing at 7.5%. This is driven by aging vehicle fleets and the increasing complexity of emission control systems requiring specialized service and components.

Commercial vehicle segments, particularly heavy-duty trucks and buses, constitute the largest market share at approximately 62% of total demand. This dominance stems from the higher particulate matter emissions associated with these vehicles and the corresponding regulatory focus on this sector. The passenger vehicle segment, while smaller, is showing accelerated growth rates of 9.3% annually as diesel passenger cars face mounting pressure to meet emission standards.

Regional analysis reveals Europe as the leading market for advanced DPF solutions, accounting for 41% of global demand. This leadership position is attributed to the region's early adoption of stringent emission standards and substantial diesel vehicle fleet. North America and Asia-Pacific follow with market shares of 28% and 24% respectively, with the latter demonstrating the fastest growth rate due to rapid industrialization and tightening regulations in countries like China and India.

Industry surveys indicate evolving customer requirements, with fleet operators increasingly demanding DPF solutions that maintain efficiency under varying operational conditions while minimizing maintenance requirements. Key performance indicators valued by end-users include regeneration frequency reduction (cited by 78% of fleet managers), backpressure management capabilities (67%), and thermal durability (82%).

Emerging market trends include growing demand for retrofit solutions in developing economies where complete fleet replacement is economically unfeasible. This retrofit market segment is projected to grow at 11.2% annually through 2027. Additionally, there is increasing interest in integrated emission control systems that combine DPF technology with selective catalytic reduction (SCR) systems, creating comprehensive solutions that address both particulate matter and NOx emissions simultaneously.

The aftermarket for DPF maintenance and replacement represents another significant growth segment, valued at $3.8 billion annually and growing at 7.5%. This is driven by aging vehicle fleets and the increasing complexity of emission control systems requiring specialized service and components.

Global DPF Technology Status and Challenges

Diesel Particulate Filter (DPF) technology has evolved significantly since its introduction in the early 2000s, with global adoption accelerating due to increasingly stringent emission regulations. Currently, the global DPF market is dominated by ceramic wall-flow filters, which capture particulate matter with efficiency rates exceeding 95% under optimal conditions. However, significant regional disparities exist in technology implementation, with Europe and North America leading in advanced DPF systems while emerging markets still struggle with basic adoption.

The primary technical challenge facing DPF technology is maintaining high filtration efficiency across varying operating conditions. Laboratory testing demonstrates near-perfect performance, but real-world driving conditions present significant efficiency fluctuations. Cold-start operations, where exhaust temperatures remain below 200°C, result in dramatically reduced filtration efficiency, sometimes dropping below 60%. Similarly, high-load conditions can cause thermal stress that compromises filter integrity over time.

Regeneration processes—essential for removing accumulated soot—present another critical challenge. Passive regeneration systems rely on normal exhaust temperatures and NO₂ presence, but often fail in low-temperature driving cycles. Active regeneration systems require precise control algorithms and additional fuel consumption, reducing overall vehicle efficiency by 1-3%. The balance between regeneration frequency and filter longevity remains problematic across the industry.

Material limitations constitute a significant barrier to advancement. Current cordierite and silicon carbide substrates offer good thermal resistance but face durability issues under extreme thermal cycling. Alternative materials like aluminum titanate show promise but present manufacturing scalability challenges and higher production costs, limiting widespread adoption.

Sensor technology and control systems represent another challenge area. Current on-board diagnostic systems struggle to accurately predict filter loading states and optimal regeneration timing. The correlation between pressure differential measurements and actual soot loading becomes increasingly non-linear as filters age, complicating control algorithms.

Emerging markets face unique challenges including fuel quality variations, with high sulfur content fuels poisoning catalytic coatings and accelerating filter degradation. Additionally, maintenance infrastructure limitations in these regions often result in improper service practices that compromise long-term DPF performance.

Research indicates that next-generation DPF systems must address these challenges through advanced material science, improved sensing technologies, and more sophisticated control algorithms to maintain high efficiency across all operating conditions while minimizing the economic and efficiency penalties currently associated with the technology.

The primary technical challenge facing DPF technology is maintaining high filtration efficiency across varying operating conditions. Laboratory testing demonstrates near-perfect performance, but real-world driving conditions present significant efficiency fluctuations. Cold-start operations, where exhaust temperatures remain below 200°C, result in dramatically reduced filtration efficiency, sometimes dropping below 60%. Similarly, high-load conditions can cause thermal stress that compromises filter integrity over time.

Regeneration processes—essential for removing accumulated soot—present another critical challenge. Passive regeneration systems rely on normal exhaust temperatures and NO₂ presence, but often fail in low-temperature driving cycles. Active regeneration systems require precise control algorithms and additional fuel consumption, reducing overall vehicle efficiency by 1-3%. The balance between regeneration frequency and filter longevity remains problematic across the industry.

Material limitations constitute a significant barrier to advancement. Current cordierite and silicon carbide substrates offer good thermal resistance but face durability issues under extreme thermal cycling. Alternative materials like aluminum titanate show promise but present manufacturing scalability challenges and higher production costs, limiting widespread adoption.

Sensor technology and control systems represent another challenge area. Current on-board diagnostic systems struggle to accurately predict filter loading states and optimal regeneration timing. The correlation between pressure differential measurements and actual soot loading becomes increasingly non-linear as filters age, complicating control algorithms.

Emerging markets face unique challenges including fuel quality variations, with high sulfur content fuels poisoning catalytic coatings and accelerating filter degradation. Additionally, maintenance infrastructure limitations in these regions often result in improper service practices that compromise long-term DPF performance.

Research indicates that next-generation DPF systems must address these challenges through advanced material science, improved sensing technologies, and more sophisticated control algorithms to maintain high efficiency across all operating conditions while minimizing the economic and efficiency penalties currently associated with the technology.

Current DPF Efficiency Solutions Under Variable Conditions

01 Filter structure and material optimization

The efficiency of diesel particulate filters can be improved through structural design and material selection. This includes using advanced ceramic materials, optimizing pore size distribution, and developing wall-flow filters with enhanced filtration capabilities. These structural improvements help to capture more particulate matter while maintaining acceptable back pressure levels in the exhaust system.- Filter material composition and structure: The efficiency of diesel particulate filters is significantly influenced by the materials used and their structural design. Advanced ceramic materials, such as cordierite and silicon carbide, offer high filtration efficiency while maintaining durability under extreme temperature conditions. The pore size, wall thickness, and channel geometry of the filter substrate are critical factors that determine particulate capture efficiency. Innovations in filter substrate design include asymmetric cell structures and variable porosity that optimize the balance between filtration efficiency and pressure drop.

- Regeneration systems and strategies: Regeneration systems are essential for maintaining diesel particulate filter efficiency by periodically removing accumulated soot. Active regeneration methods involve raising exhaust temperatures to burn off particulate matter, while passive systems utilize catalytic coatings to lower the soot combustion temperature. Advanced regeneration strategies include controlled injection timing, post-injection techniques, and intelligent thermal management systems that optimize regeneration frequency based on operating conditions. These systems prevent filter clogging while minimizing fuel consumption penalties associated with the regeneration process.

- Catalytic coating technologies: Catalytic coatings applied to diesel particulate filters significantly enhance their efficiency by promoting the oxidation of particulate matter at lower temperatures. These coatings typically contain precious metals like platinum, palladium, and rhodium, or base metal oxides that facilitate soot combustion. Advanced formulations incorporate multiple catalytic layers with specific functionalities, such as NOx reduction combined with particulate oxidation. The distribution and loading of catalytic materials on the filter substrate are optimized to ensure uniform activity while minimizing pressure drop across the filter.

- Monitoring and diagnostic systems: Sophisticated monitoring and diagnostic systems are crucial for maintaining diesel particulate filter efficiency throughout its operational life. These systems employ pressure differential sensors, temperature sensors, and soot load estimation algorithms to accurately determine filter condition. Advanced diagnostic techniques include real-time efficiency monitoring, predictive maintenance scheduling, and fault detection systems that can identify partial blockages or damage. Integration with engine control units allows for adaptive strategies that optimize filter performance based on actual operating conditions and filter status.

- Integration with other emission control systems: The efficiency of diesel particulate filters is enhanced through strategic integration with other emission control technologies. Combined systems such as SCR-on-filter (selective catalytic reduction) simultaneously address particulate matter and NOx emissions. Integrated approaches that coordinate the operation of diesel oxidation catalysts, particulate filters, and NOx reduction systems optimize overall emission control while minimizing system complexity and backpressure. Advanced control strategies ensure that these integrated systems work synergistically across various engine operating conditions to maximize filtration efficiency while meeting increasingly stringent emission standards.

02 Regeneration systems and methods

Various regeneration techniques are employed to periodically clean diesel particulate filters by burning off accumulated soot. These include active regeneration using fuel injection or electric heating, passive regeneration using catalytic coatings, and combined approaches. Efficient regeneration systems are crucial for maintaining filter performance over time and preventing excessive back pressure that can reduce engine efficiency.Expand Specific Solutions03 Catalytic coatings and additives

The application of catalytic coatings and fuel additives can significantly enhance diesel particulate filter efficiency. These catalysts lower the combustion temperature of trapped particulate matter, facilitating more frequent and complete regeneration cycles. Common catalytic materials include platinum group metals, cerium oxide, and various metal oxides that promote soot oxidation at lower temperatures.Expand Specific Solutions04 Monitoring and diagnostic systems

Advanced monitoring systems are essential for evaluating diesel particulate filter efficiency in real-time. These include pressure differential sensors, temperature sensors, and soot load estimation algorithms. Such diagnostic tools help optimize filter operation, predict maintenance needs, and ensure compliance with emission regulations by detecting performance degradation or failures early.Expand Specific Solutions05 Integration with exhaust aftertreatment systems

The efficiency of diesel particulate filters can be enhanced through strategic integration with other exhaust aftertreatment components. This includes combining DPFs with selective catalytic reduction (SCR) systems, diesel oxidation catalysts (DOC), and NOx traps. Such integrated approaches provide synergistic effects that improve overall emission control while optimizing filter performance and durability.Expand Specific Solutions

Major DPF Manufacturers and Industry Landscape

The diesel particulate filter (DPF) efficiency market is currently in a growth phase, with increasing regulatory pressure driving adoption across automotive and industrial sectors. The market size is expanding significantly due to stringent emission standards worldwide, particularly in Europe, North America, and Asia. Technologically, the field shows varying maturity levels, with established players like Corning, Robert Bosch GmbH, and Johnson Matthey leading innovation through advanced ceramic substrate technologies and regeneration systems. Emerging competitors including IBIDEN, Vitesco Technologies, and specialized manufacturers like Dinex Finland are challenging incumbents with novel filtration materials and control systems. The competitive landscape is further shaped by automotive OEMs such as GM, Ford, and Hyundai, who are integrating proprietary DPF solutions into their emission control strategies to meet increasingly demanding performance requirements under real-world operating conditions.

Corning, Inc.

Technical Solution: Corning has pioneered advanced ceramic substrate technologies for Diesel Particulate Filters with their proprietary cellular ceramic designs. Their DuraTrap® filter technology utilizes a honeycomb structure with alternately plugged channels that force exhaust gases through porous ceramic walls, capturing over 99% of particulate matter. Corning's latest generation filters feature optimized cell geometry with asymmetric channel designs that increase filtration surface area by up to 30% while maintaining manageable back pressure levels. The company has developed specialized material compositions that enhance thermal durability, allowing their filters to withstand temperatures exceeding 1000°C during regeneration cycles without compromising structural integrity. Their advanced thin-wall technology reduces thermal mass, enabling faster light-off and more efficient regeneration under varying engine load conditions. Corning's filters incorporate tailored porosity distributions that optimize the balance between filtration efficiency and pressure drop across diverse operating conditions, from cold-start urban driving to high-load highway operation.

Strengths: Exceptional thermal durability withstanding extreme temperature fluctuations; advanced ceramic formulations providing optimal porosity and filtration efficiency; proven long-term reliability with minimal ash-related performance degradation. Weaknesses: Higher manufacturing costs compared to some competitors; limited flexibility in physical design once manufactured; requires careful integration with regeneration systems to prevent thermal damage during extreme conditions.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced Diesel Particulate Filter (DPF) systems that utilize intelligent sensing technology to optimize filtration efficiency across varying operating conditions. Their technology incorporates closed-loop control systems that continuously monitor exhaust gas parameters including temperature, pressure differential, and particulate matter concentration to dynamically adjust regeneration strategies. Bosch's DPF systems feature innovative coating technologies with catalytically active materials that lower the regeneration temperature threshold by approximately 50-100°C compared to conventional filters, enabling more frequent and efficient regeneration cycles even during low-temperature urban driving conditions. Their latest generation systems integrate predictive algorithms that analyze driving patterns and environmental conditions to preemptively optimize filter performance, resulting in up to 30% improvement in filtration efficiency during cold-start and low-load operations while maintaining back-pressure within acceptable limits for engine performance.

Strengths: Superior sensing and control technology enables real-time adaptation to changing conditions; advanced catalyst formulations allow for more efficient low-temperature regeneration; comprehensive system integration with engine management systems. Weaknesses: Higher initial cost compared to basic DPF systems; complex control algorithms require sophisticated ECU capabilities; potential reliability concerns with multiple integrated sensors in harsh exhaust environments.

Key DPF Filtration Mechanisms and Materials Analysis

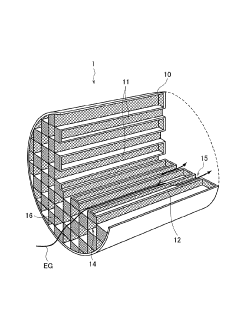

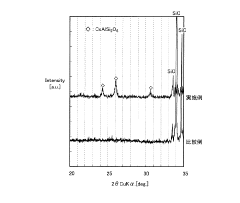

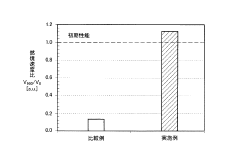

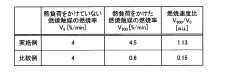

Diesel particulate filter and particulate matter combustion catalyst filter using the same

PatentInactiveJP2017000973A

Innovation

- A diesel particulate filter made of silicon carbide with a composite oxide layer containing cesium, aluminum, and silicon is used, which suppresses catalyst deterioration and maintains combustion efficiency.

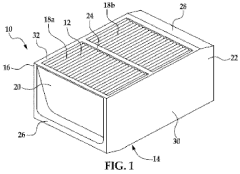

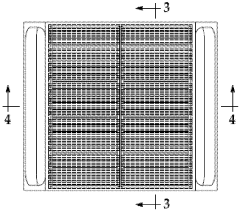

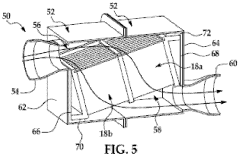

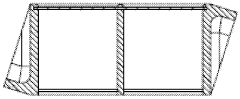

Diesel particulate filter assembly

PatentWO2008157487A2

Innovation

- A diesel particulate filter assembly featuring pleated ceramic media supported by a ceramic frame, configured to be incorporated into exhaust treatment devices, allowing for increased filtration area and soot loading capacity, with an angled alignment to reduce backpressure and enhance packaging flexibility.

Emissions Regulations Impact on DPF Development

The evolution of emissions regulations has been a primary driver for Diesel Particulate Filter (DPF) development over the past three decades. Beginning with the introduction of Euro 1 standards in 1992, regulatory frameworks have progressively tightened particulate matter (PM) emission limits, necessitating increasingly sophisticated filtration technologies. The transition from Euro 3 to Euro 6 standards saw PM limits decrease by over 80%, compelling manufacturers to develop more efficient DPF systems capable of capturing ultrafine particles.

In the United States, the Environmental Protection Agency's Tier 3 standards and California Air Resources Board (CARB) regulations have similarly pushed DPF technology forward, with requirements for near-zero PM emissions and mandatory on-board diagnostic systems to monitor filter performance. These regulations have effectively mandated DPF installation on virtually all new diesel vehicles since 2007.

The regulatory landscape continues to evolve with increasing focus on real-world emissions performance rather than laboratory testing alone. The introduction of Real Driving Emissions (RDE) testing in Europe has highlighted the need for DPF systems that maintain high efficiency across diverse operating conditions, including cold starts, low-speed urban driving, and high-load highway operation.

China's rapid implementation of China VI standards, equivalent to Euro 6, represents another significant regulatory influence on global DPF development. This expansion of stringent emissions standards to emerging markets has accelerated technology transfer and innovation in cost-effective DPF solutions suitable for diverse global applications.

Regulatory requirements for DPF durability have also intensified, with systems now expected to maintain performance for up to 700,000 kilometers in heavy-duty applications. This has driven research into advanced substrate materials, catalyst formulations, and regeneration strategies that can withstand thermal cycling and chemical exposure over extended periods.

Future regulatory trends indicate continued tightening of emissions standards, with particular emphasis on particle number (PN) limits alongside traditional mass-based measurements. The Euro 7 proposal and EPA's planned future standards will likely require DPF systems capable of filtering particles below 23 nanometers, presenting new technical challenges for filter media design and porosity optimization.

The regulatory push toward greenhouse gas reduction is creating additional complexity, as DPF systems must achieve high filtration efficiency while minimizing fuel consumption penalties associated with exhaust backpressure and regeneration events. This dual optimization challenge is reshaping DPF development priorities and driving integration with other emissions control technologies.

In the United States, the Environmental Protection Agency's Tier 3 standards and California Air Resources Board (CARB) regulations have similarly pushed DPF technology forward, with requirements for near-zero PM emissions and mandatory on-board diagnostic systems to monitor filter performance. These regulations have effectively mandated DPF installation on virtually all new diesel vehicles since 2007.

The regulatory landscape continues to evolve with increasing focus on real-world emissions performance rather than laboratory testing alone. The introduction of Real Driving Emissions (RDE) testing in Europe has highlighted the need for DPF systems that maintain high efficiency across diverse operating conditions, including cold starts, low-speed urban driving, and high-load highway operation.

China's rapid implementation of China VI standards, equivalent to Euro 6, represents another significant regulatory influence on global DPF development. This expansion of stringent emissions standards to emerging markets has accelerated technology transfer and innovation in cost-effective DPF solutions suitable for diverse global applications.

Regulatory requirements for DPF durability have also intensified, with systems now expected to maintain performance for up to 700,000 kilometers in heavy-duty applications. This has driven research into advanced substrate materials, catalyst formulations, and regeneration strategies that can withstand thermal cycling and chemical exposure over extended periods.

Future regulatory trends indicate continued tightening of emissions standards, with particular emphasis on particle number (PN) limits alongside traditional mass-based measurements. The Euro 7 proposal and EPA's planned future standards will likely require DPF systems capable of filtering particles below 23 nanometers, presenting new technical challenges for filter media design and porosity optimization.

The regulatory push toward greenhouse gas reduction is creating additional complexity, as DPF systems must achieve high filtration efficiency while minimizing fuel consumption penalties associated with exhaust backpressure and regeneration events. This dual optimization challenge is reshaping DPF development priorities and driving integration with other emissions control technologies.

Durability and Lifecycle Assessment of DPF Systems

The durability and lifecycle assessment of Diesel Particulate Filter (DPF) systems represents a critical aspect of their overall performance evaluation. Current generation DPF systems demonstrate significant improvements in longevity compared to earlier models, with typical service lifespans ranging from 100,000 to 200,000 kilometers under normal operating conditions. However, this durability is highly dependent on multiple factors including driving patterns, maintenance practices, and environmental conditions.

Material degradation remains a primary concern affecting DPF longevity. Thermal cycling during regeneration processes creates mechanical stress on the ceramic substrate, potentially leading to microcracking and eventual structural failure. Advanced cordierite and silicon carbide materials have substantially improved thermal resistance, but still exhibit degradation after extended exposure to high-temperature regeneration cycles exceeding 600°C.

Ash accumulation presents another significant challenge to DPF lifecycle performance. Studies indicate that non-combustible materials from engine oil additives and fuel impurities gradually accumulate within the filter, creating irreversible blockages that cannot be removed during standard regeneration processes. This ash buildup typically accounts for 10-20% reduction in filter capacity over the service life of modern DPF systems.

Maintenance protocols significantly impact DPF durability. Research demonstrates that vehicles adhering to manufacturer-recommended service intervals show 30-40% longer filter lifespans compared to those with irregular maintenance. The development of predictive maintenance algorithms utilizing onboard diagnostics has emerged as a promising approach to optimize DPF lifecycle management, potentially extending service intervals by 15-25% through more precise timing of maintenance interventions.

Economic analysis of DPF lifecycle costs reveals significant variations across different operational profiles. Long-haul transportation applications typically achieve lower lifetime costs per kilometer compared to urban delivery vehicles due to more consistent operating temperatures and fewer cold-start cycles. The total lifecycle cost assessment must incorporate not only replacement expenses but also fuel economy penalties associated with increased backpressure as filters age.

Environmental impact assessments of DPF systems must consider both the emissions reduction benefits during operation and the environmental footprint of manufacturing and disposal. Recent lifecycle analyses indicate that despite energy-intensive production processes, modern DPF systems deliver net environmental benefits within 30,000-50,000 kilometers of operation through particulate matter reduction.

Material degradation remains a primary concern affecting DPF longevity. Thermal cycling during regeneration processes creates mechanical stress on the ceramic substrate, potentially leading to microcracking and eventual structural failure. Advanced cordierite and silicon carbide materials have substantially improved thermal resistance, but still exhibit degradation after extended exposure to high-temperature regeneration cycles exceeding 600°C.

Ash accumulation presents another significant challenge to DPF lifecycle performance. Studies indicate that non-combustible materials from engine oil additives and fuel impurities gradually accumulate within the filter, creating irreversible blockages that cannot be removed during standard regeneration processes. This ash buildup typically accounts for 10-20% reduction in filter capacity over the service life of modern DPF systems.

Maintenance protocols significantly impact DPF durability. Research demonstrates that vehicles adhering to manufacturer-recommended service intervals show 30-40% longer filter lifespans compared to those with irregular maintenance. The development of predictive maintenance algorithms utilizing onboard diagnostics has emerged as a promising approach to optimize DPF lifecycle management, potentially extending service intervals by 15-25% through more precise timing of maintenance interventions.

Economic analysis of DPF lifecycle costs reveals significant variations across different operational profiles. Long-haul transportation applications typically achieve lower lifetime costs per kilometer compared to urban delivery vehicles due to more consistent operating temperatures and fewer cold-start cycles. The total lifecycle cost assessment must incorporate not only replacement expenses but also fuel economy penalties associated with increased backpressure as filters age.

Environmental impact assessments of DPF systems must consider both the emissions reduction benefits during operation and the environmental footprint of manufacturing and disposal. Recent lifecycle analyses indicate that despite energy-intensive production processes, modern DPF systems deliver net environmental benefits within 30,000-50,000 kilometers of operation through particulate matter reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!