Diesel Particulate Filter vs Variable Geometry Turbocharging

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Control Technologies Background and Objectives

Emission control technologies have evolved significantly over the past several decades in response to increasingly stringent environmental regulations and growing public awareness of air pollution impacts. The journey began in the 1970s with the introduction of basic catalytic converters and has progressed to today's sophisticated integrated systems combining multiple technologies to minimize harmful emissions from internal combustion engines.

The diesel engine sector has faced particularly challenging emission control requirements due to the inherent characteristics of compression ignition that produce higher levels of nitrogen oxides (NOx) and particulate matter (PM) compared to gasoline engines. This has driven the development of specialized technologies including Diesel Particulate Filters (DPF) and Variable Geometry Turbocharging (VGT) systems, which represent two distinct but complementary approaches to emission reduction.

DPF technology emerged in the 1980s but saw widespread commercial adoption in the early 2000s as regulations tightened. These systems physically trap particulate matter from exhaust gases, requiring periodic regeneration processes to prevent clogging. The technology has undergone continuous refinement in filter materials, regeneration strategies, and integration with other emission control components.

Concurrently, VGT technology has evolved from fixed geometry turbochargers to provide variable boost pressure across different engine operating conditions. This advancement allows for optimized air-fuel ratios that can significantly reduce emissions formation at the source, particularly NOx emissions, while maintaining or improving engine performance and fuel efficiency.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of DPF and VGT technologies, examining their respective mechanisms, effectiveness in emission reduction, impact on engine performance, reliability, cost implications, and compatibility with future emission standards. This analysis aims to identify the optimal deployment strategies for these technologies, either independently or in combination.

Additionally, this research seeks to evaluate how these technologies align with broader industry trends toward electrification, alternative fuels, and zero-emission vehicles. Understanding the evolutionary trajectory of these emission control technologies provides crucial context for strategic decision-making in powertrain development and regulatory compliance planning.

The findings will inform future research directions, investment priorities, and product development strategies in the automotive and heavy equipment industries, where balancing emission compliance, performance requirements, and cost considerations remains a critical challenge.

The diesel engine sector has faced particularly challenging emission control requirements due to the inherent characteristics of compression ignition that produce higher levels of nitrogen oxides (NOx) and particulate matter (PM) compared to gasoline engines. This has driven the development of specialized technologies including Diesel Particulate Filters (DPF) and Variable Geometry Turbocharging (VGT) systems, which represent two distinct but complementary approaches to emission reduction.

DPF technology emerged in the 1980s but saw widespread commercial adoption in the early 2000s as regulations tightened. These systems physically trap particulate matter from exhaust gases, requiring periodic regeneration processes to prevent clogging. The technology has undergone continuous refinement in filter materials, regeneration strategies, and integration with other emission control components.

Concurrently, VGT technology has evolved from fixed geometry turbochargers to provide variable boost pressure across different engine operating conditions. This advancement allows for optimized air-fuel ratios that can significantly reduce emissions formation at the source, particularly NOx emissions, while maintaining or improving engine performance and fuel efficiency.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of DPF and VGT technologies, examining their respective mechanisms, effectiveness in emission reduction, impact on engine performance, reliability, cost implications, and compatibility with future emission standards. This analysis aims to identify the optimal deployment strategies for these technologies, either independently or in combination.

Additionally, this research seeks to evaluate how these technologies align with broader industry trends toward electrification, alternative fuels, and zero-emission vehicles. Understanding the evolutionary trajectory of these emission control technologies provides crucial context for strategic decision-making in powertrain development and regulatory compliance planning.

The findings will inform future research directions, investment priorities, and product development strategies in the automotive and heavy equipment industries, where balancing emission compliance, performance requirements, and cost considerations remains a critical challenge.

Market Demand Analysis for Clean Diesel Solutions

The global market for clean diesel solutions has experienced significant growth over the past decade, driven primarily by increasingly stringent emissions regulations across major automotive markets. The demand for technologies like Diesel Particulate Filters (DPF) and Variable Geometry Turbocharging (VGT) has surged as manufacturers seek compliance with Euro 6, EPA Tier 3, and China 6 standards, which mandate substantial reductions in particulate matter and NOx emissions.

Commercial vehicle segments represent the largest market share for clean diesel technologies, with heavy-duty trucks and buses accounting for approximately 60% of the total market value. This dominance stems from diesel's continued prevalence in commercial transportation due to its superior torque characteristics and fuel efficiency compared to alternative powertrains.

Regional analysis reveals varying adoption patterns, with Europe leading in DPF implementation due to early regulatory pressure, while North America shows stronger preference for comprehensive solutions combining VGT with selective catalytic reduction systems. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected annual growth rates exceeding the global average as these nations implement more stringent emissions standards.

Consumer sentiment analysis indicates a growing preference for vehicles that balance environmental performance with operational efficiency. Fleet operators specifically prioritize technologies that minimize downtime and maintenance costs while ensuring regulatory compliance, creating market pressure for solutions that optimize regeneration cycles and system durability.

Economic factors significantly influence market dynamics, with total cost of ownership calculations increasingly favoring advanced clean diesel technologies despite higher initial investment costs. The price sensitivity varies considerably across market segments, with greater elasticity observed in developing markets where regulatory enforcement may be less stringent.

Market forecasts project continued growth for both DPF and VGT technologies through 2030, though at declining rates as electrification gradually penetrates commercial vehicle segments. The aftermarket for replacement filters and turbocharger components represents a substantial secondary market, estimated to grow at compound annual rates exceeding the primary market.

Industry surveys indicate that manufacturers and fleet operators increasingly view clean diesel technologies as transitional solutions within a broader decarbonization strategy, suggesting that future market demand will favor systems offering flexibility and upgrade pathways toward hybrid or alternative fuel compatibility.

Commercial vehicle segments represent the largest market share for clean diesel technologies, with heavy-duty trucks and buses accounting for approximately 60% of the total market value. This dominance stems from diesel's continued prevalence in commercial transportation due to its superior torque characteristics and fuel efficiency compared to alternative powertrains.

Regional analysis reveals varying adoption patterns, with Europe leading in DPF implementation due to early regulatory pressure, while North America shows stronger preference for comprehensive solutions combining VGT with selective catalytic reduction systems. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected annual growth rates exceeding the global average as these nations implement more stringent emissions standards.

Consumer sentiment analysis indicates a growing preference for vehicles that balance environmental performance with operational efficiency. Fleet operators specifically prioritize technologies that minimize downtime and maintenance costs while ensuring regulatory compliance, creating market pressure for solutions that optimize regeneration cycles and system durability.

Economic factors significantly influence market dynamics, with total cost of ownership calculations increasingly favoring advanced clean diesel technologies despite higher initial investment costs. The price sensitivity varies considerably across market segments, with greater elasticity observed in developing markets where regulatory enforcement may be less stringent.

Market forecasts project continued growth for both DPF and VGT technologies through 2030, though at declining rates as electrification gradually penetrates commercial vehicle segments. The aftermarket for replacement filters and turbocharger components represents a substantial secondary market, estimated to grow at compound annual rates exceeding the primary market.

Industry surveys indicate that manufacturers and fleet operators increasingly view clean diesel technologies as transitional solutions within a broader decarbonization strategy, suggesting that future market demand will favor systems offering flexibility and upgrade pathways toward hybrid or alternative fuel compatibility.

DPF and VGT Current Technical Challenges

Both Diesel Particulate Filter (DPF) and Variable Geometry Turbocharging (VGT) technologies face significant technical challenges in their current implementations. DPF systems struggle with regeneration efficiency, as the process of burning accumulated particulate matter requires precise temperature control between 550-650°C. This temperature window is difficult to maintain consistently during normal driving conditions, particularly in urban environments with frequent stop-start patterns.

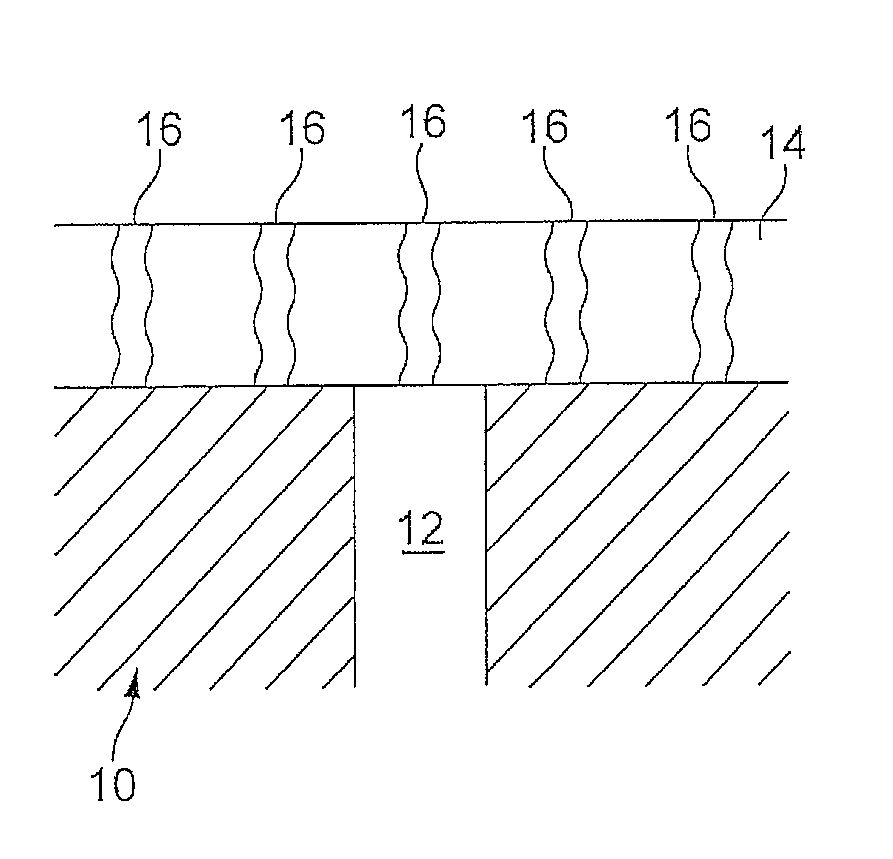

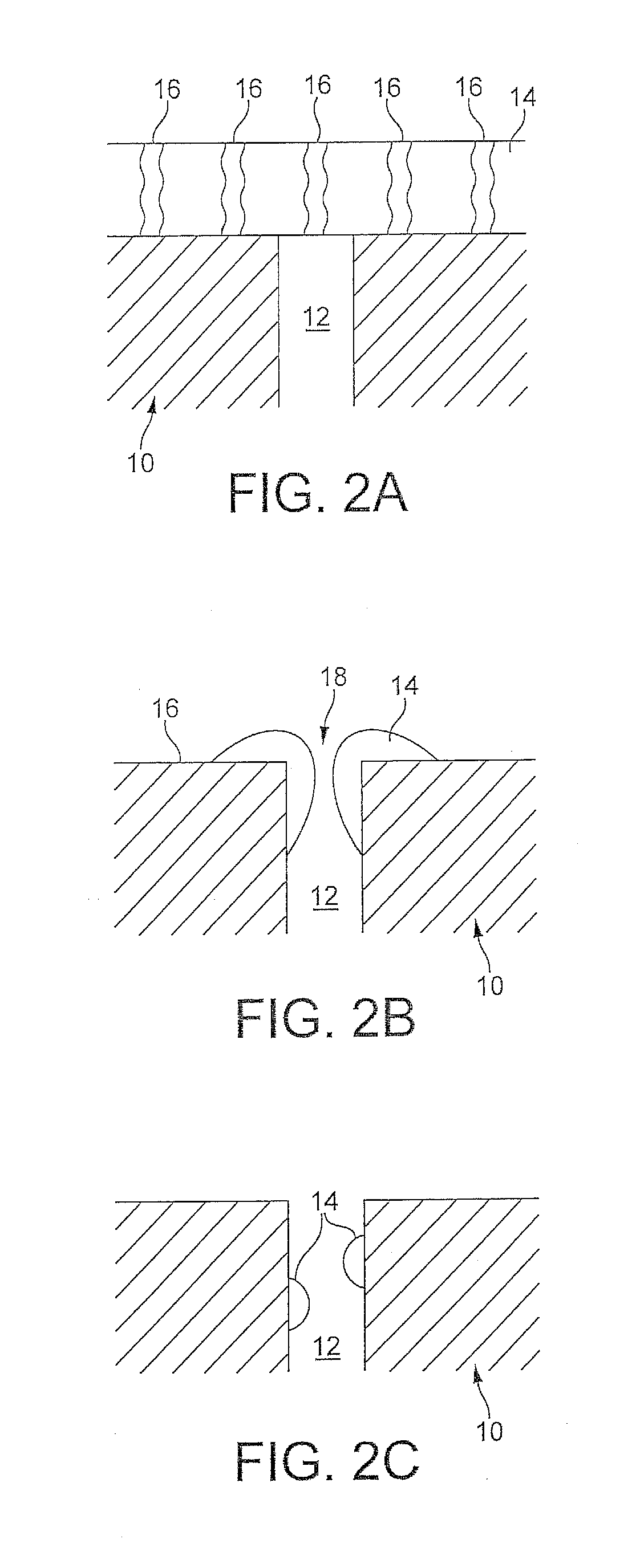

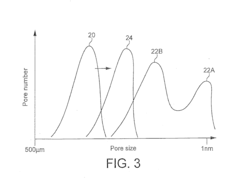

Material durability presents another major challenge for DPF technology. The filter substrates, typically made from cordierite or silicon carbide, are subjected to extreme thermal cycling during regeneration events, leading to potential cracking and reduced service life. The ash accumulation from non-combustible components of engine oil additives gradually reduces filter capacity and increases backpressure over time, necessitating periodic maintenance or replacement.

Sensor reliability and control system integration remain problematic for DPF systems. Differential pressure sensors that monitor filter loading are susceptible to fouling and calibration drift, while temperature sensors must maintain accuracy across extreme thermal ranges. These reliability issues directly impact regeneration timing and efficiency.

For VGT technology, the primary challenge lies in the mechanical complexity of the variable vane mechanisms. The movable vanes operate in an extremely harsh environment characterized by high temperatures (often exceeding 800°C) and exposure to corrosive exhaust gases containing sulfur compounds and particulates. This environment accelerates wear on pivots, bearings, and actuation components.

Control system response time presents another significant hurdle for VGT implementation. The turbocharger must respond rapidly to changing engine demands while avoiding compressor surge or over-boost conditions. Current electronic actuators struggle to provide the necessary combination of speed, precision, and durability required for optimal performance across all operating conditions.

Thermal management challenges affect both technologies but manifest differently. VGT systems must balance the conflicting requirements of providing sufficient boost at low engine speeds while preventing excessive exhaust backpressure at high speeds. This balancing act is further complicated by the need to maintain appropriate exhaust gas temperatures for aftertreatment systems, including DPF regeneration.

Cost-effectiveness remains a persistent challenge for both technologies. DPF systems add significant manufacturing costs through the use of precious metal catalysts and specialized filter materials, while VGT systems incorporate complex mechanical assemblies with tight tolerances. These costs are particularly problematic for smaller displacement engines in cost-sensitive market segments.

Material durability presents another major challenge for DPF technology. The filter substrates, typically made from cordierite or silicon carbide, are subjected to extreme thermal cycling during regeneration events, leading to potential cracking and reduced service life. The ash accumulation from non-combustible components of engine oil additives gradually reduces filter capacity and increases backpressure over time, necessitating periodic maintenance or replacement.

Sensor reliability and control system integration remain problematic for DPF systems. Differential pressure sensors that monitor filter loading are susceptible to fouling and calibration drift, while temperature sensors must maintain accuracy across extreme thermal ranges. These reliability issues directly impact regeneration timing and efficiency.

For VGT technology, the primary challenge lies in the mechanical complexity of the variable vane mechanisms. The movable vanes operate in an extremely harsh environment characterized by high temperatures (often exceeding 800°C) and exposure to corrosive exhaust gases containing sulfur compounds and particulates. This environment accelerates wear on pivots, bearings, and actuation components.

Control system response time presents another significant hurdle for VGT implementation. The turbocharger must respond rapidly to changing engine demands while avoiding compressor surge or over-boost conditions. Current electronic actuators struggle to provide the necessary combination of speed, precision, and durability required for optimal performance across all operating conditions.

Thermal management challenges affect both technologies but manifest differently. VGT systems must balance the conflicting requirements of providing sufficient boost at low engine speeds while preventing excessive exhaust backpressure at high speeds. This balancing act is further complicated by the need to maintain appropriate exhaust gas temperatures for aftertreatment systems, including DPF regeneration.

Cost-effectiveness remains a persistent challenge for both technologies. DPF systems add significant manufacturing costs through the use of precious metal catalysts and specialized filter materials, while VGT systems incorporate complex mechanical assemblies with tight tolerances. These costs are particularly problematic for smaller displacement engines in cost-sensitive market segments.

Current Implementation Approaches and Solutions

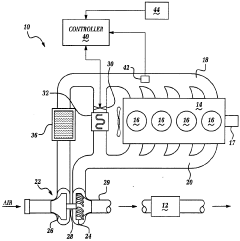

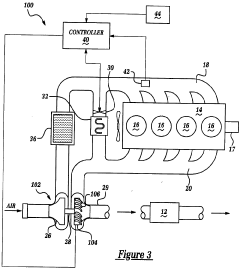

01 Integration of DPF and VGT systems for emission control

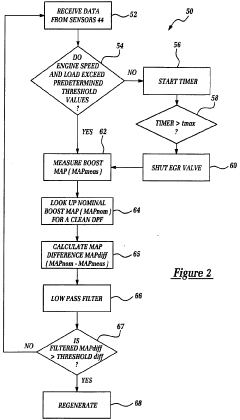

The integration of Diesel Particulate Filters (DPF) with Variable Geometry Turbocharging (VGT) systems provides enhanced emission control in diesel engines. This combination allows for optimized exhaust gas flow management, where the VGT can adjust backpressure to assist in DPF regeneration processes. The coordinated control of these systems helps maintain engine performance while meeting stringent emission standards by efficiently capturing particulate matter and controlling NOx emissions.- Integration of DPF with VGT for emission control: The integration of Diesel Particulate Filters (DPF) with Variable Geometry Turbocharging (VGT) systems provides enhanced emission control in diesel engines. This combination allows for optimized exhaust gas flow management, where the VGT can adjust backpressure to assist in DPF regeneration processes. The coordinated control of these systems helps maintain engine performance while meeting stringent emission standards by efficiently capturing particulate matter and managing exhaust temperatures.

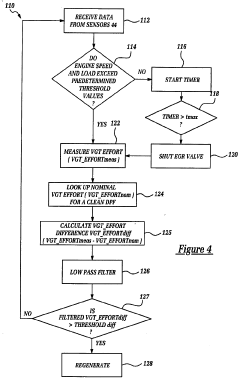

- DPF regeneration strategies using VGT control: Various regeneration strategies for Diesel Particulate Filters utilize Variable Geometry Turbocharging to control exhaust temperature and flow conditions. By adjusting the VGT vane positions, the system can increase exhaust gas temperatures to initiate and maintain the regeneration process, burning off accumulated soot in the filter. These strategies include active regeneration through temperature management and passive regeneration through pressure control, optimizing the cleaning process while minimizing fuel consumption penalties.

- Sensor systems for DPF and VGT performance monitoring: Advanced sensor systems are implemented to monitor the performance of both Diesel Particulate Filters and Variable Geometry Turbochargers. These sensors measure parameters such as differential pressure across the DPF, exhaust gas temperature, turbocharger speed, and vane position. The collected data enables real-time diagnostics, predictive maintenance, and adaptive control strategies that optimize system performance, prevent damage, and ensure compliance with emission regulations throughout the operational life of the components.

- Materials and coatings for DPF with VGT compatibility: Specialized materials and coatings are developed for Diesel Particulate Filters that maintain compatibility with Variable Geometry Turbocharging systems. These materials include advanced ceramics, cordierite, silicon carbide, and metal substrates with catalytic coatings that enhance filtration efficiency and thermal durability. The coatings also reduce the regeneration temperature requirements, allowing for more efficient operation of the VGT system while maintaining optimal backpressure levels and extending the service life of both components.

- Control algorithms for integrated DPF-VGT systems: Sophisticated control algorithms are designed to manage the interaction between Diesel Particulate Filters and Variable Geometry Turbochargers. These algorithms optimize engine performance by balancing the competing demands of emissions control, fuel efficiency, and power output. The control systems use model-based approaches to predict filter loading, determine optimal regeneration timing, and adjust turbocharger geometry accordingly. Advanced features include adaptive learning capabilities that account for component aging and varying operating conditions to maintain system efficiency over time.

02 DPF regeneration strategies using VGT control

Various regeneration strategies for Diesel Particulate Filters utilize Variable Geometry Turbocharging to control exhaust temperature and flow conditions. By adjusting the VGT vane positions, the system can increase exhaust gas temperature to initiate and maintain the regeneration process, burning off accumulated soot in the filter. These strategies include active regeneration through fuel injection timing modification, post-injection techniques, and precise airflow management to achieve optimal regeneration conditions while minimizing fuel consumption penalties.Expand Specific Solutions03 Sensor systems for DPF and VGT performance monitoring

Advanced sensor systems are implemented to monitor the performance of both Diesel Particulate Filters and Variable Geometry Turbochargers. These sensor networks include pressure differential sensors across the DPF, temperature sensors at various points in the exhaust system, and position sensors for the VGT mechanism. The collected data enables real-time diagnostics, predictive maintenance, and adaptive control strategies that optimize system performance, detect potential failures, and ensure compliance with emission regulations.Expand Specific Solutions04 Materials and coatings for DPF with VGT compatibility

Specialized materials and coatings are developed for Diesel Particulate Filters that maintain compatibility with Variable Geometry Turbocharging systems. These materials include advanced ceramics, cordierite, silicon carbide, and metal substrates with catalytic coatings that enhance filtration efficiency and thermal durability. The coatings often incorporate precious metals and rare earth elements that lower the soot ignition temperature, improving passive regeneration capabilities while withstanding the variable pressure and temperature conditions created by VGT operation.Expand Specific Solutions05 Electronic control systems for DPF-VGT coordination

Sophisticated electronic control systems are employed to coordinate the operation of Diesel Particulate Filters and Variable Geometry Turbochargers. These systems utilize engine control units (ECUs) with advanced algorithms that process inputs from multiple sensors to determine optimal VGT positions and DPF regeneration timing. The control strategies balance competing requirements such as emissions reduction, fuel efficiency, engine response, and component durability through adaptive learning mechanisms and model-based control approaches.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The diesel particulate filter (DPF) and variable geometry turbocharging (VGT) technologies market is in a mature growth phase, with an estimated global market size exceeding $10 billion. Leading players like BorgWarner, Cummins, and Honeywell have established strong technological foundations in both areas, while automotive OEMs including Toyota, Hyundai, and Mercedes-Benz continue integrating these technologies to meet stringent emission standards. The competitive landscape shows varying levels of technological maturity, with companies like Rolls-Royce Solutions and IHI Corp focusing on advanced VGT systems, while DENSO and BorgWarner lead in DPF innovation. Regional players such as Chongqing Jiangzeng and Shandong Aofu are expanding their presence, particularly in emerging markets, creating a dynamic competitive environment where integration capabilities and cost-effectiveness are becoming key differentiators.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed advanced Diesel Particulate Filter (DPF) systems featuring their proprietary Reactive Air Management (RAM) technology that optimizes regeneration cycles by precisely controlling airflow and temperature. Their DPF systems incorporate catalyzed substrates with high cell density (200-300 cpsi) and advanced coating technologies that enhance passive regeneration efficiency by up to 30% compared to conventional systems. For Variable Geometry Turbocharging (VGT), BorgWarner's latest generation features electronically actuated vanes with response times under 100ms and can withstand exhaust temperatures up to 830°C. Their dual-wall turbine housing design reduces heat transfer to surrounding components by approximately 25%, improving overall system efficiency. BorgWarner has also integrated their VGT technology with exhaust gas recirculation (EGR) systems to achieve up to 8% reduction in NOx emissions while maintaining power output.

Strengths: Industry-leading thermal management in both DPF and VGT systems; proprietary materials that extend component lifespan by up to 20%; comprehensive integration capabilities with engine management systems. Weaknesses: Higher initial cost compared to competitors; DPF systems require more frequent maintenance in certain duty cycles; VGT technology shows slightly slower response at very low engine speeds compared to some competitors.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered Variable Geometry Turbocharging technology with their Garrett® VNT™ (Variable Nozzle Turbine) series, featuring aerodynamically optimized vanes that precisely control exhaust gas flow across the turbine wheel. Their patented cartridge design allows for maintenance of tight manufacturing tolerances even under extreme thermal cycling conditions, maintaining vane positioning accuracy within 0.1mm throughout the service life. Honeywell's VGT systems incorporate advanced electric actuators with closed-loop control that achieve position accuracy within 0.05 degrees and response times of approximately 80ms. For Diesel Particulate Filters, Honeywell offers integrated systems with their turbocharging technology, featuring advanced substrate materials with asymmetric cell structures that increase filtration surface area by up to 25% while maintaining acceptable backpressure levels. Their thermal management algorithms optimize regeneration cycles based on real-time soot loading calculations, reducing fuel consumption during regeneration by approximately 15% compared to fixed-interval systems.

Strengths: Superior aerodynamic efficiency in VGT designs with demonstrated fuel economy improvements of 3-5%; excellent durability with validated field testing showing consistent performance beyond 500,000 miles; comprehensive integration with OEM engine management systems. Weaknesses: Premium pricing structure limits adoption in cost-sensitive markets; DPF solutions have shown slightly higher backpressure in certain applications compared to specialized DPF manufacturers; more complex installation requirements for aftermarket applications.

Technical Deep Dive: DPF and VGT Core Mechanisms

Monitoring of a diesel particulate filter

PatentInactiveGB2397134B

Innovation

- Using the control effort of a variable geometry turbine (VGT) as an indicator for diesel particulate filter (DPF) loading status, eliminating the need for additional sensors.

- Implementing a comparative analysis between measured VGT control effort and nominal control effort to determine DPF filling status in a closed-loop boost pressure system.

- Creating a monitoring system that leverages existing engine control infrastructure without requiring dedicated DPF monitoring hardware.

Exhaust system for a vehicular positive ignition internal combustion engine

PatentActiveUS20110158871A1

Innovation

- The design of an exhaust system with a three-way catalyst washcoat on a separate upstream substrate monolith, which allows sufficient pollutants to slip through and be converted downstream, generating an exotherm to raise the filter temperature and combust particulate matter, while optimizing washcoat loading and pore size to balance filtration efficiency and catalytic activity at acceptable backpressures.

Environmental Impact Assessment

The environmental impact of diesel engine emissions has become a critical concern in the automotive and transportation sectors, driving the development of technologies like Diesel Particulate Filters (DPF) and Variable Geometry Turbocharging (VGT). These technologies represent different approaches to addressing emission challenges, with distinct environmental implications.

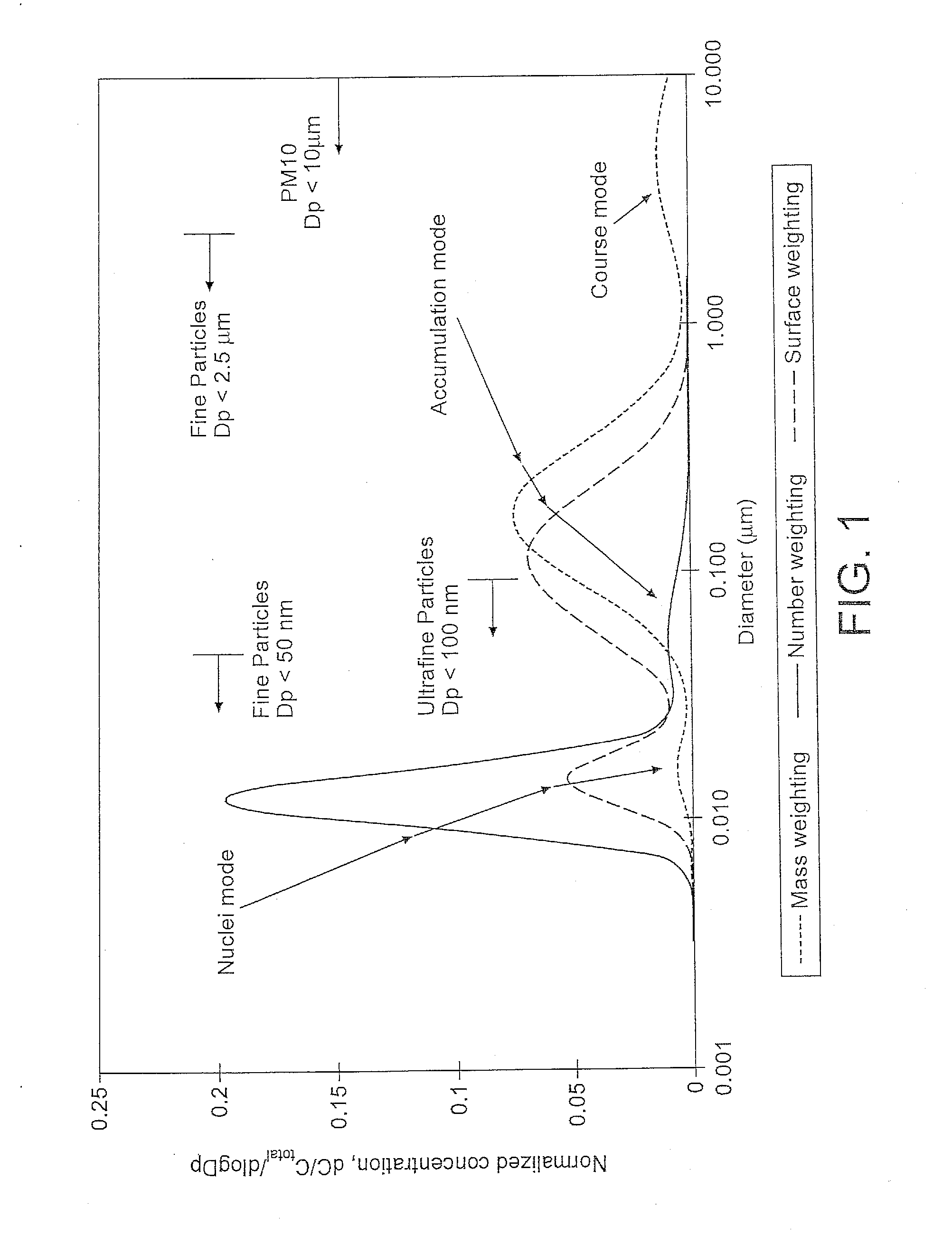

DPF systems directly target particulate matter (PM) emissions, capturing up to 99% of diesel soot particles. This significant reduction in PM emissions has profound public health implications, particularly in urban environments where diesel vehicles contribute substantially to air pollution. Studies indicate that widespread DPF implementation has contributed to measurable improvements in air quality in regions with strict emission regulations, with corresponding reductions in respiratory and cardiovascular diseases associated with particulate exposure.

However, DPF technology presents certain environmental trade-offs. The regeneration process required to clean filters typically increases fuel consumption by 2-4%, resulting in higher CO2 emissions. Additionally, the manufacturing of DPFs requires rare earth metals and specialized materials, creating upstream environmental impacts through mining and processing activities.

In contrast, VGT technology approaches emissions reduction indirectly by optimizing engine performance across various operating conditions. By improving combustion efficiency, VGT systems can reduce overall emissions, including nitrogen oxides (NOx) by 15-20% and carbon dioxide by 5-10% compared to fixed geometry turbochargers. This efficiency gain translates to lower fuel consumption, offering a different environmental benefit pathway than DPFs.

Life cycle assessment (LCA) studies comparing these technologies reveal interesting sustainability profiles. While DPFs provide immediate and substantial reductions in particulate emissions, their environmental footprint includes increased fuel consumption and end-of-life disposal challenges. VGT systems generally demonstrate better overall energy efficiency throughout their operational lifetime but may not achieve the same level of particulate matter reduction without complementary technologies.

From a regulatory compliance perspective, DPF technology has become essential for meeting Euro 6/VI, US EPA Tier 3, and similar stringent emission standards worldwide. VGT, while valuable for efficiency improvements, typically requires integration with other emission control technologies to meet the most stringent regulatory requirements.

The environmental impact assessment must also consider the technologies' adaptability to alternative fuels. VGT systems have demonstrated compatibility with biofuels and synthetic fuels, potentially enhancing their long-term environmental value proposition as the transportation sector transitions toward carbon neutrality. DPF systems, meanwhile, may require modifications to function optimally with alternative fuel compositions.

DPF systems directly target particulate matter (PM) emissions, capturing up to 99% of diesel soot particles. This significant reduction in PM emissions has profound public health implications, particularly in urban environments where diesel vehicles contribute substantially to air pollution. Studies indicate that widespread DPF implementation has contributed to measurable improvements in air quality in regions with strict emission regulations, with corresponding reductions in respiratory and cardiovascular diseases associated with particulate exposure.

However, DPF technology presents certain environmental trade-offs. The regeneration process required to clean filters typically increases fuel consumption by 2-4%, resulting in higher CO2 emissions. Additionally, the manufacturing of DPFs requires rare earth metals and specialized materials, creating upstream environmental impacts through mining and processing activities.

In contrast, VGT technology approaches emissions reduction indirectly by optimizing engine performance across various operating conditions. By improving combustion efficiency, VGT systems can reduce overall emissions, including nitrogen oxides (NOx) by 15-20% and carbon dioxide by 5-10% compared to fixed geometry turbochargers. This efficiency gain translates to lower fuel consumption, offering a different environmental benefit pathway than DPFs.

Life cycle assessment (LCA) studies comparing these technologies reveal interesting sustainability profiles. While DPFs provide immediate and substantial reductions in particulate emissions, their environmental footprint includes increased fuel consumption and end-of-life disposal challenges. VGT systems generally demonstrate better overall energy efficiency throughout their operational lifetime but may not achieve the same level of particulate matter reduction without complementary technologies.

From a regulatory compliance perspective, DPF technology has become essential for meeting Euro 6/VI, US EPA Tier 3, and similar stringent emission standards worldwide. VGT, while valuable for efficiency improvements, typically requires integration with other emission control technologies to meet the most stringent regulatory requirements.

The environmental impact assessment must also consider the technologies' adaptability to alternative fuels. VGT systems have demonstrated compatibility with biofuels and synthetic fuels, potentially enhancing their long-term environmental value proposition as the transportation sector transitions toward carbon neutrality. DPF systems, meanwhile, may require modifications to function optimally with alternative fuel compositions.

Cost-Benefit Analysis of Implementation Strategies

The implementation of either Diesel Particulate Filter (DPF) or Variable Geometry Turbocharging (VGT) technologies requires careful financial analysis to determine the most cost-effective strategy for manufacturers and end-users. Initial capital expenditure for DPF systems typically ranges from $1,500 to $3,000 per unit, with additional installation costs of $500-$1,000 depending on vehicle configuration. In contrast, VGT systems generally require $2,000-$4,000 per unit with similar installation expenses.

Operational expenses present significant differences between these technologies. DPF systems incur higher maintenance costs due to periodic regeneration requirements and filter replacement (approximately every 100,000-150,000 miles), averaging $600-$1,200 annually. VGT systems demonstrate lower maintenance requirements, with estimated annual costs of $300-$700, primarily for actuator maintenance and calibration.

Fuel economy impacts further differentiate these technologies. DPF systems typically reduce fuel efficiency by 1-3% due to increased back pressure and regeneration cycles, translating to approximately $200-$600 in additional annual fuel costs for commercial vehicles. VGT systems, conversely, can improve fuel efficiency by 2-5% through optimized air delivery across the engine's operating range, potentially saving $400-$1,000 annually in fuel expenses.

Regulatory compliance benefits must be factored into the cost-benefit equation. DPF technology directly addresses particulate matter emissions, reducing them by 85-95%, which can prevent non-compliance penalties ranging from $5,000-$25,000 depending on jurisdiction. VGT systems primarily target NOx emissions with 20-40% reduction potential, offering less direct regulatory benefit but contributing to overall emissions management strategies.

Vehicle lifetime value considerations reveal that while DPF systems have higher upfront and maintenance costs, they provide more substantial emissions reduction benefits. VGT systems offer better performance enhancements and fuel economy improvements, potentially increasing vehicle resale value by 3-7% compared to 1-3% for DPF-equipped vehicles.

Implementation strategy optimization suggests phased approaches for fleet operators. Large fleets benefit from gradual DPF implementation prioritizing urban-operating vehicles, while VGT technology may be more cost-effective for long-haul applications where fuel economy benefits accumulate more rapidly. Manufacturers should consider bundled technology packages offering both systems at reduced combined costs, potentially decreasing total implementation expenses by 10-15% compared to separate installations.

Operational expenses present significant differences between these technologies. DPF systems incur higher maintenance costs due to periodic regeneration requirements and filter replacement (approximately every 100,000-150,000 miles), averaging $600-$1,200 annually. VGT systems demonstrate lower maintenance requirements, with estimated annual costs of $300-$700, primarily for actuator maintenance and calibration.

Fuel economy impacts further differentiate these technologies. DPF systems typically reduce fuel efficiency by 1-3% due to increased back pressure and regeneration cycles, translating to approximately $200-$600 in additional annual fuel costs for commercial vehicles. VGT systems, conversely, can improve fuel efficiency by 2-5% through optimized air delivery across the engine's operating range, potentially saving $400-$1,000 annually in fuel expenses.

Regulatory compliance benefits must be factored into the cost-benefit equation. DPF technology directly addresses particulate matter emissions, reducing them by 85-95%, which can prevent non-compliance penalties ranging from $5,000-$25,000 depending on jurisdiction. VGT systems primarily target NOx emissions with 20-40% reduction potential, offering less direct regulatory benefit but contributing to overall emissions management strategies.

Vehicle lifetime value considerations reveal that while DPF systems have higher upfront and maintenance costs, they provide more substantial emissions reduction benefits. VGT systems offer better performance enhancements and fuel economy improvements, potentially increasing vehicle resale value by 3-7% compared to 1-3% for DPF-equipped vehicles.

Implementation strategy optimization suggests phased approaches for fleet operators. Large fleets benefit from gradual DPF implementation prioritizing urban-operating vehicles, while VGT technology may be more cost-effective for long-haul applications where fuel economy benefits accumulate more rapidly. Manufacturers should consider bundled technology packages offering both systems at reduced combined costs, potentially decreasing total implementation expenses by 10-15% compared to separate installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!