Measuring Diesel Particulate Filter Flow Resistance

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emission regulations worldwide. These filtration systems were designed to capture and remove particulate matter (PM) from diesel engine exhaust, addressing one of the most significant environmental concerns associated with diesel combustion. The evolution of DPF technology has been marked by continuous improvements in filter materials, regeneration strategies, and monitoring systems to enhance efficiency and durability.

The primary function of a DPF is to trap soot particles while allowing exhaust gases to pass through. This filtration process inevitably creates flow resistance, which directly impacts engine backpressure and consequently affects fuel efficiency and engine performance. Understanding and accurately measuring this flow resistance has become a critical aspect of DPF design and optimization.

Historical developments in DPF technology show a progression from simple ceramic monolith structures to advanced cordierite and silicon carbide materials with optimized channel geometries. Each advancement has aimed to balance the conflicting requirements of high filtration efficiency and minimal flow resistance. The technical trajectory demonstrates a shift from passive systems requiring manual intervention to sophisticated active systems with integrated sensors and control algorithms.

Current industry trends indicate a growing emphasis on real-time monitoring and predictive maintenance capabilities for DPF systems. This shift is driven by the need to optimize vehicle performance while maintaining compliance with increasingly stringent emission standards such as Euro 7, China 7, and US EPA 2027 regulations. These standards are pushing the technological boundaries, requiring more precise measurement and control of DPF flow resistance.

The technical objectives for measuring DPF flow resistance encompass several dimensions. First, developing accurate and reliable measurement methodologies that can be implemented both in laboratory settings and on-board vehicles. Second, establishing standardized testing protocols to ensure consistency across the industry. Third, creating predictive models that can anticipate changes in flow resistance based on operating conditions and soot loading levels.

Additionally, there is a growing need for cost-effective solutions that can be integrated into existing vehicle diagnostic systems. This integration would enable real-time monitoring of DPF condition, optimizing regeneration timing and reducing unnecessary fuel consumption. The ultimate goal is to achieve a balance between environmental compliance, vehicle performance, and operational efficiency through precise understanding and control of DPF flow resistance characteristics.

As emission regulations continue to evolve globally, the importance of accurate DPF flow resistance measurement will only increase, driving further innovation in this critical area of automotive engineering.

The primary function of a DPF is to trap soot particles while allowing exhaust gases to pass through. This filtration process inevitably creates flow resistance, which directly impacts engine backpressure and consequently affects fuel efficiency and engine performance. Understanding and accurately measuring this flow resistance has become a critical aspect of DPF design and optimization.

Historical developments in DPF technology show a progression from simple ceramic monolith structures to advanced cordierite and silicon carbide materials with optimized channel geometries. Each advancement has aimed to balance the conflicting requirements of high filtration efficiency and minimal flow resistance. The technical trajectory demonstrates a shift from passive systems requiring manual intervention to sophisticated active systems with integrated sensors and control algorithms.

Current industry trends indicate a growing emphasis on real-time monitoring and predictive maintenance capabilities for DPF systems. This shift is driven by the need to optimize vehicle performance while maintaining compliance with increasingly stringent emission standards such as Euro 7, China 7, and US EPA 2027 regulations. These standards are pushing the technological boundaries, requiring more precise measurement and control of DPF flow resistance.

The technical objectives for measuring DPF flow resistance encompass several dimensions. First, developing accurate and reliable measurement methodologies that can be implemented both in laboratory settings and on-board vehicles. Second, establishing standardized testing protocols to ensure consistency across the industry. Third, creating predictive models that can anticipate changes in flow resistance based on operating conditions and soot loading levels.

Additionally, there is a growing need for cost-effective solutions that can be integrated into existing vehicle diagnostic systems. This integration would enable real-time monitoring of DPF condition, optimizing regeneration timing and reducing unnecessary fuel consumption. The ultimate goal is to achieve a balance between environmental compliance, vehicle performance, and operational efficiency through precise understanding and control of DPF flow resistance characteristics.

As emission regulations continue to evolve globally, the importance of accurate DPF flow resistance measurement will only increase, driving further innovation in this critical area of automotive engineering.

Market Demand Analysis for DPF Flow Resistance Measurement

The global market for Diesel Particulate Filter (DPF) flow resistance measurement technologies has experienced significant growth in recent years, driven primarily by increasingly stringent emission regulations worldwide. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's National VI emission standards have all created substantial demand for precise DPF monitoring and testing equipment. This regulatory landscape has transformed what was once a niche market into a critical component of the automotive and heavy equipment industries.

Market research indicates that the DPF testing equipment market reached approximately $1.2 billion in 2022, with a projected compound annual growth rate of 5.7% through 2028. The demand is particularly strong in regions with mature automotive manufacturing sectors, including Western Europe, North America, and East Asia. The aftermarket segment represents nearly 40% of this demand, as regular DPF maintenance becomes standard practice for fleet operators and service centers.

Commercial vehicle applications currently dominate the market demand, accounting for roughly 65% of total sales. This is attributed to the higher soot accumulation rates in commercial diesel engines and the significant operational costs associated with DPF failures in these vehicles. However, the passenger vehicle segment is showing the fastest growth rate as diesel cars, particularly in European markets, face similar regulatory pressures.

Industry surveys reveal that end-users prioritize measurement accuracy, testing speed, and integration capabilities when selecting DPF flow resistance measurement solutions. There is a growing preference for portable testing equipment that can be used in field conditions, with 78% of fleet maintenance managers expressing interest in on-site diagnostic capabilities rather than laboratory-only solutions.

The market is also witnessing a shift toward comprehensive DPF monitoring systems that incorporate real-time flow resistance measurement alongside other parameters such as temperature distribution and particulate matter concentration. This trend reflects the industry's move toward predictive maintenance approaches rather than reactive replacements.

Emerging economies present significant growth opportunities, with India, Brazil, and Southeast Asian nations implementing stricter emission standards that necessitate advanced DPF testing capabilities. Market penetration in these regions remains relatively low, with adoption rates at approximately 30% compared to developed markets, indicating substantial room for expansion.

Customer feedback indicates growing demand for measurement technologies that can accurately predict DPF lifespan and optimize regeneration cycles, potentially reducing operational costs by 15-20% through improved maintenance scheduling. This represents a key value proposition for manufacturers developing next-generation flow resistance measurement solutions.

Market research indicates that the DPF testing equipment market reached approximately $1.2 billion in 2022, with a projected compound annual growth rate of 5.7% through 2028. The demand is particularly strong in regions with mature automotive manufacturing sectors, including Western Europe, North America, and East Asia. The aftermarket segment represents nearly 40% of this demand, as regular DPF maintenance becomes standard practice for fleet operators and service centers.

Commercial vehicle applications currently dominate the market demand, accounting for roughly 65% of total sales. This is attributed to the higher soot accumulation rates in commercial diesel engines and the significant operational costs associated with DPF failures in these vehicles. However, the passenger vehicle segment is showing the fastest growth rate as diesel cars, particularly in European markets, face similar regulatory pressures.

Industry surveys reveal that end-users prioritize measurement accuracy, testing speed, and integration capabilities when selecting DPF flow resistance measurement solutions. There is a growing preference for portable testing equipment that can be used in field conditions, with 78% of fleet maintenance managers expressing interest in on-site diagnostic capabilities rather than laboratory-only solutions.

The market is also witnessing a shift toward comprehensive DPF monitoring systems that incorporate real-time flow resistance measurement alongside other parameters such as temperature distribution and particulate matter concentration. This trend reflects the industry's move toward predictive maintenance approaches rather than reactive replacements.

Emerging economies present significant growth opportunities, with India, Brazil, and Southeast Asian nations implementing stricter emission standards that necessitate advanced DPF testing capabilities. Market penetration in these regions remains relatively low, with adoption rates at approximately 30% compared to developed markets, indicating substantial room for expansion.

Customer feedback indicates growing demand for measurement technologies that can accurately predict DPF lifespan and optimize regeneration cycles, potentially reducing operational costs by 15-20% through improved maintenance scheduling. This represents a key value proposition for manufacturers developing next-generation flow resistance measurement solutions.

Current Challenges in DPF Flow Resistance Measurement

Despite significant advancements in Diesel Particulate Filter (DPF) technology, accurate measurement of flow resistance remains a persistent challenge for researchers and manufacturers. Current measurement methodologies suffer from several limitations that impact reliability and reproducibility of results. The primary challenge lies in the dynamic nature of DPF systems, where flow resistance continuously changes as soot accumulates and regeneration cycles occur, making point-in-time measurements potentially misleading for long-term performance evaluation.

Laboratory testing environments often fail to replicate real-world operating conditions, creating a disconnect between bench test results and actual on-road performance. Temperature variations, exhaust gas composition, and flow rate fluctuations in real driving scenarios significantly affect DPF flow resistance characteristics, yet standardized testing protocols struggle to account for these variables comprehensively.

Measurement precision presents another significant hurdle, particularly for advanced DPF designs with complex channel geometries and variable cell densities. Traditional pressure drop measurements across the filter may not adequately characterize localized flow resistance variations, which can lead to incomplete understanding of filter performance and premature failure predictions.

The industry also faces challenges with measurement equipment calibration and standardization. Different testing apparatus and methodologies employed across research institutions and manufacturers create difficulties in comparing results and establishing universal performance benchmarks. This lack of standardization impedes knowledge sharing and slows technological advancement in the field.

Non-uniform soot loading patterns further complicate accurate flow resistance measurement. Uneven distribution of particulate matter within the filter creates zones of varying resistance that are difficult to characterize with current measurement techniques. Most existing methods provide only aggregate resistance values rather than spatial distribution data that would be valuable for optimizing filter designs.

Time-dependent phenomena, such as ash accumulation and thermal aging effects, introduce additional complexity to flow resistance measurement. Current testing protocols typically focus on short-term performance, failing to capture the gradual changes in filter characteristics over thousands of operating hours. This limitation hinders the development of predictive models for DPF lifespan and maintenance intervals.

Integration of sensors for continuous in-situ monitoring represents a promising but underdeveloped approach. Current sensor technologies suffer from durability issues in the harsh exhaust environment and often lack the sensitivity required for early detection of flow resistance changes. The cost-effectiveness of advanced sensing solutions also remains a barrier to widespread implementation in commercial vehicles.

Laboratory testing environments often fail to replicate real-world operating conditions, creating a disconnect between bench test results and actual on-road performance. Temperature variations, exhaust gas composition, and flow rate fluctuations in real driving scenarios significantly affect DPF flow resistance characteristics, yet standardized testing protocols struggle to account for these variables comprehensively.

Measurement precision presents another significant hurdle, particularly for advanced DPF designs with complex channel geometries and variable cell densities. Traditional pressure drop measurements across the filter may not adequately characterize localized flow resistance variations, which can lead to incomplete understanding of filter performance and premature failure predictions.

The industry also faces challenges with measurement equipment calibration and standardization. Different testing apparatus and methodologies employed across research institutions and manufacturers create difficulties in comparing results and establishing universal performance benchmarks. This lack of standardization impedes knowledge sharing and slows technological advancement in the field.

Non-uniform soot loading patterns further complicate accurate flow resistance measurement. Uneven distribution of particulate matter within the filter creates zones of varying resistance that are difficult to characterize with current measurement techniques. Most existing methods provide only aggregate resistance values rather than spatial distribution data that would be valuable for optimizing filter designs.

Time-dependent phenomena, such as ash accumulation and thermal aging effects, introduce additional complexity to flow resistance measurement. Current testing protocols typically focus on short-term performance, failing to capture the gradual changes in filter characteristics over thousands of operating hours. This limitation hinders the development of predictive models for DPF lifespan and maintenance intervals.

Integration of sensors for continuous in-situ monitoring represents a promising but underdeveloped approach. Current sensor technologies suffer from durability issues in the harsh exhaust environment and often lack the sensitivity required for early detection of flow resistance changes. The cost-effectiveness of advanced sensing solutions also remains a barrier to widespread implementation in commercial vehicles.

Current Methodologies for DPF Flow Resistance Assessment

01 Filter design and structure for optimizing flow resistance

The design and structure of diesel particulate filters significantly impact flow resistance. Key design elements include pore size distribution, wall thickness, cell density, and channel geometry. Optimized filter structures can reduce backpressure while maintaining filtration efficiency. Advanced manufacturing techniques allow for creating filters with balanced flow characteristics that minimize engine performance impacts while effectively capturing particulate matter.- Filter design and structure for flow resistance optimization: The design and structure of diesel particulate filters significantly impact flow resistance. Innovations include optimized cell density, wall thickness, and channel configurations to reduce backpressure while maintaining filtration efficiency. Advanced geometric designs such as asymmetric channels and variable cell structures help balance the trade-off between flow resistance and particulate capture capability.

- Flow resistance monitoring and measurement techniques: Various methods and systems have been developed to monitor and measure flow resistance in diesel particulate filters. These include pressure differential sensors, flow rate measurements, and advanced diagnostic systems that can detect changes in filter performance. Real-time monitoring allows for timely regeneration decisions and helps prevent excessive backpressure that could damage the engine or reduce efficiency.

- Regeneration strategies to manage flow resistance: Regeneration strategies are crucial for managing flow resistance in diesel particulate filters. These include active regeneration using fuel injection or heating elements, passive regeneration through catalyst coatings, and combined approaches. Optimized regeneration timing and conditions help maintain acceptable flow resistance levels while ensuring complete soot oxidation and preventing thermal damage to the filter.

- Material innovations for improved flow characteristics: Advanced materials and coatings have been developed to improve flow characteristics in diesel particulate filters. These include porous ceramic materials with optimized pore size distribution, catalyst coatings that lower soot ignition temperatures, and novel substrate materials with enhanced thermal stability. These innovations help reduce flow resistance while maintaining or improving filtration efficiency and durability.

- System integration and control strategies: Comprehensive system integration and control strategies are essential for managing diesel particulate filter flow resistance. These include adaptive control algorithms that adjust engine operation based on filter condition, integration with other emission control systems, and predictive models that optimize regeneration timing. Advanced control strategies help balance flow resistance management with fuel efficiency, emissions compliance, and system durability requirements.

02 Measurement and monitoring of DPF flow resistance

Various methods and systems are employed to measure and monitor flow resistance in diesel particulate filters. These include pressure differential sensors, flow rate measurements, and computational models. Real-time monitoring systems can detect changes in filter resistance, allowing for timely regeneration or maintenance. Advanced diagnostic techniques help predict filter clogging and optimize vehicle performance by providing accurate data on filter condition and flow characteristics.Expand Specific Solutions03 Regeneration strategies to reduce flow resistance

Regeneration strategies are crucial for managing flow resistance in diesel particulate filters. These include active regeneration using fuel injection or heating elements, passive regeneration through catalyst coatings, and combined approaches. Controlled regeneration processes help remove accumulated soot and ash that increase backpressure. Optimized regeneration timing and conditions can extend filter life while maintaining acceptable flow resistance levels throughout the operational cycle.Expand Specific Solutions04 Catalyst coatings and materials to improve flow characteristics

Specialized catalyst coatings and filter materials can significantly improve flow characteristics in diesel particulate filters. Advanced materials such as cordierite, silicon carbide, and aluminum titanate provide thermal stability while optimizing pore structure. Catalyst formulations containing precious metals or metal oxides promote passive soot oxidation at lower temperatures, reducing the buildup of flow-restricting deposits. These materials can be engineered to balance filtration efficiency with acceptable flow resistance.Expand Specific Solutions05 System integration and control strategies for managing DPF flow resistance

Comprehensive system integration and control strategies are essential for managing diesel particulate filter flow resistance. These include adaptive engine control algorithms, exhaust system design optimization, and integration with other aftertreatment components. Advanced control systems can adjust operating parameters based on filter condition, driving patterns, and environmental factors. Holistic approaches that consider the entire exhaust system help maintain optimal flow characteristics while meeting emissions requirements and fuel efficiency targets.Expand Specific Solutions

Key Industry Players in DPF Measurement Systems

The diesel particulate filter (DPF) flow resistance measurement technology market is currently in a growth phase, driven by increasingly stringent global emissions regulations. The market size is expanding steadily, with projections indicating significant growth as diesel vehicles continue to require advanced filtration systems. Technologically, this field shows varying maturity levels across different applications. Leading automotive manufacturers like Robert Bosch, Nissan, Hyundai, BMW, and Ford are developing proprietary measurement technologies, while specialized component suppliers such as Corning, IBIDEN, and NGK Insulators focus on filter substrate innovations. Research institutions like MIT and Jilin University contribute fundamental knowledge, while environmental technology companies including Umicore and Kailong High Technology are advancing catalyst integration with measurement systems. The competitive landscape features both established players and emerging specialists working to optimize DPF performance monitoring.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Diesel Particulate Filter (DPF) flow resistance measurement systems that integrate pressure differential sensors with sophisticated algorithms for real-time monitoring. Their approach utilizes multiple pressure sensors positioned strategically across the filter to measure pressure drop under various operating conditions. The system incorporates temperature compensation mechanisms to account for exhaust gas density variations, ensuring accurate measurements across different engine loads and ambient conditions. Bosch's technology includes predictive modeling capabilities that can estimate filter loading based on historical data patterns and current operating parameters, allowing for optimized regeneration timing. Their solution also features closed-loop control systems that continuously adjust engine parameters based on measured DPF backpressure to maintain optimal engine performance while ensuring emission compliance.

Strengths: High measurement accuracy across diverse operating conditions; integrated system approach that combines hardware sensors with sophisticated software algorithms; robust temperature compensation. Weaknesses: Higher system complexity and cost compared to simpler measurement approaches; requires extensive calibration for different engine types and DPF configurations.

Corning, Inc.

Technical Solution: Corning has pioneered innovative approaches to measuring DPF flow resistance through their DuraTrap® filter technology. Their methodology incorporates specialized testing equipment that measures pressure drop across their ceramic filters under standardized conditions. Corning's approach includes both laboratory bench testing and in-situ measurement techniques. For laboratory testing, they utilize controlled airflow systems that precisely measure filter permeability at different soot loading levels. Their in-vehicle measurement systems employ differential pressure sensors combined with mass airflow measurements to calculate real-time flow resistance. Corning has developed proprietary mathematical models that correlate pressure drop measurements with soot loading levels, enabling accurate prediction of filter status. Their technology also includes specialized testing protocols for measuring both clean filter resistance and resistance changes throughout the filter lifecycle, providing comprehensive data for filter performance optimization.

Strengths: Extensive experience with ceramic substrate materials allows for highly accurate baseline measurements; comprehensive testing methodology covering both clean and loaded filter states; advanced correlation models between pressure drop and soot loading. Weaknesses: Laboratory measurements may not always translate perfectly to real-world conditions; requires specialized equipment for accurate measurements.

Core Measurement Technologies and Patents Analysis

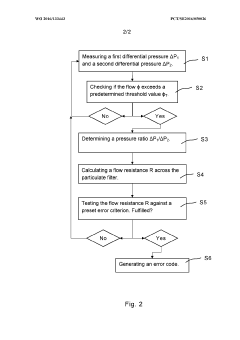

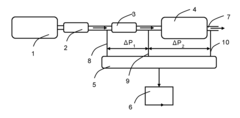

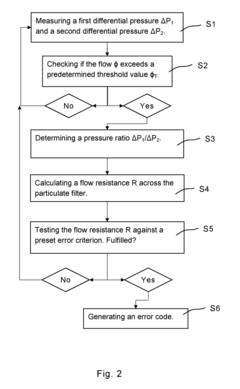

A method and a system for determining a flow resistance across a particulate filter

PatentWO2016133443A1

Innovation

- Measuring the second differential pressure across a selective catalytic reduction (SCR) system, which has a constant flow resistance, allows for accurate determination of the flow resistance across the particulate filter using a single pressure sensing device, compensating for measurement errors and optimizing volume flow estimation.

A method and a system for determining a flow resistance across a particulate filter

PatentActiveUS20180087431A1

Innovation

- Measuring the second differential pressure across a selective catalytic reduction (SCR) system, which has a constant flow resistance, allows for accurate determination of flow resistance across the particulate filter using a single pressure sensing device, compensating for measurement errors and optimizing conditions for accurate volume flow estimation.

Environmental Regulations Impact on DPF Technology

Environmental regulations have been a primary driving force behind the evolution of Diesel Particulate Filter (DPF) technology over the past two decades. The implementation of increasingly stringent emission standards, particularly in Europe, North America, and Asia, has necessitated continuous advancements in DPF design and flow resistance measurement techniques. The Euro 6/VI, US EPA Tier 3, and China 6 standards have established progressively lower particulate matter (PM) emission limits, making efficient DPF systems mandatory for diesel engine manufacturers.

These regulations have directly influenced the technical specifications of DPFs, requiring higher filtration efficiencies while maintaining acceptable back pressure levels. The trade-off between filtration efficiency and flow resistance has become a critical design consideration, with regulatory bodies now specifying not only emission limits but also durability requirements and in-use compliance testing protocols that directly relate to filter flow characteristics.

The regulatory landscape has also shifted toward real-world driving emissions (RDE) testing, which has exposed the limitations of laboratory-optimized DPF systems. This regulatory evolution has accelerated the development of more sophisticated flow resistance measurement methodologies that can accurately predict DPF performance under variable operating conditions, including cold starts and low-speed urban driving scenarios where traditional measurement approaches often fall short.

Regulatory requirements for on-board diagnostics (OBD) have further complicated DPF technology development, as systems must now continuously monitor filter condition and provide early warning of potential failures. This has led to innovations in indirect flow resistance measurement techniques that can be implemented in production vehicles, such as differential pressure sensors coupled with advanced algorithms to compensate for varying exhaust temperatures and flow rates.

The timeline of regulatory implementation has created distinct technology adoption patterns across global markets. Regions with earlier implementation of strict PM standards, such as Europe and Japan, have developed more mature measurement methodologies and DPF technologies. Meanwhile, emerging markets are experiencing accelerated technology transfer as they adopt similar regulatory frameworks, often leapfrogging intermediate technological stages.

Looking forward, upcoming regulations are focusing on particle number (PN) limits rather than just mass-based measurements, which will further challenge current DPF designs and necessitate even more precise flow resistance characterization methods. The regulatory trend toward lifecycle emissions accounting is also likely to influence future DPF technology, with increasing emphasis on maintaining optimal flow characteristics throughout the vehicle's operational life.

These regulations have directly influenced the technical specifications of DPFs, requiring higher filtration efficiencies while maintaining acceptable back pressure levels. The trade-off between filtration efficiency and flow resistance has become a critical design consideration, with regulatory bodies now specifying not only emission limits but also durability requirements and in-use compliance testing protocols that directly relate to filter flow characteristics.

The regulatory landscape has also shifted toward real-world driving emissions (RDE) testing, which has exposed the limitations of laboratory-optimized DPF systems. This regulatory evolution has accelerated the development of more sophisticated flow resistance measurement methodologies that can accurately predict DPF performance under variable operating conditions, including cold starts and low-speed urban driving scenarios where traditional measurement approaches often fall short.

Regulatory requirements for on-board diagnostics (OBD) have further complicated DPF technology development, as systems must now continuously monitor filter condition and provide early warning of potential failures. This has led to innovations in indirect flow resistance measurement techniques that can be implemented in production vehicles, such as differential pressure sensors coupled with advanced algorithms to compensate for varying exhaust temperatures and flow rates.

The timeline of regulatory implementation has created distinct technology adoption patterns across global markets. Regions with earlier implementation of strict PM standards, such as Europe and Japan, have developed more mature measurement methodologies and DPF technologies. Meanwhile, emerging markets are experiencing accelerated technology transfer as they adopt similar regulatory frameworks, often leapfrogging intermediate technological stages.

Looking forward, upcoming regulations are focusing on particle number (PN) limits rather than just mass-based measurements, which will further challenge current DPF designs and necessitate even more precise flow resistance characterization methods. The regulatory trend toward lifecycle emissions accounting is also likely to influence future DPF technology, with increasing emphasis on maintaining optimal flow characteristics throughout the vehicle's operational life.

Cost-Benefit Analysis of Advanced DPF Measurement Systems

When evaluating the implementation of advanced Diesel Particulate Filter (DPF) measurement systems, a comprehensive cost-benefit analysis is essential for stakeholders to make informed decisions. The initial investment in sophisticated DPF flow resistance measurement equipment typically ranges from $50,000 to $200,000, depending on the technology sophistication, measurement accuracy, and automation capabilities. This capital expenditure represents a significant barrier for smaller operations but may be justified for larger fleet managers and manufacturing facilities.

Operational costs must also be considered, including calibration requirements (typically $2,000-5,000 annually), specialized training for technicians ($1,500-3,000 per technician), and maintenance contracts (approximately 10-15% of the initial equipment cost annually). These recurring expenses can accumulate substantially over the equipment's lifecycle, estimated at 7-10 years.

The quantifiable benefits of advanced measurement systems include significant reductions in false DPF replacements, which average $1,500-4,000 per unit. Studies indicate that precise measurement systems can reduce unnecessary replacements by 30-40%, translating to substantial savings for operations with large diesel fleets. Additionally, optimized regeneration cycles enabled by accurate flow resistance data can extend DPF lifespan by 15-25%, representing considerable long-term value.

Improved fuel efficiency presents another measurable benefit. Advanced measurement systems allow for more precise DPF maintenance scheduling, potentially improving fuel economy by 2-5%. For commercial fleets consuming thousands of gallons annually, this efficiency gain translates to substantial operational savings.

Less tangible but equally important benefits include reduced vehicle downtime, with advanced systems capable of completing measurements in minutes rather than hours. This efficiency can reduce diagnostic time by up to 70%, significantly improving workshop throughput and vehicle availability.

Environmental compliance benefits must also factor into the analysis. With increasingly stringent emissions regulations worldwide, accurate DPF performance monitoring helps organizations avoid non-compliance penalties, which can range from $10,000 to over $100,000 depending on jurisdiction and violation severity.

The return on investment timeline varies by implementation scale. Large fleet operations typically achieve ROI within 18-24 months, while smaller operations may require 3-4 years to realize full financial benefits. This timeline consideration is crucial for financial planning and justification of the initial investment.

For organizations considering advanced DPF measurement systems, a phased implementation approach often provides the optimal balance between immediate costs and long-term benefits, allowing for validation of the technology's value before full-scale deployment.

Operational costs must also be considered, including calibration requirements (typically $2,000-5,000 annually), specialized training for technicians ($1,500-3,000 per technician), and maintenance contracts (approximately 10-15% of the initial equipment cost annually). These recurring expenses can accumulate substantially over the equipment's lifecycle, estimated at 7-10 years.

The quantifiable benefits of advanced measurement systems include significant reductions in false DPF replacements, which average $1,500-4,000 per unit. Studies indicate that precise measurement systems can reduce unnecessary replacements by 30-40%, translating to substantial savings for operations with large diesel fleets. Additionally, optimized regeneration cycles enabled by accurate flow resistance data can extend DPF lifespan by 15-25%, representing considerable long-term value.

Improved fuel efficiency presents another measurable benefit. Advanced measurement systems allow for more precise DPF maintenance scheduling, potentially improving fuel economy by 2-5%. For commercial fleets consuming thousands of gallons annually, this efficiency gain translates to substantial operational savings.

Less tangible but equally important benefits include reduced vehicle downtime, with advanced systems capable of completing measurements in minutes rather than hours. This efficiency can reduce diagnostic time by up to 70%, significantly improving workshop throughput and vehicle availability.

Environmental compliance benefits must also factor into the analysis. With increasingly stringent emissions regulations worldwide, accurate DPF performance monitoring helps organizations avoid non-compliance penalties, which can range from $10,000 to over $100,000 depending on jurisdiction and violation severity.

The return on investment timeline varies by implementation scale. Large fleet operations typically achieve ROI within 18-24 months, while smaller operations may require 3-4 years to realize full financial benefits. This timeline consideration is crucial for financial planning and justification of the initial investment.

For organizations considering advanced DPF measurement systems, a phased implementation approach often provides the optimal balance between immediate costs and long-term benefits, allowing for validation of the technology's value before full-scale deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!