Diesel Particulate Filter's Role in Hybrid Engines

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Evolution and Objectives

Diesel Particulate Filters (DPFs) have evolved significantly since their introduction in the early 1980s as a response to increasingly stringent emission regulations. Initially developed for heavy-duty diesel applications, these filtration systems were primarily designed to capture particulate matter (PM) emissions, which pose serious health and environmental concerns. The first-generation DPFs featured simple wall-flow monolith structures made of cordierite or silicon carbide, offering filtration efficiencies of approximately 70-85%.

By the late 1990s, second-generation DPFs emerged with improved substrate materials and enhanced coating technologies, pushing filtration efficiencies beyond 95%. This period marked a critical transition as automotive manufacturers began integrating these systems into passenger vehicles to meet Euro 4 and US Tier 2 emission standards. The technology's evolution was characterized by advancements in regeneration strategies, transitioning from active systems requiring external heating to more sophisticated passive-active hybrid approaches.

The 2010s witnessed the third generation of DPF technology, featuring multi-functional substrates that combined particulate filtration with catalytic conversion capabilities. These integrated systems addressed multiple pollutants simultaneously, representing a significant leap in emission control technology. Concurrently, sensor technology and control algorithms evolved to enable real-time monitoring and adaptive regeneration strategies, optimizing filter performance across diverse operating conditions.

In the context of hybrid powertrains, DPF technology faces unique challenges and opportunities. Hybrid vehicles' intermittent engine operation creates distinctive temperature profiles and exhaust flow patterns that conventional DPF systems were not designed to accommodate. The primary technical objective for DPF integration in hybrid applications is maintaining effective regeneration during shorter engine operation periods and lower average exhaust temperatures.

Current development trajectories focus on several key objectives: reducing thermal mass to enable faster light-off and regeneration cycles; developing advanced materials capable of withstanding rapid temperature fluctuations; implementing predictive control algorithms that anticipate driving patterns to optimize regeneration timing; and creating compact designs that accommodate the space constraints of hybrid architectures.

The evolution of DPF technology for hybrid applications also aims to address the "cold start" challenge, which is exacerbated in hybrid vehicles due to frequent engine shutdowns. Innovative approaches include electrically heated substrates, phase-change materials for thermal management, and integration with other emission control components to create more compact and efficient exhaust aftertreatment systems.

Looking forward, DPF technology for hybrid applications is evolving toward intelligent systems that communicate with vehicle powertrain controllers to optimize engine operation for both emissions control and fuel efficiency. This represents a paradigm shift from reactive aftertreatment to proactive emission management strategies tailored to the unique operational characteristics of hybrid powertrains.

By the late 1990s, second-generation DPFs emerged with improved substrate materials and enhanced coating technologies, pushing filtration efficiencies beyond 95%. This period marked a critical transition as automotive manufacturers began integrating these systems into passenger vehicles to meet Euro 4 and US Tier 2 emission standards. The technology's evolution was characterized by advancements in regeneration strategies, transitioning from active systems requiring external heating to more sophisticated passive-active hybrid approaches.

The 2010s witnessed the third generation of DPF technology, featuring multi-functional substrates that combined particulate filtration with catalytic conversion capabilities. These integrated systems addressed multiple pollutants simultaneously, representing a significant leap in emission control technology. Concurrently, sensor technology and control algorithms evolved to enable real-time monitoring and adaptive regeneration strategies, optimizing filter performance across diverse operating conditions.

In the context of hybrid powertrains, DPF technology faces unique challenges and opportunities. Hybrid vehicles' intermittent engine operation creates distinctive temperature profiles and exhaust flow patterns that conventional DPF systems were not designed to accommodate. The primary technical objective for DPF integration in hybrid applications is maintaining effective regeneration during shorter engine operation periods and lower average exhaust temperatures.

Current development trajectories focus on several key objectives: reducing thermal mass to enable faster light-off and regeneration cycles; developing advanced materials capable of withstanding rapid temperature fluctuations; implementing predictive control algorithms that anticipate driving patterns to optimize regeneration timing; and creating compact designs that accommodate the space constraints of hybrid architectures.

The evolution of DPF technology for hybrid applications also aims to address the "cold start" challenge, which is exacerbated in hybrid vehicles due to frequent engine shutdowns. Innovative approaches include electrically heated substrates, phase-change materials for thermal management, and integration with other emission control components to create more compact and efficient exhaust aftertreatment systems.

Looking forward, DPF technology for hybrid applications is evolving toward intelligent systems that communicate with vehicle powertrain controllers to optimize engine operation for both emissions control and fuel efficiency. This represents a paradigm shift from reactive aftertreatment to proactive emission management strategies tailored to the unique operational characteristics of hybrid powertrains.

Hybrid Market DPF Demand Analysis

The hybrid vehicle market has witnessed significant growth over the past decade, with global sales increasing from 1.98 million units in 2010 to over 5.8 million units in 2022. This growth trajectory creates a specialized demand for Diesel Particulate Filters (DPFs) that differs substantially from traditional diesel vehicle applications. Market analysis indicates that approximately 27% of hybrid vehicles globally incorporate diesel powertrains, primarily in the mid-size to large vehicle segments and commercial applications.

Regional analysis reveals distinct patterns in hybrid-DPF demand. Europe leads with the highest adoption rate of diesel hybrid systems at 38% of its hybrid market, driven by stringent Euro 6d and upcoming Euro 7 emissions standards. Asia-Pacific follows with 22% adoption, while North America shows limited demand at only 8% of hybrid sales incorporating diesel technology.

The commercial vehicle sector represents the most promising growth segment for hybrid-DPF systems. Market forecasts project a compound annual growth rate of 14.3% for diesel hybrid commercial vehicles through 2028, compared to 9.7% for the broader hybrid market. This specialized segment values the extended range and torque characteristics of diesel hybrids for delivery, utility, and medium-duty applications.

Consumer demand patterns indicate a preference shift toward hybrid systems that maximize both emissions reduction and fuel efficiency. Survey data from fleet operators shows 67% prioritize total cost of ownership over initial purchase price, creating opportunities for advanced DPF systems that demonstrate superior longevity and regeneration efficiency in hybrid-specific duty cycles.

Market pricing analysis reveals a premium positioning for hybrid-specific DPF systems, commanding 15-20% higher prices than conventional diesel counterparts due to their specialized design requirements. This premium is justified by the unique operating conditions in hybrid powertrains, where intermittent engine operation creates distinct particulate accumulation patterns requiring specialized filtration strategies.

Competitive landscape assessment identifies three emerging market segments: premium hybrid SUVs and luxury vehicles, commercial delivery fleets, and specialized industrial applications. Each segment presents distinct requirements for DPF technology, with varying emphasis on size constraints, regeneration frequency, and integration with hybrid control systems.

Future market projections indicate that while overall diesel vehicle sales may decline, the specialized hybrid-diesel segment will maintain growth through 2030, particularly in commercial applications where electrification faces infrastructure and range limitations.

Regional analysis reveals distinct patterns in hybrid-DPF demand. Europe leads with the highest adoption rate of diesel hybrid systems at 38% of its hybrid market, driven by stringent Euro 6d and upcoming Euro 7 emissions standards. Asia-Pacific follows with 22% adoption, while North America shows limited demand at only 8% of hybrid sales incorporating diesel technology.

The commercial vehicle sector represents the most promising growth segment for hybrid-DPF systems. Market forecasts project a compound annual growth rate of 14.3% for diesel hybrid commercial vehicles through 2028, compared to 9.7% for the broader hybrid market. This specialized segment values the extended range and torque characteristics of diesel hybrids for delivery, utility, and medium-duty applications.

Consumer demand patterns indicate a preference shift toward hybrid systems that maximize both emissions reduction and fuel efficiency. Survey data from fleet operators shows 67% prioritize total cost of ownership over initial purchase price, creating opportunities for advanced DPF systems that demonstrate superior longevity and regeneration efficiency in hybrid-specific duty cycles.

Market pricing analysis reveals a premium positioning for hybrid-specific DPF systems, commanding 15-20% higher prices than conventional diesel counterparts due to their specialized design requirements. This premium is justified by the unique operating conditions in hybrid powertrains, where intermittent engine operation creates distinct particulate accumulation patterns requiring specialized filtration strategies.

Competitive landscape assessment identifies three emerging market segments: premium hybrid SUVs and luxury vehicles, commercial delivery fleets, and specialized industrial applications. Each segment presents distinct requirements for DPF technology, with varying emphasis on size constraints, regeneration frequency, and integration with hybrid control systems.

Future market projections indicate that while overall diesel vehicle sales may decline, the specialized hybrid-diesel segment will maintain growth through 2030, particularly in commercial applications where electrification faces infrastructure and range limitations.

DPF Integration Challenges in Hybrid Systems

The integration of Diesel Particulate Filters (DPFs) into hybrid engine systems presents unique technical challenges that differ significantly from their implementation in conventional diesel powertrains. The primary challenge stems from the intermittent operation of diesel engines in hybrid configurations, which disrupts the normal regeneration cycles necessary for effective DPF functioning.

Temperature management represents a critical obstacle in hybrid applications. DPFs require specific exhaust temperature ranges (typically 550-650°C) to initiate and maintain regeneration processes. In hybrid systems, where the internal combustion engine experiences frequent start-stop cycles or operates at varying loads, maintaining optimal exhaust temperatures becomes problematic. This temperature inconsistency can lead to incomplete regeneration, increased back pressure, and accelerated filter clogging.

Space constraints pose another significant integration challenge. Hybrid powertrains already accommodate multiple systems—electric motors, battery packs, power electronics—in addition to conventional engine components. Finding adequate space for DPF systems without compromising vehicle design or performance parameters requires sophisticated packaging solutions and often necessitates redesign of exhaust routing systems.

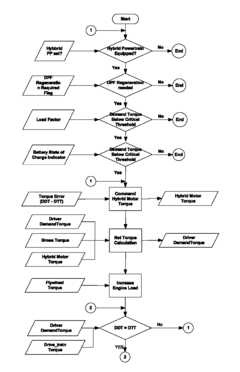

Control system complexity increases substantially when integrating DPFs into hybrid architectures. The engine control unit must coordinate regeneration events with hybrid operation modes, battery state of charge, and driver demands. This requires advanced algorithms capable of predicting optimal regeneration windows and potentially forcing engine operation specifically for filter maintenance, which can counteract the efficiency benefits of hybridization.

Cold-start emissions management becomes more challenging in hybrid vehicles. With reduced engine operation, particularly in urban driving cycles, DPFs may remain at sub-optimal temperatures for extended periods. This can result in increased particulate accumulation and potentially higher emissions during the limited engine operation windows.

Durability concerns also emerge due to thermal cycling. The frequent heating and cooling of the DPF system in hybrid applications can accelerate thermal fatigue of filter materials and mounting components. This may necessitate the development of more robust materials or alternative regeneration strategies specifically designed for hybrid duty cycles.

Cost implications cannot be overlooked. The addition of sophisticated DPF systems to already expensive hybrid powertrains increases vehicle cost, potentially affecting market competitiveness. Manufacturers must balance regulatory compliance with cost-effective solutions that maintain the value proposition of hybrid vehicles.

Addressing these integration challenges requires cross-disciplinary approaches combining thermal management expertise, advanced control strategies, and innovative materials science to develop DPF systems specifically optimized for the unique operational characteristics of hybrid powertrains.

Temperature management represents a critical obstacle in hybrid applications. DPFs require specific exhaust temperature ranges (typically 550-650°C) to initiate and maintain regeneration processes. In hybrid systems, where the internal combustion engine experiences frequent start-stop cycles or operates at varying loads, maintaining optimal exhaust temperatures becomes problematic. This temperature inconsistency can lead to incomplete regeneration, increased back pressure, and accelerated filter clogging.

Space constraints pose another significant integration challenge. Hybrid powertrains already accommodate multiple systems—electric motors, battery packs, power electronics—in addition to conventional engine components. Finding adequate space for DPF systems without compromising vehicle design or performance parameters requires sophisticated packaging solutions and often necessitates redesign of exhaust routing systems.

Control system complexity increases substantially when integrating DPFs into hybrid architectures. The engine control unit must coordinate regeneration events with hybrid operation modes, battery state of charge, and driver demands. This requires advanced algorithms capable of predicting optimal regeneration windows and potentially forcing engine operation specifically for filter maintenance, which can counteract the efficiency benefits of hybridization.

Cold-start emissions management becomes more challenging in hybrid vehicles. With reduced engine operation, particularly in urban driving cycles, DPFs may remain at sub-optimal temperatures for extended periods. This can result in increased particulate accumulation and potentially higher emissions during the limited engine operation windows.

Durability concerns also emerge due to thermal cycling. The frequent heating and cooling of the DPF system in hybrid applications can accelerate thermal fatigue of filter materials and mounting components. This may necessitate the development of more robust materials or alternative regeneration strategies specifically designed for hybrid duty cycles.

Cost implications cannot be overlooked. The addition of sophisticated DPF systems to already expensive hybrid powertrains increases vehicle cost, potentially affecting market competitiveness. Manufacturers must balance regulatory compliance with cost-effective solutions that maintain the value proposition of hybrid vehicles.

Addressing these integration challenges requires cross-disciplinary approaches combining thermal management expertise, advanced control strategies, and innovative materials science to develop DPF systems specifically optimized for the unique operational characteristics of hybrid powertrains.

Current DPF Solutions for Hybrid Powertrains

01 DPF Regeneration Systems

Various regeneration systems are employed to burn off accumulated particulate matter in diesel particulate filters, thereby maintaining filter efficiency and reducing emissions. These systems include active regeneration using fuel injection or heating elements, passive regeneration utilizing catalytic coatings, and combined approaches. Advanced control strategies optimize the regeneration timing and conditions based on sensor data, engine load, and exhaust temperature to ensure complete combustion of trapped particulates while minimizing fuel consumption.- DPF Regeneration Systems: Various regeneration systems are employed to burn off accumulated particulate matter in diesel particulate filters. These systems include active regeneration using fuel injection, heating elements, or catalysts to raise exhaust temperatures, and passive regeneration utilizing catalytic coatings that lower the combustion temperature of soot. Effective regeneration systems prevent filter clogging and maintain optimal emission reduction performance while minimizing fuel consumption penalties.

- Filter Design and Materials: Advanced filter designs and materials significantly impact DPF performance. Innovations include wall-flow monoliths with alternately plugged channels, ceramic substrates with optimized porosity, and metal fiber filters with enhanced thermal durability. Novel materials such as silicon carbide, cordierite, and aluminum titanate provide improved filtration efficiency, reduced backpressure, and better thermal resistance, leading to more effective particulate matter capture and lower emissions.

- Catalytic Coatings and Additives: Specialized catalytic coatings and fuel additives enhance DPF performance by lowering soot ignition temperatures and promoting more complete oxidation of particulate matter. These include platinum group metals, base metal oxides, and rare earth compounds applied to filter surfaces. Fuel-borne catalysts containing cerium, iron, or manganese compounds can be added to diesel fuel to improve regeneration efficiency and reduce the formation of ash, resulting in more effective emissions control.

- System Integration and Control Strategies: Sophisticated control strategies and system integration approaches optimize DPF operation across various driving conditions. These include advanced sensors for soot load monitoring, predictive algorithms for regeneration timing, and integration with other emission control systems such as SCR (Selective Catalytic Reduction) and EGR (Exhaust Gas Recirculation). Intelligent control systems balance regeneration needs with fuel economy, adapting to driving patterns and environmental conditions to maximize emission reduction efficiency.

- Combined DPF and NOx Reduction Technologies: Integrated systems combining particulate filtration with NOx reduction technologies provide comprehensive emissions control. These include SCRF (Selective Catalytic Reduction Filter) systems that incorporate SCR catalysts directly onto the DPF substrate, allowing simultaneous removal of particulate matter and NOx. Other approaches involve close-coupled DPF and SCR systems with optimized thermal management to ensure both systems operate within their ideal temperature windows, maximizing overall emission reduction performance.

02 Catalytic Coating Technologies

Specialized catalytic coatings applied to diesel particulate filters enhance their effectiveness in reducing emissions. These coatings typically contain precious metals like platinum, palladium, and rhodium, or other catalytic materials that lower the combustion temperature of particulate matter and convert harmful gases into less toxic substances. Some advanced formulations incorporate multiple layers with different functionalities, such as NOx reduction capabilities combined with particulate matter oxidation, creating multifunctional emission control systems.Expand Specific Solutions03 Filter Design and Material Innovations

Innovations in filter design and materials significantly improve DPF performance and durability. Advanced ceramic materials like silicon carbide and cordierite offer improved thermal resistance and filtration efficiency. Structural innovations include asymmetric cell configurations, variable porosity designs, and optimized channel geometries that maximize filtration area while minimizing backpressure. Some designs incorporate integrated sensors to monitor filter condition and performance in real-time, enabling more precise control of regeneration processes.Expand Specific Solutions04 Exhaust Gas Recirculation and Treatment Systems

Comprehensive exhaust treatment systems combine DPFs with other technologies like Exhaust Gas Recirculation (EGR), Selective Catalytic Reduction (SCR), and Diesel Oxidation Catalysts (DOC) to achieve greater emissions reduction. These integrated systems manage multiple pollutants simultaneously, with sophisticated control algorithms optimizing the operation of each component based on driving conditions, engine parameters, and emission requirements. Some systems incorporate urea injection or other reducing agents to further enhance NOx reduction capabilities.Expand Specific Solutions05 Intelligent Control and Monitoring Systems

Advanced electronic control systems optimize DPF performance through real-time monitoring and adaptive management strategies. These systems utilize multiple sensors to track parameters such as differential pressure, exhaust temperature, and particulate matter load, enabling predictive maintenance and optimized regeneration timing. Machine learning algorithms analyze operational patterns to adapt regeneration strategies to specific driving conditions and usage profiles, while onboard diagnostics provide early warning of potential issues and ensure regulatory compliance throughout the filter's lifecycle.Expand Specific Solutions

Key DPF Manufacturers and OEMs

The diesel particulate filter (DPF) market in hybrid engines is currently in a growth phase, with increasing adoption driven by stringent emission regulations worldwide. The market is projected to expand significantly as hybrid vehicle production increases, particularly in commercial and passenger segments. Technologically, DPF systems for hybrids are evolving rapidly, with companies like Ford Global Technologies, GM Global Technology Operations, and Volvo Lastvagnar leading innovation in integration with hybrid powertrains. Corning and Johnson Matthey dominate in filter substrate technology, while Umicore and Infineum International are advancing catalyst formulations. Automotive OEMs including Hyundai, Stellantis, and Peugeot are focusing on system optimization for hybrid-specific duty cycles. Research collaborations between manufacturers and institutions like MIT and Rutgers are accelerating development of next-generation DPF technologies with enhanced regeneration capabilities specifically designed for hybrid operating conditions.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Diesel Particulate Filter (DPF) system specifically optimized for hybrid powertrains that integrates thermal management strategies with hybrid operation modes. Their solution incorporates a passive regeneration approach that leverages the electric motor during hybrid operation to maintain optimal exhaust temperatures for continuous DPF cleaning. The system uses predictive algorithms to anticipate DPF loading based on driving patterns and automatically adjusts the power split between combustion engine and electric motor to maintain filter efficiency. Ford's technology includes a specialized coating on the DPF substrate that reduces the temperature required for particulate oxidation by approximately 50°C compared to conventional filters, making it particularly suitable for hybrid applications where engines may operate intermittently and at lower temperatures.

Strengths: Seamless integration with hybrid powertrain control systems; reduced need for active regeneration cycles; lower temperature operation suitable for hybrid duty cycles. Weaknesses: May require more complex control algorithms; potential for increased system cost; performance dependent on driving patterns and hybrid usage profile.

Corning, Inc.

Technical Solution: Corning has pioneered specialized DPF substrates designed specifically for hybrid diesel applications. Their DuraTrap® filter technology features an advanced cordierite ceramic honeycomb structure with optimized wall porosity and channel geometry that addresses the unique challenges of hybrid diesel engines. The filters incorporate asymmetric cell technology that increases soot loading capacity by up to 30% while maintaining lower backpressure, critical for maintaining efficiency in hybrid powertrains where the diesel engine operates intermittently. Corning's latest generation filters include a proprietary catalyst coating process that enables effective particulate capture and oxidation at temperatures as low as 250°C, addressing the "cold exhaust" challenge common in hybrid systems. Their manufacturing process creates a precise pore structure distribution that balances filtration efficiency (>98% for PM2.5) with pressure drop characteristics optimized for variable load conditions typical in hybrid operation.

Strengths: Industry-leading filtration efficiency; specialized designs for hybrid thermal profiles; proven durability in field applications. Weaknesses: Premium pricing compared to conventional DPFs; requires specific installation parameters; may need specialized regeneration strategies in certain hybrid architectures.

Critical DPF Patents and Technical Innovations

Method for diesel particulate filter regeneration in a vehicle equipped with a hybrid engine background of the invention

PatentInactiveUS8306710B2

Innovation

- A method that utilizes messaging over a communication bus to control the interaction between the diesel particulate filter aftertreatment system and the hybrid power train, increasing diesel engine load with or without electric motor assistance to elevate exhaust temperatures, and optionally using a resistive heating element when the battery is fully charged to optimize regeneration time.

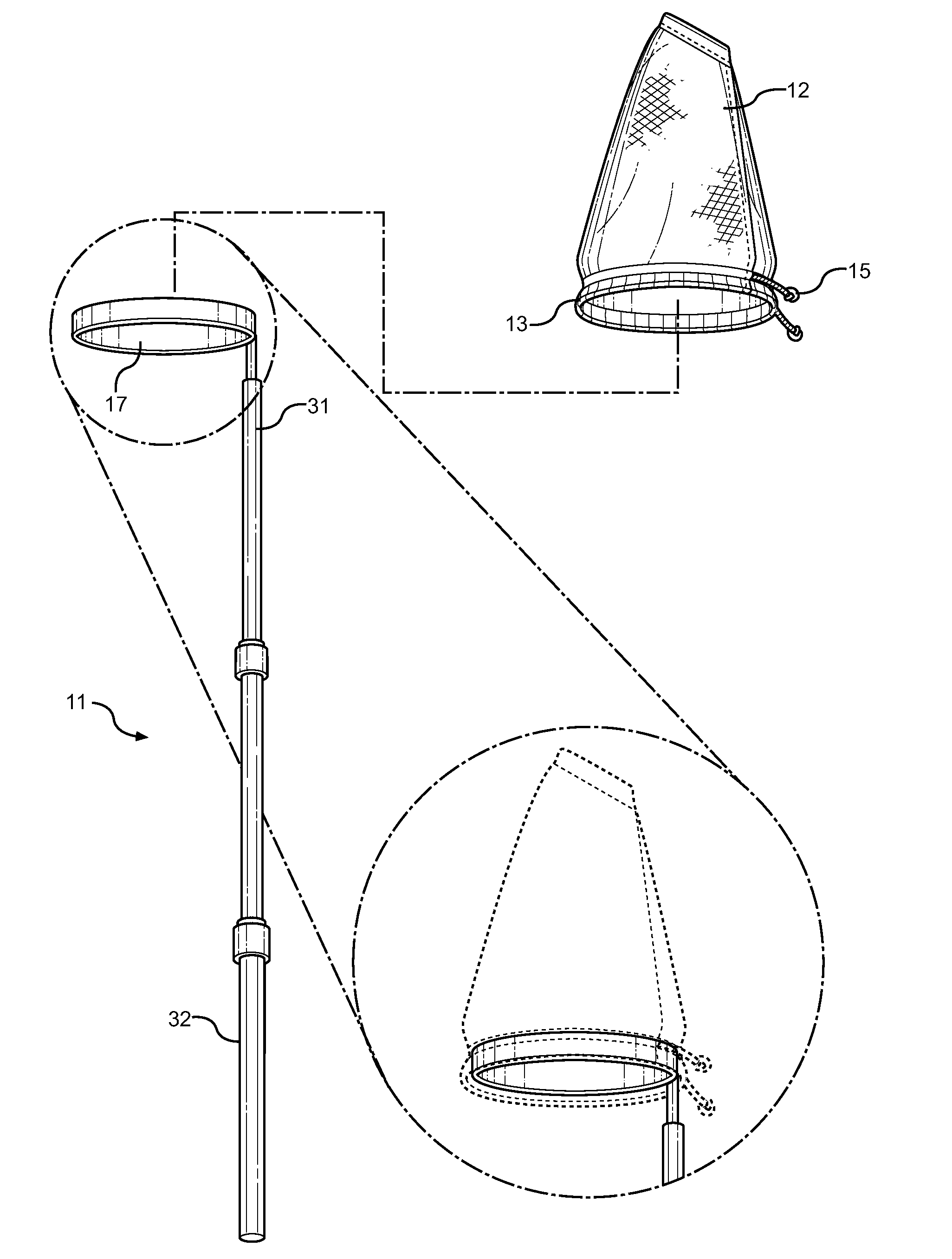

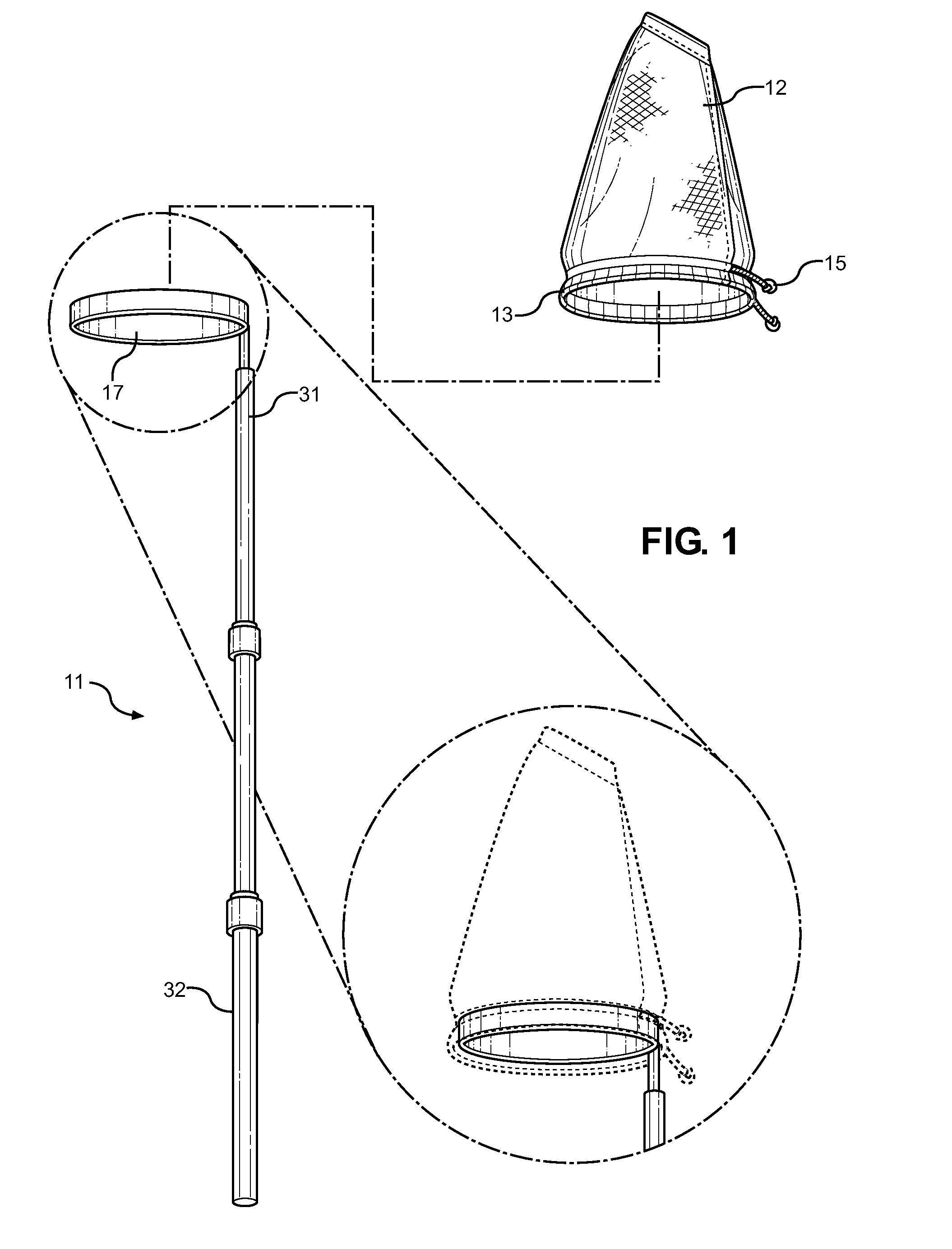

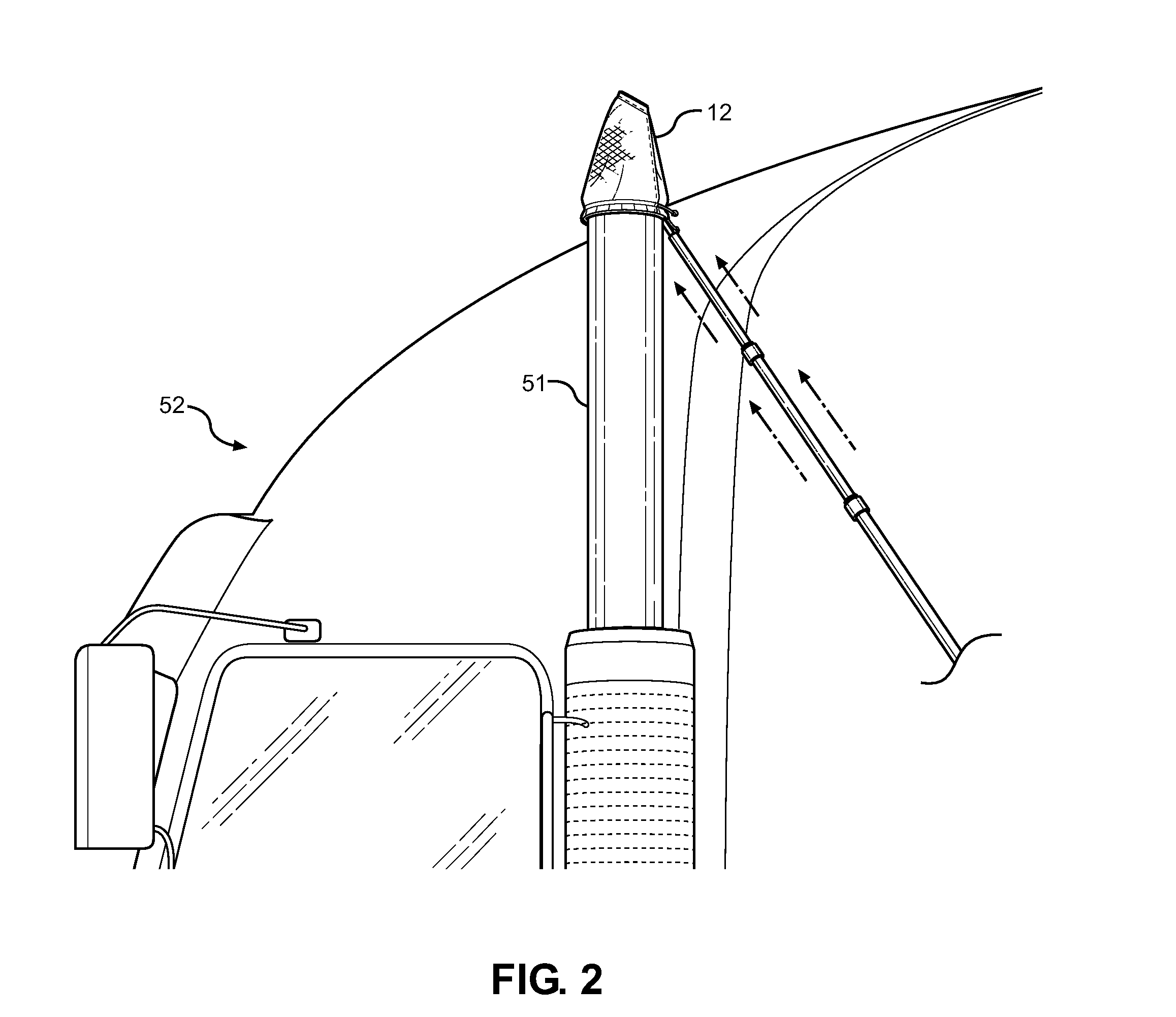

Diesel Exhaust Particulate Filter

PatentInactiveUS20140237992A1

Innovation

- A portable device with an elongated pole and a removable filtration means composed of porous cloth, which can be easily affixed over a diesel engine exhaust pipe to capture particulates for visual inspection, allowing users to determine the filter's functionality without needing additional systems or technical expertise.

Emissions Regulations Impact on Hybrid DPF Systems

The evolving landscape of emissions regulations has significantly shaped the development and implementation of Diesel Particulate Filter (DPF) systems in hybrid vehicles. Since the introduction of Euro 5 standards in 2009 and subsequent Euro 6 regulations in 2014, automotive manufacturers have faced increasingly stringent requirements for particulate matter (PM) and nitrogen oxide (NOx) emissions. These regulations have directly influenced the design parameters and operational strategies of DPF systems in hybrid powertrains.

In the United States, the Environmental Protection Agency's Tier 3 standards and California Air Resources Board's (CARB) Low Emission Vehicle III program have similarly pushed for near-zero emissions levels, creating a regulatory environment that necessitates advanced DPF technologies even in hybrid applications. The regulatory trend globally shows a clear convergence toward real-world driving emissions testing protocols, moving away from laboratory-only certification procedures.

For hybrid vehicles specifically, these regulations present unique challenges and opportunities. The intermittent operation of internal combustion engines in hybrid systems creates distinctive thermal management issues for DPF regeneration cycles. Regulatory bodies have responded by developing specialized test cycles that account for the unique operational profiles of hybrid powertrains, ensuring that emissions control systems remain effective across all driving conditions.

China's implementation of China 6 standards, which exceed Euro 6 requirements in some aspects, has become a significant market driver for advanced DPF technologies in hybrid vehicles. Similarly, Japan's post-new long-term regulations have established some of the world's most stringent PM limits, influencing global DPF design standards.

The regulatory framework has also begun addressing non-exhaust particulate emissions, including those from brake wear, which has implications for regenerative braking systems in hybrids and their integration with DPF technology. This holistic approach to emissions control represents an emerging regulatory frontier that will shape future hybrid DPF systems.

Compliance costs associated with these regulations have become a major factor in hybrid powertrain development decisions. The additional expense of sophisticated DPF systems must be balanced against alternative powertrain strategies, including full electrification. This cost-benefit analysis varies significantly across different vehicle segments and regional markets, creating a complex decision matrix for manufacturers.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in other regions will likely demand even greater integration between hybrid powertrain management and emissions control systems, potentially driving innovations in predictive control algorithms that optimize DPF operation based on hybrid system states and driving patterns.

In the United States, the Environmental Protection Agency's Tier 3 standards and California Air Resources Board's (CARB) Low Emission Vehicle III program have similarly pushed for near-zero emissions levels, creating a regulatory environment that necessitates advanced DPF technologies even in hybrid applications. The regulatory trend globally shows a clear convergence toward real-world driving emissions testing protocols, moving away from laboratory-only certification procedures.

For hybrid vehicles specifically, these regulations present unique challenges and opportunities. The intermittent operation of internal combustion engines in hybrid systems creates distinctive thermal management issues for DPF regeneration cycles. Regulatory bodies have responded by developing specialized test cycles that account for the unique operational profiles of hybrid powertrains, ensuring that emissions control systems remain effective across all driving conditions.

China's implementation of China 6 standards, which exceed Euro 6 requirements in some aspects, has become a significant market driver for advanced DPF technologies in hybrid vehicles. Similarly, Japan's post-new long-term regulations have established some of the world's most stringent PM limits, influencing global DPF design standards.

The regulatory framework has also begun addressing non-exhaust particulate emissions, including those from brake wear, which has implications for regenerative braking systems in hybrids and their integration with DPF technology. This holistic approach to emissions control represents an emerging regulatory frontier that will shape future hybrid DPF systems.

Compliance costs associated with these regulations have become a major factor in hybrid powertrain development decisions. The additional expense of sophisticated DPF systems must be balanced against alternative powertrain strategies, including full electrification. This cost-benefit analysis varies significantly across different vehicle segments and regional markets, creating a complex decision matrix for manufacturers.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in other regions will likely demand even greater integration between hybrid powertrain management and emissions control systems, potentially driving innovations in predictive control algorithms that optimize DPF operation based on hybrid system states and driving patterns.

Thermal Management Strategies for Hybrid DPF

Thermal management in hybrid diesel particulate filter (DPF) systems presents unique challenges and opportunities compared to conventional diesel engines. The integration of electric powertrains with diesel engines creates a complex thermal environment that requires sophisticated management strategies to ensure optimal DPF performance and longevity.

The primary challenge in hybrid DPF thermal management stems from the intermittent operation of the diesel engine. Unlike conventional vehicles where the engine runs continuously during operation, hybrid vehicles frequently switch between electric and diesel power, resulting in lower exhaust temperatures during many driving cycles. This can impede the passive regeneration process that typically occurs at temperatures above 350°C.

Advanced thermal management strategies have emerged to address these challenges. Active thermal management systems utilize electric heaters positioned upstream of the DPF to rapidly increase exhaust temperatures when needed for regeneration. These systems can be programmed to activate during periods of electric-only driving, ensuring the DPF maintains proper functionality regardless of engine operation status.

Predictive thermal management represents another innovative approach, leveraging machine learning algorithms and GPS data to anticipate driving conditions. These systems can proactively adjust regeneration timing based on predicted route characteristics, optimizing the process for fuel efficiency and emissions reduction. For instance, regeneration might be delayed if the system predicts an upcoming highway segment where natural exhaust temperatures will be sufficient.

Heat recovery systems have also proven effective in hybrid applications. Waste heat from the DPF during regeneration can be captured and redirected to other vehicle systems, such as cabin heating or battery thermal management. This integration improves overall vehicle efficiency while maintaining optimal DPF temperatures.

Coordinated control strategies between the hybrid powertrain and emission control systems represent perhaps the most sophisticated approach. These systems dynamically adjust the power split between electric and diesel operation to maintain ideal DPF temperatures. For example, the engine management system might slightly increase diesel utilization when the DPF approaches regeneration temperature thresholds, even if battery charge is available.

Thermal insulation technologies specifically designed for hybrid applications help retain heat within the exhaust system during electric-only operation. Advanced ceramic materials and multi-layer heat shields minimize temperature drops during engine-off periods, extending the effectiveness of passive regeneration cycles and reducing the frequency of active regeneration events.

The primary challenge in hybrid DPF thermal management stems from the intermittent operation of the diesel engine. Unlike conventional vehicles where the engine runs continuously during operation, hybrid vehicles frequently switch between electric and diesel power, resulting in lower exhaust temperatures during many driving cycles. This can impede the passive regeneration process that typically occurs at temperatures above 350°C.

Advanced thermal management strategies have emerged to address these challenges. Active thermal management systems utilize electric heaters positioned upstream of the DPF to rapidly increase exhaust temperatures when needed for regeneration. These systems can be programmed to activate during periods of electric-only driving, ensuring the DPF maintains proper functionality regardless of engine operation status.

Predictive thermal management represents another innovative approach, leveraging machine learning algorithms and GPS data to anticipate driving conditions. These systems can proactively adjust regeneration timing based on predicted route characteristics, optimizing the process for fuel efficiency and emissions reduction. For instance, regeneration might be delayed if the system predicts an upcoming highway segment where natural exhaust temperatures will be sufficient.

Heat recovery systems have also proven effective in hybrid applications. Waste heat from the DPF during regeneration can be captured and redirected to other vehicle systems, such as cabin heating or battery thermal management. This integration improves overall vehicle efficiency while maintaining optimal DPF temperatures.

Coordinated control strategies between the hybrid powertrain and emission control systems represent perhaps the most sophisticated approach. These systems dynamically adjust the power split between electric and diesel operation to maintain ideal DPF temperatures. For example, the engine management system might slightly increase diesel utilization when the DPF approaches regeneration temperature thresholds, even if battery charge is available.

Thermal insulation technologies specifically designed for hybrid applications help retain heat within the exhaust system during electric-only operation. Advanced ceramic materials and multi-layer heat shields minimize temperature drops during engine-off periods, extending the effectiveness of passive regeneration cycles and reducing the frequency of active regeneration events.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!