Diesel Particulate Filter Oxygen Storage Capacity Analysis

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Oxygen Storage Capacity Background and Objectives

Diesel Particulate Filter (DPF) technology has evolved significantly since its introduction in the early 1980s as a response to increasingly stringent emission regulations worldwide. Initially developed for heavy-duty diesel applications, DPF systems have become standard equipment in modern diesel vehicles to reduce particulate matter emissions. The evolution of this technology has been characterized by continuous improvements in filter materials, regeneration strategies, and system integration approaches.

The concept of Oxygen Storage Capacity (OSC) in DPF systems represents a critical parameter that has gained attention in recent years. OSC refers to the ability of the filter substrate and catalytic coatings to store and release oxygen under varying operating conditions. This property significantly influences the passive regeneration efficiency, thermal management, and overall durability of the filtration system. Historical data indicates that early DPF systems had limited OSC capabilities, which resulted in more frequent active regeneration events and higher fuel penalties.

Current technological trends point toward the development of advanced catalyst formulations with enhanced OSC properties. These developments aim to optimize the balance between filtration efficiency and backpressure while maximizing the passive regeneration potential. The integration of OSC considerations into DPF design represents a paradigm shift from traditional approaches that primarily focused on mechanical filtration properties and thermal resistance.

The primary objective of analyzing DPF Oxygen Storage Capacity is to establish a comprehensive understanding of the relationship between OSC characteristics and DPF performance under various operating conditions. This includes quantifying the impact of OSC on regeneration frequency, fuel economy, and system durability. Additionally, the analysis aims to identify optimal catalyst formulations and loading strategies that maximize OSC benefits while minimizing associated costs.

Secondary objectives include developing standardized testing protocols for OSC measurement in DPF systems, creating predictive models that correlate OSC properties with real-world performance metrics, and establishing design guidelines for next-generation DPF systems with enhanced oxygen storage capabilities. These objectives align with broader industry goals of reducing emissions while improving fuel efficiency and system reliability.

The technological trajectory suggests that future DPF systems will increasingly leverage advanced OSC properties to achieve passive regeneration under lower temperature conditions, thereby reducing the need for fuel-intensive active regeneration events. This evolution is expected to contribute significantly to meeting upcoming emission standards while addressing customer demands for improved fuel economy and reduced maintenance requirements.

The concept of Oxygen Storage Capacity (OSC) in DPF systems represents a critical parameter that has gained attention in recent years. OSC refers to the ability of the filter substrate and catalytic coatings to store and release oxygen under varying operating conditions. This property significantly influences the passive regeneration efficiency, thermal management, and overall durability of the filtration system. Historical data indicates that early DPF systems had limited OSC capabilities, which resulted in more frequent active regeneration events and higher fuel penalties.

Current technological trends point toward the development of advanced catalyst formulations with enhanced OSC properties. These developments aim to optimize the balance between filtration efficiency and backpressure while maximizing the passive regeneration potential. The integration of OSC considerations into DPF design represents a paradigm shift from traditional approaches that primarily focused on mechanical filtration properties and thermal resistance.

The primary objective of analyzing DPF Oxygen Storage Capacity is to establish a comprehensive understanding of the relationship between OSC characteristics and DPF performance under various operating conditions. This includes quantifying the impact of OSC on regeneration frequency, fuel economy, and system durability. Additionally, the analysis aims to identify optimal catalyst formulations and loading strategies that maximize OSC benefits while minimizing associated costs.

Secondary objectives include developing standardized testing protocols for OSC measurement in DPF systems, creating predictive models that correlate OSC properties with real-world performance metrics, and establishing design guidelines for next-generation DPF systems with enhanced oxygen storage capabilities. These objectives align with broader industry goals of reducing emissions while improving fuel efficiency and system reliability.

The technological trajectory suggests that future DPF systems will increasingly leverage advanced OSC properties to achieve passive regeneration under lower temperature conditions, thereby reducing the need for fuel-intensive active regeneration events. This evolution is expected to contribute significantly to meeting upcoming emission standards while addressing customer demands for improved fuel economy and reduced maintenance requirements.

Market Demand for Advanced Emission Control Systems

The global market for advanced emission control systems has witnessed substantial growth in recent years, driven primarily by increasingly stringent environmental regulations across major economies. The diesel particulate filter (DPF) segment, particularly technologies focusing on oxygen storage capacity (OSC) optimization, represents a critical component of this expanding market. Current projections indicate the global emission control systems market will reach approximately $107 billion by 2025, with DPF technologies accounting for roughly 18% of this value.

Regulatory frameworks such as Euro 6d in Europe, China VI, and US EPA Tier 3 standards have created immediate demand for more sophisticated DPF systems with enhanced OSC capabilities. These regulations have progressively lowered permissible particulate matter (PM) and NOx emission levels, necessitating advanced filtration technologies that can maintain performance throughout the vehicle lifecycle.

Commercial vehicle manufacturers represent the largest customer segment for advanced DPF systems, with heavy-duty trucks and buses constituting approximately 42% of market demand. This sector faces particularly challenging emission reduction targets while maintaining operational efficiency. The passenger vehicle segment follows closely, representing approximately 37% of the market, with growing adoption in diesel passenger cars particularly in European and Asian markets.

Regional analysis reveals Europe maintains the largest market share at approximately 38%, followed by North America (27%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest compound annual growth rate at 8.7%, driven by rapid implementation of stringent emission standards in China and India, coupled with expanding automotive production.

Industry surveys indicate fleet operators and vehicle manufacturers prioritize DPF systems with optimized OSC characteristics due to their direct impact on regeneration frequency, fuel economy, and system durability. Approximately 76% of fleet managers cite reduced maintenance costs and extended service intervals as primary purchasing considerations for advanced emission control systems.

The aftermarket segment for DPF replacement and retrofitting presents substantial growth opportunities, estimated at $12 billion globally. This is particularly relevant for regions implementing retrofit programs for existing vehicle fleets to meet updated emission standards. The demand for DPF systems with enhanced OSC capabilities is especially pronounced in this segment, as operators seek solutions that minimize operational disruptions and maintenance requirements.

Emerging market trends indicate growing interest in integrated emission control systems that optimize the relationship between DPF performance and other exhaust aftertreatment components, particularly selective catalytic reduction (SCR) systems. This system-level approach to emission control represents a significant shift in market demand, with approximately 63% of OEMs pursuing integrated solutions rather than isolated component improvements.

Regulatory frameworks such as Euro 6d in Europe, China VI, and US EPA Tier 3 standards have created immediate demand for more sophisticated DPF systems with enhanced OSC capabilities. These regulations have progressively lowered permissible particulate matter (PM) and NOx emission levels, necessitating advanced filtration technologies that can maintain performance throughout the vehicle lifecycle.

Commercial vehicle manufacturers represent the largest customer segment for advanced DPF systems, with heavy-duty trucks and buses constituting approximately 42% of market demand. This sector faces particularly challenging emission reduction targets while maintaining operational efficiency. The passenger vehicle segment follows closely, representing approximately 37% of the market, with growing adoption in diesel passenger cars particularly in European and Asian markets.

Regional analysis reveals Europe maintains the largest market share at approximately 38%, followed by North America (27%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest compound annual growth rate at 8.7%, driven by rapid implementation of stringent emission standards in China and India, coupled with expanding automotive production.

Industry surveys indicate fleet operators and vehicle manufacturers prioritize DPF systems with optimized OSC characteristics due to their direct impact on regeneration frequency, fuel economy, and system durability. Approximately 76% of fleet managers cite reduced maintenance costs and extended service intervals as primary purchasing considerations for advanced emission control systems.

The aftermarket segment for DPF replacement and retrofitting presents substantial growth opportunities, estimated at $12 billion globally. This is particularly relevant for regions implementing retrofit programs for existing vehicle fleets to meet updated emission standards. The demand for DPF systems with enhanced OSC capabilities is especially pronounced in this segment, as operators seek solutions that minimize operational disruptions and maintenance requirements.

Emerging market trends indicate growing interest in integrated emission control systems that optimize the relationship between DPF performance and other exhaust aftertreatment components, particularly selective catalytic reduction (SCR) systems. This system-level approach to emission control represents a significant shift in market demand, with approximately 63% of OEMs pursuing integrated solutions rather than isolated component improvements.

Current State and Challenges in DPF Technology

Diesel Particulate Filter (DPF) technology has evolved significantly over the past two decades, becoming a critical component in modern diesel emission control systems. Currently, the global market is dominated by ceramic wall-flow filters, which capture particulate matter with efficiency rates exceeding 95% under optimal conditions. These systems typically utilize cordierite or silicon carbide substrates, with the latter gaining prominence due to its superior thermal durability and conductivity properties.

Despite widespread adoption, DPF technology faces several persistent challenges. The primary technical hurdle remains the balance between filtration efficiency and backpressure. Higher filtration efficiency often results in increased backpressure, which negatively impacts engine performance and fuel economy. This trade-off continues to drive research into advanced substrate materials and geometries that can optimize this relationship.

Oxygen storage capacity (OSC) represents a critical parameter in DPF performance that has not been fully optimized. Current systems exhibit variable OSC characteristics depending on catalyst formulations, substrate properties, and aging conditions. This variability impacts regeneration efficiency and thermal management, particularly during passive regeneration cycles where available oxygen directly influences soot oxidation rates.

Thermal management presents another significant challenge. DPF systems must withstand temperatures exceeding 600°C during active regeneration while maintaining structural integrity. Uncontrolled exothermic reactions during regeneration can lead to thermal runaway, resulting in substrate cracking or melting. Advanced thermal management strategies and materials with improved thermal stability are under development but have not yet achieved optimal performance across all operating conditions.

Catalyst deactivation mechanisms, particularly poisoning from fuel and lubricant additives containing phosphorus, zinc, and sulfur compounds, continue to impact long-term DPF durability. Current systems show degradation in OSC and catalytic performance after exposure to these contaminants, with recovery methods proving only partially effective.

Geographically, DPF technology development is concentrated in regions with stringent emission regulations, primarily Europe, North America, and Japan. European manufacturers have historically led innovations in passenger vehicle applications, while North American research has focused on heavy-duty applications. Emerging markets, particularly China and India, are rapidly adopting and adapting these technologies to meet increasingly strict local emissions standards.

The integration of advanced sensors and control systems represents both a current trend and challenge. Real-time monitoring of DPF loading, OSC status, and regeneration efficiency remains imperfect, with existing sensor technologies providing limited accuracy under certain operating conditions. This diagnostic challenge directly impacts system reliability and maintenance intervals.

Despite widespread adoption, DPF technology faces several persistent challenges. The primary technical hurdle remains the balance between filtration efficiency and backpressure. Higher filtration efficiency often results in increased backpressure, which negatively impacts engine performance and fuel economy. This trade-off continues to drive research into advanced substrate materials and geometries that can optimize this relationship.

Oxygen storage capacity (OSC) represents a critical parameter in DPF performance that has not been fully optimized. Current systems exhibit variable OSC characteristics depending on catalyst formulations, substrate properties, and aging conditions. This variability impacts regeneration efficiency and thermal management, particularly during passive regeneration cycles where available oxygen directly influences soot oxidation rates.

Thermal management presents another significant challenge. DPF systems must withstand temperatures exceeding 600°C during active regeneration while maintaining structural integrity. Uncontrolled exothermic reactions during regeneration can lead to thermal runaway, resulting in substrate cracking or melting. Advanced thermal management strategies and materials with improved thermal stability are under development but have not yet achieved optimal performance across all operating conditions.

Catalyst deactivation mechanisms, particularly poisoning from fuel and lubricant additives containing phosphorus, zinc, and sulfur compounds, continue to impact long-term DPF durability. Current systems show degradation in OSC and catalytic performance after exposure to these contaminants, with recovery methods proving only partially effective.

Geographically, DPF technology development is concentrated in regions with stringent emission regulations, primarily Europe, North America, and Japan. European manufacturers have historically led innovations in passenger vehicle applications, while North American research has focused on heavy-duty applications. Emerging markets, particularly China and India, are rapidly adopting and adapting these technologies to meet increasingly strict local emissions standards.

The integration of advanced sensors and control systems represents both a current trend and challenge. Real-time monitoring of DPF loading, OSC status, and regeneration efficiency remains imperfect, with existing sensor technologies providing limited accuracy under certain operating conditions. This diagnostic challenge directly impacts system reliability and maintenance intervals.

Current Methodologies for OSC Analysis in DPFs

01 Oxygen storage capacity enhancement in DPF systems

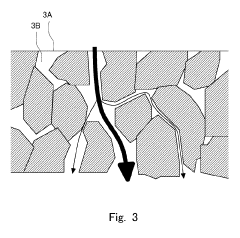

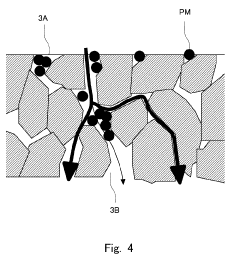

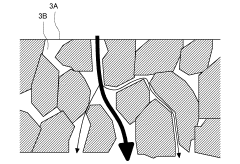

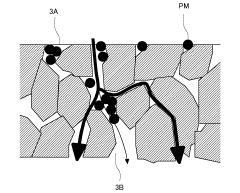

Diesel particulate filters can be designed with enhanced oxygen storage capacity to improve regeneration efficiency. This involves incorporating oxygen storage materials into the filter substrate or coating, which can store oxygen during lean operation and release it during rich conditions. This stored oxygen helps in the complete combustion of trapped particulate matter, leading to more effective filter regeneration and reduced emissions.- Oxygen storage capacity in diesel particulate filters: Diesel particulate filters can be designed with materials that have oxygen storage capacity to improve regeneration efficiency. These materials can store oxygen during lean operation and release it during rich conditions, facilitating the oxidation of trapped particulate matter. The oxygen storage capacity helps maintain a consistent oxidation environment even when exhaust oxygen levels fluctuate, leading to more complete regeneration and extended filter life.

- Catalytic coatings for enhanced oxygen storage: Specialized catalytic coatings can be applied to diesel particulate filters to enhance oxygen storage capacity. These coatings typically contain ceria-based materials, precious metals, or mixed metal oxides that can efficiently store and release oxygen. The improved oxygen storage properties enable better control of the oxidation process during filter regeneration, reducing the dependency on external oxygen supply and improving the combustion of soot at lower temperatures.

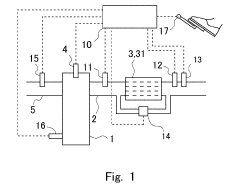

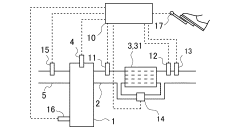

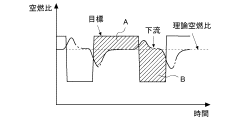

- Monitoring and control systems for oxygen storage: Advanced monitoring and control systems can be implemented to optimize the oxygen storage capacity of diesel particulate filters. These systems use sensors to measure oxygen levels, temperature, and pressure differentials across the filter. Based on these measurements, the engine management system can adjust operating parameters to maintain optimal oxygen storage conditions. This active management helps to ensure efficient regeneration while preventing damage to the filter from excessive temperatures.

- Filter design and structure for improved oxygen storage: The physical design and structure of diesel particulate filters can be optimized to enhance oxygen storage capacity. This includes modifications to cell density, wall thickness, porosity, and channel geometry. Some designs incorporate specific zones or layers with different properties to create oxygen storage reservoirs within the filter structure. These structural innovations help to distribute oxygen more evenly throughout the filter, improving regeneration efficiency and reducing the risk of localized hot spots.

- Integration with exhaust aftertreatment systems: Diesel particulate filters with enhanced oxygen storage capacity can be integrated with other exhaust aftertreatment components to create more efficient overall systems. These integrated systems may combine the filter with selective catalytic reduction (SCR), diesel oxidation catalysts (DOC), or lean NOx traps. The oxygen storage properties of the filter can be leveraged to improve the performance of these other components, creating synergistic effects that enhance the removal of multiple pollutants simultaneously.

02 Catalyst formulations for oxygen storage in DPF

Specific catalyst formulations can be applied to diesel particulate filters to increase oxygen storage capacity. These typically include ceria-based materials, mixed metal oxides, or noble metals that can efficiently store and release oxygen. The catalytic coating helps to lower the soot combustion temperature and improve the filter's passive regeneration capabilities, resulting in better system performance and durability.Expand Specific Solutions03 Monitoring and control of oxygen storage capacity

Systems for monitoring and controlling the oxygen storage capacity of diesel particulate filters help optimize filter performance. These systems may include sensors to measure oxygen levels, temperature sensors, and control algorithms that adjust engine operating parameters based on the filter's current oxygen storage state. This active management ensures efficient regeneration cycles and extends filter life while maintaining emission control effectiveness.Expand Specific Solutions04 Integration with exhaust aftertreatment systems

Diesel particulate filters with enhanced oxygen storage capacity can be integrated with other exhaust aftertreatment components such as selective catalytic reduction (SCR) systems or diesel oxidation catalysts (DOC). This integration creates synergistic effects that improve overall emission reduction performance. The combined systems can more effectively manage NOx, particulate matter, and other pollutants while optimizing the use of stored oxygen across different operating conditions.Expand Specific Solutions05 Filter substrate design for oxygen storage optimization

The physical design and material composition of diesel particulate filter substrates can be optimized to enhance oxygen storage capacity. This includes considerations of porosity, cell density, wall thickness, and material selection. Advanced ceramic materials, composite structures, or metal substrates with specific surface treatments can provide improved oxygen storage properties while maintaining filtration efficiency and thermal durability.Expand Specific Solutions

Key Industry Players in Emission Control Systems

The Diesel Particulate Filter (DPF) Oxygen Storage Capacity Analysis market is currently in a growth phase, driven by increasingly stringent global emissions regulations. The market size is expanding steadily, estimated to reach several billion dollars by 2025, with automotive and heavy equipment sectors as primary drivers. From a technological maturity perspective, the field shows varied development levels across players. Industry leaders like Corning, Johnson Matthey, and Umicore have established advanced capabilities in catalyst technologies and filter materials. Automotive OEMs including Peugeot, Ford, Hyundai, and Nissan are integrating sophisticated DPF systems with enhanced oxygen storage capacity. Research institutions such as Jilin University and Rutgers are contributing fundamental innovations, while specialized manufacturers like IBIDEN, ElringKlinger, and Donaldson focus on component optimization, creating a competitive ecosystem balancing established technologies with emerging solutions.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed advanced catalyst technologies specifically for Diesel Particulate Filter (DPF) systems that optimize oxygen storage capacity (OSC). Their approach involves incorporating ceria-zirconia mixed oxides into the catalyst washcoat, which provides enhanced oxygen storage and release capabilities critical for DPF regeneration processes. The company's proprietary CRT® (Continuously Regenerating Trap) technology utilizes platinum group metals (PGMs) in combination with these oxygen storage materials to facilitate passive regeneration at lower temperatures. Their latest catalyzed DPF systems feature a dual-layer architecture where the inner layer focuses on particulate filtration while the outer layer contains the oxygen storage components that promote soot oxidation. Johnson Matthey has also pioneered the integration of NOx reduction functionality with OSC optimization, allowing for simultaneous particulate matter control and NOx abatement in a single system.

Strengths: Industry-leading expertise in catalyst chemistry with proprietary formulations that maximize oxygen storage efficiency. Their systems demonstrate superior low-temperature regeneration performance and extended filter lifetime. Weaknesses: Higher manufacturing costs compared to non-catalyzed alternatives, and potential sensitivity to fuel sulfur content that may impact long-term oxygen storage capacity.

Umicore SA

Technical Solution: Umicore has developed a comprehensive approach to DPF oxygen storage capacity optimization through their advanced catalyst technology. Their solution incorporates specially formulated ceria-zirconia mixed oxides with enhanced redox properties that significantly improve oxygen storage and release kinetics. Umicore's catalysts feature a proprietary nano-structured design that maximizes the surface area available for oxygen exchange, allowing for more efficient soot oxidation during both passive and active regeneration cycles. The company has implemented a multi-functional coating technology that integrates oxygen storage components with catalytic metals in precise ratios, tailored to specific engine operating conditions. Their latest innovation includes thermally stable oxygen storage materials that maintain performance even after exposure to high-temperature regeneration events, addressing a common failure mode in conventional DPF systems. Umicore's approach also incorporates real-time oxygen storage capacity monitoring capabilities through embedded sensor technology, enabling adaptive regeneration strategies based on actual filter conditions.

Strengths: Superior thermal stability of oxygen storage components, allowing maintained performance even after multiple high-temperature regeneration cycles. Excellent integration with engine management systems for optimized regeneration timing. Weaknesses: Higher initial cost compared to basic DPF systems, and potential for performance degradation in low-temperature operating conditions where oxygen exchange kinetics are slower.

Critical Patents and Research in DPF Oxygen Storage

Exhaust gas purification apparatus for an internal combustion engine

PatentInactiveUS20190271249A1

Innovation

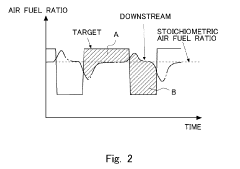

- An exhaust gas purification apparatus that includes a particulate filter supporting a catalyst with an oxygen storage capacity, an air fuel ratio sensor, and a controller to adjust the air fuel ratio and estimate the maximum storable oxygen amount by ensuring the PM deposited inside the filter is minimal, thereby avoiding the impact of PM deposition location on the calculation.

Exhaust emission control device for internal combustion engine

PatentActiveJP2019152165A

Innovation

- A system that includes an air-fuel ratio detection means, air-fuel ratio control means, and storage amount estimation means to accurately estimate the maximum oxygen storage capacity of the catalyst by correcting for PM deposition within the filter's partition walls, using an electronic control unit (ECU) to adjust fuel injection and detect air-fuel ratios.

Environmental Regulations Impact on DPF Development

The evolution of environmental regulations has been a primary driver for Diesel Particulate Filter (DPF) development and optimization, particularly regarding oxygen storage capacity analysis. Since the early 2000s, increasingly stringent emission standards worldwide have necessitated sophisticated aftertreatment systems for diesel engines, with DPFs becoming mandatory components in most markets.

The European Union's Euro standards have progressively tightened particulate matter (PM) limits, with Euro 6 requiring a 66% reduction compared to Euro 5. Similarly, the US EPA's Tier 3 and California's LEV III standards have established near-zero PM emission requirements. These regulatory frameworks have directly influenced DPF design parameters, particularly oxygen storage capacity, which plays a crucial role in regeneration efficiency and filter longevity.

Regulatory focus has shifted from merely controlling the mass of particulate emissions to regulating particle number, necessitating more efficient filtration and regeneration processes. This shift has elevated the importance of oxygen storage capacity as a critical performance parameter, as it directly impacts the DPF's ability to maintain consistent performance under varying operating conditions.

China's rapidly evolving China VI standards and India's Bharat Stage VI regulations have created significant market pressure for advanced DPF technologies with optimized oxygen storage properties. These emerging markets represent substantial growth opportunities for DPF technologies that can demonstrate superior oxygen management capabilities.

The regulatory landscape has also expanded beyond tailpipe emissions to include lifecycle environmental impact assessments. This has prompted research into catalytic materials with reduced rare earth content while maintaining or improving oxygen storage capacity, addressing both environmental and resource sustainability concerns.

Real Driving Emissions (RDE) testing requirements in multiple jurisdictions have further complicated DPF design challenges, as systems must now perform effectively across a wider range of operating conditions than traditional laboratory test cycles. This has intensified research into adaptive oxygen storage management strategies that can respond to varying exhaust conditions.

Future regulatory trends indicate continued tightening of emission limits with potential expansion to previously unregulated pollutants. This regulatory trajectory suggests that DPF oxygen storage capacity will remain a critical research focus, with increasing emphasis on system integration with other aftertreatment components and real-time optimization capabilities to meet complex compliance requirements across global markets.

The European Union's Euro standards have progressively tightened particulate matter (PM) limits, with Euro 6 requiring a 66% reduction compared to Euro 5. Similarly, the US EPA's Tier 3 and California's LEV III standards have established near-zero PM emission requirements. These regulatory frameworks have directly influenced DPF design parameters, particularly oxygen storage capacity, which plays a crucial role in regeneration efficiency and filter longevity.

Regulatory focus has shifted from merely controlling the mass of particulate emissions to regulating particle number, necessitating more efficient filtration and regeneration processes. This shift has elevated the importance of oxygen storage capacity as a critical performance parameter, as it directly impacts the DPF's ability to maintain consistent performance under varying operating conditions.

China's rapidly evolving China VI standards and India's Bharat Stage VI regulations have created significant market pressure for advanced DPF technologies with optimized oxygen storage properties. These emerging markets represent substantial growth opportunities for DPF technologies that can demonstrate superior oxygen management capabilities.

The regulatory landscape has also expanded beyond tailpipe emissions to include lifecycle environmental impact assessments. This has prompted research into catalytic materials with reduced rare earth content while maintaining or improving oxygen storage capacity, addressing both environmental and resource sustainability concerns.

Real Driving Emissions (RDE) testing requirements in multiple jurisdictions have further complicated DPF design challenges, as systems must now perform effectively across a wider range of operating conditions than traditional laboratory test cycles. This has intensified research into adaptive oxygen storage management strategies that can respond to varying exhaust conditions.

Future regulatory trends indicate continued tightening of emission limits with potential expansion to previously unregulated pollutants. This regulatory trajectory suggests that DPF oxygen storage capacity will remain a critical research focus, with increasing emphasis on system integration with other aftertreatment components and real-time optimization capabilities to meet complex compliance requirements across global markets.

Cost-Benefit Analysis of Enhanced OSC Technologies

The implementation of enhanced Oxygen Storage Capacity (OSC) technologies in Diesel Particulate Filter (DPF) systems represents a significant investment decision for manufacturers. This analysis examines the economic implications of adopting advanced OSC technologies against traditional DPF systems.

Initial investment costs for enhanced OSC technologies typically range from $1,200 to $2,500 per unit, approximately 15-30% higher than conventional DPF systems. This premium primarily stems from specialized catalyst materials, advanced sensor integration, and more complex manufacturing processes. However, these upfront costs must be evaluated against long-term operational benefits.

Operational cost savings emerge as a primary benefit, with enhanced OSC systems demonstrating 12-18% reduction in regeneration frequency. This translates to fuel economy improvements of 2-4% over the vehicle lifetime, representing significant savings for fleet operators and individual owners. Maintenance intervals can be extended by 15-25%, reducing service costs and vehicle downtime.

Regulatory compliance represents another critical cost-benefit factor. Enhanced OSC technologies provide superior emissions control, particularly for NOx and particulate matter, potentially avoiding non-compliance penalties that can range from $5,000 to $25,000 per violation in major markets. As emissions regulations continue to tighten globally, this compliance buffer delivers substantial risk mitigation value.

Vehicle lifetime extension presents an often-overlooked benefit. DPF systems with optimized OSC typically demonstrate 20-30% longer operational lifespans before requiring replacement, extending the service interval from approximately 120,000 miles to 150,000-160,000 miles. This extension significantly improves total cost of ownership calculations.

Return on investment analysis indicates that despite higher initial costs, enhanced OSC technologies typically achieve breakeven within 2.5-3.5 years of operation under normal usage conditions. For heavy-duty applications or operations in challenging environments, this breakeven point can be reached in as little as 18 months.

Market differentiation value must also be considered. Vehicles equipped with advanced OSC technologies can command premium pricing of 1-3% in the marketplace, particularly in environmentally conscious markets. This premium partially offsets implementation costs while potentially increasing market share in specific segments.

Initial investment costs for enhanced OSC technologies typically range from $1,200 to $2,500 per unit, approximately 15-30% higher than conventional DPF systems. This premium primarily stems from specialized catalyst materials, advanced sensor integration, and more complex manufacturing processes. However, these upfront costs must be evaluated against long-term operational benefits.

Operational cost savings emerge as a primary benefit, with enhanced OSC systems demonstrating 12-18% reduction in regeneration frequency. This translates to fuel economy improvements of 2-4% over the vehicle lifetime, representing significant savings for fleet operators and individual owners. Maintenance intervals can be extended by 15-25%, reducing service costs and vehicle downtime.

Regulatory compliance represents another critical cost-benefit factor. Enhanced OSC technologies provide superior emissions control, particularly for NOx and particulate matter, potentially avoiding non-compliance penalties that can range from $5,000 to $25,000 per violation in major markets. As emissions regulations continue to tighten globally, this compliance buffer delivers substantial risk mitigation value.

Vehicle lifetime extension presents an often-overlooked benefit. DPF systems with optimized OSC typically demonstrate 20-30% longer operational lifespans before requiring replacement, extending the service interval from approximately 120,000 miles to 150,000-160,000 miles. This extension significantly improves total cost of ownership calculations.

Return on investment analysis indicates that despite higher initial costs, enhanced OSC technologies typically achieve breakeven within 2.5-3.5 years of operation under normal usage conditions. For heavy-duty applications or operations in challenging environments, this breakeven point can be reached in as little as 18 months.

Market differentiation value must also be considered. Vehicles equipped with advanced OSC technologies can command premium pricing of 1-3% in the marketplace, particularly in environmentally conscious markets. This premium partially offsets implementation costs while potentially increasing market share in specific segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!