Diesel Particulate Filter Functionality vs Altitude

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emission regulations worldwide. Initially developed for heavy-duty diesel applications, these filtration systems have evolved significantly over the past four decades to become standard components in modern diesel vehicles. The primary function of a DPF is to capture and remove particulate matter (PM) from diesel exhaust gases, thereby reducing harmful emissions that contribute to air pollution and associated health concerns.

The technological evolution of DPFs has been marked by several key advancements, including improved filter materials, enhanced regeneration strategies, and more sophisticated control systems. Early DPFs utilized cordierite or silicon carbide substrates, while contemporary designs incorporate advanced materials with optimized porosity and thermal properties to enhance filtration efficiency and durability under varying operating conditions.

A critical aspect of DPF technology is the regeneration process, which involves periodically burning accumulated soot to prevent filter clogging. This process has evolved from simple passive systems relying solely on exhaust temperature to complex active systems that can initiate regeneration regardless of driving conditions. The integration of sensors, electronic control units, and fuel injection strategies has significantly improved regeneration management.

The relationship between DPF functionality and altitude presents unique challenges that have not been fully addressed in current designs. As vehicles operate at higher elevations, changes in atmospheric pressure, oxygen concentration, and temperature can significantly impact DPF performance. These altitude-related factors affect combustion efficiency, exhaust gas composition, and regeneration dynamics, potentially leading to reduced filtration effectiveness, increased backpressure, and premature filter failure.

The primary technical objectives for advancing DPF technology in relation to altitude include: developing altitude-adaptive regeneration strategies that can compensate for reduced oxygen levels; creating more robust filter materials capable of withstanding thermal stress variations at different elevations; implementing intelligent control systems that can predict and adjust to changing atmospheric conditions; and establishing comprehensive testing protocols that accurately simulate high-altitude operating environments.

Future DPF technology must address the growing demand for systems that maintain optimal performance across diverse geographical regions, from sea level to high mountain passes. This requires a multidisciplinary approach combining materials science, fluid dynamics, combustion engineering, and advanced control algorithms. The ultimate goal is to develop next-generation DPFs that deliver consistent emission reduction performance regardless of altitude, while maintaining fuel efficiency and system durability throughout the vehicle's operational life.

The technological evolution of DPFs has been marked by several key advancements, including improved filter materials, enhanced regeneration strategies, and more sophisticated control systems. Early DPFs utilized cordierite or silicon carbide substrates, while contemporary designs incorporate advanced materials with optimized porosity and thermal properties to enhance filtration efficiency and durability under varying operating conditions.

A critical aspect of DPF technology is the regeneration process, which involves periodically burning accumulated soot to prevent filter clogging. This process has evolved from simple passive systems relying solely on exhaust temperature to complex active systems that can initiate regeneration regardless of driving conditions. The integration of sensors, electronic control units, and fuel injection strategies has significantly improved regeneration management.

The relationship between DPF functionality and altitude presents unique challenges that have not been fully addressed in current designs. As vehicles operate at higher elevations, changes in atmospheric pressure, oxygen concentration, and temperature can significantly impact DPF performance. These altitude-related factors affect combustion efficiency, exhaust gas composition, and regeneration dynamics, potentially leading to reduced filtration effectiveness, increased backpressure, and premature filter failure.

The primary technical objectives for advancing DPF technology in relation to altitude include: developing altitude-adaptive regeneration strategies that can compensate for reduced oxygen levels; creating more robust filter materials capable of withstanding thermal stress variations at different elevations; implementing intelligent control systems that can predict and adjust to changing atmospheric conditions; and establishing comprehensive testing protocols that accurately simulate high-altitude operating environments.

Future DPF technology must address the growing demand for systems that maintain optimal performance across diverse geographical regions, from sea level to high mountain passes. This requires a multidisciplinary approach combining materials science, fluid dynamics, combustion engineering, and advanced control algorithms. The ultimate goal is to develop next-generation DPFs that deliver consistent emission reduction performance regardless of altitude, while maintaining fuel efficiency and system durability throughout the vehicle's operational life.

Market Analysis of High-Altitude Diesel Applications

The diesel engine market in high-altitude regions presents unique challenges and opportunities that significantly impact the adoption and performance of Diesel Particulate Filter (DPF) systems. High-altitude environments, typically defined as areas above 1,500 meters (4,921 feet), constitute approximately 15% of the Earth's land surface but represent a growing segment for diesel applications due to increasing industrialization, mining operations, and transportation needs in mountainous regions.

Market research indicates that the primary sectors driving demand for high-altitude diesel applications include mining operations, construction equipment, power generation, military applications, and transportation infrastructure. The mining sector alone accounts for a substantial portion of this market, with operations in the Andes, Himalayas, and Rocky Mountains requiring specialized diesel equipment capable of functioning efficiently at elevations exceeding 4,000 meters.

The global market for high-altitude diesel applications was valued at approximately $7.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2028. This growth is primarily driven by expanding mining operations in high-altitude regions of South America, Central Asia, and Africa, as well as increasing infrastructure development projects in mountainous territories.

Customer requirements in these markets emphasize reliability, performance consistency across varying altitudes, and compliance with increasingly stringent emissions regulations. A survey of equipment operators in high-altitude regions revealed that 78% consider altitude-related performance issues as a critical factor in purchasing decisions, with DPF functionality ranking among the top three concerns.

Regional analysis shows that South America represents the largest market for high-altitude diesel applications, accounting for approximately 32% of global demand, followed by Asia-Pacific (27%) and North America (21%). The South American market is primarily driven by extensive mining operations in the Andean region, where diesel engines operate at elevations exceeding 5,000 meters.

Competitive analysis reveals that manufacturers who have successfully addressed altitude-related DPF functionality issues command premium pricing, with customers willing to pay 15-20% more for systems demonstrating reliable performance across elevation changes. This price premium underscores the significant market opportunity for technological solutions addressing the specific challenges of DPF functionality at varying altitudes.

Market forecasts suggest that regulatory pressures will intensify demand for effective high-altitude DPF solutions, as emissions standards increasingly apply to previously exempt high-altitude operations. This regulatory evolution is expected to expand the addressable market by approximately 18% over the next five years, creating substantial opportunities for innovative technical solutions.

Market research indicates that the primary sectors driving demand for high-altitude diesel applications include mining operations, construction equipment, power generation, military applications, and transportation infrastructure. The mining sector alone accounts for a substantial portion of this market, with operations in the Andes, Himalayas, and Rocky Mountains requiring specialized diesel equipment capable of functioning efficiently at elevations exceeding 4,000 meters.

The global market for high-altitude diesel applications was valued at approximately $7.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2028. This growth is primarily driven by expanding mining operations in high-altitude regions of South America, Central Asia, and Africa, as well as increasing infrastructure development projects in mountainous territories.

Customer requirements in these markets emphasize reliability, performance consistency across varying altitudes, and compliance with increasingly stringent emissions regulations. A survey of equipment operators in high-altitude regions revealed that 78% consider altitude-related performance issues as a critical factor in purchasing decisions, with DPF functionality ranking among the top three concerns.

Regional analysis shows that South America represents the largest market for high-altitude diesel applications, accounting for approximately 32% of global demand, followed by Asia-Pacific (27%) and North America (21%). The South American market is primarily driven by extensive mining operations in the Andean region, where diesel engines operate at elevations exceeding 5,000 meters.

Competitive analysis reveals that manufacturers who have successfully addressed altitude-related DPF functionality issues command premium pricing, with customers willing to pay 15-20% more for systems demonstrating reliable performance across elevation changes. This price premium underscores the significant market opportunity for technological solutions addressing the specific challenges of DPF functionality at varying altitudes.

Market forecasts suggest that regulatory pressures will intensify demand for effective high-altitude DPF solutions, as emissions standards increasingly apply to previously exempt high-altitude operations. This regulatory evolution is expected to expand the addressable market by approximately 18% over the next five years, creating substantial opportunities for innovative technical solutions.

Current DPF Challenges at Varying Altitudes

Diesel Particulate Filters (DPFs) face significant operational challenges when vehicles operate across varying altitudes, with performance degradation becoming increasingly pronounced at higher elevations. The primary challenge stems from the altered air density and oxygen concentration, which directly impacts combustion efficiency and exhaust gas characteristics. At higher altitudes, the reduced oxygen availability leads to incomplete combustion, resulting in increased soot production that accelerates DPF loading rates by up to 30% compared to sea-level operation.

Temperature management presents another critical challenge for DPF systems at elevation. The lower ambient temperatures commonly encountered at high altitudes, combined with reduced exhaust gas temperatures due to altered combustion dynamics, frequently prevent DPFs from reaching optimal regeneration temperatures (typically 550-650°C). This temperature deficit can lead to incomplete regeneration cycles, causing accumulated particulate matter to form carbonaceous deposits that are increasingly difficult to remove through standard regeneration processes.

Barometric pressure variations across altitude changes significantly affect the pressure differential measurements that modern DPF systems rely on for load estimation and regeneration timing. Research indicates that pressure sensor readings can deviate by up to 15% when a vehicle rapidly changes altitude, potentially triggering premature or delayed regeneration cycles. This sensor calibration challenge becomes particularly problematic for vehicles that regularly traverse mountainous terrain, where altitude can change by thousands of feet within relatively short distances.

The reduced air density at higher altitudes also impacts the back-pressure dynamics of the entire exhaust system. DPFs operating at elevations above 2,500 meters experience approximately 25% higher back-pressure for equivalent soot loading compared to sea-level operation. This increased resistance restricts exhaust flow, potentially leading to power loss, increased fuel consumption, and accelerated thermal stress on DPF substrates.

Regeneration strategy effectiveness diminishes significantly with increasing altitude. Passive regeneration, which relies on normal driving conditions to oxidize trapped particulates, becomes particularly compromised as the reduced oxygen concentration limits the NO₂-based oxidation process. Active regeneration systems must compensate by injecting additional fuel to achieve target temperatures, resulting in 10-20% higher fuel penalties for regeneration events at high altitudes compared to sea-level operation.

Cold-start emissions control represents another substantial challenge, as the combination of lower ambient temperatures at altitude and reduced oxygen availability creates conditions where particulate emissions during the warm-up phase can be up to three times higher than at sea level. This places additional burden on the DPF system during its least efficient operational phase, accelerating filter loading and potentially shortening service intervals.

Temperature management presents another critical challenge for DPF systems at elevation. The lower ambient temperatures commonly encountered at high altitudes, combined with reduced exhaust gas temperatures due to altered combustion dynamics, frequently prevent DPFs from reaching optimal regeneration temperatures (typically 550-650°C). This temperature deficit can lead to incomplete regeneration cycles, causing accumulated particulate matter to form carbonaceous deposits that are increasingly difficult to remove through standard regeneration processes.

Barometric pressure variations across altitude changes significantly affect the pressure differential measurements that modern DPF systems rely on for load estimation and regeneration timing. Research indicates that pressure sensor readings can deviate by up to 15% when a vehicle rapidly changes altitude, potentially triggering premature or delayed regeneration cycles. This sensor calibration challenge becomes particularly problematic for vehicles that regularly traverse mountainous terrain, where altitude can change by thousands of feet within relatively short distances.

The reduced air density at higher altitudes also impacts the back-pressure dynamics of the entire exhaust system. DPFs operating at elevations above 2,500 meters experience approximately 25% higher back-pressure for equivalent soot loading compared to sea-level operation. This increased resistance restricts exhaust flow, potentially leading to power loss, increased fuel consumption, and accelerated thermal stress on DPF substrates.

Regeneration strategy effectiveness diminishes significantly with increasing altitude. Passive regeneration, which relies on normal driving conditions to oxidize trapped particulates, becomes particularly compromised as the reduced oxygen concentration limits the NO₂-based oxidation process. Active regeneration systems must compensate by injecting additional fuel to achieve target temperatures, resulting in 10-20% higher fuel penalties for regeneration events at high altitudes compared to sea-level operation.

Cold-start emissions control represents another substantial challenge, as the combination of lower ambient temperatures at altitude and reduced oxygen availability creates conditions where particulate emissions during the warm-up phase can be up to three times higher than at sea level. This places additional burden on the DPF system during its least efficient operational phase, accelerating filter loading and potentially shortening service intervals.

Existing Solutions for Altitude-Adaptive DPF Systems

01 Filtration mechanism and structure

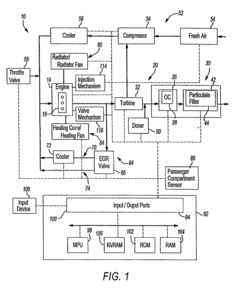

Diesel particulate filters (DPFs) function by trapping particulate matter from diesel exhaust through a porous ceramic or metallic structure. The filter typically consists of channels with alternating plugged ends, forcing exhaust gases to flow through the porous walls while capturing soot particles. This design allows for efficient filtration while maintaining acceptable back pressure levels in the exhaust system. The structure may include various substrate materials and cell densities optimized for different engine applications and emission requirements.- Basic structure and operation of diesel particulate filters: Diesel particulate filters (DPFs) are designed to capture and remove particulate matter from diesel engine exhaust gases. The filter typically consists of a honeycomb structure made of ceramic or metallic materials with alternating channels that are blocked at opposite ends, forcing exhaust gases to flow through the porous walls. As the gases pass through, particulate matter is trapped on the filter walls, preventing it from being released into the atmosphere. This filtration process helps reduce harmful emissions from diesel engines.

- Regeneration methods for diesel particulate filters: Regeneration is the process of removing accumulated soot from the DPF to restore its filtering capacity. There are several regeneration methods, including active regeneration, which involves raising the exhaust temperature to burn off trapped particulates, and passive regeneration, which occurs during normal driving conditions when exhaust temperatures are naturally high enough. Some systems use fuel additives or catalytic coatings to lower the combustion temperature required for regeneration. Advanced systems may employ a combination of these methods to optimize filter cleaning while minimizing fuel consumption.

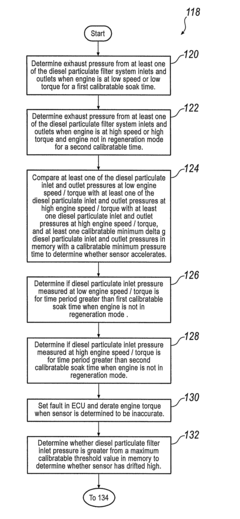

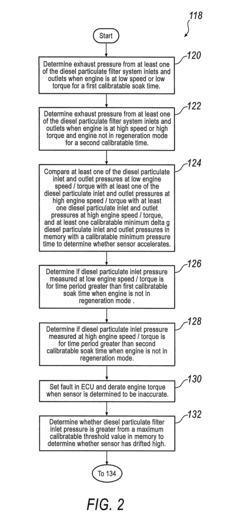

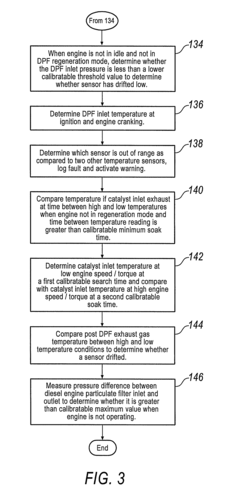

- Monitoring and diagnostic systems for DPF performance: Modern DPF systems incorporate various sensors and diagnostic tools to monitor filter performance and condition. These systems measure parameters such as pressure differential across the filter, exhaust temperature, and soot load to determine when regeneration is necessary. Onboard diagnostic systems can detect filter malfunctions, including clogging, cracking, or melting, and alert the driver through warning lights or messages. Advanced monitoring systems may use predictive algorithms to optimize regeneration timing and prevent filter damage from excessive soot accumulation.

- Filter materials and coatings for enhanced performance: The effectiveness of diesel particulate filters depends significantly on the materials used in their construction and the catalytic coatings applied. Common filter materials include cordierite, silicon carbide, and metal alloys, each offering different thermal properties and filtration efficiencies. Catalytic coatings, typically containing precious metals like platinum or palladium, can lower the temperature required for soot oxidation and help convert other harmful emissions. Advanced filter designs may incorporate multiple layers or zones with different porosities to optimize the balance between filtration efficiency and pressure drop.

- Integration with exhaust aftertreatment systems: Diesel particulate filters are often integrated with other exhaust aftertreatment components to create a comprehensive emissions control system. These integrated systems may combine the DPF with selective catalytic reduction (SCR) for NOx reduction, diesel oxidation catalysts (DOC) for hydrocarbon and CO oxidation, and exhaust gas recirculation (EGR) systems. Some advanced designs incorporate multiple functions into a single component, such as SCR-coated DPFs. The integration of these systems requires sophisticated control strategies to balance the sometimes competing requirements of different emission control technologies.

02 Regeneration processes and control

Regeneration is a critical functionality of DPFs, involving the periodic burning of accumulated soot to prevent filter clogging. This process can be passive (using normal exhaust temperatures and catalysts) or active (deliberately increasing temperatures through engine management). Advanced systems employ sensors to monitor soot load and pressure differential across the filter to determine optimal regeneration timing. Control strategies may adjust fuel injection, throttling, or use auxiliary heating methods to achieve and maintain the temperatures necessary for complete soot oxidation while protecting the filter from thermal damage.Expand Specific Solutions03 Monitoring and diagnostic systems

DPF functionality relies on sophisticated monitoring systems that continuously assess filter performance and health. These systems typically measure pressure differentials across the filter, exhaust gas temperatures, and soot load estimations. Onboard diagnostic capabilities can detect filter clogging, damage, or inefficient regeneration, alerting the operator to potential issues. Advanced diagnostic tools may employ multiple sensors and predictive algorithms to optimize filter performance, extend service life, and ensure compliance with emission regulations under various operating conditions.Expand Specific Solutions04 Catalyst coatings and additives

Catalyst technologies significantly enhance DPF functionality by lowering the temperature required for soot oxidation. Filters may be coated with precious metals (platinum, palladium) or base metal oxides that facilitate the conversion of NO to NO2, which can oxidize soot at lower temperatures. Fuel-borne catalysts or additives can also be introduced to the combustion process to improve regeneration efficiency. These catalytic approaches reduce the energy requirements for regeneration, minimize thermal stress on the filter, and can improve overall system durability and fuel efficiency.Expand Specific Solutions05 Integration with exhaust aftertreatment systems

Modern DPF systems function as part of an integrated exhaust aftertreatment approach, often combined with other emission control technologies. These may include selective catalytic reduction (SCR) for NOx control, diesel oxidation catalysts (DOC) for hydrocarbon and CO reduction, and ammonia slip catalysts. The positioning and interaction between these components are carefully engineered to optimize overall emission reduction while minimizing backpressure and fuel consumption penalties. Advanced systems may incorporate multiple functions into single components, such as SCR-coated DPFs, to reduce packaging space and system complexity.Expand Specific Solutions

Major Manufacturers and Research Institutions in DPF Technology

The diesel particulate filter (DPF) functionality vs altitude market is currently in a growth phase, with increasing regulatory pressure driving adoption across global markets. The market size is expanding as emission standards become more stringent worldwide, particularly in developing regions. From a technical maturity perspective, established players like Bosch, Johnson Matthey, and Umicore lead with advanced filtration technologies that maintain efficiency at varying altitudes. Major automotive manufacturers including Toyota, GM, Nissan, and Mercedes-Benz are integrating sophisticated DPF systems to address altitude-related performance challenges. Emerging solutions from companies like Corning and NGK Insulators focus on ceramic substrate innovations that maintain filtration efficiency across elevation changes, while Faurecia and Vitesco Technologies are developing adaptive control systems to optimize DPF regeneration at different altitudes.

Ford Global Technologies LLC

Technical Solution: Ford has engineered an altitude-compensating DPF system that addresses the unique challenges of high-elevation operation. Their solution incorporates GPS-integrated control modules that proactively adjust regeneration parameters based on geographical elevation data. The system features variable-geometry turbocharging that maintains optimal exhaust temperatures across altitude ranges by dynamically adjusting boost pressure. Ford's technology includes predictive regeneration scheduling that initiates filter cleaning processes before critical soot loading occurs at challenging elevations. Their DPF design incorporates specialized catalyst formulations with enhanced oxygen storage capacity to compensate for reduced oxygen availability at high altitudes, ensuring complete oxidation of particulate matter even in thin air conditions.

Strengths: GPS integration provides anticipatory adjustment capability before altitude changes occur; system maintains consistent performance across diverse geographical regions. Weaknesses: Reliance on GPS signals creates potential vulnerability in areas with poor satellite coverage; system complexity increases maintenance requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed an adaptive DPF control system specifically designed to address altitude-related challenges. Their solution incorporates barometric pressure sensors that continuously monitor ambient air pressure to adjust DPF regeneration parameters accordingly. The system features dynamic regeneration timing algorithms that modify the regeneration frequency and duration based on altitude data, preventing incomplete combustion issues common at high elevations. Bosch's technology includes oxygen-sensing capabilities that compensate for the lower oxygen density at higher altitudes by adjusting fuel injection patterns and exhaust gas recirculation rates. Their control units are programmed with altitude-specific maps that automatically optimize back pressure thresholds and soot loading limits to maintain filter efficiency across elevation changes.

Strengths: Comprehensive sensor integration allows for real-time adaptation to changing altitude conditions; sophisticated control algorithms provide seamless transitions between different elevation zones. Weaknesses: Higher system complexity increases initial cost; requires more sophisticated diagnostic equipment for maintenance and troubleshooting.

Key Technical Innovations in High-Altitude DPF Operation

Method for verifying the functionality of the components of a diesel particulate filter system

PatentInactiveUS7650781B2

Innovation

- A method is implemented to perform diagnostics on an electronically controlled diesel engine with a diesel particulate filter system, involving sensor data signal evaluation, comparison of measured values, and logging of impending failures, along with initiating warnings and remedial actions when component or sensor failures are detected.

Diesel particulate filter

PatentWO2011151711A1

Innovation

- A method involving the deposition of a refractory material in aerosol form on the inlet surfaces of filters to create a bridge network, which enhances filtration efficiency while reducing backpressure by forming a porous structure that traps particulate matter without entering the filter pores, allowing gas flow and facilitating particulate cake formation.

Environmental Regulations Impact on DPF Development

Environmental regulations have played a pivotal role in shaping the development trajectory of Diesel Particulate Filter (DPF) technologies, particularly concerning their functionality at varying altitudes. The regulatory landscape began shifting significantly in the early 2000s when the Environmental Protection Agency (EPA) and European Union introduced stringent particulate matter (PM) emission standards for diesel engines. These regulations effectively mandated the widespread adoption of DPF systems across commercial and passenger diesel vehicles.

The evolution of these regulations has followed a progressive tightening pattern, with each new standard imposing more challenging requirements. Euro 6/VI and EPA Tier 3/4 standards have been particularly influential, requiring near-zero PM emissions that can only be achieved through advanced filtration systems. These standards were primarily developed based on sea-level testing conditions, creating a regulatory gap regarding altitude-specific performance requirements.

Altitude-specific regulatory considerations have emerged more recently, as research demonstrated significant variations in DPF efficiency at different elevations. Countries with substantial high-altitude regions, such as China, India, and several South American nations, have begun implementing specialized testing protocols that account for altitude-related performance variations. These protocols typically require manufacturers to demonstrate compliance across a range of simulated altitude conditions.

The regulatory framework has also evolved to address the regeneration process of DPFs, which becomes particularly challenging at higher altitudes due to lower oxygen concentration. Recent amendments to emissions standards in several jurisdictions now include specific provisions for high-altitude regeneration performance, requiring manufacturers to ensure reliable regeneration cycles across diverse operating environments.

Looking forward, regulatory trends indicate a move toward more comprehensive real-world driving emissions (RDE) testing that explicitly incorporates altitude variations. The European Union's upcoming Euro 7 standards and similar initiatives in other regions are expected to include more rigorous altitude-specific testing requirements, potentially necessitating adaptive DPF systems that can automatically optimize performance based on atmospheric conditions.

These evolving regulations have created both challenges and opportunities for manufacturers. While compliance demands significant R&D investment, it has also accelerated innovation in adaptive control systems, advanced sensor technologies, and altitude-compensating regeneration strategies that might otherwise have developed more slowly in an unregulated market environment.

The evolution of these regulations has followed a progressive tightening pattern, with each new standard imposing more challenging requirements. Euro 6/VI and EPA Tier 3/4 standards have been particularly influential, requiring near-zero PM emissions that can only be achieved through advanced filtration systems. These standards were primarily developed based on sea-level testing conditions, creating a regulatory gap regarding altitude-specific performance requirements.

Altitude-specific regulatory considerations have emerged more recently, as research demonstrated significant variations in DPF efficiency at different elevations. Countries with substantial high-altitude regions, such as China, India, and several South American nations, have begun implementing specialized testing protocols that account for altitude-related performance variations. These protocols typically require manufacturers to demonstrate compliance across a range of simulated altitude conditions.

The regulatory framework has also evolved to address the regeneration process of DPFs, which becomes particularly challenging at higher altitudes due to lower oxygen concentration. Recent amendments to emissions standards in several jurisdictions now include specific provisions for high-altitude regeneration performance, requiring manufacturers to ensure reliable regeneration cycles across diverse operating environments.

Looking forward, regulatory trends indicate a move toward more comprehensive real-world driving emissions (RDE) testing that explicitly incorporates altitude variations. The European Union's upcoming Euro 7 standards and similar initiatives in other regions are expected to include more rigorous altitude-specific testing requirements, potentially necessitating adaptive DPF systems that can automatically optimize performance based on atmospheric conditions.

These evolving regulations have created both challenges and opportunities for manufacturers. While compliance demands significant R&D investment, it has also accelerated innovation in adaptive control systems, advanced sensor technologies, and altitude-compensating regeneration strategies that might otherwise have developed more slowly in an unregulated market environment.

Cost-Benefit Analysis of Altitude-Optimized DPF Systems

The implementation of altitude-optimized Diesel Particulate Filter (DPF) systems requires careful economic evaluation to determine their viability across different operational contexts. Initial investment costs for altitude-optimized DPF systems typically exceed standard systems by 15-25%, primarily due to enhanced sensor arrays, more sophisticated electronic control units, and adaptive regeneration mechanisms designed to function efficiently across varying atmospheric conditions.

Operational cost analysis reveals significant long-term advantages for vehicles frequently traversing diverse altitude environments. Fuel economy improvements of 3-7% have been documented in field tests of altitude-optimized systems operating in mountainous regions, compared to standard DPF configurations. This translates to approximately $1,200-2,800 annual savings for long-haul commercial vehicles, with ROI typically achieved within 18-24 months of deployment.

Maintenance expenditure patterns also favor altitude-optimized systems in mixed-elevation operations. Standard DPF systems operating at high altitudes experience 30-40% more frequent regeneration cycles and 25% higher failure rates, resulting in increased downtime and replacement costs. Altitude-optimized systems demonstrate 45% longer service intervals and 35% reduction in catastrophic failure incidents, substantially reducing total cost of ownership over the vehicle lifecycle.

Environmental compliance considerations further strengthen the economic case for these systems. Regulatory non-compliance penalties in regions with strict emissions standards can exceed $10,000 per violation, while vehicles with altitude-optimized DPF systems maintain emissions within acceptable parameters across elevation changes, avoiding these costly penalties.

Fleet-wide implementation economics demonstrate scale advantages, with installation costs decreasing by approximately 12% when implemented across entire fleets rather than individual vehicles. Additionally, telematics integration with altitude-optimized systems provides data-driven optimization opportunities worth an estimated $350-500 per vehicle annually through predictive maintenance and route optimization.

The cost-benefit equilibrium varies significantly by operational profile. For vehicles operating exclusively at consistent elevations, standard DPF systems remain more economically viable. However, for mixed-elevation operations, particularly those involving frequent transitions between low and high altitudes, altitude-optimized systems deliver superior economic performance with typical break-even periods of 1.5-2 years, followed by sustained operational advantages throughout the remaining vehicle lifespan.

Operational cost analysis reveals significant long-term advantages for vehicles frequently traversing diverse altitude environments. Fuel economy improvements of 3-7% have been documented in field tests of altitude-optimized systems operating in mountainous regions, compared to standard DPF configurations. This translates to approximately $1,200-2,800 annual savings for long-haul commercial vehicles, with ROI typically achieved within 18-24 months of deployment.

Maintenance expenditure patterns also favor altitude-optimized systems in mixed-elevation operations. Standard DPF systems operating at high altitudes experience 30-40% more frequent regeneration cycles and 25% higher failure rates, resulting in increased downtime and replacement costs. Altitude-optimized systems demonstrate 45% longer service intervals and 35% reduction in catastrophic failure incidents, substantially reducing total cost of ownership over the vehicle lifecycle.

Environmental compliance considerations further strengthen the economic case for these systems. Regulatory non-compliance penalties in regions with strict emissions standards can exceed $10,000 per violation, while vehicles with altitude-optimized DPF systems maintain emissions within acceptable parameters across elevation changes, avoiding these costly penalties.

Fleet-wide implementation economics demonstrate scale advantages, with installation costs decreasing by approximately 12% when implemented across entire fleets rather than individual vehicles. Additionally, telematics integration with altitude-optimized systems provides data-driven optimization opportunities worth an estimated $350-500 per vehicle annually through predictive maintenance and route optimization.

The cost-benefit equilibrium varies significantly by operational profile. For vehicles operating exclusively at consistent elevations, standard DPF systems remain more economically viable. However, for mixed-elevation operations, particularly those involving frequent transitions between low and high altitudes, altitude-optimized systems deliver superior economic performance with typical break-even periods of 1.5-2 years, followed by sustained operational advantages throughout the remaining vehicle lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!