Optimizing Diesel Particulate Filter Reaction Rates

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Optimization Goals

Diesel Particulate Filters (DPFs) emerged in the 1980s as a response to increasingly stringent emissions regulations targeting particulate matter (PM) from diesel engines. The technology has evolved significantly over the past four decades, transitioning from simple mechanical filtration systems to sophisticated catalytic devices capable of capturing and oxidizing soot particles. Early DPF systems relied primarily on passive regeneration, which often proved insufficient for complete soot removal, leading to filter clogging and performance degradation.

The fundamental operating principle of DPFs involves trapping soot particles in a honeycomb-structured ceramic filter while allowing exhaust gases to pass through. The accumulated soot must be periodically oxidized through a process called regeneration to prevent backpressure buildup that can negatively impact engine performance and fuel efficiency. This regeneration process represents the core technical challenge in DPF technology optimization.

Current technological trends in DPF development focus on enhancing reaction rates during both passive and active regeneration phases. Passive regeneration occurs continuously at lower temperatures (approximately 250-400°C) through NO₂-assisted oxidation, while active regeneration requires higher temperatures (550-650°C) to initiate direct oxidation with oxygen. The industry is moving toward systems that can maximize passive regeneration efficiency to reduce the frequency of fuel-consuming active regeneration events.

The primary optimization goals for DPF reaction rates include reducing the regeneration temperature threshold, accelerating soot oxidation kinetics, improving catalyst performance, and enhancing thermal management. Lowering the temperature required for effective regeneration would significantly improve system efficiency and durability while reducing the fuel penalty associated with active regeneration strategies.

Another critical objective is to develop advanced catalyst formulations that can promote soot oxidation at lower temperatures. Current research focuses on novel catalyst materials including platinum group metals (PGMs), base metal oxides, and mixed oxide systems that demonstrate superior oxygen storage capacity and improved low-temperature activity. These catalytic innovations aim to bridge the gap between laboratory performance and real-world driving conditions.

The optimization of DPF reaction rates also seeks to address the challenges posed by modern diesel engines operating at lower exhaust temperatures due to improved efficiency. This trend has complicated the regeneration process, as exhaust temperatures in many driving scenarios may not reach levels required for effective soot oxidation. Therefore, developing solutions that can function effectively within these constraints represents a key technological goal.

Ultimately, the industry aims to create DPF systems with enhanced durability, reduced maintenance requirements, and minimal impact on engine performance while maintaining compliance with increasingly stringent emissions standards worldwide. This requires a multidisciplinary approach combining materials science, chemical engineering, and advanced computational modeling to predict and optimize reaction kinetics under diverse operating conditions.

The fundamental operating principle of DPFs involves trapping soot particles in a honeycomb-structured ceramic filter while allowing exhaust gases to pass through. The accumulated soot must be periodically oxidized through a process called regeneration to prevent backpressure buildup that can negatively impact engine performance and fuel efficiency. This regeneration process represents the core technical challenge in DPF technology optimization.

Current technological trends in DPF development focus on enhancing reaction rates during both passive and active regeneration phases. Passive regeneration occurs continuously at lower temperatures (approximately 250-400°C) through NO₂-assisted oxidation, while active regeneration requires higher temperatures (550-650°C) to initiate direct oxidation with oxygen. The industry is moving toward systems that can maximize passive regeneration efficiency to reduce the frequency of fuel-consuming active regeneration events.

The primary optimization goals for DPF reaction rates include reducing the regeneration temperature threshold, accelerating soot oxidation kinetics, improving catalyst performance, and enhancing thermal management. Lowering the temperature required for effective regeneration would significantly improve system efficiency and durability while reducing the fuel penalty associated with active regeneration strategies.

Another critical objective is to develop advanced catalyst formulations that can promote soot oxidation at lower temperatures. Current research focuses on novel catalyst materials including platinum group metals (PGMs), base metal oxides, and mixed oxide systems that demonstrate superior oxygen storage capacity and improved low-temperature activity. These catalytic innovations aim to bridge the gap between laboratory performance and real-world driving conditions.

The optimization of DPF reaction rates also seeks to address the challenges posed by modern diesel engines operating at lower exhaust temperatures due to improved efficiency. This trend has complicated the regeneration process, as exhaust temperatures in many driving scenarios may not reach levels required for effective soot oxidation. Therefore, developing solutions that can function effectively within these constraints represents a key technological goal.

Ultimately, the industry aims to create DPF systems with enhanced durability, reduced maintenance requirements, and minimal impact on engine performance while maintaining compliance with increasingly stringent emissions standards worldwide. This requires a multidisciplinary approach combining materials science, chemical engineering, and advanced computational modeling to predict and optimize reaction kinetics under diverse operating conditions.

Market Demand Analysis for Advanced DPF Solutions

The global market for advanced Diesel Particulate Filter (DPF) solutions is experiencing robust growth driven by increasingly stringent emission regulations worldwide. The automotive industry faces mounting pressure to reduce particulate matter emissions, with Euro 7 standards in Europe, China 6 in Asia, and Tier 3 regulations in North America pushing manufacturers toward more efficient filtration technologies. Current market valuation for DPF systems stands at approximately 12 billion USD, with projections indicating growth to 18 billion USD by 2028, representing a compound annual growth rate of 7.2%.

Commercial vehicle segments, particularly heavy-duty trucks and off-road equipment, represent the largest market share for advanced DPF solutions at 43% of total demand. These sectors prioritize DPF systems with optimized reaction rates to minimize regeneration frequency and reduce operational downtime. Fleet operators consistently report that vehicles with inefficient DPF systems experience 15-20% more downtime due to maintenance requirements, translating to significant operational losses.

Consumer demand patterns reveal a growing preference for DPF solutions that balance performance with fuel efficiency. Market research indicates that fuel consumption penalties associated with DPF regeneration cycles remain a primary concern among fleet operators, with 78% of surveyed companies ranking this as their top consideration when evaluating new vehicle purchases. This creates substantial market pull for catalytic technologies that can lower DPF regeneration temperatures and accelerate reaction rates.

Regional market analysis shows Europe leading DPF technology adoption with 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly India and Brazil, where tightening emission standards are creating new demand centers with projected growth rates exceeding 12% annually through 2027.

The aftermarket segment for DPF replacement and retrofitting solutions represents a significant opportunity, valued at 3.2 billion USD annually. This segment is expected to grow as older vehicle fleets require upgrades to meet new emission standards, particularly in developing economies where complete fleet replacement is economically unfeasible.

Industry surveys indicate that manufacturers are willing to invest 20-30% premium for DPF systems that demonstrate superior reaction rates and reduced regeneration frequency. This price elasticity creates significant market opportunities for innovative catalyst formulations and advanced thermal management systems that can optimize particulate oxidation processes while minimizing energy consumption.

Commercial vehicle segments, particularly heavy-duty trucks and off-road equipment, represent the largest market share for advanced DPF solutions at 43% of total demand. These sectors prioritize DPF systems with optimized reaction rates to minimize regeneration frequency and reduce operational downtime. Fleet operators consistently report that vehicles with inefficient DPF systems experience 15-20% more downtime due to maintenance requirements, translating to significant operational losses.

Consumer demand patterns reveal a growing preference for DPF solutions that balance performance with fuel efficiency. Market research indicates that fuel consumption penalties associated with DPF regeneration cycles remain a primary concern among fleet operators, with 78% of surveyed companies ranking this as their top consideration when evaluating new vehicle purchases. This creates substantial market pull for catalytic technologies that can lower DPF regeneration temperatures and accelerate reaction rates.

Regional market analysis shows Europe leading DPF technology adoption with 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly India and Brazil, where tightening emission standards are creating new demand centers with projected growth rates exceeding 12% annually through 2027.

The aftermarket segment for DPF replacement and retrofitting solutions represents a significant opportunity, valued at 3.2 billion USD annually. This segment is expected to grow as older vehicle fleets require upgrades to meet new emission standards, particularly in developing economies where complete fleet replacement is economically unfeasible.

Industry surveys indicate that manufacturers are willing to invest 20-30% premium for DPF systems that demonstrate superior reaction rates and reduced regeneration frequency. This price elasticity creates significant market opportunities for innovative catalyst formulations and advanced thermal management systems that can optimize particulate oxidation processes while minimizing energy consumption.

Current DPF Technology Challenges and Limitations

Despite significant advancements in Diesel Particulate Filter (DPF) technology over the past two decades, several critical challenges continue to impede optimal reaction rates and overall system efficiency. The primary limitation remains the inherent trade-off between filtration efficiency and backpressure. As filtration efficiency increases through denser filter substrates, engine backpressure rises correspondingly, negatively impacting fuel economy and engine performance. This fundamental contradiction has not been fully resolved in current DPF designs.

Temperature management presents another significant challenge. DPF regeneration processes require specific temperature windows (typically 550-650°C) to effectively oxidize trapped particulate matter. However, modern diesel engines, particularly under urban driving conditions or light loads, often operate at lower exhaust temperatures, making it difficult to achieve and maintain optimal regeneration conditions without external heating mechanisms. This leads to incomplete regeneration cycles and accelerated ash accumulation.

The catalyst degradation issue severely impacts long-term DPF performance. Current catalytic coatings experience thermal deactivation after repeated high-temperature regeneration events, reducing their effectiveness over time. Additionally, catalyst poisoning from fuel and lubricant additives containing phosphorus, zinc, and sulfur compounds progressively diminishes catalytic activity, necessitating more frequent regeneration cycles or premature filter replacement.

Ash accumulation represents a persistent limitation in DPF technology. Unlike soot, ash derived from lubricant additives and engine wear cannot be removed through regeneration processes. This irreversible accumulation gradually reduces the filter's effective volume, increases backpressure, and shortens service intervals. Current DPF designs lack effective mechanisms for managing ash without physical filter removal and cleaning.

Sensor technology limitations further complicate DPF operation. Existing pressure differential and temperature sensors provide only indirect measurements of soot loading and regeneration efficiency. The absence of real-time, direct particulate matter sensing within the filter structure forces control systems to rely on predictive models rather than actual conditions, often resulting in suboptimal regeneration timing and duration.

Cold-start emissions control remains particularly challenging. During engine warm-up phases, low exhaust temperatures prevent effective catalyst light-off, allowing significant particulate matter to pass through the system before optimal operating conditions are reached. This "cold-start penalty" contributes disproportionately to overall emissions profiles, especially in short-trip urban driving scenarios.

The complexity of control algorithms represents another limitation. Current engine control units struggle to optimize regeneration strategies across the wide range of operating conditions experienced in real-world driving. The integration of DPF management with other emission control systems (EGR, SCR) creates competing priorities that often result in compromised performance across multiple parameters.

Temperature management presents another significant challenge. DPF regeneration processes require specific temperature windows (typically 550-650°C) to effectively oxidize trapped particulate matter. However, modern diesel engines, particularly under urban driving conditions or light loads, often operate at lower exhaust temperatures, making it difficult to achieve and maintain optimal regeneration conditions without external heating mechanisms. This leads to incomplete regeneration cycles and accelerated ash accumulation.

The catalyst degradation issue severely impacts long-term DPF performance. Current catalytic coatings experience thermal deactivation after repeated high-temperature regeneration events, reducing their effectiveness over time. Additionally, catalyst poisoning from fuel and lubricant additives containing phosphorus, zinc, and sulfur compounds progressively diminishes catalytic activity, necessitating more frequent regeneration cycles or premature filter replacement.

Ash accumulation represents a persistent limitation in DPF technology. Unlike soot, ash derived from lubricant additives and engine wear cannot be removed through regeneration processes. This irreversible accumulation gradually reduces the filter's effective volume, increases backpressure, and shortens service intervals. Current DPF designs lack effective mechanisms for managing ash without physical filter removal and cleaning.

Sensor technology limitations further complicate DPF operation. Existing pressure differential and temperature sensors provide only indirect measurements of soot loading and regeneration efficiency. The absence of real-time, direct particulate matter sensing within the filter structure forces control systems to rely on predictive models rather than actual conditions, often resulting in suboptimal regeneration timing and duration.

Cold-start emissions control remains particularly challenging. During engine warm-up phases, low exhaust temperatures prevent effective catalyst light-off, allowing significant particulate matter to pass through the system before optimal operating conditions are reached. This "cold-start penalty" contributes disproportionately to overall emissions profiles, especially in short-trip urban driving scenarios.

The complexity of control algorithms represents another limitation. Current engine control units struggle to optimize regeneration strategies across the wide range of operating conditions experienced in real-world driving. The integration of DPF management with other emission control systems (EGR, SCR) creates competing priorities that often result in compromised performance across multiple parameters.

Current Reaction Rate Enhancement Methodologies

01 Catalyst compositions for enhancing DPF reaction rates

Various catalyst compositions can be used to enhance the reaction rates in diesel particulate filters. These catalysts typically include noble metals, transition metals, or metal oxides that facilitate the oxidation of particulate matter at lower temperatures. The catalysts can be applied as coatings on the filter substrate or incorporated into the filter material itself, improving the efficiency of particulate matter removal and reducing regeneration temperatures.- Catalyst compositions for enhancing DPF reaction rates: Various catalyst compositions can be incorporated into diesel particulate filters to enhance the oxidation reaction rates of trapped particulate matter. These catalysts typically include precious metals like platinum, palladium, and rhodium, as well as base metal oxides that promote soot combustion at lower temperatures. The catalytic coatings can be applied directly to the filter substrate or incorporated into washcoat formulations to maximize contact with exhaust gases and particulates, thereby increasing the efficiency of the regeneration process.

- Temperature control strategies for optimizing DPF regeneration rates: Temperature management is crucial for controlling reaction rates within diesel particulate filters during regeneration. Various strategies include active regeneration through fuel injection or heating elements, passive regeneration utilizing exhaust heat, and combined approaches. Optimal temperature profiles can be maintained to ensure complete combustion of particulate matter while preventing thermal damage to the filter substrate. Advanced control algorithms adjust regeneration parameters based on soot load, exhaust flow, and ambient conditions to achieve efficient particulate oxidation.

- Monitoring and sensing technologies for DPF reaction rate assessment: Advanced sensing technologies enable real-time monitoring of reaction rates within diesel particulate filters. Pressure differential sensors, temperature sensors, and soot load estimators provide data for determining the progression of oxidation reactions. Some systems incorporate oxygen sensors to measure oxygen consumption during regeneration, while others use predictive models to estimate reaction kinetics. These monitoring systems allow for adaptive control of the regeneration process and optimization of filter performance based on actual operating conditions.

- Filter substrate design for improved reaction kinetics: The physical structure of the filter substrate significantly impacts reaction rates within diesel particulate filters. Innovations in substrate geometry, porosity, and channel design enhance contact between exhaust gases and trapped particulates. Wall-flow filters with optimized pore size distributions balance filtration efficiency with pressure drop characteristics. Advanced manufacturing techniques create asymmetric channel structures and variable cell densities that improve soot distribution and oxidation rates, leading to more efficient and complete regeneration cycles.

- Integration of DPF systems with exhaust aftertreatment for enhanced reaction efficiency: Integrating diesel particulate filters with other exhaust aftertreatment components creates synergistic effects that improve overall reaction rates. Combined SCR (Selective Catalytic Reduction) and DPF systems utilize ammonia for NOx reduction while simultaneously promoting soot oxidation. DOC (Diesel Oxidation Catalyst) placement upstream of DPFs generates NO2, which serves as a powerful oxidizing agent for particulate matter at lower temperatures. These integrated systems optimize the chemical environment within the exhaust stream to accelerate particulate oxidation reactions while addressing multiple emissions simultaneously.

02 Temperature control systems for optimizing DPF reaction kinetics

Temperature management systems are crucial for controlling reaction rates within diesel particulate filters. These systems monitor and adjust the filter temperature to maintain optimal conditions for particulate matter oxidation. Advanced control algorithms can predict regeneration needs based on soot loading and adjust exhaust temperatures accordingly, ensuring efficient reaction rates while preventing thermal damage to the filter substrate.Expand Specific Solutions03 Sensor technologies for monitoring DPF reaction progress

Various sensor technologies are employed to monitor reaction rates and efficiency in diesel particulate filters. These include pressure differential sensors, temperature sensors, and soot load sensors that provide real-time data on filter conditions. The sensor data helps in determining the optimal timing for regeneration cycles and evaluating the effectiveness of the ongoing reactions, thereby improving overall system efficiency and filter longevity.Expand Specific Solutions04 Regeneration strategies to enhance reaction rates

Different regeneration strategies can be implemented to enhance reaction rates in diesel particulate filters. These include active regeneration using fuel injection or heating elements, passive regeneration utilizing exhaust heat and catalysts, and forced regeneration during specific operating conditions. The choice of regeneration strategy affects the reaction kinetics, energy consumption, and overall efficiency of the particulate matter removal process.Expand Specific Solutions05 Filter substrate designs for improved reaction efficiency

The design of filter substrates significantly impacts reaction rates in diesel particulate filters. Innovations in substrate materials, channel geometries, porosity, and wall thickness can enhance contact between exhaust gases and catalytic surfaces, improving reaction kinetics. Advanced substrate designs also focus on optimizing the balance between filtration efficiency, pressure drop, and thermal durability to ensure consistent reaction rates throughout the filter's operational life.Expand Specific Solutions

Key Industry Players in DPF Manufacturing and Research

The diesel particulate filter (DPF) optimization market is currently in a growth phase, with increasing regulatory pressure driving innovation. The global market size is expanding significantly due to stringent emission standards worldwide. From a technological maturity perspective, major automotive manufacturers like GM, Volkswagen, Renault-Nissan, and Hyundai-Kia are leading mainstream implementation, while specialized component suppliers such as Bosch, Corning, and ElringKlinger are advancing filter technology. Research institutions like IFP Energies Nouvelles and companies like Dinex Finland are pushing boundaries in reaction chemistry optimization. Chinese players including Sinopec Luoyang and Shandong Aofu are rapidly entering the market with cost-effective solutions. The competitive landscape shows a clear division between established Western manufacturers focusing on premium solutions and emerging Asian companies targeting value segments.

Corning, Inc.

Technical Solution: Corning has revolutionized DPF technology with their advanced ceramic substrate designs that significantly enhance reaction rates. Their proprietary cellular ceramic technology features thin-walled, honeycomb structures with carefully engineered porosity that maximizes filtration efficiency while minimizing backpressure. Corning's latest DuraTrap® filters utilize asymmetric cell technology with alternating plugged channels that force exhaust gases through porous walls, capturing particulate matter while allowing gases to flow through. The company has developed specialized catalyst coating methods that ensure uniform distribution throughout the filter substrate, increasing active surface area and improving reaction kinetics[2]. Corning's thermal shock resistant materials allow for higher temperature regeneration cycles, which accelerate oxidation reactions of trapped particulates. Their advanced manufacturing processes create precise microstructures that optimize the balance between filtration efficiency and pressure drop, a critical factor in maintaining engine performance while maximizing particulate capture. Recent innovations include incorporating rare earth metals into the substrate material to catalyze soot oxidation at lower temperatures.

Strengths: Industry-leading substrate technology with exceptional durability and thermal stability. Advanced manufacturing capabilities allow for precise control of pore size and distribution. Weaknesses: Higher initial cost compared to some competitors. Limited control over the complete exhaust aftertreatment system as they primarily supply components to OEMs rather than complete systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Diesel Particulate Filter (DPF) systems that utilize precise electronic control units to optimize regeneration timing and duration. Their technology employs multiple temperature and pressure sensors throughout the exhaust system to continuously monitor filter loading conditions. Bosch's approach incorporates predictive algorithms that analyze driving patterns and engine operation to determine optimal regeneration timing, reducing fuel consumption associated with active regeneration events. Their latest systems feature variable geometry turbochargers that can increase exhaust temperatures when needed for regeneration without requiring additional fuel injection. Bosch has also pioneered the integration of selective catalytic reduction (SCR) with DPF systems, creating a combined unit that optimizes both NOx and particulate matter reduction simultaneously[1]. This integration reduces overall system complexity while improving reaction efficiency through careful thermal management of both catalytic processes.

Strengths: Superior sensor integration and electronic control capabilities allow for precise regeneration timing. Combined SCR-DPF systems reduce packaging requirements and improve overall efficiency. Weaknesses: Systems tend to be more expensive than competitors due to complex electronic controls and premium components. Requires sophisticated diagnostic equipment for maintenance and repair.

Critical Catalyst and Substrate Technology Analysis

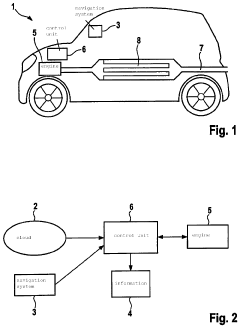

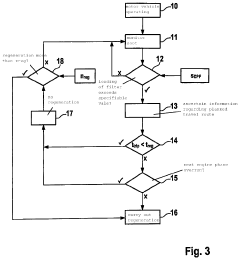

Method for optimizing an active regeneration of a diesel particulate filter

PatentActiveUS11073060B2

Innovation

- A method that uses information about the planned travel route, obtained from navigation systems or cloud data, to determine suitable sections for regeneration, preventing unnecessary regeneration attempts and ensuring timely completion by initiating regeneration only when conditions are favorable.

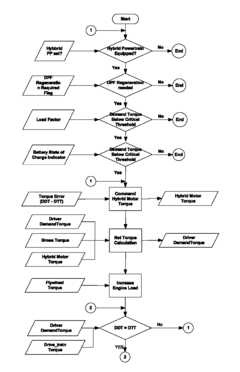

Method for diesel particulate filter regeneration in a vehicle equipped with a hybrid engine background of the invention

PatentInactiveUS8306710B2

Innovation

- A method that utilizes messaging over a communication bus to control the interaction between the diesel particulate filter aftertreatment system and the hybrid power train, increasing diesel engine load with or without electric motor assistance to elevate exhaust temperatures, and optionally using a resistive heating element when the battery is fully charged to optimize regeneration time.

Emissions Regulations and Compliance Requirements

The global regulatory landscape for diesel particulate emissions has evolved significantly over the past two decades, creating a complex framework that directly impacts DPF technology development. The European Union's Euro standards have progressively tightened particulate matter (PM) limits, with Euro 6d requiring less than 0.0045 g/km for passenger vehicles. Similarly, the United States EPA's Tier 3 standards mandate a 70% reduction in PM compared to previous regulations, while California's CARB maintains even stricter requirements.

These increasingly stringent regulations have fundamentally shaped DPF technology advancement, driving the need for higher filtration efficiency and improved regeneration processes. Compliance requirements now extend beyond simple PM mass measurements to include particle number limits, which address ultrafine particles that pose significant health risks despite their minimal mass contribution.

Real-world testing protocols have become central to regulatory frameworks following emissions scandals. The Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests ensure DPF systems perform effectively across diverse operating conditions, not just in laboratory settings. This shift has necessitated more sophisticated DPF reaction rate optimization to maintain compliance across variable driving patterns.

Regulatory timelines present significant challenges for manufacturers. The accelerated implementation schedule for Euro 7 standards (expected by 2025) and similar tightening of regulations in North America and Asia require rapid innovation in DPF technology. The industry faces a 24-36 month development cycle to meet these approaching deadlines while ensuring reliability and cost-effectiveness.

Penalties for non-compliance have escalated dramatically, with manufacturers facing fines exceeding billions of dollars, mandatory recalls, and significant reputational damage. This economic pressure serves as a powerful incentive for investment in advanced DPF technologies that can consistently meet or exceed regulatory requirements.

The global harmonization trend in emissions standards is creating more uniform requirements across major markets, though regional variations in testing procedures and implementation timelines persist. This convergence benefits technology developers by allowing more standardized approaches to DPF design, while still requiring adaptability to address market-specific requirements such as fuel quality variations and typical driving conditions.

These increasingly stringent regulations have fundamentally shaped DPF technology advancement, driving the need for higher filtration efficiency and improved regeneration processes. Compliance requirements now extend beyond simple PM mass measurements to include particle number limits, which address ultrafine particles that pose significant health risks despite their minimal mass contribution.

Real-world testing protocols have become central to regulatory frameworks following emissions scandals. The Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests ensure DPF systems perform effectively across diverse operating conditions, not just in laboratory settings. This shift has necessitated more sophisticated DPF reaction rate optimization to maintain compliance across variable driving patterns.

Regulatory timelines present significant challenges for manufacturers. The accelerated implementation schedule for Euro 7 standards (expected by 2025) and similar tightening of regulations in North America and Asia require rapid innovation in DPF technology. The industry faces a 24-36 month development cycle to meet these approaching deadlines while ensuring reliability and cost-effectiveness.

Penalties for non-compliance have escalated dramatically, with manufacturers facing fines exceeding billions of dollars, mandatory recalls, and significant reputational damage. This economic pressure serves as a powerful incentive for investment in advanced DPF technologies that can consistently meet or exceed regulatory requirements.

The global harmonization trend in emissions standards is creating more uniform requirements across major markets, though regional variations in testing procedures and implementation timelines persist. This convergence benefits technology developers by allowing more standardized approaches to DPF design, while still requiring adaptability to address market-specific requirements such as fuel quality variations and typical driving conditions.

Thermal Management Strategies for Optimal DPF Performance

Thermal management is a critical factor in optimizing Diesel Particulate Filter (DPF) reaction rates. The efficiency of particulate matter oxidation within DPFs is highly temperature-dependent, with optimal reaction rates typically occurring between 550°C and 650°C. However, normal diesel exhaust temperatures often range from 200°C to 400°C during standard operation, creating a significant thermal gap that must be addressed through strategic management approaches.

Active thermal management systems employ various heating methods to elevate DPF temperatures to the optimal reaction range. These include post-injection strategies, where additional fuel is injected late in the combustion cycle to increase exhaust gas temperatures, and electrical heating elements integrated into the DPF structure or positioned upstream. The latter approach offers precise temperature control but increases system complexity and power consumption.

Passive thermal management techniques focus on optimizing heat retention within the DPF system. Advanced insulation materials surrounding the filter housing can minimize heat loss to the environment, while strategic positioning of the DPF closer to the engine exhaust manifold capitalizes on higher exhaust temperatures. Computational fluid dynamics modeling has enabled more efficient DPF designs that balance pressure drop considerations with optimal thermal distribution.

Catalyst technology plays a significant role in thermal management by lowering the activation energy required for particulate oxidation. Platinum group metals (PGMs) remain the industry standard, but recent innovations in base metal catalysts and mixed oxide formulations have shown promise in reducing the temperature threshold for effective regeneration by up to 100°C. These advancements are particularly valuable for cold-start conditions and low-load operation scenarios.

Intelligent control systems represent the frontier of thermal management for DPFs. These systems utilize real-time monitoring of multiple parameters—including exhaust temperature, backpressure, and soot loading—to implement dynamic regeneration strategies. Machine learning algorithms are increasingly being deployed to predict optimal regeneration timing and adjust thermal management strategies based on driving patterns and environmental conditions, resulting in up to 15% improvement in regeneration efficiency.

The integration of thermal management with broader engine control strategies presents significant opportunities for optimization. Coordinated approaches that balance NOx control, fuel efficiency, and particulate filtration requirements can achieve synergistic benefits. For instance, selective catalyst reduction (SCR) systems generate exothermic reactions that can be harnessed to support DPF thermal requirements, creating a more holistic approach to emissions control system management.

Active thermal management systems employ various heating methods to elevate DPF temperatures to the optimal reaction range. These include post-injection strategies, where additional fuel is injected late in the combustion cycle to increase exhaust gas temperatures, and electrical heating elements integrated into the DPF structure or positioned upstream. The latter approach offers precise temperature control but increases system complexity and power consumption.

Passive thermal management techniques focus on optimizing heat retention within the DPF system. Advanced insulation materials surrounding the filter housing can minimize heat loss to the environment, while strategic positioning of the DPF closer to the engine exhaust manifold capitalizes on higher exhaust temperatures. Computational fluid dynamics modeling has enabled more efficient DPF designs that balance pressure drop considerations with optimal thermal distribution.

Catalyst technology plays a significant role in thermal management by lowering the activation energy required for particulate oxidation. Platinum group metals (PGMs) remain the industry standard, but recent innovations in base metal catalysts and mixed oxide formulations have shown promise in reducing the temperature threshold for effective regeneration by up to 100°C. These advancements are particularly valuable for cold-start conditions and low-load operation scenarios.

Intelligent control systems represent the frontier of thermal management for DPFs. These systems utilize real-time monitoring of multiple parameters—including exhaust temperature, backpressure, and soot loading—to implement dynamic regeneration strategies. Machine learning algorithms are increasingly being deployed to predict optimal regeneration timing and adjust thermal management strategies based on driving patterns and environmental conditions, resulting in up to 15% improvement in regeneration efficiency.

The integration of thermal management with broader engine control strategies presents significant opportunities for optimization. Coordinated approaches that balance NOx control, fuel efficiency, and particulate filtration requirements can achieve synergistic benefits. For instance, selective catalyst reduction (SCR) systems generate exothermic reactions that can be harnessed to support DPF thermal requirements, creating a more holistic approach to emissions control system management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!