Using AI for Diesel Particulate Filter Maintenance

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF AI Maintenance Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emission regulations worldwide. These filtration systems were designed to capture and remove particulate matter (PM) from diesel engine exhaust, significantly reducing harmful emissions. The evolution of DPF technology has progressed from simple passive systems to more sophisticated active regeneration mechanisms, with the latest developments incorporating advanced sensors and control systems.

The diesel industry has faced mounting pressure from environmental regulations such as Euro 6, EPA Tier 4, and China VI standards, which mandate substantial reductions in particulate emissions. This regulatory landscape has accelerated the need for more efficient and reliable DPF systems, creating both challenges and opportunities for technological innovation.

Traditional DPF maintenance relies heavily on scheduled service intervals or simplistic pressure differential measurements, often resulting in either premature maintenance or delayed interventions that can cause system damage. These approaches lack precision and fail to account for the complex variables affecting DPF performance, including driving conditions, fuel quality, and engine operating parameters.

Artificial Intelligence presents a transformative opportunity in this domain by enabling predictive and adaptive maintenance strategies. Machine learning algorithms can process vast amounts of sensor data to identify patterns and anomalies that human operators or conventional systems might miss. Deep learning techniques can model the complex relationships between operating conditions and filter degradation, while reinforcement learning approaches can optimize regeneration timing and strategies.

The primary objective of AI integration in DPF maintenance is to transition from reactive to predictive maintenance paradigms. This shift aims to maximize filter lifespan, optimize fuel efficiency, reduce downtime, and ensure consistent emissions compliance. By accurately predicting maintenance needs before critical failures occur, AI systems can significantly reduce total cost of ownership while enhancing environmental performance.

Secondary objectives include developing self-learning systems capable of adapting to individual vehicle usage patterns and environmental conditions, creating standardized AI frameworks that can be deployed across diverse diesel applications from passenger vehicles to heavy machinery, and establishing robust data collection infrastructures to continuously improve predictive models through fleet-wide learning.

The technological trajectory suggests a convergence of IoT sensor networks, edge computing capabilities, and cloud-based AI analytics to create comprehensive DPF health monitoring ecosystems. These systems will likely evolve from current diagnostic tools to fully autonomous maintenance decision support systems, potentially culminating in self-maintaining filter systems that dynamically adjust their operation based on real-time conditions and predictive insights.

The diesel industry has faced mounting pressure from environmental regulations such as Euro 6, EPA Tier 4, and China VI standards, which mandate substantial reductions in particulate emissions. This regulatory landscape has accelerated the need for more efficient and reliable DPF systems, creating both challenges and opportunities for technological innovation.

Traditional DPF maintenance relies heavily on scheduled service intervals or simplistic pressure differential measurements, often resulting in either premature maintenance or delayed interventions that can cause system damage. These approaches lack precision and fail to account for the complex variables affecting DPF performance, including driving conditions, fuel quality, and engine operating parameters.

Artificial Intelligence presents a transformative opportunity in this domain by enabling predictive and adaptive maintenance strategies. Machine learning algorithms can process vast amounts of sensor data to identify patterns and anomalies that human operators or conventional systems might miss. Deep learning techniques can model the complex relationships between operating conditions and filter degradation, while reinforcement learning approaches can optimize regeneration timing and strategies.

The primary objective of AI integration in DPF maintenance is to transition from reactive to predictive maintenance paradigms. This shift aims to maximize filter lifespan, optimize fuel efficiency, reduce downtime, and ensure consistent emissions compliance. By accurately predicting maintenance needs before critical failures occur, AI systems can significantly reduce total cost of ownership while enhancing environmental performance.

Secondary objectives include developing self-learning systems capable of adapting to individual vehicle usage patterns and environmental conditions, creating standardized AI frameworks that can be deployed across diverse diesel applications from passenger vehicles to heavy machinery, and establishing robust data collection infrastructures to continuously improve predictive models through fleet-wide learning.

The technological trajectory suggests a convergence of IoT sensor networks, edge computing capabilities, and cloud-based AI analytics to create comprehensive DPF health monitoring ecosystems. These systems will likely evolve from current diagnostic tools to fully autonomous maintenance decision support systems, potentially culminating in self-maintaining filter systems that dynamically adjust their operation based on real-time conditions and predictive insights.

Market Demand Analysis for AI-Enhanced DPF Solutions

The global market for AI-enhanced Diesel Particulate Filter (DPF) maintenance solutions is experiencing significant growth, driven by increasingly stringent emission regulations across major automotive markets. The European Union's Euro 6d standards, the US EPA's Tier 3 regulations, and China's National VI emission standards have collectively created substantial demand for more efficient DPF maintenance technologies. This regulatory pressure has transformed what was once a niche aftermarket service into a critical component of fleet management and vehicle maintenance programs worldwide.

Current market research indicates that the commercial vehicle sector represents the largest demand segment for AI-enhanced DPF solutions. Fleet operators managing medium and heavy-duty trucks face significant operational challenges when DPF systems fail, including costly downtime and repair expenses that can exceed $10,000 per incident. This economic pressure has created a receptive market for predictive maintenance solutions that can forecast DPF issues before they cause vehicle failures.

The off-highway equipment market presents another substantial growth opportunity, with construction, mining, and agricultural machinery operators seeking solutions to extend equipment lifespan and reduce maintenance costs. These specialized vehicles often operate in harsh conditions that accelerate DPF clogging, creating unique maintenance challenges that AI systems are particularly well-suited to address through adaptive learning algorithms.

Market analysis reveals a growing preference for integrated telematics solutions that incorporate DPF health monitoring as part of broader vehicle diagnostics systems. This trend is particularly evident in the North American and European markets, where fleet management software adoption has reached maturity. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment as these countries implement more stringent emission controls while simultaneously expanding their commercial vehicle fleets.

From a customer perspective, the primary market drivers include reduced total cost of ownership, minimized vehicle downtime, and compliance with environmental regulations. Fleet managers increasingly recognize that proactive DPF maintenance enabled by AI can extend filter life by 30-40% compared to traditional maintenance schedules, representing significant operational savings.

The aftermarket service sector has also emerged as a key market segment, with specialized maintenance providers adopting AI-enhanced diagnostic tools to improve service quality and efficiency. This has created a secondary market for software-as-a-service solutions targeting independent repair facilities and dealership service departments seeking competitive advantages through advanced diagnostic capabilities.

Current market research indicates that the commercial vehicle sector represents the largest demand segment for AI-enhanced DPF solutions. Fleet operators managing medium and heavy-duty trucks face significant operational challenges when DPF systems fail, including costly downtime and repair expenses that can exceed $10,000 per incident. This economic pressure has created a receptive market for predictive maintenance solutions that can forecast DPF issues before they cause vehicle failures.

The off-highway equipment market presents another substantial growth opportunity, with construction, mining, and agricultural machinery operators seeking solutions to extend equipment lifespan and reduce maintenance costs. These specialized vehicles often operate in harsh conditions that accelerate DPF clogging, creating unique maintenance challenges that AI systems are particularly well-suited to address through adaptive learning algorithms.

Market analysis reveals a growing preference for integrated telematics solutions that incorporate DPF health monitoring as part of broader vehicle diagnostics systems. This trend is particularly evident in the North American and European markets, where fleet management software adoption has reached maturity. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment as these countries implement more stringent emission controls while simultaneously expanding their commercial vehicle fleets.

From a customer perspective, the primary market drivers include reduced total cost of ownership, minimized vehicle downtime, and compliance with environmental regulations. Fleet managers increasingly recognize that proactive DPF maintenance enabled by AI can extend filter life by 30-40% compared to traditional maintenance schedules, representing significant operational savings.

The aftermarket service sector has also emerged as a key market segment, with specialized maintenance providers adopting AI-enhanced diagnostic tools to improve service quality and efficiency. This has created a secondary market for software-as-a-service solutions targeting independent repair facilities and dealership service departments seeking competitive advantages through advanced diagnostic capabilities.

Current State and Challenges in DPF Maintenance Technology

Diesel Particulate Filter (DPF) maintenance technology currently faces significant challenges despite advancements in diagnostic and cleaning methods. Traditional DPF maintenance relies heavily on scheduled service intervals or reactive approaches triggered by dashboard warning lights, often resulting in suboptimal timing for interventions. This conventional approach fails to account for the highly variable nature of DPF loading, which depends on numerous factors including driving patterns, fuel quality, engine condition, and environmental factors.

Current diagnostic methods primarily utilize differential pressure sensors to estimate soot load, but these measurements can be imprecise and fail to provide comprehensive information about filter condition. More advanced systems incorporate temperature sensors and exhaust gas oxygen sensors, yet these still offer limited visibility into the actual state of the DPF. The industry lacks reliable, real-time monitoring solutions that can accurately predict maintenance needs before performance degradation occurs.

The cleaning and regeneration processes present their own set of challenges. Passive regeneration depends on specific driving conditions that may not be consistently achievable, particularly in urban driving environments. Active regeneration systems consume additional fuel and may not completely remove accumulated ash, leading to gradual performance deterioration over time. Physical cleaning methods, including thermal, pneumatic, and chemical approaches, require filter removal and specialized equipment, resulting in vehicle downtime and significant maintenance costs.

Geographic variations in DPF technology adoption and maintenance practices further complicate the landscape. Developed markets have established infrastructure for DPF maintenance, while emerging markets often lack specialized service centers and technical expertise. This disparity creates inconsistent maintenance quality and approaches worldwide. Additionally, regulatory frameworks governing emissions control systems vary significantly across regions, creating a complex compliance environment for global fleet operators.

Technical limitations of current DPF systems include sensitivity to fuel quality, vulnerability to oil contamination, and susceptibility to thermal damage during regeneration cycles. These factors contribute to premature failures and increased maintenance frequency. The industry also faces challenges in data collection and standardization, with limited sharing of maintenance records and performance data that could inform predictive models.

The economic burden of DPF maintenance remains substantial, with costs including direct service expenses, vehicle downtime, and fuel penalties associated with regeneration processes. These factors create significant pressure to develop more efficient, predictive maintenance solutions that can optimize filter performance while minimizing operational disruptions and extending service intervals.

Current diagnostic methods primarily utilize differential pressure sensors to estimate soot load, but these measurements can be imprecise and fail to provide comprehensive information about filter condition. More advanced systems incorporate temperature sensors and exhaust gas oxygen sensors, yet these still offer limited visibility into the actual state of the DPF. The industry lacks reliable, real-time monitoring solutions that can accurately predict maintenance needs before performance degradation occurs.

The cleaning and regeneration processes present their own set of challenges. Passive regeneration depends on specific driving conditions that may not be consistently achievable, particularly in urban driving environments. Active regeneration systems consume additional fuel and may not completely remove accumulated ash, leading to gradual performance deterioration over time. Physical cleaning methods, including thermal, pneumatic, and chemical approaches, require filter removal and specialized equipment, resulting in vehicle downtime and significant maintenance costs.

Geographic variations in DPF technology adoption and maintenance practices further complicate the landscape. Developed markets have established infrastructure for DPF maintenance, while emerging markets often lack specialized service centers and technical expertise. This disparity creates inconsistent maintenance quality and approaches worldwide. Additionally, regulatory frameworks governing emissions control systems vary significantly across regions, creating a complex compliance environment for global fleet operators.

Technical limitations of current DPF systems include sensitivity to fuel quality, vulnerability to oil contamination, and susceptibility to thermal damage during regeneration cycles. These factors contribute to premature failures and increased maintenance frequency. The industry also faces challenges in data collection and standardization, with limited sharing of maintenance records and performance data that could inform predictive models.

The economic burden of DPF maintenance remains substantial, with costs including direct service expenses, vehicle downtime, and fuel penalties associated with regeneration processes. These factors create significant pressure to develop more efficient, predictive maintenance solutions that can optimize filter performance while minimizing operational disruptions and extending service intervals.

Current AI Solutions for DPF Maintenance

01 Predictive maintenance using AI

Artificial intelligence systems can be used to predict equipment failures and maintenance needs by analyzing operational data patterns. These systems use machine learning algorithms to identify anomalies and potential issues before they cause downtime. Predictive maintenance AI can continuously monitor equipment performance, learn from historical data, and provide recommendations for optimal maintenance scheduling, thereby reducing unexpected failures and extending equipment lifespan.- Predictive maintenance using AI: Artificial intelligence systems can be used to predict equipment failures before they occur by analyzing patterns in operational data. These predictive maintenance solutions use machine learning algorithms to identify anomalies and potential issues, allowing for scheduled maintenance before critical failures. This approach reduces downtime, extends equipment lifespan, and optimizes maintenance resources by transitioning from reactive to proactive maintenance strategies.

- AI-based diagnostic and monitoring systems: AI systems can continuously monitor equipment performance and health through sensors and data collection mechanisms. These systems use advanced algorithms to diagnose issues in real-time, detect deviations from normal operating parameters, and provide detailed analysis of system performance. The monitoring solutions can track multiple parameters simultaneously and identify complex patterns that might indicate developing problems, enabling more efficient maintenance operations.

- Self-healing and autonomous maintenance systems: Advanced AI maintenance systems incorporate self-healing capabilities that can automatically address certain issues without human intervention. These autonomous systems can reconfigure settings, redistribute workloads, or activate backup systems when problems are detected. The technology enables systems to learn from past maintenance events and continuously improve their response to similar situations, reducing the need for manual intervention and minimizing system downtime.

- AI-enhanced maintenance workflow optimization: Artificial intelligence can optimize maintenance workflows by prioritizing tasks, allocating resources efficiently, and scheduling maintenance activities. These systems analyze historical maintenance data, current system status, and available resources to create optimal maintenance plans. The AI solutions can adapt schedules in real-time based on changing conditions, ensuring critical systems receive timely attention while maximizing the efficiency of maintenance personnel and minimizing operational disruptions.

- Knowledge management and decision support for maintenance: AI systems can serve as knowledge repositories and decision support tools for maintenance personnel. These systems aggregate expertise from various sources, including maintenance manuals, historical repair data, and expert knowledge. When maintenance issues arise, the AI can provide technicians with relevant information, step-by-step guidance, and potential solutions based on similar past cases. This approach enhances the capabilities of maintenance teams and helps preserve institutional knowledge about complex systems.

02 AI-based diagnostic and troubleshooting systems

AI systems can be implemented to diagnose problems and provide troubleshooting solutions for complex equipment and systems. These diagnostic tools use natural language processing, computer vision, and expert systems to identify issues based on symptoms or inspection data. The AI can suggest repair procedures, provide step-by-step guidance to maintenance personnel, and learn from each repair instance to improve future diagnostics, making maintenance processes more efficient and accurate.Expand Specific Solutions03 Self-maintaining AI systems

Advanced AI systems can be designed with self-maintenance capabilities, allowing them to monitor their own performance, detect degradation, and implement corrective measures. These systems can automatically optimize their algorithms, clean data repositories, and adjust parameters to maintain optimal functionality. Self-maintaining AI can identify when human intervention is needed and provide detailed reports on their operational status, ensuring continuous and reliable AI performance with minimal manual maintenance.Expand Specific Solutions04 AI for maintenance resource optimization

AI systems can optimize the allocation of maintenance resources including personnel, parts, and equipment. These systems analyze maintenance requirements across multiple assets, prioritize tasks based on criticality and available resources, and create efficient scheduling plans. By considering factors such as technician skills, parts availability, and maintenance urgency, AI can reduce downtime, minimize costs, and ensure that critical systems receive timely maintenance while maximizing workforce utilization.Expand Specific Solutions05 AI maintenance knowledge management systems

AI-powered knowledge management systems can capture, organize, and distribute maintenance expertise throughout an organization. These systems use natural language processing to extract information from maintenance manuals, repair logs, and expert knowledge, creating searchable repositories of maintenance procedures and solutions. The AI can continuously learn from new maintenance activities, identify best practices, and provide contextually relevant information to maintenance personnel, preserving institutional knowledge and improving maintenance quality.Expand Specific Solutions

Key Industry Players in AI-Powered DPF Maintenance

The AI-powered Diesel Particulate Filter (DPF) maintenance market is in its growth phase, with increasing adoption driven by stringent emission regulations worldwide. The market is projected to expand significantly as automotive manufacturers seek advanced solutions to meet environmental standards. Major automotive players like Ford, Nissan, GM, Hyundai, and Volkswagen (through International Truck) are investing heavily in this technology, while specialized component manufacturers such as Tokyo Roki, IBIDEN, and Robert Bosch are developing innovative filter technologies. Equipment manufacturers including Caterpillar, Deere, and Kubota are integrating AI-based predictive maintenance systems for DPF in heavy machinery. The technology is maturing rapidly with advancements in sensor integration, machine learning algorithms for predictive maintenance, and real-time monitoring capabilities that optimize filter performance and extend service life.

GM Global Technology Operations LLC

Technical Solution: GM has developed an integrated AI solution for DPF maintenance that combines onboard diagnostics with cloud-based predictive analytics. Their system utilizes a multi-layered neural network that processes data from existing engine sensors along with proprietary exhaust monitoring technology. The AI continuously analyzes exhaust gas composition, filter backpressure trends, and thermal patterns during both passive and active regeneration events. GM's approach incorporates driver behavior analysis, recognizing how different driving patterns affect DPF loading rates and regeneration efficiency. The system creates individualized DPF maintenance profiles for each vehicle based on its specific usage patterns and environmental exposure. Their technology includes a driver feedback component that provides real-time guidance to optimize driving patterns for DPF health, such as suggesting highway driving when partial regeneration would be beneficial. The cloud platform aggregates anonymized data across the GM fleet to continuously improve prediction accuracy and identify emerging patterns in DPF performance across different vehicle models and operating conditions.

Strengths: GM's solution seamlessly integrates with their existing vehicle telematics infrastructure, providing a comprehensive maintenance approach without requiring significant additional hardware. Their extensive vehicle fleet provides a massive data pool for continuous AI model improvement. Weaknesses: The system's effectiveness is somewhat dependent on consistent connectivity for cloud-based analytics, which may be limited in some remote operating environments.

Caterpillar, Inc.

Technical Solution: Caterpillar has pioneered an AI-powered DPF maintenance system specifically designed for heavy-duty applications in construction and mining equipment. Their solution leverages machine learning algorithms that analyze operational data from their proprietary Equipment Management Analytics Platform. The system continuously monitors exhaust temperature profiles, backpressure readings, and engine load patterns to create a comprehensive DPF health assessment. Caterpillar's AI models are trained on millions of hours of equipment operation data, enabling them to distinguish between normal variations and early warning signs of DPF issues. The technology incorporates environmental factors such as altitude, ambient temperature, and dust conditions to adjust maintenance predictions accordingly. Their system features adaptive regeneration timing that optimizes the cleaning process based on actual soot accumulation rates and equipment utilization schedules, minimizing downtime during critical operations. The AI also provides operators with specific recommendations for operational adjustments that can extend DPF life, such as modified idle patterns or load management strategies.

Strengths: Caterpillar's solution is exceptionally robust for extreme operating conditions and has been field-tested across diverse environments worldwide. Their AI models benefit from one of the largest datasets of heavy equipment operation in the industry. Weaknesses: The system is primarily optimized for Caterpillar equipment and may require significant adaptation for use with other manufacturers' machinery.

Core AI Technologies for DPF Diagnostics and Optimization

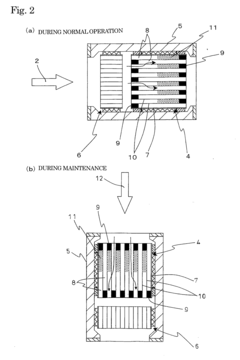

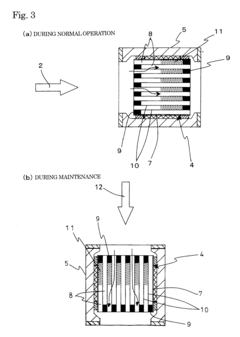

Maintenance method for particulate filter

PatentInactiveUS20090241780A1

Innovation

- Filling passages with a filler material, such as fine particles, rods, or gel, to reduce the inner volume and direct backwash air specifically through areas where ash is accumulated, preventing air from escaping through unaccumulated regions.

Patent

Innovation

- AI-driven predictive maintenance system for diesel particulate filters that analyzes sensor data to forecast filter clogging and optimize regeneration cycles.

- Machine learning algorithms that adapt to specific engine types and operating conditions to provide customized DPF maintenance recommendations.

- Automated regeneration scheduling based on AI analysis that minimizes fuel consumption and extends filter life compared to time-based maintenance approaches.

Environmental Regulations Impact on DPF Technology

Environmental regulations have become increasingly stringent worldwide, significantly influencing the development and implementation of Diesel Particulate Filter (DPF) technology. The European Union's Euro standards have progressively tightened particulate matter (PM) emission limits, with Euro 6 requiring a 97% reduction in PM emissions compared to Euro 1. Similarly, the United States EPA's Tier 4 Final standards and California Air Resources Board (CARB) regulations have established strict emission control requirements for diesel engines.

These regulatory frameworks have catalyzed rapid technological advancement in DPF systems, necessitating more sophisticated monitoring and maintenance approaches. Manufacturers have been compelled to develop DPFs with enhanced filtration efficiency, durability, and regeneration capabilities to meet compliance standards while maintaining engine performance.

The regulatory landscape continues to evolve, with many jurisdictions implementing in-use compliance monitoring and on-board diagnostic (OBD) requirements. These regulations mandate continuous monitoring of DPF performance and efficiency throughout the vehicle's operational life, creating a natural application space for AI-based predictive maintenance solutions.

Regulatory non-compliance carries significant consequences, including substantial fines, vehicle recalls, and damage to brand reputation. This has elevated DPF maintenance from a mere operational concern to a critical compliance issue for fleet operators and vehicle manufacturers alike. The financial implications of non-compliance have justified increased investment in advanced maintenance technologies, including AI-driven solutions.

Emerging markets are also adopting similar regulatory frameworks, albeit with varying implementation timelines. China's China VI standards and India's Bharat Stage VI regulations closely mirror European emission standards, expanding the global market for advanced DPF technologies and maintenance solutions.

The regulatory trend toward real-world emissions testing, exemplified by the EU's Real Driving Emissions (RDE) test procedures, has further emphasized the importance of consistent DPF performance across diverse operating conditions. This shift has exposed limitations in traditional maintenance schedules and highlighted the need for adaptive, condition-based maintenance approaches that AI can effectively enable.

Looking forward, anticipated regulatory developments include stricter particulate number (PN) limits, expanded temperature operating windows for emissions compliance, and potentially lifetime compliance requirements for emissions control systems. These evolving regulations will likely accelerate the adoption of AI-based predictive maintenance technologies as manufacturers and operators seek cost-effective compliance strategies.

These regulatory frameworks have catalyzed rapid technological advancement in DPF systems, necessitating more sophisticated monitoring and maintenance approaches. Manufacturers have been compelled to develop DPFs with enhanced filtration efficiency, durability, and regeneration capabilities to meet compliance standards while maintaining engine performance.

The regulatory landscape continues to evolve, with many jurisdictions implementing in-use compliance monitoring and on-board diagnostic (OBD) requirements. These regulations mandate continuous monitoring of DPF performance and efficiency throughout the vehicle's operational life, creating a natural application space for AI-based predictive maintenance solutions.

Regulatory non-compliance carries significant consequences, including substantial fines, vehicle recalls, and damage to brand reputation. This has elevated DPF maintenance from a mere operational concern to a critical compliance issue for fleet operators and vehicle manufacturers alike. The financial implications of non-compliance have justified increased investment in advanced maintenance technologies, including AI-driven solutions.

Emerging markets are also adopting similar regulatory frameworks, albeit with varying implementation timelines. China's China VI standards and India's Bharat Stage VI regulations closely mirror European emission standards, expanding the global market for advanced DPF technologies and maintenance solutions.

The regulatory trend toward real-world emissions testing, exemplified by the EU's Real Driving Emissions (RDE) test procedures, has further emphasized the importance of consistent DPF performance across diverse operating conditions. This shift has exposed limitations in traditional maintenance schedules and highlighted the need for adaptive, condition-based maintenance approaches that AI can effectively enable.

Looking forward, anticipated regulatory developments include stricter particulate number (PN) limits, expanded temperature operating windows for emissions compliance, and potentially lifetime compliance requirements for emissions control systems. These evolving regulations will likely accelerate the adoption of AI-based predictive maintenance technologies as manufacturers and operators seek cost-effective compliance strategies.

Cost-Benefit Analysis of AI DPF Maintenance Systems

The implementation of AI systems for Diesel Particulate Filter (DPF) maintenance presents a compelling economic case when analyzed through comprehensive cost-benefit frameworks. Initial investment costs for AI-powered DPF maintenance systems typically range from $5,000 to $25,000 per vehicle fleet, depending on the sophistication of sensors, data processing capabilities, and integration complexity with existing vehicle management systems. These upfront expenditures include hardware components, software licenses, installation labor, and initial staff training.

Operational costs must also be considered, including system maintenance (approximately $500-1,500 annually), software updates ($200-800 per year), and potential cloud storage fees for data management ($50-200 monthly depending on fleet size). However, these ongoing expenses are significantly offset by the substantial benefits realized through implementation.

The primary financial benefits derive from multiple sources. DPF replacement costs, averaging $2,000-4,000 per unit, can be reduced by 30-45% through AI-optimized maintenance scheduling that extends filter lifespan. Maintenance labor costs typically decrease by 25-35% as AI systems enable condition-based maintenance rather than time-based approaches, reducing unnecessary service interventions.

Fuel efficiency improvements of 3-7% have been documented in fleets utilizing AI DPF maintenance systems, representing substantial savings for operations with high annual mileage. Vehicle downtime reduction of 15-30% translates directly to increased operational availability and revenue generation potential, particularly critical for commercial transportation businesses.

The return on investment (ROI) analysis indicates most fleet operations achieve breakeven within 12-24 months of implementation, with larger fleets realizing faster returns due to economies of scale. Five-year projections demonstrate cumulative savings of $3,000-7,500 per vehicle when accounting for all direct and indirect benefits.

Environmental compliance benefits, while more difficult to quantify precisely, include reduced risk of regulatory fines (which can exceed $10,000 per violation) and potential qualification for environmental incentive programs in certain jurisdictions. Additionally, the carbon footprint reduction associated with optimized DPF operation aligns with corporate sustainability objectives and may enhance brand reputation.

Sensitivity analysis reveals that ROI is most heavily influenced by fleet size, annual mileage, and regional fuel costs. Organizations operating in areas with stringent emissions regulations and high fuel prices experience the most favorable economic outcomes from AI DPF maintenance system adoption.

Operational costs must also be considered, including system maintenance (approximately $500-1,500 annually), software updates ($200-800 per year), and potential cloud storage fees for data management ($50-200 monthly depending on fleet size). However, these ongoing expenses are significantly offset by the substantial benefits realized through implementation.

The primary financial benefits derive from multiple sources. DPF replacement costs, averaging $2,000-4,000 per unit, can be reduced by 30-45% through AI-optimized maintenance scheduling that extends filter lifespan. Maintenance labor costs typically decrease by 25-35% as AI systems enable condition-based maintenance rather than time-based approaches, reducing unnecessary service interventions.

Fuel efficiency improvements of 3-7% have been documented in fleets utilizing AI DPF maintenance systems, representing substantial savings for operations with high annual mileage. Vehicle downtime reduction of 15-30% translates directly to increased operational availability and revenue generation potential, particularly critical for commercial transportation businesses.

The return on investment (ROI) analysis indicates most fleet operations achieve breakeven within 12-24 months of implementation, with larger fleets realizing faster returns due to economies of scale. Five-year projections demonstrate cumulative savings of $3,000-7,500 per vehicle when accounting for all direct and indirect benefits.

Environmental compliance benefits, while more difficult to quantify precisely, include reduced risk of regulatory fines (which can exceed $10,000 per violation) and potential qualification for environmental incentive programs in certain jurisdictions. Additionally, the carbon footprint reduction associated with optimized DPF operation aligns with corporate sustainability objectives and may enhance brand reputation.

Sensitivity analysis reveals that ROI is most heavily influenced by fleet size, annual mileage, and regional fuel costs. Organizations operating in areas with stringent emissions regulations and high fuel prices experience the most favorable economic outcomes from AI DPF maintenance system adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!