Formulating Diesel Particulate Filter for Legacy Engines

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Background and Objectives

Diesel Particulate Filters (DPFs) emerged in the 1980s as a response to growing concerns about diesel engine emissions, particularly particulate matter (PM) which poses significant health and environmental risks. The technology has evolved from simple ceramic wall-flow filters to sophisticated systems incorporating advanced materials and regeneration strategies. This evolution has been driven by increasingly stringent emission regulations worldwide, including the US EPA's Tier standards, European Euro norms, and similar frameworks in Asia.

Legacy diesel engines, those manufactured before DPF technology became standard or mandated, represent a significant portion of the global diesel fleet. These engines, often found in commercial vehicles, construction equipment, and agricultural machinery, can have operational lifespans exceeding 20-30 years, contributing substantially to particulate pollution without proper emission controls.

The technical objective of DPF formulation for legacy engines centers on developing retrofit solutions that can effectively reduce particulate emissions while addressing the unique challenges these older engines present. These challenges include limited electronic control systems, variable exhaust temperature profiles, and higher baseline emission levels compared to modern engines.

A comprehensive DPF solution for legacy engines must balance multiple technical goals: achieving at least 85-90% particulate matter reduction efficiency, maintaining acceptable back pressure levels to prevent engine performance degradation, ensuring durability under various operating conditions, and providing cost-effective implementation pathways for fleet operators.

The technology trajectory indicates a shift from passive systems requiring minimal integration with engine controls to more active solutions that can be adapted to legacy platforms. Recent innovations focus on developing catalyst formulations that lower regeneration temperatures, making them more compatible with the exhaust temperature profiles of older engines.

Future objectives include developing DPF systems with enhanced sensing capabilities to monitor filter loading and performance without requiring extensive modifications to existing engine systems. Additionally, there is growing interest in creating modular DPF designs that can be customized to fit diverse legacy engine configurations and duty cycles.

The ultimate goal extends beyond mere regulatory compliance to creating sustainable pathways for extending the service life of legacy diesel equipment while minimizing their environmental impact. This approach recognizes the economic reality that immediate replacement of all legacy diesel engines is neither feasible nor economically viable for many operators.

Legacy diesel engines, those manufactured before DPF technology became standard or mandated, represent a significant portion of the global diesel fleet. These engines, often found in commercial vehicles, construction equipment, and agricultural machinery, can have operational lifespans exceeding 20-30 years, contributing substantially to particulate pollution without proper emission controls.

The technical objective of DPF formulation for legacy engines centers on developing retrofit solutions that can effectively reduce particulate emissions while addressing the unique challenges these older engines present. These challenges include limited electronic control systems, variable exhaust temperature profiles, and higher baseline emission levels compared to modern engines.

A comprehensive DPF solution for legacy engines must balance multiple technical goals: achieving at least 85-90% particulate matter reduction efficiency, maintaining acceptable back pressure levels to prevent engine performance degradation, ensuring durability under various operating conditions, and providing cost-effective implementation pathways for fleet operators.

The technology trajectory indicates a shift from passive systems requiring minimal integration with engine controls to more active solutions that can be adapted to legacy platforms. Recent innovations focus on developing catalyst formulations that lower regeneration temperatures, making them more compatible with the exhaust temperature profiles of older engines.

Future objectives include developing DPF systems with enhanced sensing capabilities to monitor filter loading and performance without requiring extensive modifications to existing engine systems. Additionally, there is growing interest in creating modular DPF designs that can be customized to fit diverse legacy engine configurations and duty cycles.

The ultimate goal extends beyond mere regulatory compliance to creating sustainable pathways for extending the service life of legacy diesel equipment while minimizing their environmental impact. This approach recognizes the economic reality that immediate replacement of all legacy diesel engines is neither feasible nor economically viable for many operators.

Market Analysis for Retrofit DPF Solutions

The global market for retrofit Diesel Particulate Filter (DPF) solutions has experienced significant growth over the past decade, driven primarily by increasingly stringent emissions regulations across major economies. The retrofit DPF market was valued at approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2028, reaching an estimated $1.7 billion by the end of the forecast period.

North America currently represents the largest market share at 38%, followed by Europe at 35%, Asia-Pacific at 20%, and the rest of the world accounting for 7%. This regional distribution closely correlates with the implementation timeline and stringency of emissions regulations in these regions. The United States, particularly California with its aggressive emissions reduction targets, has been a key driver for retrofit DPF adoption.

Market segmentation reveals that commercial vehicles constitute the largest application segment (65%), followed by off-road machinery (25%) and public transportation fleets (10%). Within the commercial vehicle segment, medium and heavy-duty trucks represent the most substantial opportunity due to their long service life and significant contribution to particulate emissions.

Customer demand is primarily driven by regulatory compliance rather than voluntary adoption. Fleet operators typically seek retrofit solutions when faced with regulatory requirements that would otherwise force vehicle retirement. The average age of vehicles receiving retrofit DPF installations is 7-12 years, representing the sweet spot where vehicles retain sufficient remaining useful life to justify the investment.

Price sensitivity remains high among end-users, with installation costs ranging from $5,000 to $15,000 per vehicle depending on engine size and complexity. This represents a significant investment for fleet operators, particularly small businesses with limited capital resources. Government subsidies and incentive programs have proven critical in accelerating market adoption in regions with established retrofit programs.

The competitive landscape features both OEM-affiliated suppliers and independent aftermarket manufacturers. Key market players include Johnson Matthey, BASF, Tenneco, Donaldson Company, and Corning, collectively holding approximately 65% market share. Regional players and specialized retrofit solution providers compete primarily on price and service offerings tailored to local market needs.

Future market growth will be influenced by the expansion of low emission zones in urban areas, the implementation of more stringent emissions standards in developing economies, and the gradual transition toward zero-emission technologies. The retrofit DPF market is expected to experience sustained growth in the medium term before eventually declining as legacy diesel engines are phased out of operation.

North America currently represents the largest market share at 38%, followed by Europe at 35%, Asia-Pacific at 20%, and the rest of the world accounting for 7%. This regional distribution closely correlates with the implementation timeline and stringency of emissions regulations in these regions. The United States, particularly California with its aggressive emissions reduction targets, has been a key driver for retrofit DPF adoption.

Market segmentation reveals that commercial vehicles constitute the largest application segment (65%), followed by off-road machinery (25%) and public transportation fleets (10%). Within the commercial vehicle segment, medium and heavy-duty trucks represent the most substantial opportunity due to their long service life and significant contribution to particulate emissions.

Customer demand is primarily driven by regulatory compliance rather than voluntary adoption. Fleet operators typically seek retrofit solutions when faced with regulatory requirements that would otherwise force vehicle retirement. The average age of vehicles receiving retrofit DPF installations is 7-12 years, representing the sweet spot where vehicles retain sufficient remaining useful life to justify the investment.

Price sensitivity remains high among end-users, with installation costs ranging from $5,000 to $15,000 per vehicle depending on engine size and complexity. This represents a significant investment for fleet operators, particularly small businesses with limited capital resources. Government subsidies and incentive programs have proven critical in accelerating market adoption in regions with established retrofit programs.

The competitive landscape features both OEM-affiliated suppliers and independent aftermarket manufacturers. Key market players include Johnson Matthey, BASF, Tenneco, Donaldson Company, and Corning, collectively holding approximately 65% market share. Regional players and specialized retrofit solution providers compete primarily on price and service offerings tailored to local market needs.

Future market growth will be influenced by the expansion of low emission zones in urban areas, the implementation of more stringent emissions standards in developing economies, and the gradual transition toward zero-emission technologies. The retrofit DPF market is expected to experience sustained growth in the medium term before eventually declining as legacy diesel engines are phased out of operation.

Technical Challenges in Legacy Engine DPF Integration

Integrating Diesel Particulate Filters (DPFs) into legacy engines presents a multifaceted technical challenge due to the fundamental design differences between modern and older engine systems. Legacy diesel engines, typically manufactured before stringent emission regulations, were not originally designed with exhaust aftertreatment systems in mind, creating significant compatibility issues.

The primary technical hurdle involves the backpressure management. DPF systems inherently increase exhaust backpressure, which can severely impact engine performance, fuel efficiency, and durability in legacy engines. These older engines often operate with narrower performance margins and lack the sophisticated electronic control systems that help modern engines adapt to increased backpressure conditions.

Thermal management represents another critical challenge. DPF regeneration requires specific exhaust temperature profiles to effectively burn off accumulated particulate matter. Legacy engines frequently exhibit lower exhaust temperatures during normal operation and lack the precise fuel injection control needed to facilitate active regeneration cycles, potentially leading to filter clogging or incomplete regeneration events.

Space constraints further complicate integration efforts. Retrofitting DPF systems into legacy vehicles or equipment often encounters significant packaging limitations, as original designs did not allocate space for aftertreatment components. This necessitates custom engineering solutions that may compromise other system functionalities or require extensive modifications to surrounding components.

Control system integration poses substantial technical difficulties. Modern DPF systems rely on sophisticated sensors, actuators, and electronic control units to monitor filter conditions and manage regeneration processes. Legacy engines typically feature rudimentary or entirely mechanical control systems, creating a technological gap that requires complex bridging solutions or complete control system overhauls.

Material compatibility issues arise when introducing DPF systems to legacy engines. Older exhaust system components may utilize materials incompatible with the higher temperatures and different chemical environments created by DPF operation, potentially leading to accelerated component degradation or failure.

Durability testing presents unique challenges for legacy engine DPF integration. The wide variety of legacy engine designs, coupled with their aging components and varying maintenance histories, makes standardized validation protocols difficult to establish. This necessitates extensive field testing across diverse operating conditions to ensure reliable performance.

Calibration complexity significantly increases when adapting DPF systems to legacy engines. Without access to original engine development data and modern calibration tools, engineers must develop empirical approaches to optimize DPF performance while maintaining acceptable engine operation parameters, often requiring iterative testing and refinement.

The primary technical hurdle involves the backpressure management. DPF systems inherently increase exhaust backpressure, which can severely impact engine performance, fuel efficiency, and durability in legacy engines. These older engines often operate with narrower performance margins and lack the sophisticated electronic control systems that help modern engines adapt to increased backpressure conditions.

Thermal management represents another critical challenge. DPF regeneration requires specific exhaust temperature profiles to effectively burn off accumulated particulate matter. Legacy engines frequently exhibit lower exhaust temperatures during normal operation and lack the precise fuel injection control needed to facilitate active regeneration cycles, potentially leading to filter clogging or incomplete regeneration events.

Space constraints further complicate integration efforts. Retrofitting DPF systems into legacy vehicles or equipment often encounters significant packaging limitations, as original designs did not allocate space for aftertreatment components. This necessitates custom engineering solutions that may compromise other system functionalities or require extensive modifications to surrounding components.

Control system integration poses substantial technical difficulties. Modern DPF systems rely on sophisticated sensors, actuators, and electronic control units to monitor filter conditions and manage regeneration processes. Legacy engines typically feature rudimentary or entirely mechanical control systems, creating a technological gap that requires complex bridging solutions or complete control system overhauls.

Material compatibility issues arise when introducing DPF systems to legacy engines. Older exhaust system components may utilize materials incompatible with the higher temperatures and different chemical environments created by DPF operation, potentially leading to accelerated component degradation or failure.

Durability testing presents unique challenges for legacy engine DPF integration. The wide variety of legacy engine designs, coupled with their aging components and varying maintenance histories, makes standardized validation protocols difficult to establish. This necessitates extensive field testing across diverse operating conditions to ensure reliable performance.

Calibration complexity significantly increases when adapting DPF systems to legacy engines. Without access to original engine development data and modern calibration tools, engineers must develop empirical approaches to optimize DPF performance while maintaining acceptable engine operation parameters, often requiring iterative testing and refinement.

Current DPF Formulation Approaches

01 Filter material composition and structure

The composition and structure of filter materials significantly impact the filtration efficiency of diesel particulate filters. Advanced ceramic materials, such as cordierite, silicon carbide, and aluminum titanate, are commonly used due to their high temperature resistance and durability. The porosity, pore size distribution, and wall thickness of these materials are carefully engineered to optimize the balance between filtration efficiency and pressure drop. Multi-layer structures with varying pore sizes can enhance particle capture while maintaining acceptable flow resistance.- Filter material composition and structure: The composition and structure of filter materials significantly impact the filtration efficiency of diesel particulate filters. Advanced ceramic materials, such as cordierite, silicon carbide, and aluminum titanate, offer high temperature resistance and improved particulate capture. Multi-layer structures with varying pore sizes can enhance filtration efficiency while maintaining acceptable back pressure. The arrangement of channels, wall thickness, and porosity are critical design factors that determine the filter's ability to trap particulate matter while allowing exhaust gases to flow through.

- Filtration efficiency measurement and testing methods: Various methods and systems have been developed to measure and test the filtration efficiency of diesel particulate filters. These include pressure drop measurements across the filter, particle counting before and after filtration, and optical measurement techniques. Real-time monitoring systems can evaluate filter performance under different operating conditions, such as varying engine loads and exhaust temperatures. Standardized testing protocols ensure consistent evaluation of filtration efficiency, allowing for comparison between different filter designs and technologies.

- Regeneration strategies for maintaining filtration efficiency: Regeneration processes are essential for maintaining the filtration efficiency of diesel particulate filters over time. Active regeneration methods involve raising exhaust temperatures to burn off accumulated soot, while passive regeneration utilizes catalytic materials to lower the combustion temperature of particulate matter. Controlled regeneration strategies prevent thermal damage to the filter while ensuring complete removal of trapped particles. Advanced regeneration control algorithms can optimize the timing and duration of regeneration events based on filter loading conditions and vehicle operation patterns.

- Catalytic coatings to enhance filtration performance: Catalytic coatings applied to diesel particulate filters can significantly improve filtration efficiency and promote passive regeneration. Noble metals such as platinum and palladium, as well as base metal oxides, can be incorporated into filter walls to oxidize particulate matter at lower temperatures. The distribution and loading of catalytic materials affect both filtration efficiency and pressure drop characteristics. Innovative coating technologies ensure uniform catalyst distribution throughout the filter substrate, maximizing contact between exhaust gases and catalytic surfaces.

- System integration and control strategies: The integration of diesel particulate filters into the overall exhaust aftertreatment system and the implementation of sophisticated control strategies are crucial for optimizing filtration efficiency. Combining particulate filters with other emission control devices, such as selective catalytic reduction (SCR) systems, can address multiple pollutants simultaneously. Advanced sensors and control algorithms monitor filter condition and adjust engine parameters to maintain optimal filtration performance. Predictive models can anticipate filter loading and initiate preventive measures to ensure consistent filtration efficiency across various operating conditions.

02 Filtration efficiency measurement and testing methods

Various methods and systems have been developed to accurately measure and test the filtration efficiency of diesel particulate filters. These include real-time monitoring systems that use sensors to detect particulate matter concentration before and after the filter, pressure differential measurements across the filter, and optical techniques to analyze particle size distribution. Standardized testing protocols ensure consistent evaluation of filter performance under different operating conditions, including various engine loads, exhaust temperatures, and soot loading levels.Expand Specific Solutions03 Regeneration strategies for maintaining filtration efficiency

Regeneration processes are crucial for maintaining the filtration efficiency of diesel particulate filters over time. Active regeneration methods involve raising exhaust temperatures to burn off accumulated soot, while passive regeneration utilizes catalytic materials to lower the soot combustion temperature. Controlled regeneration strategies prevent thermal damage to the filter while ensuring complete soot removal. Advanced systems incorporate sensors and control algorithms to optimize regeneration timing based on soot load, driving conditions, and filter back pressure.Expand Specific Solutions04 Catalytic coatings to enhance filtration performance

Catalytic coatings applied to diesel particulate filters can significantly improve filtration efficiency while reducing regeneration requirements. These coatings typically contain precious metals like platinum, palladium, and rhodium, or base metal oxides that facilitate soot oxidation at lower temperatures. The distribution, loading, and composition of catalytic materials are optimized to ensure uniform activity across the filter surface. Some advanced formulations combine multiple catalytic functions to simultaneously address particulate matter, nitrogen oxides, and hydrocarbon emissions.Expand Specific Solutions05 Filter system integration and optimization

The integration of diesel particulate filters into the overall exhaust aftertreatment system significantly impacts filtration efficiency. Optimal positioning relative to other components such as oxidation catalysts and SCR systems can improve thermal management and overall emission reduction. Advanced system designs incorporate bypass mechanisms, pressure relief valves, and variable geometry elements to maintain filtration efficiency across different operating conditions. Computational fluid dynamics and real-world testing are used to optimize flow distribution, thermal management, and backpressure characteristics of the integrated system.Expand Specific Solutions

Key Manufacturers and Market Competition

The diesel particulate filter (DPF) market for legacy engines is in a mature growth phase, characterized by increasing regulatory pressure and technological refinement. The market size is substantial, driven by global emission standards requiring retrofitting of older diesel engines. Technologically, companies like Johnson Matthey, Umicore, and Corning lead with advanced substrate and catalyst technologies, while automotive manufacturers including Toyota, Nissan, and Ford focus on integration solutions. Major heavy equipment manufacturers such as Deere & Co. are developing specialized DPF formulations for off-road applications. The competitive landscape shows a clear division between catalyst technology specialists and vehicle manufacturers, with increasing collaboration between these sectors to address the technical challenges of retrofitting older engines with effective particulate capture systems.

Umicore SA

Technical Solution: Umicore has developed a specialized catalyst formulation for DPF applications in legacy diesel engines that addresses the unique challenges of retrofitting older systems. Their technology centers on a proprietary platinum-palladium-rhodium catalyst with optimized loading ratios (typically 4:1:0.5) that significantly reduces the soot ignition temperature to approximately 375°C, making regeneration feasible even in older engines with lower exhaust temperatures. The catalyst incorporates rare earth metal oxides like cerium and lanthanum that enhance oxygen storage capacity and promote complete oxidation of particulate matter. Umicore's solution includes a washcoat technology that improves catalyst adhesion to filter substrates, extending service life in high-vibration environments common in aging equipment. Their formulation also demonstrates remarkable resistance to catalyst poisoning from sulfur and other contaminants often present in higher concentrations in legacy engine emissions.

Strengths: Superior catalyst performance with lower precious metal loading reduces overall system cost; excellent resistance to contaminant poisoning extends service intervals in real-world applications. Weaknesses: May require supplemental fuel additives in extremely old engines to achieve optimal regeneration performance; limited compatibility with certain filter substrate materials.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced retrofit DPF system specifically designed for legacy diesel engines that combines passive and active regeneration strategies. Their solution incorporates a multi-layer catalyst coating technology that enhances soot oxidation at lower temperatures (approximately 350°C compared to traditional 550°C requirements). The system utilizes a proprietary platinum-palladium catalyst formulation with optimized precious metal loading to balance cost and performance. Ford's approach includes an intelligent control module that monitors backpressure and temperature conditions to determine optimal regeneration timing, preventing performance degradation in older engine architectures. The system also features a modular design allowing for customization based on specific engine displacement and emission profiles, making it adaptable across various legacy vehicle platforms.

Strengths: Exceptional adaptability across diverse legacy engine platforms without requiring major engine modifications; lower regeneration temperature requirements reduce thermal stress on aging engine components. Weaknesses: Higher initial implementation cost compared to basic retrofit solutions; may require periodic maintenance to ensure optimal catalyst performance in high-mileage applications.

Critical Patents in DPF Catalyst Technology

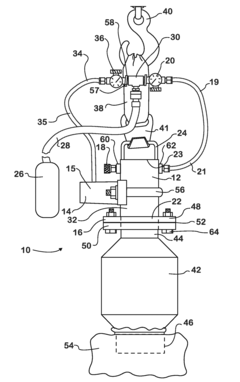

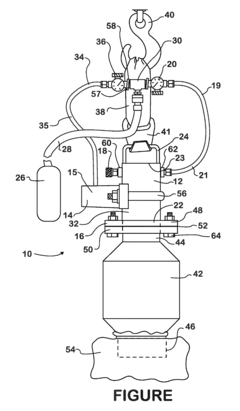

Diesel particulate filter cleaning apparatus and method

PatentInactiveUS7819978B2

Innovation

- An air chamber connected to the diesel particulate filter with a pressure relief valve and a vibrator is used to dislodge and remove particulate material using pressurized air and vibrations, allowing for quick and economical cleaning with readily available shop equipment.

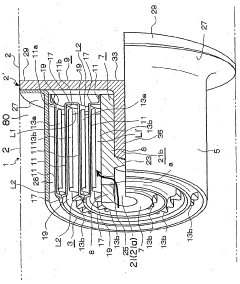

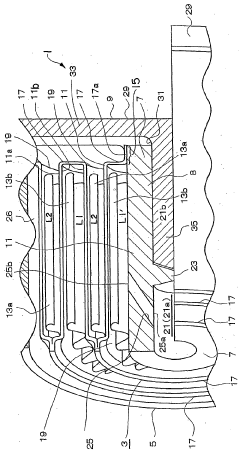

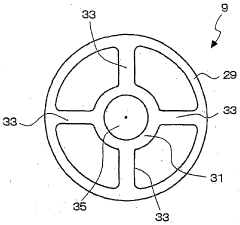

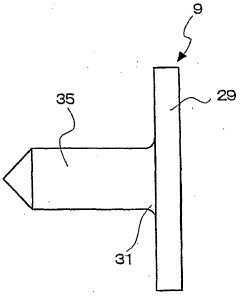

Particulate filter

PatentWO2001063102A1

Innovation

- A particulate filter design featuring a columnar laminate made of heat-resistant metal non-woven fabric and corrugated sheets, wound around a core and housed in a heat-resistant container, with a connecting member to prevent axial movement and a communication hole to reduce pressure on the non-woven fabric, allowing for efficient ash removal without combustion.

Emissions Regulations Impact Assessment

The evolution of emissions regulations globally has created significant challenges for operators of legacy diesel engines. These regulations have progressively tightened particulate matter (PM) emission limits, with the European Union's Euro VI standards requiring a 92% reduction compared to Euro V, and the US EPA's Tier 4 Final standards imposing similarly stringent requirements. For fleet operators with pre-regulation engines, these changes represent not just compliance challenges but potential operational restrictions in low emission zones being established in major urban centers worldwide.

The regulatory landscape creates a complex matrix of requirements across different jurisdictions. California's Air Resources Board (CARB) has implemented particularly aggressive retrofit requirements for older diesel vehicles, while the International Maritime Organization's regulations have extended emissions control to maritime applications. These overlapping regulatory frameworks create significant market pressure for retrofit solutions that can bring legacy engines into compliance without necessitating complete powertrain replacement.

Economic impact assessments indicate that non-compliance costs are increasingly prohibitive. Operators in the European Union face fines averaging €1,500-7,000 per vehicle for emissions violations, while access restrictions to urban centers can result in revenue losses estimated at €3,000-15,000 annually per vehicle. The total economic burden of non-compliance across the global legacy diesel fleet is projected to exceed $24 billion by 2025, creating strong financial incentives for cost-effective retrofit solutions.

Regulatory timelines present another critical factor in DPF formulation strategies. Most major markets have established phase-in periods for emissions compliance, but these grace periods are rapidly closing. The EU's final implementation deadlines for Euro VI compatibility in urban zones will be complete by 2025, while similar deadlines exist in North America, Asia, and emerging markets. This regulatory convergence creates a time-limited market opportunity for DPF solutions specifically designed for legacy engines.

The technical certification requirements for retrofit DPF systems add another layer of complexity. Solutions must demonstrate durability for at least 435,000 km of operation under the EU's requirements, while maintaining a minimum filtration efficiency of 90%. These performance standards must be achieved while accommodating the higher particulate loads and different exhaust characteristics typical of older engine designs, creating unique formulation challenges that differ substantially from OEM applications for new engines.

The regulatory landscape creates a complex matrix of requirements across different jurisdictions. California's Air Resources Board (CARB) has implemented particularly aggressive retrofit requirements for older diesel vehicles, while the International Maritime Organization's regulations have extended emissions control to maritime applications. These overlapping regulatory frameworks create significant market pressure for retrofit solutions that can bring legacy engines into compliance without necessitating complete powertrain replacement.

Economic impact assessments indicate that non-compliance costs are increasingly prohibitive. Operators in the European Union face fines averaging €1,500-7,000 per vehicle for emissions violations, while access restrictions to urban centers can result in revenue losses estimated at €3,000-15,000 annually per vehicle. The total economic burden of non-compliance across the global legacy diesel fleet is projected to exceed $24 billion by 2025, creating strong financial incentives for cost-effective retrofit solutions.

Regulatory timelines present another critical factor in DPF formulation strategies. Most major markets have established phase-in periods for emissions compliance, but these grace periods are rapidly closing. The EU's final implementation deadlines for Euro VI compatibility in urban zones will be complete by 2025, while similar deadlines exist in North America, Asia, and emerging markets. This regulatory convergence creates a time-limited market opportunity for DPF solutions specifically designed for legacy engines.

The technical certification requirements for retrofit DPF systems add another layer of complexity. Solutions must demonstrate durability for at least 435,000 km of operation under the EU's requirements, while maintaining a minimum filtration efficiency of 90%. These performance standards must be achieved while accommodating the higher particulate loads and different exhaust characteristics typical of older engine designs, creating unique formulation challenges that differ substantially from OEM applications for new engines.

Cost-Benefit Analysis of DPF Retrofitting

Retrofitting legacy diesel engines with Diesel Particulate Filters (DPFs) represents a significant financial decision for fleet operators and individual vehicle owners. The cost-benefit analysis must consider both immediate expenditures and long-term economic implications across the lifecycle of the retrofitted equipment.

Initial installation costs typically range from $5,000 to $15,000 per vehicle, depending on engine size, configuration complexity, and filter technology selection. This investment includes not only the DPF hardware but also necessary modifications to exhaust systems, installation labor, and potential electronic control upgrades to manage regeneration cycles effectively.

Operational expenses constitute another critical dimension of the economic assessment. DPF systems generally increase fuel consumption by 1-3% due to increased back pressure in the exhaust system. For commercial fleets covering substantial annual mileages, this translates to thousands of dollars in additional fuel costs over the vehicle's operational life. Maintenance requirements also escalate, with periodic cleaning cycles costing $300-600 per service interval, typically needed every 80,000-100,000 miles.

Against these costs, significant benefits must be weighed. Regulatory compliance represents the primary advantage, allowing continued operation in jurisdictions with stringent emissions standards without the capital expenditure of full vehicle replacement. The extended operational lifespan of legacy equipment can defer replacement costs by 3-7 years, representing substantial capital preservation.

Environmental and health benefits, while challenging to monetize directly, carry significant economic value. Studies indicate that each ton of particulate matter emissions prevented yields approximately $270,000-$360,000 in public health benefits through reduced respiratory illnesses, decreased hospitalization rates, and fewer lost workdays. For fleet operators, these translate to potential carbon credits, tax incentives, and improved corporate social responsibility profiles.

The payback period for DPF retrofitting varies considerably based on application context. Urban delivery vehicles operating in low emission zones may achieve return on investment within 2-3 years through avoided non-compliance penalties and access fees. Long-haul transport applications typically show longer payback periods of 4-6 years, primarily realized through extended asset utilization and deferred replacement costs.

Sensitivity analysis reveals that fuel price fluctuations significantly impact the economic equation. A 10% increase in diesel prices can extend the payback period by approximately 8-14 months, highlighting the importance of fuel efficiency optimization in retrofitted systems.

Initial installation costs typically range from $5,000 to $15,000 per vehicle, depending on engine size, configuration complexity, and filter technology selection. This investment includes not only the DPF hardware but also necessary modifications to exhaust systems, installation labor, and potential electronic control upgrades to manage regeneration cycles effectively.

Operational expenses constitute another critical dimension of the economic assessment. DPF systems generally increase fuel consumption by 1-3% due to increased back pressure in the exhaust system. For commercial fleets covering substantial annual mileages, this translates to thousands of dollars in additional fuel costs over the vehicle's operational life. Maintenance requirements also escalate, with periodic cleaning cycles costing $300-600 per service interval, typically needed every 80,000-100,000 miles.

Against these costs, significant benefits must be weighed. Regulatory compliance represents the primary advantage, allowing continued operation in jurisdictions with stringent emissions standards without the capital expenditure of full vehicle replacement. The extended operational lifespan of legacy equipment can defer replacement costs by 3-7 years, representing substantial capital preservation.

Environmental and health benefits, while challenging to monetize directly, carry significant economic value. Studies indicate that each ton of particulate matter emissions prevented yields approximately $270,000-$360,000 in public health benefits through reduced respiratory illnesses, decreased hospitalization rates, and fewer lost workdays. For fleet operators, these translate to potential carbon credits, tax incentives, and improved corporate social responsibility profiles.

The payback period for DPF retrofitting varies considerably based on application context. Urban delivery vehicles operating in low emission zones may achieve return on investment within 2-3 years through avoided non-compliance penalties and access fees. Long-haul transport applications typically show longer payback periods of 4-6 years, primarily realized through extended asset utilization and deferred replacement costs.

Sensitivity analysis reveals that fuel price fluctuations significantly impact the economic equation. A 10% increase in diesel prices can extend the payback period by approximately 8-14 months, highlighting the importance of fuel efficiency optimization in retrofitted systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!