Measuring Diesel Particulate Filter Emission Rates

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Emission Measurement Background and Objectives

Diesel Particulate Filters (DPFs) have emerged as a critical technology in the automotive industry's ongoing efforts to reduce harmful emissions from diesel engines. Since their introduction in the early 1980s, these filtration systems have undergone significant evolution, driven by increasingly stringent environmental regulations worldwide. The measurement of DPF emission rates represents a complex technical challenge that sits at the intersection of mechanical engineering, environmental science, and regulatory compliance.

The historical development of DPF technology has been characterized by progressive improvements in filtration efficiency, durability, and integration with engine management systems. Early DPF systems captured approximately 60-70% of particulate matter, while modern systems can achieve filtration efficiencies exceeding 95%. This remarkable progress has been instrumental in addressing public health concerns related to diesel exhaust, particularly in urban environments where exposure to particulate matter is associated with respiratory and cardiovascular diseases.

Current technological trends in DPF emission measurement are moving toward real-time monitoring capabilities, enhanced precision in nanoscale particulate detection, and integration with broader vehicle diagnostic systems. These advancements are being propelled by the global transition to more stringent emission standards, including Euro 7 in Europe, China 7 in Asia, and Tier 3 in North America, which demand unprecedented levels of emission control and verification.

The primary objectives of DPF emission measurement technology development are multifaceted. First, to establish accurate, reliable, and cost-effective methods for quantifying particulate emissions across various operating conditions. Second, to develop measurement protocols that can distinguish between different particulate sizes and compositions, particularly focusing on ultrafine particles that pose the greatest health risks. Third, to create systems capable of continuous monitoring throughout the vehicle lifecycle, enabling early detection of DPF degradation or failure.

Additionally, there is growing interest in developing measurement technologies that can function effectively in real-world driving conditions, moving beyond the controlled environment of laboratory testing. This shift reflects regulatory trends toward Real Driving Emissions (RDE) testing and in-service conformity requirements, which aim to ensure that vehicles maintain low emission levels throughout their operational life under actual driving conditions.

The convergence of these technological objectives with regulatory pressures and public health imperatives creates a dynamic landscape for DPF emission measurement innovation. Future developments will likely focus on miniaturization of sensing equipment, integration with vehicle telematics systems, and the application of artificial intelligence for predictive maintenance and emission optimization.

The historical development of DPF technology has been characterized by progressive improvements in filtration efficiency, durability, and integration with engine management systems. Early DPF systems captured approximately 60-70% of particulate matter, while modern systems can achieve filtration efficiencies exceeding 95%. This remarkable progress has been instrumental in addressing public health concerns related to diesel exhaust, particularly in urban environments where exposure to particulate matter is associated with respiratory and cardiovascular diseases.

Current technological trends in DPF emission measurement are moving toward real-time monitoring capabilities, enhanced precision in nanoscale particulate detection, and integration with broader vehicle diagnostic systems. These advancements are being propelled by the global transition to more stringent emission standards, including Euro 7 in Europe, China 7 in Asia, and Tier 3 in North America, which demand unprecedented levels of emission control and verification.

The primary objectives of DPF emission measurement technology development are multifaceted. First, to establish accurate, reliable, and cost-effective methods for quantifying particulate emissions across various operating conditions. Second, to develop measurement protocols that can distinguish between different particulate sizes and compositions, particularly focusing on ultrafine particles that pose the greatest health risks. Third, to create systems capable of continuous monitoring throughout the vehicle lifecycle, enabling early detection of DPF degradation or failure.

Additionally, there is growing interest in developing measurement technologies that can function effectively in real-world driving conditions, moving beyond the controlled environment of laboratory testing. This shift reflects regulatory trends toward Real Driving Emissions (RDE) testing and in-service conformity requirements, which aim to ensure that vehicles maintain low emission levels throughout their operational life under actual driving conditions.

The convergence of these technological objectives with regulatory pressures and public health imperatives creates a dynamic landscape for DPF emission measurement innovation. Future developments will likely focus on miniaturization of sensing equipment, integration with vehicle telematics systems, and the application of artificial intelligence for predictive maintenance and emission optimization.

Market Demand Analysis for DPF Emission Monitoring

The global market for Diesel Particulate Filter (DPF) emission monitoring systems is experiencing robust growth, driven primarily by increasingly stringent environmental regulations across major economies. The European Union's Euro 6/VI standards, the United States EPA's Tier 3 regulations, and China's National VI emission standards have collectively established demanding requirements for particulate matter emissions from diesel vehicles, creating substantial demand for advanced monitoring solutions.

Current market estimates value the global DPF monitoring systems market at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by the expanding global diesel vehicle fleet, which despite the rise of alternative powertrains, continues to dominate commercial transportation and heavy machinery sectors.

The commercial vehicle segment represents the largest market share for DPF emission monitoring systems, accounting for nearly 65% of total demand. Fleet operators face increasing pressure to maintain compliance with emission standards while optimizing operational costs, creating a dual-focused market need for monitoring solutions that can both ensure regulatory compliance and extend DPF service life through data-driven maintenance.

Regional analysis reveals that Europe currently leads the market with approximately 40% share, followed by North America at 30% and Asia-Pacific at 25%. However, the fastest growth is anticipated in emerging markets, particularly India and China, where rapid industrialization and tightening emission standards are creating new demand vectors for monitoring technology.

The aftermarket segment for DPF monitoring systems is expanding at a faster rate than OEM installations, growing at approximately 7.2% annually. This trend reflects the large existing vehicle fleet requiring retrofitting to meet new standards and the increasing awareness among fleet operators about the cost benefits of proactive DPF management.

Industry surveys indicate that end-users prioritize accuracy, reliability, and integration capabilities when selecting DPF monitoring solutions. There is growing demand for real-time monitoring systems that can provide predictive maintenance alerts and integrate with fleet management software, allowing operators to optimize vehicle performance and minimize downtime.

The market is also witnessing a shift toward more sophisticated monitoring technologies that can measure not just particulate mass but also particle number and size distribution, driven by evolving regulatory frameworks that are beginning to incorporate these parameters into compliance requirements. This trend is creating new market opportunities for advanced sensing technologies and data analytics solutions in the DPF monitoring ecosystem.

Current market estimates value the global DPF monitoring systems market at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by the expanding global diesel vehicle fleet, which despite the rise of alternative powertrains, continues to dominate commercial transportation and heavy machinery sectors.

The commercial vehicle segment represents the largest market share for DPF emission monitoring systems, accounting for nearly 65% of total demand. Fleet operators face increasing pressure to maintain compliance with emission standards while optimizing operational costs, creating a dual-focused market need for monitoring solutions that can both ensure regulatory compliance and extend DPF service life through data-driven maintenance.

Regional analysis reveals that Europe currently leads the market with approximately 40% share, followed by North America at 30% and Asia-Pacific at 25%. However, the fastest growth is anticipated in emerging markets, particularly India and China, where rapid industrialization and tightening emission standards are creating new demand vectors for monitoring technology.

The aftermarket segment for DPF monitoring systems is expanding at a faster rate than OEM installations, growing at approximately 7.2% annually. This trend reflects the large existing vehicle fleet requiring retrofitting to meet new standards and the increasing awareness among fleet operators about the cost benefits of proactive DPF management.

Industry surveys indicate that end-users prioritize accuracy, reliability, and integration capabilities when selecting DPF monitoring solutions. There is growing demand for real-time monitoring systems that can provide predictive maintenance alerts and integrate with fleet management software, allowing operators to optimize vehicle performance and minimize downtime.

The market is also witnessing a shift toward more sophisticated monitoring technologies that can measure not just particulate mass but also particle number and size distribution, driven by evolving regulatory frameworks that are beginning to incorporate these parameters into compliance requirements. This trend is creating new market opportunities for advanced sensing technologies and data analytics solutions in the DPF monitoring ecosystem.

Current DPF Measurement Technologies and Challenges

The current landscape of Diesel Particulate Filter (DPF) emission measurement technologies encompasses several established methodologies, each with specific advantages and limitations. Traditional gravimetric methods involve collecting particulate matter on filters and measuring mass changes, providing accurate total mass measurements but lacking real-time capabilities and requiring significant sampling time. This approach, while standardized in many regulatory frameworks, struggles with detecting ultra-low emission levels from modern DPF systems.

Optical measurement technologies have emerged as alternatives, utilizing light scattering principles to detect particulate matter. These include photoacoustic sensors, laser-induced incandescence, and opacity meters. While offering real-time monitoring capabilities, these methods often face challenges in distinguishing between different particle compositions and sizes, potentially leading to measurement inaccuracies in complex exhaust streams.

Particle counting technologies represent the cutting edge in DPF emission measurement, capable of detecting individual particles and providing size distribution data. Condensation Particle Counters (CPCs) and Scanning Mobility Particle Sizers (SMPS) offer high sensitivity but require careful calibration and maintenance. These technologies can detect particles in the nanometer range but may be affected by volatile compounds in the exhaust stream, necessitating thermal conditioning of samples.

On-board diagnostics (OBD) systems present a practical approach for continuous monitoring, utilizing pressure differential sensors across the DPF to infer loading conditions. However, these systems primarily focus on DPF functionality rather than precise emission quantification, limiting their application in regulatory compliance scenarios.

A significant challenge across all measurement technologies is the evolving nature of diesel emissions themselves. Modern DPF systems achieve filtration efficiencies exceeding 99%, resulting in extremely low particulate concentrations that push detection limits of conventional instruments. Additionally, the changing composition of emissions—with increasing proportions of volatile organic compounds and decreasing solid particle fractions—complicates measurement accuracy.

Calibration and standardization present ongoing challenges, with different measurement principles yielding varying results for the same exhaust stream. This inconsistency hampers cross-study comparisons and regulatory enforcement. Furthermore, laboratory measurements often fail to represent real-world driving conditions, where temperature variations, driving patterns, and fuel quality significantly impact DPF performance and emissions characteristics.

Cost and complexity barriers also limit widespread implementation of advanced measurement technologies, particularly for in-field testing and continuous monitoring applications. The ideal measurement system would combine accuracy, real-time capability, robustness, and cost-effectiveness—a combination not yet achieved by any single technology in the current landscape.

Optical measurement technologies have emerged as alternatives, utilizing light scattering principles to detect particulate matter. These include photoacoustic sensors, laser-induced incandescence, and opacity meters. While offering real-time monitoring capabilities, these methods often face challenges in distinguishing between different particle compositions and sizes, potentially leading to measurement inaccuracies in complex exhaust streams.

Particle counting technologies represent the cutting edge in DPF emission measurement, capable of detecting individual particles and providing size distribution data. Condensation Particle Counters (CPCs) and Scanning Mobility Particle Sizers (SMPS) offer high sensitivity but require careful calibration and maintenance. These technologies can detect particles in the nanometer range but may be affected by volatile compounds in the exhaust stream, necessitating thermal conditioning of samples.

On-board diagnostics (OBD) systems present a practical approach for continuous monitoring, utilizing pressure differential sensors across the DPF to infer loading conditions. However, these systems primarily focus on DPF functionality rather than precise emission quantification, limiting their application in regulatory compliance scenarios.

A significant challenge across all measurement technologies is the evolving nature of diesel emissions themselves. Modern DPF systems achieve filtration efficiencies exceeding 99%, resulting in extremely low particulate concentrations that push detection limits of conventional instruments. Additionally, the changing composition of emissions—with increasing proportions of volatile organic compounds and decreasing solid particle fractions—complicates measurement accuracy.

Calibration and standardization present ongoing challenges, with different measurement principles yielding varying results for the same exhaust stream. This inconsistency hampers cross-study comparisons and regulatory enforcement. Furthermore, laboratory measurements often fail to represent real-world driving conditions, where temperature variations, driving patterns, and fuel quality significantly impact DPF performance and emissions characteristics.

Cost and complexity barriers also limit widespread implementation of advanced measurement technologies, particularly for in-field testing and continuous monitoring applications. The ideal measurement system would combine accuracy, real-time capability, robustness, and cost-effectiveness—a combination not yet achieved by any single technology in the current landscape.

Current DPF Emission Rate Measurement Approaches

01 DPF design and structure for emission control

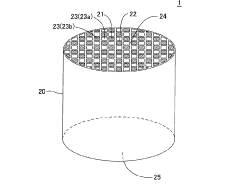

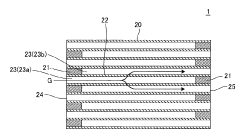

The design and structure of diesel particulate filters (DPFs) play a crucial role in controlling emission rates. Various structural elements such as filter materials, cell density, wall thickness, and channel configurations can be optimized to enhance filtration efficiency while minimizing back pressure. Advanced designs incorporate features like asymmetric channels, variable porosity, and multi-layer structures to improve particulate matter capture while maintaining engine performance.- DPF design and structure for emission control: The design and structure of diesel particulate filters (DPFs) play a crucial role in controlling emission rates. Various structural elements such as filter material composition, pore size distribution, and wall thickness affect filtration efficiency and pressure drop characteristics. Advanced designs incorporate honeycomb structures, wall-flow configurations, and specialized coatings to enhance particulate matter capture while maintaining acceptable back pressure levels. These structural innovations help achieve optimal balance between filtration efficiency and engine performance.

- Regeneration strategies for DPF performance: Regeneration processes are essential for maintaining DPF efficiency and controlling emission rates over time. Various regeneration strategies include active regeneration using fuel injection or electric heating, passive regeneration utilizing catalytic materials, and combined approaches. These methods aim to effectively burn off accumulated soot at controlled temperatures to prevent filter clogging while minimizing fuel consumption penalties. Optimized regeneration timing and conditions help maintain consistent filtration performance and extend filter lifespan.

- Catalytic coatings and materials for enhanced DPF efficiency: Specialized catalytic coatings and materials significantly improve DPF emission control capabilities. These include precious metal catalysts, base metal oxides, and zeolite formulations that promote soot oxidation at lower temperatures. Advanced material compositions enhance passive regeneration efficiency and reduce the formation of secondary emissions like NO2. The integration of these catalytic elements with filter substrates creates synergistic effects that improve overall filtration performance while reducing the energy requirements for regeneration.

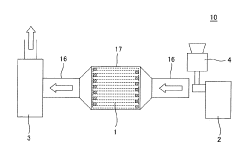

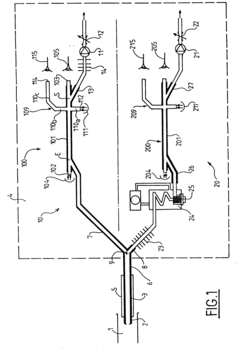

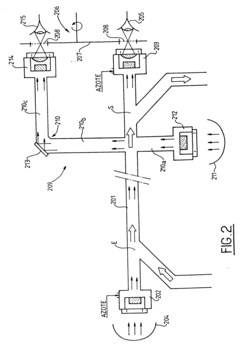

- Monitoring and control systems for DPF emission rates: Sophisticated monitoring and control systems are crucial for optimizing DPF performance and emission rates. These systems utilize pressure sensors, temperature monitors, and particulate matter sensors to track filter loading and efficiency in real-time. Advanced algorithms process this data to determine optimal regeneration timing and adjust engine parameters accordingly. On-board diagnostic capabilities detect filter malfunctions and ensure compliance with emission standards throughout the vehicle's operational life.

- Integration of DPF with other emission control technologies: The integration of DPFs with complementary emission control technologies creates comprehensive systems for managing diesel emissions. These integrated approaches combine DPFs with selective catalytic reduction (SCR), diesel oxidation catalysts (DOC), and exhaust gas recirculation (EGR) systems. Such combinations address multiple pollutants simultaneously, including particulate matter, nitrogen oxides, and hydrocarbons. System-level optimization ensures that these technologies work synergistically to achieve the lowest possible emission rates while maintaining acceptable fuel efficiency.

02 Regeneration methods for DPF emission management

Regeneration processes are essential for maintaining optimal DPF performance and controlling emission rates. These processes involve burning off accumulated soot through active methods (using external heat sources or fuel injection strategies) or passive methods (using catalytic materials). Controlled regeneration timing and temperature profiles help prevent filter damage while ensuring complete particulate oxidation, thereby maintaining low emission rates over the filter's operational lifetime.Expand Specific Solutions03 Catalytic coatings and materials for enhanced DPF performance

Specialized catalytic coatings and materials can significantly improve DPF emission control capabilities. These include precious metals (platinum, palladium), base metal oxides, and rare earth compounds that lower the soot ignition temperature and promote continuous regeneration. Advanced materials with optimized porosity, thermal stability, and surface area characteristics enhance filtration efficiency while reducing the frequency of regeneration cycles needed to maintain low emission rates.Expand Specific Solutions04 DPF monitoring and diagnostic systems

Sophisticated monitoring and diagnostic systems are crucial for maintaining optimal DPF emission rates. These systems employ pressure sensors, temperature sensors, and particulate matter sensors to continuously track filter loading and performance. Advanced algorithms analyze sensor data to predict regeneration needs, detect malfunctions, and optimize engine operation parameters. Real-time monitoring ensures compliance with emission standards while maximizing filter lifespan and fuel efficiency.Expand Specific Solutions05 Integration of DPF with other emission control technologies

Integrating DPFs with complementary emission control technologies creates synergistic systems that achieve lower overall emission rates. Combined systems may incorporate selective catalytic reduction (SCR), diesel oxidation catalysts (DOC), exhaust gas recirculation (EGR), and advanced fuel injection strategies. These integrated approaches address multiple pollutants simultaneously, including particulate matter, nitrogen oxides, and hydrocarbons, resulting in comprehensive emission control across various operating conditions.Expand Specific Solutions

Key Industry Players in DPF Measurement Solutions

The diesel particulate filter (DPF) emission rate measurement technology landscape is currently in a mature growth phase, with increasing regulatory pressures driving market expansion. The global market for DPF technologies is estimated to exceed $15 billion, growing at approximately 8% annually as emission standards tighten worldwide. Leading the technological innovation are established automotive suppliers like Robert Bosch GmbH, Continental Automotive, and DENSO Corp, who have developed advanced sensor-based measurement systems. Specialized companies such as Corning, IBIDEN, and NGK Insulators dominate the filter substrate manufacturing segment, while major OEMs including Ford, Renault, Nissan, and Volkswagen (through International Engine IP) are actively integrating these technologies into their emission control systems. Johnson Matthey and AVL List represent significant players in testing and validation technologies.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Diesel Particulate Filter (DPF) monitoring systems that integrate multiple sensor technologies for real-time emission rate measurement. Their solution combines differential pressure sensors across the DPF with particle matter sensors in the exhaust stream to provide comprehensive monitoring. The system utilizes proprietary algorithms that correlate pressure drop patterns with soot loading levels, enabling precise calculation of particulate emission rates. Bosch's technology incorporates temperature compensation mechanisms to ensure measurement accuracy across varying operating conditions. Their latest systems feature OBD (On-Board Diagnostics) integration that allows continuous monitoring of DPF efficiency and emission rates during normal vehicle operation, providing early detection of filter deterioration or malfunction.

Strengths: Comprehensive sensor integration allows for high accuracy measurements across various operating conditions. Their extensive automotive industry presence enables widespread implementation. Weaknesses: Systems can be relatively expensive compared to simpler solutions, and may require periodic recalibration to maintain accuracy over the vehicle lifetime.

Corning, Inc.

Technical Solution: Corning has pioneered advanced ceramic substrate technologies for DPFs with integrated measurement capabilities. Their DuraTrap® filter technology incorporates embedded sensing elements within the filter structure itself, allowing for direct measurement of particulate accumulation and emission rates. The company has developed specialized coating technologies that enhance both filtration efficiency and measurement accuracy. Corning's approach includes thermal sensors strategically positioned throughout the filter to create thermal maps that correlate with soot distribution patterns. This enables precise calculation of particulate capture efficiency and emission rates. Their latest innovation involves optical sensing technology embedded within the filter structure that can directly detect particulate matter concentrations before and after the filter, providing real-time emission rate data.

Strengths: Direct integration of sensing technology within filter material provides more accurate measurements than external sensor systems. Their ceramic expertise enables highly durable measurement solutions. Weaknesses: Replacement costs can be high when the entire integrated filter/sensor system needs replacement, and retrofitting to existing vehicles can be challenging.

Critical Technologies in Particulate Matter Detection

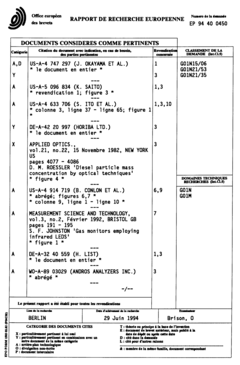

Measuring apparatus for measuring solid component capture efficiency of diesel particulate filter, and measuring method

PatentActiveJP2016188633A

Innovation

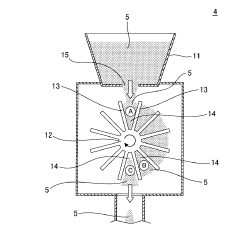

- A measuring apparatus and method using an air supply device, exhaust device, and simulated solid component supply device to intermittently feed simulated particles like carbon black or quicklime into a DPF, mimicking the solid components in diesel engine exhaust, allowing for quick and safe measurement of collection efficiency.

Method and device for measuring and analyzing solid particles emitted by a diesel engine

PatentInactiveEP0616205A1

Innovation

- A method and apparatus that separate the gas sample into two parts, maintaining one at a high temperature for gaseous hydrocarbons and cooling the other to condense hydrocarbons, using specific wavelengths to measure soot and hydrocarbon concentrations, allowing for precise calculation of total solid particle emissions by distinguishing between condensed and uncondensed hydrocarbons.

Environmental Regulations Impact on DPF Technology

Environmental regulations have been the primary driving force behind the development and widespread adoption of Diesel Particulate Filter (DPF) technology. Since the early 2000s, increasingly stringent emission standards in major markets have necessitated advanced particulate matter control systems for diesel engines. The European Union's Euro standards, the United States EPA's Tier regulations, and similar frameworks in Japan and other developed economies have progressively lowered permissible particulate matter (PM) emission levels, making DPF systems virtually mandatory for diesel vehicles.

These regulations have evolved through multiple phases, with each iteration demanding more sophisticated measurement and control technologies. For instance, the transition from Euro 5 to Euro 6 standards reduced the allowable PM emissions by 80%, requiring significant advancements in DPF efficiency and measurement precision. Similarly, the EPA's Tier 4 Final standards for off-road diesel engines mandated a 90% reduction in particulate emissions compared to previous tiers.

The regulatory landscape has also expanded beyond simply controlling the mass of particulate emissions to include particle number limits, recognizing the health impacts of ultrafine particles. This shift has necessitated more advanced measurement methodologies capable of accurately quantifying both the mass and number of particles across various size distributions, directly influencing DPF design parameters and regeneration strategies.

Compliance verification requirements have similarly evolved, moving from laboratory-based certification testing to real-world driving emissions (RDE) testing in Europe and in-use testing programs in the United States. These changes have created demand for on-board diagnostic systems and sensors capable of continuously monitoring DPF performance and emission rates under actual operating conditions.

Looking forward, upcoming regulatory frameworks are focusing on lifecycle emissions performance, requiring DPF systems that maintain high efficiency throughout the vehicle's operational life. The European Commission's proposed Euro 7 standards and similar initiatives globally are expected to further tighten emission limits while expanding the range of operating conditions under which compliance must be maintained.

Regional variations in regulatory approaches have created a complex global landscape for DPF technology developers. While developed markets are moving toward harmonization of standards, emerging economies are implementing regulations at different paces, creating diverse market requirements for DPF systems and measurement technologies tailored to specific regulatory frameworks and enforcement capabilities.

These regulations have evolved through multiple phases, with each iteration demanding more sophisticated measurement and control technologies. For instance, the transition from Euro 5 to Euro 6 standards reduced the allowable PM emissions by 80%, requiring significant advancements in DPF efficiency and measurement precision. Similarly, the EPA's Tier 4 Final standards for off-road diesel engines mandated a 90% reduction in particulate emissions compared to previous tiers.

The regulatory landscape has also expanded beyond simply controlling the mass of particulate emissions to include particle number limits, recognizing the health impacts of ultrafine particles. This shift has necessitated more advanced measurement methodologies capable of accurately quantifying both the mass and number of particles across various size distributions, directly influencing DPF design parameters and regeneration strategies.

Compliance verification requirements have similarly evolved, moving from laboratory-based certification testing to real-world driving emissions (RDE) testing in Europe and in-use testing programs in the United States. These changes have created demand for on-board diagnostic systems and sensors capable of continuously monitoring DPF performance and emission rates under actual operating conditions.

Looking forward, upcoming regulatory frameworks are focusing on lifecycle emissions performance, requiring DPF systems that maintain high efficiency throughout the vehicle's operational life. The European Commission's proposed Euro 7 standards and similar initiatives globally are expected to further tighten emission limits while expanding the range of operating conditions under which compliance must be maintained.

Regional variations in regulatory approaches have created a complex global landscape for DPF technology developers. While developed markets are moving toward harmonization of standards, emerging economies are implementing regulations at different paces, creating diverse market requirements for DPF systems and measurement technologies tailored to specific regulatory frameworks and enforcement capabilities.

Cost-Benefit Analysis of Advanced DPF Measurement Systems

The implementation of advanced Diesel Particulate Filter (DPF) measurement systems represents a significant investment for both manufacturers and regulatory bodies. This analysis examines the economic implications of adopting cutting-edge DPF emission rate measurement technologies compared to conventional methods.

Initial capital expenditure for advanced DPF measurement systems typically ranges from $75,000 to $250,000, depending on the sophistication of sensors, data processing capabilities, and integration requirements. While this represents a substantial upfront cost, particularly for smaller operations, the long-term operational benefits often justify the investment.

Operational cost reductions manifest in several areas. Advanced systems reduce labor requirements by approximately 35-40% through automation of sampling and analysis processes. Maintenance costs decrease by an estimated 25% due to improved durability and self-diagnostic capabilities of modern sensors. Additionally, calibration intervals can be extended by up to 300% compared to traditional methods, significantly reducing downtime and associated costs.

The precision of advanced measurement systems delivers substantial compliance benefits. Studies indicate that facilities utilizing high-precision DPF measurement technologies experience 65% fewer regulatory violations, with average penalty savings of $50,000-$100,000 annually for medium to large operations. The improved accuracy also enables optimization of regeneration cycles, extending DPF lifetime by 15-20% and reducing replacement frequency.

From a product development perspective, the enhanced data quality from advanced systems accelerates R&D cycles by approximately 30%. This translates to faster time-to-market for improved DPF designs and competitive advantage in an increasingly regulated market. The granular emission data enables more targeted engineering solutions, reducing development iterations and associated costs.

Environmental and public health benefits, while difficult to quantify directly, represent significant societal value. More accurate DPF emission measurements ensure better real-world performance of diesel filtration systems, potentially preventing thousands of tons of particulate matter from entering the atmosphere annually. The WHO estimates that each 10% improvement in particulate control delivers healthcare cost savings of $4-7 per capita in urban areas.

Return on investment calculations indicate that most advanced DPF measurement systems achieve breakeven within 2-3 years for large operations and 3-5 years for smaller facilities. This timeline continues to improve as technology costs decrease and regulatory requirements become more stringent, further enhancing the value proposition of advanced measurement solutions.

Initial capital expenditure for advanced DPF measurement systems typically ranges from $75,000 to $250,000, depending on the sophistication of sensors, data processing capabilities, and integration requirements. While this represents a substantial upfront cost, particularly for smaller operations, the long-term operational benefits often justify the investment.

Operational cost reductions manifest in several areas. Advanced systems reduce labor requirements by approximately 35-40% through automation of sampling and analysis processes. Maintenance costs decrease by an estimated 25% due to improved durability and self-diagnostic capabilities of modern sensors. Additionally, calibration intervals can be extended by up to 300% compared to traditional methods, significantly reducing downtime and associated costs.

The precision of advanced measurement systems delivers substantial compliance benefits. Studies indicate that facilities utilizing high-precision DPF measurement technologies experience 65% fewer regulatory violations, with average penalty savings of $50,000-$100,000 annually for medium to large operations. The improved accuracy also enables optimization of regeneration cycles, extending DPF lifetime by 15-20% and reducing replacement frequency.

From a product development perspective, the enhanced data quality from advanced systems accelerates R&D cycles by approximately 30%. This translates to faster time-to-market for improved DPF designs and competitive advantage in an increasingly regulated market. The granular emission data enables more targeted engineering solutions, reducing development iterations and associated costs.

Environmental and public health benefits, while difficult to quantify directly, represent significant societal value. More accurate DPF emission measurements ensure better real-world performance of diesel filtration systems, potentially preventing thousands of tons of particulate matter from entering the atmosphere annually. The WHO estimates that each 10% improvement in particulate control delivers healthcare cost savings of $4-7 per capita in urban areas.

Return on investment calculations indicate that most advanced DPF measurement systems achieve breakeven within 2-3 years for large operations and 3-5 years for smaller facilities. This timeline continues to improve as technology costs decrease and regulatory requirements become more stringent, further enhancing the value proposition of advanced measurement solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!