Enhancing Diesel Particulate Filter Clogging Detection

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Clogging Detection Background and Objectives

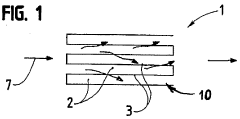

Diesel Particulate Filters (DPFs) have emerged as a critical component in modern diesel engine exhaust systems since their widespread adoption in the early 2000s. These filtration devices were developed in response to increasingly stringent emissions regulations worldwide, particularly targeting the reduction of particulate matter (PM) emissions that pose significant environmental and health concerns. The evolution of DPF technology represents a remarkable engineering achievement in balancing filtration efficiency with engine performance and durability.

The fundamental challenge with DPFs lies in their inherent operational principle: as they capture soot and ash particles from exhaust gases, they gradually accumulate these contaminants, leading to increased backpressure in the exhaust system. This accumulation process, commonly referred to as "clogging," presents a complex technical problem that impacts engine efficiency, fuel consumption, and overall vehicle performance if not properly managed.

Current detection methods for DPF clogging rely primarily on differential pressure sensors that measure the pressure drop across the filter. While functional, these systems often lack precision in distinguishing between different types of clogging (reversible soot accumulation versus irreversible ash buildup) and typically provide limited advance warning before critical clogging levels are reached. The industry has recognized these limitations as increasingly problematic as emissions standards continue to tighten globally.

The primary objective of enhancing DPF clogging detection is to develop more sophisticated, accurate, and predictive monitoring systems that can differentiate between various clogging mechanisms and provide earlier intervention opportunities. This advancement aims to optimize regeneration cycles (the process of burning off accumulated soot), extend filter service life, reduce maintenance costs, and maintain optimal engine performance throughout the vehicle's operational lifetime.

Secondary objectives include the integration of these enhanced detection systems with broader vehicle diagnostics and telematics platforms, enabling predictive maintenance scheduling and real-time fleet management. Additionally, there is growing interest in developing detection methods that can function effectively across varying driving conditions and operational environments, from urban stop-and-go traffic to highway cruising and heavy-load applications.

The technological trajectory in this field is moving toward multi-sensor approaches that combine traditional differential pressure measurements with advanced analytics, thermal modeling, and potentially novel sensing technologies such as radio frequency (RF) sensors or acoustic monitoring. Machine learning algorithms are increasingly being explored to interpret complex sensor data patterns and improve prediction accuracy of clogging progression.

As global emissions regulations continue to evolve and the automotive industry shifts toward more sustainable technologies, enhancing DPF clogging detection represents a critical enabling technology for maintaining the viability of diesel engines in various applications while meeting environmental compliance requirements.

The fundamental challenge with DPFs lies in their inherent operational principle: as they capture soot and ash particles from exhaust gases, they gradually accumulate these contaminants, leading to increased backpressure in the exhaust system. This accumulation process, commonly referred to as "clogging," presents a complex technical problem that impacts engine efficiency, fuel consumption, and overall vehicle performance if not properly managed.

Current detection methods for DPF clogging rely primarily on differential pressure sensors that measure the pressure drop across the filter. While functional, these systems often lack precision in distinguishing between different types of clogging (reversible soot accumulation versus irreversible ash buildup) and typically provide limited advance warning before critical clogging levels are reached. The industry has recognized these limitations as increasingly problematic as emissions standards continue to tighten globally.

The primary objective of enhancing DPF clogging detection is to develop more sophisticated, accurate, and predictive monitoring systems that can differentiate between various clogging mechanisms and provide earlier intervention opportunities. This advancement aims to optimize regeneration cycles (the process of burning off accumulated soot), extend filter service life, reduce maintenance costs, and maintain optimal engine performance throughout the vehicle's operational lifetime.

Secondary objectives include the integration of these enhanced detection systems with broader vehicle diagnostics and telematics platforms, enabling predictive maintenance scheduling and real-time fleet management. Additionally, there is growing interest in developing detection methods that can function effectively across varying driving conditions and operational environments, from urban stop-and-go traffic to highway cruising and heavy-load applications.

The technological trajectory in this field is moving toward multi-sensor approaches that combine traditional differential pressure measurements with advanced analytics, thermal modeling, and potentially novel sensing technologies such as radio frequency (RF) sensors or acoustic monitoring. Machine learning algorithms are increasingly being explored to interpret complex sensor data patterns and improve prediction accuracy of clogging progression.

As global emissions regulations continue to evolve and the automotive industry shifts toward more sustainable technologies, enhancing DPF clogging detection represents a critical enabling technology for maintaining the viability of diesel engines in various applications while meeting environmental compliance requirements.

Market Demand Analysis for Advanced DPF Monitoring

The global market for Diesel Particulate Filter (DPF) monitoring systems is experiencing significant growth driven by increasingly stringent emission regulations worldwide. The European Union's Euro 6d standards, the US EPA's Tier 3 regulations, and China's National VI standards have all established strict particulate matter emission limits, creating substantial demand for advanced DPF monitoring solutions. This regulatory pressure is expected to intensify further with upcoming Euro 7 standards and similar tightening measures globally, projected to expand the market at a CAGR of 8.2% through 2028.

Commercial fleet operators represent a particularly strong demand segment, as DPF clogging issues directly impact operational costs through increased fuel consumption, unplanned downtime, and premature filter replacement. Research indicates that advanced monitoring systems can reduce DPF-related maintenance costs by up to 30% and extend filter lifespan by 25%, offering compelling return on investment for fleet managers facing average DPF replacement costs between $2,000 and $5,000 per vehicle.

The off-highway equipment sector presents another significant market opportunity, with construction, mining, and agricultural machinery manufacturers seeking reliable DPF monitoring solutions adapted to harsh operating environments and variable load conditions. These applications often experience accelerated filter clogging due to duty cycles characterized by frequent idling and low-temperature operation.

Original Equipment Manufacturers (OEMs) are increasingly integrating sophisticated DPF monitoring capabilities as standard features rather than optional add-ons, responding to customer demands for predictive maintenance capabilities and total cost of ownership reduction. This shift represents a fundamental market evolution from reactive to proactive DPF management approaches.

The aftermarket segment shows promising growth potential, particularly for retrofit solutions compatible with older diesel vehicles that lack advanced onboard diagnostics. This segment is especially relevant in developing markets where aging commercial vehicle fleets remain operational for extended periods, creating demand for cost-effective monitoring upgrades.

Geographically, North America and Europe currently dominate market revenue share due to early adoption of strict emission standards, while Asia-Pacific represents the fastest-growing regional market, driven by rapid implementation of equivalent regulations in China, India, and other emerging economies with large diesel vehicle populations.

Consumer awareness regarding the environmental and economic benefits of proper DPF maintenance is also rising, further stimulating market demand for user-friendly monitoring solutions that provide clear, actionable information to vehicle operators and maintenance personnel.

Commercial fleet operators represent a particularly strong demand segment, as DPF clogging issues directly impact operational costs through increased fuel consumption, unplanned downtime, and premature filter replacement. Research indicates that advanced monitoring systems can reduce DPF-related maintenance costs by up to 30% and extend filter lifespan by 25%, offering compelling return on investment for fleet managers facing average DPF replacement costs between $2,000 and $5,000 per vehicle.

The off-highway equipment sector presents another significant market opportunity, with construction, mining, and agricultural machinery manufacturers seeking reliable DPF monitoring solutions adapted to harsh operating environments and variable load conditions. These applications often experience accelerated filter clogging due to duty cycles characterized by frequent idling and low-temperature operation.

Original Equipment Manufacturers (OEMs) are increasingly integrating sophisticated DPF monitoring capabilities as standard features rather than optional add-ons, responding to customer demands for predictive maintenance capabilities and total cost of ownership reduction. This shift represents a fundamental market evolution from reactive to proactive DPF management approaches.

The aftermarket segment shows promising growth potential, particularly for retrofit solutions compatible with older diesel vehicles that lack advanced onboard diagnostics. This segment is especially relevant in developing markets where aging commercial vehicle fleets remain operational for extended periods, creating demand for cost-effective monitoring upgrades.

Geographically, North America and Europe currently dominate market revenue share due to early adoption of strict emission standards, while Asia-Pacific represents the fastest-growing regional market, driven by rapid implementation of equivalent regulations in China, India, and other emerging economies with large diesel vehicle populations.

Consumer awareness regarding the environmental and economic benefits of proper DPF maintenance is also rising, further stimulating market demand for user-friendly monitoring solutions that provide clear, actionable information to vehicle operators and maintenance personnel.

Current Technologies and Challenges in DPF Diagnostics

Diesel Particulate Filter (DPF) diagnostics currently employ several technologies to detect clogging and assess filter condition. Pressure differential sensors remain the most widely implemented method, measuring the pressure drop across the DPF to infer particulate accumulation levels. These sensors typically operate by comparing upstream and downstream pressure values, with higher differential readings indicating increased soot loading. While cost-effective and relatively simple to implement, this approach suffers from accuracy limitations, particularly during low exhaust flow conditions or when ash accumulation becomes significant.

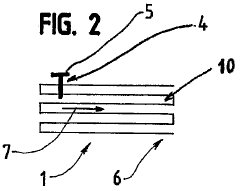

Temperature-based monitoring systems represent another common diagnostic approach, utilizing strategically placed temperature sensors before and after the DPF. These systems analyze temperature patterns during both normal operation and regeneration events to detect abnormal thermal behaviors indicative of clogging issues. However, temperature-based methods can be confounded by various driving conditions and may provide delayed indications of developing problems.

Advanced diagnostic systems increasingly incorporate exhaust gas composition analysis, using oxygen sensors and NOx sensors to indirectly assess DPF condition. By analyzing changes in exhaust gas composition, these systems can detect efficiency reductions that may signal filter clogging. While offering improved accuracy, these methods require sophisticated algorithms and additional sensor hardware, increasing system complexity and cost.

Radio frequency (RF) sensing technology has emerged as a promising diagnostic method, measuring the dielectric properties of the filter substrate to directly quantify soot and ash accumulation. This approach offers the advantage of distinguishing between soot and ash deposits, providing more comprehensive filter condition assessment. Despite its potential, RF sensing remains primarily in the development phase, with limited commercial implementation due to calibration challenges and cost considerations.

The primary challenges facing current DPF diagnostic technologies include accuracy limitations under variable operating conditions, difficulty in distinguishing between soot and ash accumulation, and delayed detection of developing problems. Most systems struggle to provide reliable early warnings before performance degradation becomes significant. Additionally, current technologies often cannot accurately predict remaining filter life or optimize regeneration timing, leading to either premature regeneration events that waste fuel or delayed regeneration that risks filter damage.

Integration challenges also persist, as diagnostic systems must interface effectively with engine control units while minimizing false alarms that could trigger unnecessary service events. Furthermore, the increasing diversity of driving conditions, particularly with the growth of hybrid powertrains, creates additional complexity for diagnostic algorithms that must function reliably across widely varying operational profiles.

Temperature-based monitoring systems represent another common diagnostic approach, utilizing strategically placed temperature sensors before and after the DPF. These systems analyze temperature patterns during both normal operation and regeneration events to detect abnormal thermal behaviors indicative of clogging issues. However, temperature-based methods can be confounded by various driving conditions and may provide delayed indications of developing problems.

Advanced diagnostic systems increasingly incorporate exhaust gas composition analysis, using oxygen sensors and NOx sensors to indirectly assess DPF condition. By analyzing changes in exhaust gas composition, these systems can detect efficiency reductions that may signal filter clogging. While offering improved accuracy, these methods require sophisticated algorithms and additional sensor hardware, increasing system complexity and cost.

Radio frequency (RF) sensing technology has emerged as a promising diagnostic method, measuring the dielectric properties of the filter substrate to directly quantify soot and ash accumulation. This approach offers the advantage of distinguishing between soot and ash deposits, providing more comprehensive filter condition assessment. Despite its potential, RF sensing remains primarily in the development phase, with limited commercial implementation due to calibration challenges and cost considerations.

The primary challenges facing current DPF diagnostic technologies include accuracy limitations under variable operating conditions, difficulty in distinguishing between soot and ash accumulation, and delayed detection of developing problems. Most systems struggle to provide reliable early warnings before performance degradation becomes significant. Additionally, current technologies often cannot accurately predict remaining filter life or optimize regeneration timing, leading to either premature regeneration events that waste fuel or delayed regeneration that risks filter damage.

Integration challenges also persist, as diagnostic systems must interface effectively with engine control units while minimizing false alarms that could trigger unnecessary service events. Furthermore, the increasing diversity of driving conditions, particularly with the growth of hybrid powertrains, creates additional complexity for diagnostic algorithms that must function reliably across widely varying operational profiles.

Existing DPF Clogging Detection Solutions

01 Pressure-based DPF clogging detection methods

Pressure sensors are used to monitor the differential pressure across the DPF. As the filter becomes clogged with particulate matter, the pressure difference between the inlet and outlet increases. By analyzing these pressure measurements and comparing them to predetermined thresholds, the system can detect when the DPF is becoming clogged and requires regeneration or maintenance. This method provides real-time monitoring of filter condition and can trigger warning signals to the driver or control systems.- Pressure-based DPF clogging detection: Pressure sensors are used to detect DPF clogging by measuring the pressure differential across the filter. When the DPF becomes clogged, the pressure difference between the inlet and outlet increases. This method involves installing pressure sensors before and after the DPF to continuously monitor the pressure drop. Advanced systems can analyze pressure patterns to determine the severity of clogging and trigger appropriate warnings or regeneration processes when predetermined threshold values are exceeded.

- Temperature-based detection methods: Temperature sensors positioned at strategic locations in the exhaust system can detect DPF clogging by monitoring temperature variations. As particulate matter accumulates in the filter, exhaust flow is restricted, causing temperature changes that can be measured and analyzed. These systems typically use multiple temperature sensors to create a temperature profile across the DPF. Algorithms process this temperature data to determine clogging status and can trigger regeneration when necessary.

- Exhaust gas analysis for DPF monitoring: This approach involves analyzing exhaust gas composition to detect DPF clogging. Sensors measure parameters such as oxygen content, particulate matter concentration, and other exhaust gas components. As the filter clogs, changes in these parameters can be detected and analyzed. Some systems use specialized gas sensors or optical sensors to directly measure particulate matter in the exhaust stream. This method provides comprehensive data about filter performance and can detect clogging at earlier stages.

- Integrated sensor systems with ECU processing: These detection systems combine multiple sensor inputs with advanced electronic control unit (ECU) processing to comprehensively monitor DPF condition. Data from pressure sensors, temperature sensors, exhaust gas sensors, and engine performance parameters are integrated and analyzed using sophisticated algorithms. Machine learning and artificial intelligence techniques may be employed to improve detection accuracy and predict clogging before it becomes critical. These systems can adapt to different driving conditions and provide early warnings of potential DPF issues.

- Model-based estimation and predictive diagnostics: This approach uses mathematical models and predictive algorithms to estimate DPF clogging status without relying solely on direct measurements. The system analyzes various engine parameters such as fuel consumption, exhaust flow rate, and operating conditions to predict particulate accumulation in the filter. Historical data and driving patterns are incorporated to improve prediction accuracy. Some advanced systems can estimate remaining filter capacity and predict when regeneration will be needed, allowing for optimized maintenance scheduling and improved vehicle performance.

02 Temperature-based detection systems

Temperature sensors placed at strategic locations around the DPF monitor thermal patterns during operation. Clogged filters exhibit distinctive temperature profiles due to restricted exhaust flow and increased backpressure. Advanced systems use multiple temperature sensors to create thermal maps of the filter, allowing for more precise detection of partial clogging or uneven soot distribution. These systems can also monitor regeneration processes to ensure proper cleaning of the filter.Expand Specific Solutions03 Exhaust gas analysis for DPF monitoring

This approach involves analyzing the composition of exhaust gases before and after the DPF to determine filter efficiency and clogging status. Sensors measure parameters such as particulate matter concentration, NOx levels, and opacity of the exhaust. By comparing these measurements with expected values for a properly functioning filter, the system can detect reduced filtration efficiency indicative of clogging. Some advanced systems incorporate machine learning algorithms to improve detection accuracy over time.Expand Specific Solutions04 Integrated sensor networks with ECU processing

These systems combine multiple sensor inputs (pressure, temperature, exhaust composition) with sophisticated electronic control unit (ECU) processing to provide comprehensive DPF monitoring. The ECU applies algorithms that account for various operating conditions, engine load, and environmental factors to accurately assess filter condition. These integrated systems can predict clogging before it reaches critical levels, allowing for preventive maintenance or optimized regeneration timing.Expand Specific Solutions05 Predictive and AI-based clogging detection

Advanced systems employ predictive models and artificial intelligence to forecast DPF clogging based on historical data, driving patterns, and engine performance metrics. These systems analyze trends in sensor data over time rather than relying solely on threshold values. Machine learning algorithms continuously improve prediction accuracy by correlating various parameters with actual filter conditions. Some systems can adapt to individual vehicle usage patterns and environmental conditions to provide personalized maintenance recommendations.Expand Specific Solutions

Key Industry Players in DPF Technology

The diesel particulate filter (DPF) clogging detection technology market is in a growth phase, with increasing regulatory pressure driving innovation. The market is expanding due to stricter emission standards globally, estimated at $2-3 billion annually with 5-7% growth. Leading automotive manufacturers like Toyota, Nissan, Mercedes-Benz, and Isuzu are competing with specialized component suppliers such as Robert Bosch, Corning, and IBIDEN. Technology maturity varies, with established players like Bosch and Corning offering advanced sensor-based solutions, while newer entrants like Proterial and Magneti Marelli focus on innovative detection algorithms. The competitive landscape is characterized by a mix of OEM-developed proprietary systems and third-party solutions, with increasing emphasis on predictive diagnostics and integration with vehicle telematics systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced DPF monitoring system that combines multiple sensor technologies for comprehensive clogging detection. Their solution integrates differential pressure sensors with temperature sensors placed strategically before and after the filter to create a multi-parameter monitoring approach. The system employs proprietary algorithms that analyze exhaust flow patterns, backpressure variations, and temperature differentials to accurately determine filter loading status. Bosch's technology can distinguish between different types of particulate accumulation (soot vs. ash) based on sensor signal characteristics and thermal response patterns. Their latest generation systems incorporate machine learning algorithms that adapt to individual driving patterns and engine conditions, improving detection accuracy by up to 30% compared to conventional systems. The technology also features predictive maintenance capabilities, alerting drivers to potential clogging issues before performance degradation occurs.

Strengths: Exceptional accuracy in differentiating between various clogging types; comprehensive sensor integration; adaptive learning capabilities that improve over time; extensive automotive industry partnerships. Weaknesses: Higher implementation cost compared to simpler systems; requires more complex calibration; dependent on multiple sensor inputs which increases potential failure points.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated DPF monitoring system called "Intelligent Particulate Management" that combines traditional differential pressure monitoring with advanced exhaust gas composition analysis. Their system utilizes specialized NOx sensors that can indirectly infer particulate loading by analyzing exhaust gas oxygen content and temperature patterns. Mercedes has implemented a unique regeneration prediction algorithm that calculates optimal regeneration timing based on driving patterns, filter loading status, and anticipated future driving conditions. The system features adaptive threshold management that adjusts warning levels based on vehicle usage patterns and environmental conditions. Mercedes' technology incorporates ultrasonic sensors in newer models to detect filter structural integrity issues that might affect clogging patterns. Their integrated approach connects DPF monitoring with the vehicle's broader diagnostic system, allowing for correlation between engine performance parameters and filter loading characteristics to identify root causes of abnormal clogging.

Strengths: Highly integrated with vehicle systems for comprehensive diagnostics; sophisticated regeneration management; adaptation to driving patterns for optimized performance; premium sensor technology with high durability. Weaknesses: Higher system cost limits application to premium vehicles; complex calibration requirements; higher computational demands on vehicle ECU.

Critical Patents and Research in DPF Monitoring

Method of detecting the clogging level of a diesel vehicle particle filter

PatentWO2004055337A1

Innovation

- A method that measures and compares the maximum temperature reached and temperature progression during regeneration cycles to determine the level of fouling by referencing established temperature values, with alerts provided to the driver when cleaning is necessary.

Filter Clogging Determination Apparatus for Diesel Engine

PatentInactiveUS20090038288A1

Innovation

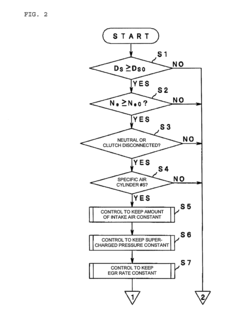

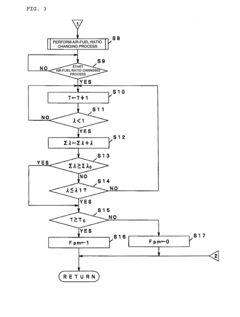

- A filter clogging determination apparatus that uses an exhaust sensor to detect air-fuel ratio or oxygen concentration, calculates response time to air-fuel ratio changes, and determines clogging based on this response time, eliminating the need for separate pressure sensors and map data.

Environmental Regulations Impact on DPF Technology

Environmental regulations worldwide have become increasingly stringent regarding vehicle emissions, directly influencing the development and implementation of Diesel Particulate Filter (DPF) technology. The European Union's Euro standards have progressively tightened particulate matter (PM) emission limits, with Euro 6 requiring a 66% reduction compared to Euro 5. Similarly, the United States EPA's Tier 3 standards and China's China 6 regulations have established comparable restrictions, compelling manufacturers to enhance DPF efficiency and monitoring capabilities.

These regulatory frameworks have accelerated innovation in DPF technology, particularly in detection systems that can identify clogging before it impacts vehicle performance. Regulations now mandate not only the presence of DPF systems but also sophisticated on-board diagnostic (OBD) capabilities that can alert drivers to potential filter issues before emissions exceed legal thresholds.

The regulatory landscape has created a technological imperative for more accurate and earlier detection of DPF clogging conditions. Traditional pressure differential methods are increasingly supplemented by advanced sensor technologies and predictive algorithms to meet these requirements. Manufacturers must now demonstrate compliance through rigorous testing protocols that simulate various driving conditions and filter loading scenarios.

Financial implications of these regulations are substantial, with non-compliance penalties reaching millions of dollars for manufacturers. This has shifted DPF technology from an optional environmental feature to a critical compliance component, driving significant investment in research and development of enhanced detection systems.

The regulatory timeline reveals an accelerating pace of implementation, with phase-in periods becoming shorter between successive standards. This compressed timeline challenges engineering teams to develop more sophisticated clogging detection technologies that can be rapidly deployed across vehicle fleets while maintaining reliability and cost-effectiveness.

Regional variations in regulations create additional complexity, as manufacturers must design detection systems that can adapt to different regulatory requirements across global markets. This has led to modular approaches in DPF monitoring systems, with software-configurable parameters that can be adjusted to meet local compliance standards.

The regulatory focus has expanded beyond laboratory testing to real-world driving emissions (RDE), requiring DPF clogging detection systems to perform consistently across diverse operating conditions. This shift has prompted the development of more robust detection algorithms that can account for variables such as driving style, ambient conditions, and fuel quality.

These regulatory frameworks have accelerated innovation in DPF technology, particularly in detection systems that can identify clogging before it impacts vehicle performance. Regulations now mandate not only the presence of DPF systems but also sophisticated on-board diagnostic (OBD) capabilities that can alert drivers to potential filter issues before emissions exceed legal thresholds.

The regulatory landscape has created a technological imperative for more accurate and earlier detection of DPF clogging conditions. Traditional pressure differential methods are increasingly supplemented by advanced sensor technologies and predictive algorithms to meet these requirements. Manufacturers must now demonstrate compliance through rigorous testing protocols that simulate various driving conditions and filter loading scenarios.

Financial implications of these regulations are substantial, with non-compliance penalties reaching millions of dollars for manufacturers. This has shifted DPF technology from an optional environmental feature to a critical compliance component, driving significant investment in research and development of enhanced detection systems.

The regulatory timeline reveals an accelerating pace of implementation, with phase-in periods becoming shorter between successive standards. This compressed timeline challenges engineering teams to develop more sophisticated clogging detection technologies that can be rapidly deployed across vehicle fleets while maintaining reliability and cost-effectiveness.

Regional variations in regulations create additional complexity, as manufacturers must design detection systems that can adapt to different regulatory requirements across global markets. This has led to modular approaches in DPF monitoring systems, with software-configurable parameters that can be adjusted to meet local compliance standards.

The regulatory focus has expanded beyond laboratory testing to real-world driving emissions (RDE), requiring DPF clogging detection systems to perform consistently across diverse operating conditions. This shift has prompted the development of more robust detection algorithms that can account for variables such as driving style, ambient conditions, and fuel quality.

Cost-Benefit Analysis of Enhanced Detection Systems

The implementation of enhanced diesel particulate filter (DPF) clogging detection systems represents a significant investment for fleet operators and vehicle manufacturers. This analysis examines the financial implications of adopting advanced detection technologies compared to traditional monitoring methods.

Initial implementation costs for enhanced DPF detection systems typically range from $300 to $1,200 per vehicle, depending on the sophistication of sensors and integration complexity. These systems generally incorporate multiple sensor arrays, specialized software algorithms, and dashboard interfaces. For large fleets, this represents a substantial capital expenditure that must be justified through operational benefits.

Maintenance cost reductions constitute the primary financial benefit of these systems. Traditional reactive approaches to DPF management result in emergency servicing costs averaging $3,000-$5,000 per incident, including towing, repairs, and downtime. Enhanced detection systems can reduce these incidents by 65-85%, according to field studies conducted across commercial fleets in Europe and North America.

Vehicle downtime represents another critical cost factor. A commercial vehicle experiencing DPF failure typically remains out of service for 2-4 days, resulting in revenue losses of $800-$1,500 per day depending on the operation type. Advanced detection systems provide early warnings that enable scheduled maintenance during planned downtime periods, significantly reducing these opportunity costs.

Fuel efficiency improvements of 2-5% have been documented in vehicles equipped with enhanced DPF monitoring systems. This efficiency gain stems from maintaining optimal exhaust backpressure levels and preventing the performance degradation associated with partially clogged filters. For a typical long-haul truck consuming 20,000 gallons annually, this translates to savings of $1,200-$3,000 per year at current diesel prices.

Extended DPF lifespan represents another significant benefit. Advanced detection systems help prevent the thermal damage that occurs during emergency regeneration events, potentially extending filter life by 30-50%. With replacement DPFs costing $1,500-$2,500, this extension translates to substantial savings over a vehicle's operational life.

Return on investment calculations indicate that most enhanced detection systems achieve payback within 8-14 months of operation, depending on vehicle usage patterns and regional operating conditions. Heavy-duty applications in severe environments show the fastest returns, while light-duty vehicles in optimal conditions experience longer but still favorable payback periods.

Initial implementation costs for enhanced DPF detection systems typically range from $300 to $1,200 per vehicle, depending on the sophistication of sensors and integration complexity. These systems generally incorporate multiple sensor arrays, specialized software algorithms, and dashboard interfaces. For large fleets, this represents a substantial capital expenditure that must be justified through operational benefits.

Maintenance cost reductions constitute the primary financial benefit of these systems. Traditional reactive approaches to DPF management result in emergency servicing costs averaging $3,000-$5,000 per incident, including towing, repairs, and downtime. Enhanced detection systems can reduce these incidents by 65-85%, according to field studies conducted across commercial fleets in Europe and North America.

Vehicle downtime represents another critical cost factor. A commercial vehicle experiencing DPF failure typically remains out of service for 2-4 days, resulting in revenue losses of $800-$1,500 per day depending on the operation type. Advanced detection systems provide early warnings that enable scheduled maintenance during planned downtime periods, significantly reducing these opportunity costs.

Fuel efficiency improvements of 2-5% have been documented in vehicles equipped with enhanced DPF monitoring systems. This efficiency gain stems from maintaining optimal exhaust backpressure levels and preventing the performance degradation associated with partially clogged filters. For a typical long-haul truck consuming 20,000 gallons annually, this translates to savings of $1,200-$3,000 per year at current diesel prices.

Extended DPF lifespan represents another significant benefit. Advanced detection systems help prevent the thermal damage that occurs during emergency regeneration events, potentially extending filter life by 30-50%. With replacement DPFs costing $1,500-$2,500, this extension translates to substantial savings over a vehicle's operational life.

Return on investment calculations indicate that most enhanced detection systems achieve payback within 8-14 months of operation, depending on vehicle usage patterns and regional operating conditions. Heavy-duty applications in severe environments show the fastest returns, while light-duty vehicles in optimal conditions experience longer but still favorable payback periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!