Comparative analysis of Dual-ion batteries layered oxide versus phosphate cathodes

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Evolution and Objectives

Dual-ion batteries (DIBs) have emerged as a promising alternative to conventional lithium-ion batteries, offering potential advantages in energy density, cost, and environmental impact. The evolution of DIB technology can be traced back to the early 1990s when the concept was first introduced by researchers exploring alternative battery chemistries. Initially, DIBs utilized graphite as both cathode and anode materials, with limited performance characteristics.

The significant breakthrough came in the early 2000s with the development of advanced electrolytes capable of supporting efficient anion intercalation, which addressed one of the key limitations of early DIB designs. This period marked the transition from conceptual research to practical implementation, with the first laboratory prototypes demonstrating the feasibility of dual-ion intercalation mechanisms.

Between 2010 and 2015, research focus shifted toward cathode material optimization, with layered oxide materials emerging as promising candidates due to their high theoretical capacity and structural stability. Concurrently, phosphate-based cathodes gained attention for their thermal stability and safety advantages, creating two distinct technological pathways in DIB development.

The current technological landscape is characterized by intensive research into both layered oxide and phosphate cathode materials, each offering distinct advantages. Layered oxide cathodes typically provide higher energy density and better rate capability, while phosphate cathodes demonstrate superior cycling stability and thermal performance. This dichotomy represents a critical junction in DIB evolution, with significant implications for future commercialization strategies.

Recent advancements in electrolyte formulations and electrode architectures have further enhanced DIB performance, narrowing the gap with commercial lithium-ion technologies. The integration of advanced manufacturing techniques, such as atomic layer deposition and solution-based synthesis methods, has improved material uniformity and reduced production costs, accelerating the path toward practical applications.

The primary objective of current DIB research is to develop cathode materials that combine the high energy density of layered oxides with the stability and safety of phosphates. This goal necessitates a comprehensive understanding of structure-property relationships in both material classes and innovative approaches to material design and synthesis.

Additional objectives include improving the voltage stability window of electrolytes to accommodate higher operating voltages, enhancing the rate capability for fast-charging applications, and developing scalable manufacturing processes suitable for mass production. The ultimate aim is to position DIBs as a viable alternative to conventional battery technologies in specific application niches, particularly where cost, safety, and resource availability are primary concerns.

The significant breakthrough came in the early 2000s with the development of advanced electrolytes capable of supporting efficient anion intercalation, which addressed one of the key limitations of early DIB designs. This period marked the transition from conceptual research to practical implementation, with the first laboratory prototypes demonstrating the feasibility of dual-ion intercalation mechanisms.

Between 2010 and 2015, research focus shifted toward cathode material optimization, with layered oxide materials emerging as promising candidates due to their high theoretical capacity and structural stability. Concurrently, phosphate-based cathodes gained attention for their thermal stability and safety advantages, creating two distinct technological pathways in DIB development.

The current technological landscape is characterized by intensive research into both layered oxide and phosphate cathode materials, each offering distinct advantages. Layered oxide cathodes typically provide higher energy density and better rate capability, while phosphate cathodes demonstrate superior cycling stability and thermal performance. This dichotomy represents a critical junction in DIB evolution, with significant implications for future commercialization strategies.

Recent advancements in electrolyte formulations and electrode architectures have further enhanced DIB performance, narrowing the gap with commercial lithium-ion technologies. The integration of advanced manufacturing techniques, such as atomic layer deposition and solution-based synthesis methods, has improved material uniformity and reduced production costs, accelerating the path toward practical applications.

The primary objective of current DIB research is to develop cathode materials that combine the high energy density of layered oxides with the stability and safety of phosphates. This goal necessitates a comprehensive understanding of structure-property relationships in both material classes and innovative approaches to material design and synthesis.

Additional objectives include improving the voltage stability window of electrolytes to accommodate higher operating voltages, enhancing the rate capability for fast-charging applications, and developing scalable manufacturing processes suitable for mass production. The ultimate aim is to position DIBs as a viable alternative to conventional battery technologies in specific application niches, particularly where cost, safety, and resource availability are primary concerns.

Market Analysis for Advanced Battery Technologies

The global advanced battery market is experiencing unprecedented growth, driven by the increasing demand for energy storage solutions across various sectors. The market for dual-ion batteries (DIBs) is emerging as a significant segment within this landscape, with particular interest in the comparative performance of layered oxide versus phosphate cathodes. Current market valuations place the advanced battery sector at approximately $95 billion in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030.

The electric vehicle (EV) industry remains the primary driver for advanced battery technologies, accounting for nearly 60% of the total market demand. Consumer electronics follows at 25%, while grid storage applications represent 15% of market share. Within these applications, the demand for batteries with superior energy density, longer cycle life, and enhanced safety profiles is creating specific market opportunities for dual-ion battery technologies.

Layered oxide cathodes currently dominate the commercial market with approximately 70% market share due to their higher energy density advantages. However, phosphate-based cathodes are gaining traction, growing at a faster rate of 22% annually compared to 15% for layered oxides, primarily due to their superior thermal stability and safety characteristics.

Regional analysis reveals distinct market preferences. Asian markets, particularly China, Japan, and South Korea, lead in layered oxide cathode production and implementation, controlling 78% of global manufacturing capacity. European markets show stronger preference for phosphate-based solutions, driven by stringent safety regulations and environmental considerations, with 45% of new battery installations featuring phosphate cathodes.

Market research indicates that cost remains a critical factor influencing adoption patterns. Phosphate cathodes currently offer a 15-20% cost advantage over layered oxide alternatives, though this gap is narrowing as manufacturing processes for layered oxides become more efficient. The total cost of ownership analysis favors phosphate cathodes in applications where longevity and safety are paramount, while layered oxides maintain advantage in applications requiring maximum energy density.

Industry forecasts suggest that the market for dual-ion batteries will reach $12 billion by 2028, with the distribution between layered oxide and phosphate cathodes largely dependent on technological advancements in addressing their respective limitations. Investments in research and development for both cathode types have increased by 35% in the past two years, indicating strong commercial interest in overcoming current performance barriers.

The electric vehicle (EV) industry remains the primary driver for advanced battery technologies, accounting for nearly 60% of the total market demand. Consumer electronics follows at 25%, while grid storage applications represent 15% of market share. Within these applications, the demand for batteries with superior energy density, longer cycle life, and enhanced safety profiles is creating specific market opportunities for dual-ion battery technologies.

Layered oxide cathodes currently dominate the commercial market with approximately 70% market share due to their higher energy density advantages. However, phosphate-based cathodes are gaining traction, growing at a faster rate of 22% annually compared to 15% for layered oxides, primarily due to their superior thermal stability and safety characteristics.

Regional analysis reveals distinct market preferences. Asian markets, particularly China, Japan, and South Korea, lead in layered oxide cathode production and implementation, controlling 78% of global manufacturing capacity. European markets show stronger preference for phosphate-based solutions, driven by stringent safety regulations and environmental considerations, with 45% of new battery installations featuring phosphate cathodes.

Market research indicates that cost remains a critical factor influencing adoption patterns. Phosphate cathodes currently offer a 15-20% cost advantage over layered oxide alternatives, though this gap is narrowing as manufacturing processes for layered oxides become more efficient. The total cost of ownership analysis favors phosphate cathodes in applications where longevity and safety are paramount, while layered oxides maintain advantage in applications requiring maximum energy density.

Industry forecasts suggest that the market for dual-ion batteries will reach $12 billion by 2028, with the distribution between layered oxide and phosphate cathodes largely dependent on technological advancements in addressing their respective limitations. Investments in research and development for both cathode types have increased by 35% in the past two years, indicating strong commercial interest in overcoming current performance barriers.

Current Status and Challenges in Cathode Materials

Dual-ion batteries (DIBs) represent a promising alternative to conventional lithium-ion batteries, with cathode materials playing a crucial role in their performance. Currently, two major cathode material families dominate DIB research: layered oxide and phosphate-based cathodes, each with distinct characteristics and challenges.

Layered oxide cathodes, primarily represented by LiCoO₂, LiNiO₂, and their derivatives (NMC, NCA), have achieved commercial success due to their high energy density and relatively simple synthesis processes. These materials typically deliver specific capacities of 150-220 mAh/g with operating voltages between 3.7-4.2V. However, they face significant challenges including structural instability during deep cycling, oxygen release at high voltages leading to safety concerns, and cobalt supply chain vulnerabilities due to geopolitical and ethical mining issues.

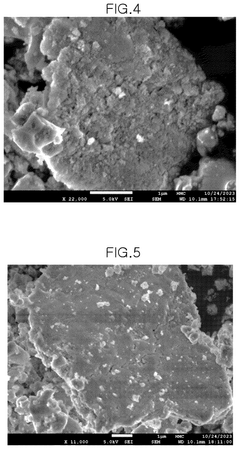

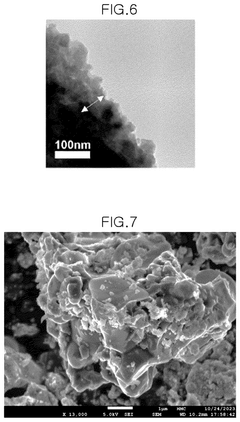

Phosphate-based cathodes, exemplified by LiFePO₄ (LFP) and related compounds, have gained attention for their exceptional thermal stability and longer cycle life. These materials operate at lower voltages (typically 3.2-3.5V) with moderate specific capacities around 150-170 mAh/g. Their olivine structure provides robust frameworks that resist structural degradation during cycling, but their inherently lower electronic conductivity necessitates carbon coating or nanostructuring to achieve practical performance.

Recent research has focused on addressing the limitations of both material classes. For layered oxides, efforts include surface coating technologies, concentration gradient structures, and dopant engineering to enhance structural stability. For phosphate materials, advanced synthesis methods to create hierarchical nanostructures and conductive networks have significantly improved rate capability and utilization efficiency.

A critical challenge for both cathode types in DIB applications is the intercalation/de-intercalation mechanism of larger ions (Na⁺, K⁺, Mg²⁺) compared to Li⁺, which introduces additional strain and diffusion barriers. Layered oxides generally offer larger interlayer spacing but suffer from greater volume changes, while phosphates provide more stable frameworks but with more constrained ion transport pathways.

Environmental and sustainability considerations are increasingly influencing cathode material development. Phosphate cathodes generally demonstrate lower environmental impact and better recyclability compared to cobalt-rich layered oxides. However, the energy-intensive processing required for phosphate materials partially offsets these advantages.

Manufacturing scalability presents different challenges for each material family. Layered oxides benefit from established large-scale production infrastructure but face increasing raw material costs. Phosphate cathodes require more specialized synthesis conditions to achieve optimal performance but utilize more abundant elements.

Layered oxide cathodes, primarily represented by LiCoO₂, LiNiO₂, and their derivatives (NMC, NCA), have achieved commercial success due to their high energy density and relatively simple synthesis processes. These materials typically deliver specific capacities of 150-220 mAh/g with operating voltages between 3.7-4.2V. However, they face significant challenges including structural instability during deep cycling, oxygen release at high voltages leading to safety concerns, and cobalt supply chain vulnerabilities due to geopolitical and ethical mining issues.

Phosphate-based cathodes, exemplified by LiFePO₄ (LFP) and related compounds, have gained attention for their exceptional thermal stability and longer cycle life. These materials operate at lower voltages (typically 3.2-3.5V) with moderate specific capacities around 150-170 mAh/g. Their olivine structure provides robust frameworks that resist structural degradation during cycling, but their inherently lower electronic conductivity necessitates carbon coating or nanostructuring to achieve practical performance.

Recent research has focused on addressing the limitations of both material classes. For layered oxides, efforts include surface coating technologies, concentration gradient structures, and dopant engineering to enhance structural stability. For phosphate materials, advanced synthesis methods to create hierarchical nanostructures and conductive networks have significantly improved rate capability and utilization efficiency.

A critical challenge for both cathode types in DIB applications is the intercalation/de-intercalation mechanism of larger ions (Na⁺, K⁺, Mg²⁺) compared to Li⁺, which introduces additional strain and diffusion barriers. Layered oxides generally offer larger interlayer spacing but suffer from greater volume changes, while phosphates provide more stable frameworks but with more constrained ion transport pathways.

Environmental and sustainability considerations are increasingly influencing cathode material development. Phosphate cathodes generally demonstrate lower environmental impact and better recyclability compared to cobalt-rich layered oxides. However, the energy-intensive processing required for phosphate materials partially offsets these advantages.

Manufacturing scalability presents different challenges for each material family. Layered oxides benefit from established large-scale production infrastructure but face increasing raw material costs. Phosphate cathodes require more specialized synthesis conditions to achieve optimal performance but utilize more abundant elements.

Comparative Analysis of Layered Oxide vs Phosphate Cathodes

01 Layered oxide cathode materials for dual-ion batteries

Layered oxide materials serve as effective cathode materials in dual-ion batteries due to their unique crystal structure that facilitates ion intercalation and deintercalation. These materials typically consist of transition metal oxides arranged in layers, providing channels for ion movement. The layered structure allows for high capacity and good cycling stability. Common examples include lithium-rich layered oxides and various transition metal oxides that can accommodate multiple ion species, making them particularly suitable for dual-ion battery systems.- Layered oxide cathode materials for dual-ion batteries: Layered oxide materials serve as effective cathodes in dual-ion batteries due to their unique crystal structure that facilitates ion intercalation and deintercalation. These materials typically contain transition metal oxides arranged in layers, allowing for efficient ion storage and transport. The layered structure provides stability during cycling and enables high energy density. Common examples include lithium-rich layered oxides and various transition metal oxides that demonstrate superior electrochemical performance compared to other cathode materials.

- Phosphate-based cathode materials for dual-ion batteries: Phosphate-based cathode materials offer distinct advantages in dual-ion batteries, particularly in terms of thermal stability and safety. These materials, including lithium iron phosphate (LiFePO4) and other metal phosphates, feature strong P-O bonds that create a stable framework for ion insertion and extraction. While they typically provide lower energy density compared to layered oxides, phosphate cathodes demonstrate excellent cycle life, better safety characteristics, and improved performance at high temperatures, making them suitable for applications where safety is paramount.

- Comparative performance of layered oxides versus phosphates: When comparing layered oxides to phosphates as cathode materials in dual-ion batteries, several performance differences emerge. Layered oxides generally provide higher energy density and voltage, resulting in greater specific capacity, while phosphates offer superior thermal stability, safety, and cycle life. Layered oxides typically demonstrate better rate capability but may suffer from structural degradation during extended cycling. Phosphates show excellent structural stability but lower electronic conductivity. The selection between these materials depends on specific application requirements, balancing energy density against safety and longevity considerations.

- Composite and modified cathode materials combining benefits: Innovative approaches to dual-ion battery cathodes involve creating composite or modified materials that combine the advantages of both layered oxides and phosphates. These hybrid materials aim to achieve enhanced performance through surface modifications, doping, or creating core-shell structures. By integrating the high energy density of layered oxides with the stability of phosphates, researchers have developed cathodes with improved cycling performance, rate capability, and thermal stability. These composite materials represent an important direction in optimizing dual-ion battery performance for various applications.

- Novel electrolyte systems for dual-ion batteries: Advanced electrolyte formulations play a crucial role in optimizing the performance of both layered oxide and phosphate cathodes in dual-ion batteries. Specialized electrolytes can mitigate the limitations of each cathode type, improving ionic conductivity, interfacial stability, and voltage windows. For layered oxides, electrolytes can be designed to prevent transition metal dissolution and structural degradation. With phosphate cathodes, electrolytes can enhance ionic transport and rate capability. Innovations include concentrated electrolytes, ionic liquids, and additives that form stable solid-electrolyte interphases, significantly improving the overall performance of dual-ion battery systems.

02 Phosphate-based cathode materials for dual-ion batteries

Phosphate-based materials, particularly lithium iron phosphate (LiFePO4) and other metal phosphates, offer advantages as cathode materials in dual-ion batteries. These materials provide excellent thermal stability, good safety characteristics, and consistent voltage profiles during cycling. The phosphate structure creates a robust framework that can withstand repeated ion insertion and extraction without significant structural degradation. While phosphate cathodes may offer lower energy density compared to some layered oxides, they compensate with superior cycle life and enhanced safety properties.Expand Specific Solutions03 Comparative performance of layered oxide vs phosphate cathodes

When comparing layered oxide and phosphate cathode materials in dual-ion batteries, several performance metrics show distinct differences. Layered oxides typically deliver higher specific capacity and energy density but may suffer from structural instability during extended cycling. Phosphate materials generally offer better cycling stability, thermal safety, and longer lifespan but with lower energy density. The choice between these materials involves trade-offs between energy density, power capability, cycle life, and safety considerations depending on the specific application requirements of the dual-ion battery system.Expand Specific Solutions04 Composite and modified cathode materials combining advantages of both structures

Innovative approaches to dual-ion battery cathodes include composite and modified materials that combine the advantages of both layered oxides and phosphates. These hybrid materials often feature surface modifications, doping strategies, or core-shell structures to enhance performance. By integrating the high capacity of layered oxides with the stability of phosphates, researchers have developed cathode materials with improved electrochemical properties. These composite approaches can mitigate the individual limitations of each material type while maximizing their respective strengths for dual-ion battery applications.Expand Specific Solutions05 Electrolyte compatibility with different cathode materials

The interaction between electrolytes and cathode materials significantly impacts dual-ion battery performance. Layered oxide cathodes often require specialized electrolyte formulations to prevent unwanted side reactions and structural degradation during cycling. Phosphate-based cathodes typically demonstrate better compatibility with conventional electrolytes due to their stable structure. Electrolyte selection must consider factors such as ion transport properties, electrochemical stability windows, and interfacial reactions specific to each cathode material type. Optimizing the electrolyte-cathode interface is crucial for maximizing the performance advantages of both layered oxide and phosphate materials in dual-ion battery systems.Expand Specific Solutions

Leading Companies and Research Institutions in DIB Field

Dual-ion batteries with layered oxide versus phosphate cathodes are emerging as a promising energy storage technology, currently in the early development stage. The market is projected to grow significantly as demand for sustainable energy solutions increases. Leading companies like LG Chem, SK ON, and Toyota are investing heavily in research, while specialized players such as Beijing Zhongke Haina Technology and Hefei Guoxuan High-Tech Power Energy are developing proprietary technologies. Academic institutions including Central South University and National University of Singapore are advancing fundamental research. The technology is approaching commercial viability, with companies like TDK and Shenzhen Zhenhua New Material transitioning from laboratory to production scale, though challenges in stability and energy density remain before widespread adoption.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive dual-ion battery technology that systematically compares layered oxide and phosphate cathodes. Their approach utilizes nickel-rich NCM (Nickel Cobalt Manganese) layered oxide cathodes with compositions like NCM811 and NCA for high energy density applications, while developing advanced LFP (Lithium Iron Phosphate) and LMFP (Lithium Manganese Iron Phosphate) cathodes for safety-critical applications. Their research demonstrates that layered oxide cathodes deliver up to 220 mAh/g specific capacity compared to phosphate cathodes' 160 mAh/g, but with different voltage profiles and thermal stability characteristics. LG Chem's dual-ion battery technology incorporates aluminum as the counter electrode material, enabling operation at higher voltages (up to 4.6V) than conventional lithium-ion batteries, with specialized electrolytes containing AlCl3 to facilitate aluminum ion intercalation.

Strengths: Superior energy density optimization across both cathode types; established manufacturing infrastructure; advanced electrolyte formulations for dual-ion systems. Weaknesses: Layered oxide options face thermal runaway risks at high states of charge; phosphate options still have lower energy density despite safety advantages.

SK ON CO LTD

Technical Solution: SK ON has pioneered a dual-ion battery technology platform that specifically addresses the comparative advantages of layered oxide versus phosphate cathode materials. Their research focuses on high-nickel layered oxides (Ni>90%) for maximum energy density applications and advanced phosphate-based materials for enhanced safety and longevity. SK ON's proprietary "Z-stacking" electrode architecture allows for optimized ion transport in both cathode types, with their layered oxide cathodes achieving energy densities of 700-800 Wh/L while their phosphate-based systems deliver 500-600 Wh/L with significantly improved cycle life. Their dual-ion battery systems incorporate graphite anodes that can intercalate both lithium and potassium ions, with specialized electrolyte systems containing dual-salt formulations to facilitate multi-ion transport. SK ON's comparative analysis demonstrates that while layered oxides offer 25-30% higher initial capacity, their phosphate cathodes retain over 90% capacity after 1000 cycles compared to 80% for layered oxides.

Strengths: Advanced manufacturing capabilities for both cathode types; proprietary electrode architectures that enhance ion transport; superior cycle life optimization. Weaknesses: Higher production costs for specialized dual-ion electrolytes; thermal management requirements for high-nickel layered oxide systems remain challenging.

Key Patents and Scientific Literature on DIB Cathode Materials

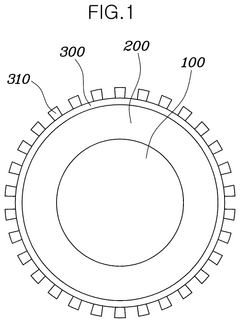

Cathode active material for lithium secondary battery and method of manufacturing same

PatentPendingUS20250266431A1

Innovation

- A cathode active material is developed with a first carbon coating layer to prevent metal element dissolution and a second carbon coating layer with lower carbon density and higher ionic conductivity, formed using a sol-gel method and heat treatment, incorporating organic materials and conductive materials like carbon black or CNTs.

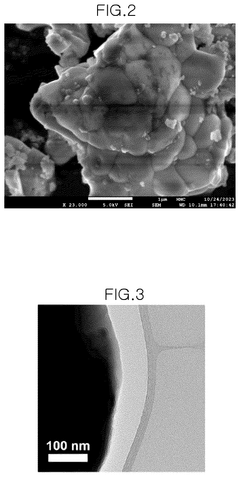

Cathode material and method for preparing the same, lithium ion battery

PatentPendingUS20240162425A1

Innovation

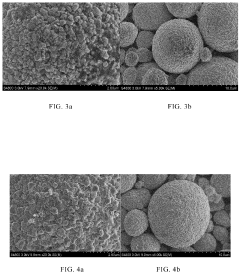

- A cathode material with a secondary particle composed of primary particles coated with a first and second phosphate compound layer, where the phosphate content is uniformly distributed to enhance structural stability, thermal stability, and rate performance, and a method involving sintering and solvent washing to achieve these coatings.

Environmental Impact and Sustainability Assessment

The environmental impact of dual-ion batteries (DIBs) varies significantly between layered oxide and phosphate cathode materials, with implications for sustainability across the entire battery lifecycle. Layered oxide cathodes, typically containing elements like cobalt, nickel, and manganese, present notable environmental challenges during extraction and processing. Mining these metals often results in habitat destruction, water pollution, and significant carbon emissions. Cobalt mining, particularly in regions like the Democratic Republic of Congo, raises additional ethical concerns regarding labor practices and human rights.

In contrast, phosphate-based cathodes, especially lithium iron phosphate (LiFP), demonstrate superior environmental credentials. The raw materials required for phosphate cathodes are generally more abundant, less toxic, and require less energy-intensive extraction processes. Life cycle assessment (LCA) studies indicate that phosphate cathode production generates approximately 30% lower greenhouse gas emissions compared to layered oxide alternatives, primarily due to reduced energy requirements during synthesis and less environmentally damaging mining operations.

Water usage represents another critical environmental factor. Manufacturing processes for layered oxide cathodes typically consume 25-40% more water than phosphate-based alternatives. Additionally, the risk of toxic leachate from improper disposal of layered oxide materials poses greater long-term environmental hazards compared to the relatively stable phosphate compounds.

From a recycling perspective, phosphate cathodes offer distinct advantages. Their more stable chemical structure facilitates safer and more efficient end-of-life processing. Current recycling technologies can recover up to 90% of materials from phosphate cathodes, compared to 70-80% for layered oxide variants. This higher recovery rate significantly reduces the need for virgin material extraction and associated environmental impacts.

Energy efficiency during operation also factors into the sustainability equation. While layered oxide cathodes typically offer higher energy density, phosphate cathodes demonstrate superior thermal stability and safety characteristics. This enhanced safety profile reduces the risk of catastrophic failures that could result in environmental contamination and resource waste.

Looking toward future sustainability, the development of DIBs with phosphate cathodes aligns more closely with circular economy principles. Their reduced reliance on critical raw materials, lower processing energy requirements, and enhanced recyclability position phosphate-based DIBs as the more environmentally responsible option for large-scale energy storage applications, particularly in grid storage systems where energy density constraints are less critical than safety and longevity.

In contrast, phosphate-based cathodes, especially lithium iron phosphate (LiFP), demonstrate superior environmental credentials. The raw materials required for phosphate cathodes are generally more abundant, less toxic, and require less energy-intensive extraction processes. Life cycle assessment (LCA) studies indicate that phosphate cathode production generates approximately 30% lower greenhouse gas emissions compared to layered oxide alternatives, primarily due to reduced energy requirements during synthesis and less environmentally damaging mining operations.

Water usage represents another critical environmental factor. Manufacturing processes for layered oxide cathodes typically consume 25-40% more water than phosphate-based alternatives. Additionally, the risk of toxic leachate from improper disposal of layered oxide materials poses greater long-term environmental hazards compared to the relatively stable phosphate compounds.

From a recycling perspective, phosphate cathodes offer distinct advantages. Their more stable chemical structure facilitates safer and more efficient end-of-life processing. Current recycling technologies can recover up to 90% of materials from phosphate cathodes, compared to 70-80% for layered oxide variants. This higher recovery rate significantly reduces the need for virgin material extraction and associated environmental impacts.

Energy efficiency during operation also factors into the sustainability equation. While layered oxide cathodes typically offer higher energy density, phosphate cathodes demonstrate superior thermal stability and safety characteristics. This enhanced safety profile reduces the risk of catastrophic failures that could result in environmental contamination and resource waste.

Looking toward future sustainability, the development of DIBs with phosphate cathodes aligns more closely with circular economy principles. Their reduced reliance on critical raw materials, lower processing energy requirements, and enhanced recyclability position phosphate-based DIBs as the more environmentally responsible option for large-scale energy storage applications, particularly in grid storage systems where energy density constraints are less critical than safety and longevity.

Cost-Performance Analysis of Competing Cathode Technologies

When evaluating dual-ion battery cathode materials, cost-performance analysis reveals significant differences between layered oxide and phosphate-based technologies. Layered oxide cathodes, such as LiCoO₂ (LCO), LiNiMnCoO₂ (NMC), and LiNiCoAlO₂ (NCA), generally offer higher energy density and voltage profiles, translating to superior performance metrics. However, this comes at a considerable cost premium, particularly for cobalt-containing compounds where raw material expenses can fluctuate dramatically due to supply chain vulnerabilities.

Phosphate cathodes, primarily represented by LiFePO₄ (LFP), demonstrate compelling cost advantages with iron being approximately 1/50th the cost of cobalt per kilogram. Manufacturing processes for phosphate cathodes typically require lower precision control and less stringent environmental conditions, further reducing production costs by an estimated 15-30% compared to layered oxide alternatives.

Lifecycle economic analysis indicates that while layered oxide cathodes provide initial performance advantages, phosphate cathodes often deliver superior total cost of ownership over extended use periods. LFP cathodes typically demonstrate cycling stability exceeding 2000 cycles at 80% capacity retention, compared to 500-1000 cycles for many layered oxide variants, effectively amortizing initial costs over longer operational lifespans.

Safety considerations also factor into the cost equation. Phosphate cathodes exhibit inherently higher thermal stability, reducing the complexity and cost of battery management systems. Insurance premiums and liability considerations increasingly favor phosphate technologies, particularly in large-scale energy storage applications where safety incidents carry significant financial implications.

Market analysis reveals regional variations in cathode technology adoption based on cost sensitivity. Asian markets, particularly China, have embraced phosphate cathodes more rapidly, while premium applications in North America and Europe have maintained stronger demand for layered oxide technologies. However, recent raw material price volatility has accelerated the shift toward phosphate cathodes even in traditionally premium segments.

Emerging manufacturing innovations are gradually narrowing the performance gap while maintaining the cost advantages of phosphate cathodes. Advanced doping techniques, nano-structuring, and carbon coating processes have improved the conductivity and rate capability of phosphate materials, addressing their traditional limitations while adding only marginal production costs.

Phosphate cathodes, primarily represented by LiFePO₄ (LFP), demonstrate compelling cost advantages with iron being approximately 1/50th the cost of cobalt per kilogram. Manufacturing processes for phosphate cathodes typically require lower precision control and less stringent environmental conditions, further reducing production costs by an estimated 15-30% compared to layered oxide alternatives.

Lifecycle economic analysis indicates that while layered oxide cathodes provide initial performance advantages, phosphate cathodes often deliver superior total cost of ownership over extended use periods. LFP cathodes typically demonstrate cycling stability exceeding 2000 cycles at 80% capacity retention, compared to 500-1000 cycles for many layered oxide variants, effectively amortizing initial costs over longer operational lifespans.

Safety considerations also factor into the cost equation. Phosphate cathodes exhibit inherently higher thermal stability, reducing the complexity and cost of battery management systems. Insurance premiums and liability considerations increasingly favor phosphate technologies, particularly in large-scale energy storage applications where safety incidents carry significant financial implications.

Market analysis reveals regional variations in cathode technology adoption based on cost sensitivity. Asian markets, particularly China, have embraced phosphate cathodes more rapidly, while premium applications in North America and Europe have maintained stronger demand for layered oxide technologies. However, recent raw material price volatility has accelerated the shift toward phosphate cathodes even in traditionally premium segments.

Emerging manufacturing innovations are gradually narrowing the performance gap while maintaining the cost advantages of phosphate cathodes. Advanced doping techniques, nano-structuring, and carbon coating processes have improved the conductivity and rate capability of phosphate materials, addressing their traditional limitations while adding only marginal production costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!