Research on Dual-ion batteries for large scale energy storage systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Background and Objectives

Dual-ion batteries (DIBs) have emerged as a promising alternative to conventional lithium-ion batteries for large-scale energy storage applications. The concept of DIBs was first introduced in the 1990s but gained significant research momentum only in the past decade due to increasing demands for sustainable and cost-effective energy storage solutions. Unlike traditional lithium-ion batteries that rely solely on cation intercalation, DIBs utilize both cation and anion intercalation mechanisms, offering unique advantages in terms of energy density, power capability, and resource utilization.

The evolution of DIB technology has been driven by the global transition toward renewable energy sources and the associated need for efficient grid-scale energy storage systems. Early DIB designs faced challenges related to electrolyte stability, electrode materials degradation, and limited cycle life. However, recent advancements in materials science and electrochemistry have led to significant improvements in these areas, positioning DIBs as a viable technology for large-scale applications.

Current research trends in DIB technology focus on developing high-performance electrode materials, stable electrolytes, and optimized cell designs. Graphite remains the predominant cathode material due to its excellent anion intercalation properties, while various carbon-based materials, metals, and alloys are being explored as potential anode materials. Concurrently, efforts are being made to develop electrolytes with wider electrochemical windows and enhanced ionic conductivity.

The primary technical objectives for DIB development include achieving higher energy densities (>200 Wh/kg), extended cycle life (>5000 cycles), improved rate capability, and enhanced safety characteristics. Additionally, there is a strong emphasis on reducing production costs and environmental impact by utilizing abundant and sustainable materials. These objectives align with the broader goals of creating economically viable and environmentally friendly energy storage solutions for grid stabilization, renewable energy integration, and peak shaving applications.

From a sustainability perspective, DIBs offer significant advantages over conventional lithium-ion batteries. They can potentially reduce dependence on critical materials such as cobalt and nickel, which face supply constraints and ethical sourcing challenges. Furthermore, the simpler cell chemistry and structure of DIBs may facilitate easier recycling and end-of-life management, contributing to a more circular economy approach in battery technology.

The technological trajectory of DIBs indicates a promising future for large-scale energy storage applications, particularly as research continues to address current limitations and optimize performance parameters. With continued investment and innovation, DIBs could play a crucial role in enabling the widespread adoption of renewable energy sources and supporting the global transition to a low-carbon energy system.

The evolution of DIB technology has been driven by the global transition toward renewable energy sources and the associated need for efficient grid-scale energy storage systems. Early DIB designs faced challenges related to electrolyte stability, electrode materials degradation, and limited cycle life. However, recent advancements in materials science and electrochemistry have led to significant improvements in these areas, positioning DIBs as a viable technology for large-scale applications.

Current research trends in DIB technology focus on developing high-performance electrode materials, stable electrolytes, and optimized cell designs. Graphite remains the predominant cathode material due to its excellent anion intercalation properties, while various carbon-based materials, metals, and alloys are being explored as potential anode materials. Concurrently, efforts are being made to develop electrolytes with wider electrochemical windows and enhanced ionic conductivity.

The primary technical objectives for DIB development include achieving higher energy densities (>200 Wh/kg), extended cycle life (>5000 cycles), improved rate capability, and enhanced safety characteristics. Additionally, there is a strong emphasis on reducing production costs and environmental impact by utilizing abundant and sustainable materials. These objectives align with the broader goals of creating economically viable and environmentally friendly energy storage solutions for grid stabilization, renewable energy integration, and peak shaving applications.

From a sustainability perspective, DIBs offer significant advantages over conventional lithium-ion batteries. They can potentially reduce dependence on critical materials such as cobalt and nickel, which face supply constraints and ethical sourcing challenges. Furthermore, the simpler cell chemistry and structure of DIBs may facilitate easier recycling and end-of-life management, contributing to a more circular economy approach in battery technology.

The technological trajectory of DIBs indicates a promising future for large-scale energy storage applications, particularly as research continues to address current limitations and optimize performance parameters. With continued investment and innovation, DIBs could play a crucial role in enabling the widespread adoption of renewable energy sources and supporting the global transition to a low-carbon energy system.

Market Analysis for Grid-Scale Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. As of 2023, the grid-scale energy storage market is valued at approximately $7.9 billion and is projected to reach $31.2 billion by 2030, representing a compound annual growth rate of 21.6%. This remarkable expansion is primarily fueled by the urgent need to balance intermittent renewable energy generation and ensure grid stability.

Dual-ion batteries (DIBs) are emerging as a promising contender in the large-scale energy storage landscape, competing with established technologies such as lithium-ion batteries, flow batteries, and pumped hydro storage. The market demand for DIBs is particularly strong in regions with aggressive renewable energy targets, including Europe, North America, and parts of Asia-Pacific, where grid infrastructure requires significant modernization to accommodate variable energy sources.

The commercial appeal of DIBs stems from their potential cost advantages, with raw materials typically 30-40% less expensive than traditional lithium-ion batteries. Additionally, their theoretical energy density of 150-200 Wh/kg positions them competitively for grid applications where space constraints are less critical than in portable electronics or electric vehicles.

Market segmentation reveals that utility-scale applications currently dominate the demand landscape, accounting for approximately 65% of potential DIB deployments. Commercial and industrial applications represent roughly 25%, with the remaining 10% distributed across specialized applications such as microgrids and remote power systems.

Customer requirements in the grid-scale storage sector emphasize cycle life, safety, and levelized cost of storage (LCOS). DIBs show promise in meeting these requirements, with early prototypes demonstrating cycle lives exceeding 4,000 cycles and favorable safety profiles due to their non-flammable electrolyte options.

Regulatory factors significantly influence market adoption, with policies such as investment tax credits, capacity market reforms, and renewable portfolio standards creating favorable conditions for energy storage deployment. Countries with carbon reduction commitments are increasingly implementing supportive regulatory frameworks, with the European Union's Green Deal and the United States' Inflation Reduction Act providing substantial incentives for grid-scale storage solutions.

Market barriers for DIB technology include the entrenched position of lithium-ion batteries, which benefit from manufacturing scale and established supply chains. Additionally, limited field demonstration data for DIBs creates perceived technology risk among conservative utility customers, who typically require extensive validation before adopting new technologies.

The economic value proposition of DIBs hinges on achieving a levelized cost of storage below $150/kWh, which would position them favorably against competing technologies for long-duration applications (4+ hours). Current projections suggest this threshold could be reached within 3-5 years as manufacturing processes mature and economies of scale are realized.

Dual-ion batteries (DIBs) are emerging as a promising contender in the large-scale energy storage landscape, competing with established technologies such as lithium-ion batteries, flow batteries, and pumped hydro storage. The market demand for DIBs is particularly strong in regions with aggressive renewable energy targets, including Europe, North America, and parts of Asia-Pacific, where grid infrastructure requires significant modernization to accommodate variable energy sources.

The commercial appeal of DIBs stems from their potential cost advantages, with raw materials typically 30-40% less expensive than traditional lithium-ion batteries. Additionally, their theoretical energy density of 150-200 Wh/kg positions them competitively for grid applications where space constraints are less critical than in portable electronics or electric vehicles.

Market segmentation reveals that utility-scale applications currently dominate the demand landscape, accounting for approximately 65% of potential DIB deployments. Commercial and industrial applications represent roughly 25%, with the remaining 10% distributed across specialized applications such as microgrids and remote power systems.

Customer requirements in the grid-scale storage sector emphasize cycle life, safety, and levelized cost of storage (LCOS). DIBs show promise in meeting these requirements, with early prototypes demonstrating cycle lives exceeding 4,000 cycles and favorable safety profiles due to their non-flammable electrolyte options.

Regulatory factors significantly influence market adoption, with policies such as investment tax credits, capacity market reforms, and renewable portfolio standards creating favorable conditions for energy storage deployment. Countries with carbon reduction commitments are increasingly implementing supportive regulatory frameworks, with the European Union's Green Deal and the United States' Inflation Reduction Act providing substantial incentives for grid-scale storage solutions.

Market barriers for DIB technology include the entrenched position of lithium-ion batteries, which benefit from manufacturing scale and established supply chains. Additionally, limited field demonstration data for DIBs creates perceived technology risk among conservative utility customers, who typically require extensive validation before adopting new technologies.

The economic value proposition of DIBs hinges on achieving a levelized cost of storage below $150/kWh, which would position them favorably against competing technologies for long-duration applications (4+ hours). Current projections suggest this threshold could be reached within 3-5 years as manufacturing processes mature and economies of scale are realized.

Current Status and Technical Challenges of Dual-ion Batteries

Dual-ion batteries (DIBs) have emerged as a promising alternative to conventional lithium-ion batteries for large-scale energy storage applications. Currently, DIBs are in the early commercialization stage with several pilot projects demonstrating their feasibility. The technology has gained significant attention due to its potential cost advantages, as it utilizes abundant materials like graphite for both electrodes, eliminating the need for expensive transition metals found in conventional batteries.

Research institutions across Asia, particularly in China and Japan, lead the development of DIB technology, with growing interest from European research centers. Companies like CATL, BYD, and several startups have invested in DIB research programs, though commercial deployment remains limited. The current energy density of DIBs ranges from 70-120 Wh/kg, which is lower than commercial lithium-ion batteries but potentially sufficient for stationary storage applications.

Despite promising developments, DIBs face several critical technical challenges. The primary issue is the limited cycle life, typically 500-1000 cycles, which falls short of the 3000+ cycles required for grid-scale applications. This limitation stems from the degradation of electrolytes during repeated anion intercalation/de-intercalation processes and structural changes in the graphite cathode during cycling.

Another significant challenge is the high operating voltage (often exceeding 4.5V), which accelerates electrolyte decomposition and reduces long-term stability. Current electrolyte formulations struggle to maintain stability at these high voltages, leading to capacity fading and safety concerns. The development of advanced electrolytes with wider electrochemical windows remains a critical research focus.

The low ionic conductivity of anions compared to lithium ions results in lower power density, limiting the rate capability of DIBs. This characteristic restricts their application in scenarios requiring rapid charge/discharge cycles. Additionally, the volume expansion during anion intercalation into graphite cathodes can reach 100-200%, causing mechanical stress and structural degradation over multiple cycles.

Temperature sensitivity presents another obstacle, as DIB performance deteriorates significantly at temperatures below 0°C or above 45°C, limiting deployment in regions with extreme climates. The self-discharge rate of current DIB prototypes is also higher than conventional lithium-ion batteries, reducing their efficiency for long-term energy storage.

Scaling up production while maintaining consistent performance represents a manufacturing challenge, as does the development of reliable battery management systems specifically optimized for DIB characteristics. These technical hurdles must be addressed before DIBs can achieve widespread adoption in grid-scale energy storage systems.

Research institutions across Asia, particularly in China and Japan, lead the development of DIB technology, with growing interest from European research centers. Companies like CATL, BYD, and several startups have invested in DIB research programs, though commercial deployment remains limited. The current energy density of DIBs ranges from 70-120 Wh/kg, which is lower than commercial lithium-ion batteries but potentially sufficient for stationary storage applications.

Despite promising developments, DIBs face several critical technical challenges. The primary issue is the limited cycle life, typically 500-1000 cycles, which falls short of the 3000+ cycles required for grid-scale applications. This limitation stems from the degradation of electrolytes during repeated anion intercalation/de-intercalation processes and structural changes in the graphite cathode during cycling.

Another significant challenge is the high operating voltage (often exceeding 4.5V), which accelerates electrolyte decomposition and reduces long-term stability. Current electrolyte formulations struggle to maintain stability at these high voltages, leading to capacity fading and safety concerns. The development of advanced electrolytes with wider electrochemical windows remains a critical research focus.

The low ionic conductivity of anions compared to lithium ions results in lower power density, limiting the rate capability of DIBs. This characteristic restricts their application in scenarios requiring rapid charge/discharge cycles. Additionally, the volume expansion during anion intercalation into graphite cathodes can reach 100-200%, causing mechanical stress and structural degradation over multiple cycles.

Temperature sensitivity presents another obstacle, as DIB performance deteriorates significantly at temperatures below 0°C or above 45°C, limiting deployment in regions with extreme climates. The self-discharge rate of current DIB prototypes is also higher than conventional lithium-ion batteries, reducing their efficiency for long-term energy storage.

Scaling up production while maintaining consistent performance represents a manufacturing challenge, as does the development of reliable battery management systems specifically optimized for DIB characteristics. These technical hurdles must be addressed before DIBs can achieve widespread adoption in grid-scale energy storage systems.

Current Technical Solutions for Large-Scale DIB Implementation

01 Electrode materials for dual-ion batteries

Various electrode materials can be used in dual-ion batteries to enhance performance. These include carbon-based materials, metal oxides, and composite materials that can intercalate both cations and anions. The selection of appropriate electrode materials is crucial for improving energy density, cycling stability, and rate capability of dual-ion batteries.- Electrode materials for dual-ion batteries: Various electrode materials can be used in dual-ion batteries to enhance performance. These include carbon-based materials, metal oxides, and composite materials that can intercalate both cations and anions. The selection of appropriate electrode materials is crucial for improving energy density, cycling stability, and rate capability of dual-ion batteries.

- Electrolyte compositions for dual-ion batteries: Specialized electrolyte formulations are essential for dual-ion batteries, as they must facilitate the transport of both cations and anions. These electrolytes typically contain specific salts dissolved in organic solvents or ionic liquids. The composition of the electrolyte significantly affects the battery's performance, including its voltage window, cycling stability, and ionic conductivity.

- Battery management systems for dual-ion batteries: Battery management systems designed specifically for dual-ion batteries help optimize performance and ensure safety. These systems monitor and control parameters such as voltage, current, and temperature during charging and discharging cycles. Advanced management systems may incorporate algorithms to predict battery behavior and prevent degradation mechanisms specific to dual-ion chemistry.

- Structural designs for dual-ion batteries: Innovative structural designs for dual-ion batteries focus on optimizing the arrangement of electrodes, separators, and current collectors. These designs aim to maximize ion transport efficiency while minimizing internal resistance. Various cell configurations, including pouch, prismatic, and cylindrical formats, have been adapted for dual-ion battery technology to suit different applications.

- Applications and integration of dual-ion batteries: Dual-ion batteries are being developed for various applications including portable electronics, electric vehicles, and grid-scale energy storage. Their integration into these systems requires consideration of their unique characteristics such as voltage profiles, energy density, and cycling behavior. Specialized interfaces and control systems have been designed to effectively incorporate dual-ion batteries into existing energy infrastructure.

02 Electrolyte compositions for dual-ion batteries

Specialized electrolyte formulations are essential for dual-ion batteries, as they must facilitate the movement of both cations and anions. These electrolytes typically contain specific salts dissolved in organic solvents or ionic liquids. The composition of the electrolyte significantly affects the battery's performance, including its voltage window, cycling stability, and ionic conductivity.Expand Specific Solutions03 Battery management systems for dual-ion batteries

Battery management systems specifically designed for dual-ion batteries help optimize performance and ensure safety. These systems monitor and control parameters such as voltage, current, temperature, and state of charge. Advanced management systems may incorporate algorithms that account for the unique characteristics of dual-ion batteries, including their different charge/discharge mechanisms compared to conventional lithium-ion batteries.Expand Specific Solutions04 Structural designs for dual-ion batteries

Innovative structural designs for dual-ion batteries focus on optimizing the arrangement of electrodes, separators, and current collectors. These designs aim to maximize energy density, improve ion transport, and enhance mechanical stability. Some approaches include layered structures, 3D architectures, and flexible configurations that can accommodate the volume changes during cycling.Expand Specific Solutions05 Manufacturing processes for dual-ion batteries

Specialized manufacturing techniques are developed for dual-ion batteries to ensure consistent quality and performance. These processes include methods for electrode preparation, electrolyte filling, cell assembly, and sealing. Advanced manufacturing approaches focus on scalability, cost-effectiveness, and environmental sustainability, which are crucial for the commercial viability of dual-ion battery technology.Expand Specific Solutions

Key Industry Players and Research Institutions

Dual-ion batteries (DIBs) for large-scale energy storage systems are emerging as a promising technology in the early commercialization phase. The market is projected to grow significantly due to increasing demand for sustainable energy storage solutions, with an estimated CAGR of 15-20% over the next decade. Technologically, DIBs are advancing rapidly with key players demonstrating varied maturity levels. Companies like Contemporary Amperex Technology (CATL) and LG Energy Solution are leading commercial development, while research institutions such as California Institute of Technology and Chinese Academy of Sciences are driving fundamental innovations. Asahi Kasei, Toshiba, and NEC are advancing materials technology, while startups like Hong Kong Times New Energy and Beijing Zhongke Haina are introducing novel DIB designs. The competitive landscape reflects a mix of established battery manufacturers, materials companies, and specialized research entities working to overcome challenges in cycle life, energy density, and cost reduction.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei Corporation has developed an advanced dual-ion battery technology specifically engineered for large-scale energy storage applications. Their proprietary system utilizes a highly crystalline graphite cathode and a metallic sodium anode separated by a specially formulated electrolyte containing sodium bis(fluorosulfonyl)imide (NaFSI) in a mixture of carbonate solvents. This configuration delivers operating voltages of 4.0-4.5V with energy densities of approximately 120-140 Wh/kg. Asahi Kasei's innovation includes a proprietary binder system for the graphite cathode that maintains structural integrity during repeated anion intercalation/deintercalation cycles. Their cells incorporate a ceramic-reinforced separator with enhanced thermal stability and mechanical strength, significantly improving safety characteristics for grid-scale deployments. The company has demonstrated prototype systems with exceptional cycling performance, maintaining over 85% capacity after 4000 cycles at moderate rates. Their battery management system features advanced algorithms specifically calibrated for the unique voltage profiles and thermal characteristics of dual-ion chemistry, enabling precise state-of-health monitoring and predictive maintenance capabilities for utility-scale installations.

Strengths: Excellent thermal stability enhancing safety profile; high voltage operation increasing energy density; abundant raw materials reducing supply chain risks. Weaknesses: Lower energy density compared to some competing technologies; electrolyte degradation at elevated temperatures; requires sophisticated manufacturing processes to ensure consistent performance.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed an innovative dual-ion battery technology for large-scale energy storage that addresses key limitations of conventional systems. Their approach features a graphite cathode coupled with an aluminum anode in a chloroaluminate ionic liquid electrolyte system. The technology achieves energy densities of 70-90 Wh/kg with power densities reaching 1000 W/kg. Argonne's breakthrough involves a novel electrolyte additive package that forms a stable passivation layer on the aluminum electrode, dramatically reducing parasitic reactions and improving coulombic efficiency to >99%. Their research has demonstrated cells with exceptional cycling stability, maintaining 85% capacity after 3000 cycles at 1C rates. The laboratory has also pioneered advanced in-situ characterization techniques to understand intercalation mechanisms, enabling precise control of the electrode microstructure. This has led to optimized ion transport pathways and reduced diffusion limitations. Argonne's pouch cell prototypes have demonstrated scalability potential with minimal capacity fade under accelerated testing conditions simulating grid storage applications.

Strengths: Utilizes earth-abundant materials reducing resource constraints; excellent thermal stability enhancing safety profile; low self-discharge rates ideal for long-duration storage. Weaknesses: Lower energy density compared to lithium-ion systems; electrolyte complexity increases manufacturing challenges; rate capability limitations at low temperatures.

Core Patents and Innovations in Dual-ion Battery Technology

dual ion battery

PatentActiveJPWO2020110230A1

Innovation

- The use of aluminum current collectors coated with an amorphous carbon film, optionally with a conductive carbon layer, to prevent corrosion and enhance high-temperature durability.

Dual-ion battery performance

PatentPendingUS20240006664A1

Innovation

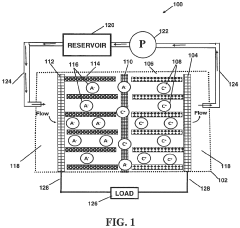

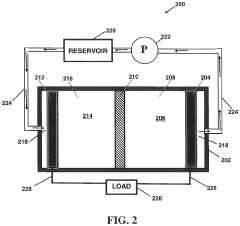

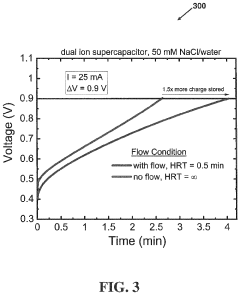

- Implementing an external electrolyte reservoir with forced convection to reduce diffusion limitations and allow for optimal conductivity, enabling the use of minimally thick separators and minimizing volume changes, thereby enhancing ion participation in energy storage.

Environmental Impact and Sustainability Assessment

Dual-ion batteries (DIBs) represent a promising technology for large-scale energy storage systems, but their environmental impact and sustainability aspects require thorough assessment. The life cycle analysis of DIBs reveals significant advantages compared to conventional lithium-ion batteries, particularly in terms of resource utilization and carbon footprint. The aluminum-based cathodes and graphite-based anodes commonly used in DIBs utilize more abundant materials, reducing dependency on critical raw materials like cobalt and nickel that face supply constraints and ethical mining concerns.

Manufacturing processes for DIBs generally require less energy input than traditional lithium-ion batteries, resulting in lower greenhouse gas emissions during production. Estimates suggest a potential reduction of 15-30% in manufacturing-related carbon emissions compared to conventional battery technologies. Additionally, the simpler cell structure of DIBs contributes to more streamlined production processes with fewer toxic chemicals involved.

The operational phase of DIBs demonstrates favorable environmental characteristics, including minimal risk of thermal runaway and reduced toxicity concerns. This translates to enhanced safety profiles and decreased environmental hazards during deployment in large-scale energy storage applications. The absence of cobalt in most DIB formulations eliminates associated environmental contamination risks that plague certain lithium-ion battery chemistries.

End-of-life management presents both challenges and opportunities for DIB sustainability. Current recycling infrastructure requires adaptation to efficiently process DIB components, but the relatively simple chemistry facilitates material recovery. Research indicates potential recovery rates of over 90% for aluminum and graphite components, significantly higher than recovery rates for conventional battery technologies. This circular economy potential represents a major sustainability advantage for large-scale implementation.

Water usage and land impact assessments reveal that DIB production generally requires less water than conventional battery manufacturing. Land disturbance for raw material extraction is also reduced due to the abundance of aluminum and carbon-based materials. However, electrolyte components still present environmental challenges that require ongoing research to develop more benign alternatives.

Policy implications for DIB deployment include the need for updated regulatory frameworks that recognize their distinct environmental profile compared to traditional battery technologies. Environmental certifications and standards specific to dual-ion battery systems would facilitate market adoption while ensuring appropriate safeguards. The development of specialized recycling protocols and infrastructure would further enhance the sustainability credentials of this emerging technology for grid-scale energy storage applications.

Manufacturing processes for DIBs generally require less energy input than traditional lithium-ion batteries, resulting in lower greenhouse gas emissions during production. Estimates suggest a potential reduction of 15-30% in manufacturing-related carbon emissions compared to conventional battery technologies. Additionally, the simpler cell structure of DIBs contributes to more streamlined production processes with fewer toxic chemicals involved.

The operational phase of DIBs demonstrates favorable environmental characteristics, including minimal risk of thermal runaway and reduced toxicity concerns. This translates to enhanced safety profiles and decreased environmental hazards during deployment in large-scale energy storage applications. The absence of cobalt in most DIB formulations eliminates associated environmental contamination risks that plague certain lithium-ion battery chemistries.

End-of-life management presents both challenges and opportunities for DIB sustainability. Current recycling infrastructure requires adaptation to efficiently process DIB components, but the relatively simple chemistry facilitates material recovery. Research indicates potential recovery rates of over 90% for aluminum and graphite components, significantly higher than recovery rates for conventional battery technologies. This circular economy potential represents a major sustainability advantage for large-scale implementation.

Water usage and land impact assessments reveal that DIB production generally requires less water than conventional battery manufacturing. Land disturbance for raw material extraction is also reduced due to the abundance of aluminum and carbon-based materials. However, electrolyte components still present environmental challenges that require ongoing research to develop more benign alternatives.

Policy implications for DIB deployment include the need for updated regulatory frameworks that recognize their distinct environmental profile compared to traditional battery technologies. Environmental certifications and standards specific to dual-ion battery systems would facilitate market adoption while ensuring appropriate safeguards. The development of specialized recycling protocols and infrastructure would further enhance the sustainability credentials of this emerging technology for grid-scale energy storage applications.

Cost Analysis and Economic Viability

The economic viability of dual-ion batteries (DIBs) for large-scale energy storage systems hinges on several cost factors that must be carefully analyzed. Current cost estimates place DIBs at approximately $150-200/kWh, positioning them competitively against lithium-ion batteries which typically range from $200-300/kWh for grid-scale applications. This cost advantage stems primarily from DIBs' utilization of abundant, low-cost materials such as aluminum, graphite, and conventional salt-based electrolytes, eliminating the need for expensive transition metals like cobalt and nickel.

Material costs constitute approximately 40-50% of total DIB production expenses, with electrolytes representing the most significant component at 15-20% of overall costs. The aluminum cathode material offers substantial cost benefits, being approximately 60% less expensive than traditional lithium-ion cathode materials on a per-weight basis. Additionally, the simplified manufacturing process for DIBs requires fewer production steps and less stringent clean room conditions, reducing capital expenditure by an estimated 25-30% compared to conventional lithium-ion battery production facilities.

Lifecycle economic analysis reveals promising metrics for DIBs in grid storage applications. With projected lifespans of 3,000-5,000 cycles at 80% depth of discharge, the levelized cost of storage (LCOS) for DIBs is estimated at $0.10-0.15/kWh, comparing favorably to lithium-ion's $0.15-0.20/kWh. This calculation incorporates installation, operation, maintenance, and end-of-life management costs over a 10-15 year operational period.

Scaling economics present both opportunities and challenges. While material supply chains for DIBs face fewer constraints than lithium-ion batteries, manufacturing scale remains limited. Current global production capacity is under 1 GWh annually, requiring significant investment to achieve the economies of scale necessary for widespread adoption. Industry analysts project that reaching 10 GWh annual production capacity would drive costs below $120/kWh, potentially approaching $100/kWh by 2030 with continued technological improvements.

Market entry barriers include high initial capital requirements for manufacturing facilities, estimated at $50-70 million for a 500 MWh annual production capacity plant. However, return on investment calculations suggest payback periods of 5-7 years for such facilities, assuming stable market demand and pricing. Government incentives for clean energy storage solutions could significantly improve these economics, with potential subsidies reducing payback periods to 3-5 years in supportive regulatory environments.

Material costs constitute approximately 40-50% of total DIB production expenses, with electrolytes representing the most significant component at 15-20% of overall costs. The aluminum cathode material offers substantial cost benefits, being approximately 60% less expensive than traditional lithium-ion cathode materials on a per-weight basis. Additionally, the simplified manufacturing process for DIBs requires fewer production steps and less stringent clean room conditions, reducing capital expenditure by an estimated 25-30% compared to conventional lithium-ion battery production facilities.

Lifecycle economic analysis reveals promising metrics for DIBs in grid storage applications. With projected lifespans of 3,000-5,000 cycles at 80% depth of discharge, the levelized cost of storage (LCOS) for DIBs is estimated at $0.10-0.15/kWh, comparing favorably to lithium-ion's $0.15-0.20/kWh. This calculation incorporates installation, operation, maintenance, and end-of-life management costs over a 10-15 year operational period.

Scaling economics present both opportunities and challenges. While material supply chains for DIBs face fewer constraints than lithium-ion batteries, manufacturing scale remains limited. Current global production capacity is under 1 GWh annually, requiring significant investment to achieve the economies of scale necessary for widespread adoption. Industry analysts project that reaching 10 GWh annual production capacity would drive costs below $120/kWh, potentially approaching $100/kWh by 2030 with continued technological improvements.

Market entry barriers include high initial capital requirements for manufacturing facilities, estimated at $50-70 million for a 500 MWh annual production capacity plant. However, return on investment calculations suggest payback periods of 5-7 years for such facilities, assuming stable market demand and pricing. Government incentives for clean energy storage solutions could significantly improve these economics, with potential subsidies reducing payback periods to 3-5 years in supportive regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!