Research on Dual-ion batteries for thermal management and high temperature applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Background and Objectives

Dual-ion batteries (DIBs) have emerged as a promising energy storage technology over the past decade, evolving from conventional lithium-ion battery systems. Unlike traditional batteries that rely solely on cation intercalation, DIBs operate on the principle of simultaneous anion and cation intercalation into different electrode materials during charge-discharge cycles. This unique mechanism offers several inherent advantages, particularly for thermal management and high-temperature applications.

The development of DIBs can be traced back to the early 2000s, but significant advancements have occurred in the last five years with the introduction of novel electrode materials and electrolyte systems. The technology has progressed from laboratory-scale demonstrations to small prototype cells, with increasing interest from both academic institutions and industrial players seeking alternatives to conventional lithium-ion batteries.

Current technological trends in DIB development focus on enhancing thermal stability, improving energy density, and extending cycle life at elevated temperatures. The inherent separation of anion and cation intercalation processes contributes to reduced heat generation during operation, making DIBs particularly suitable for applications requiring robust thermal management. Recent research has demonstrated stable operation at temperatures exceeding 80°C, significantly outperforming conventional lithium-ion systems.

The primary technical objectives for DIB advancement in thermal management applications include developing electrode materials with high thermal stability, electrolyte systems resistant to decomposition at elevated temperatures, and cell designs that facilitate efficient heat dissipation. Specifically, researchers aim to achieve stable cycling at temperatures up to 100-120°C while maintaining capacity retention above 80% after 1000 cycles.

For high-temperature applications, DIBs target sectors where conventional batteries face limitations, including industrial equipment in harsh environments, deep geothermal exploration, and certain aerospace applications. The technology aims to fill a critical gap in the energy storage landscape by providing reliable power sources for environments where thermal management is challenging.

The evolution of DIB technology aligns with broader industry trends toward safer, more thermally stable energy storage solutions. As electrification continues across multiple sectors, the demand for batteries capable of operating reliably in extreme conditions continues to grow, positioning DIBs as a strategically important technology for future energy systems.

Research objectives in this field now extend beyond basic performance metrics to include sustainability considerations, manufacturing scalability, and integration with thermal management systems in end applications. The convergence of these research directions aims to establish DIBs as a commercially viable technology for specialized high-temperature applications within the next 3-5 years.

The development of DIBs can be traced back to the early 2000s, but significant advancements have occurred in the last five years with the introduction of novel electrode materials and electrolyte systems. The technology has progressed from laboratory-scale demonstrations to small prototype cells, with increasing interest from both academic institutions and industrial players seeking alternatives to conventional lithium-ion batteries.

Current technological trends in DIB development focus on enhancing thermal stability, improving energy density, and extending cycle life at elevated temperatures. The inherent separation of anion and cation intercalation processes contributes to reduced heat generation during operation, making DIBs particularly suitable for applications requiring robust thermal management. Recent research has demonstrated stable operation at temperatures exceeding 80°C, significantly outperforming conventional lithium-ion systems.

The primary technical objectives for DIB advancement in thermal management applications include developing electrode materials with high thermal stability, electrolyte systems resistant to decomposition at elevated temperatures, and cell designs that facilitate efficient heat dissipation. Specifically, researchers aim to achieve stable cycling at temperatures up to 100-120°C while maintaining capacity retention above 80% after 1000 cycles.

For high-temperature applications, DIBs target sectors where conventional batteries face limitations, including industrial equipment in harsh environments, deep geothermal exploration, and certain aerospace applications. The technology aims to fill a critical gap in the energy storage landscape by providing reliable power sources for environments where thermal management is challenging.

The evolution of DIB technology aligns with broader industry trends toward safer, more thermally stable energy storage solutions. As electrification continues across multiple sectors, the demand for batteries capable of operating reliably in extreme conditions continues to grow, positioning DIBs as a strategically important technology for future energy systems.

Research objectives in this field now extend beyond basic performance metrics to include sustainability considerations, manufacturing scalability, and integration with thermal management systems in end applications. The convergence of these research directions aims to establish DIBs as a commercially viable technology for specialized high-temperature applications within the next 3-5 years.

Market Analysis for High-Temperature Energy Storage Solutions

The high-temperature energy storage market is experiencing significant growth driven by increasing demands across multiple sectors. Currently valued at approximately $4.2 billion, this specialized segment is projected to reach $7.5 billion by 2028, representing a compound annual growth rate of 12.3%. This growth trajectory is primarily fueled by expanding applications in industrial processes, renewable energy integration, and electric vehicle thermal management systems.

Industrial sectors, particularly steel manufacturing, glass production, and cement processing, constitute the largest market share at 42%. These industries require energy storage solutions capable of operating efficiently at temperatures exceeding 400°C, creating substantial demand for advanced thermal management technologies like dual-ion batteries with enhanced temperature tolerance.

The renewable energy sector represents the fastest-growing segment with 18% annual growth. As solar and wind installations increase globally, the need for high-temperature energy storage solutions becomes critical for grid stability and energy time-shifting. Dual-ion batteries offer promising capabilities for these applications due to their thermal stability advantages over conventional lithium-ion technologies.

Geographically, Asia-Pacific dominates the market with 38% share, led by China's aggressive industrial decarbonization initiatives and Japan's technological advancements in battery chemistry. North America follows at 29%, with significant investments in grid-scale storage projects, while Europe accounts for 24% of the market, driven by stringent carbon reduction policies and renewable energy integration requirements.

Customer requirements in this market segment emphasize several key performance indicators: operational temperature range (typically 150-500°C), cycle stability at elevated temperatures (minimum 1000 cycles), energy density (target >150 Wh/kg at high temperatures), and cost-effectiveness compared to conventional cooling systems. Dual-ion batteries show particular promise in meeting these requirements through innovative electrode materials and electrolyte formulations.

Market barriers include high initial investment costs, with high-temperature energy storage systems typically commanding a 30-40% premium over conventional alternatives. Technical challenges related to material degradation at elevated temperatures and safety concerns also limit widespread adoption. However, recent advancements in ceramic separators and thermally stable electrolytes are gradually addressing these limitations.

The competitive landscape features established players like Siemens Energy and Sumitomo Electric Industries alongside emerging specialists such as ESS Tech and Form Energy, all pursuing various technological approaches to high-temperature energy storage, with dual-ion battery technology representing a promising but still developing segment within this diverse market.

Industrial sectors, particularly steel manufacturing, glass production, and cement processing, constitute the largest market share at 42%. These industries require energy storage solutions capable of operating efficiently at temperatures exceeding 400°C, creating substantial demand for advanced thermal management technologies like dual-ion batteries with enhanced temperature tolerance.

The renewable energy sector represents the fastest-growing segment with 18% annual growth. As solar and wind installations increase globally, the need for high-temperature energy storage solutions becomes critical for grid stability and energy time-shifting. Dual-ion batteries offer promising capabilities for these applications due to their thermal stability advantages over conventional lithium-ion technologies.

Geographically, Asia-Pacific dominates the market with 38% share, led by China's aggressive industrial decarbonization initiatives and Japan's technological advancements in battery chemistry. North America follows at 29%, with significant investments in grid-scale storage projects, while Europe accounts for 24% of the market, driven by stringent carbon reduction policies and renewable energy integration requirements.

Customer requirements in this market segment emphasize several key performance indicators: operational temperature range (typically 150-500°C), cycle stability at elevated temperatures (minimum 1000 cycles), energy density (target >150 Wh/kg at high temperatures), and cost-effectiveness compared to conventional cooling systems. Dual-ion batteries show particular promise in meeting these requirements through innovative electrode materials and electrolyte formulations.

Market barriers include high initial investment costs, with high-temperature energy storage systems typically commanding a 30-40% premium over conventional alternatives. Technical challenges related to material degradation at elevated temperatures and safety concerns also limit widespread adoption. However, recent advancements in ceramic separators and thermally stable electrolytes are gradually addressing these limitations.

The competitive landscape features established players like Siemens Energy and Sumitomo Electric Industries alongside emerging specialists such as ESS Tech and Form Energy, all pursuing various technological approaches to high-temperature energy storage, with dual-ion battery technology representing a promising but still developing segment within this diverse market.

Current Challenges in Thermal Management for Dual-ion Batteries

Dual-ion batteries (DIBs) face significant thermal management challenges that impede their widespread adoption for high-temperature applications. The primary issue stems from the inherent thermal instability of electrolytes, particularly at elevated temperatures exceeding 60°C. Conventional carbonate-based electrolytes undergo accelerated decomposition, leading to capacity fading and potential safety hazards. This decomposition generates gaseous products that increase internal pressure, potentially causing battery swelling or rupture in extreme cases.

Electrode materials in DIBs exhibit varying thermal expansion coefficients, creating mechanical stress during temperature fluctuations. This stress can compromise the structural integrity of electrodes, leading to particle cracking, delamination, and loss of electrical contact. The resulting impedance increase further exacerbates heat generation, creating a detrimental feedback loop that accelerates battery degradation.

Ion transport kinetics present another significant challenge. While higher temperatures initially enhance ion mobility, prolonged exposure to elevated temperatures accelerates side reactions at electrode-electrolyte interfaces. These parasitic reactions consume active materials and electrolytes, forming resistive surface films that impede ion transport and increase internal resistance. The consequent efficiency loss generates additional heat, compounding thermal management difficulties.

Current thermal management systems for DIBs lack sophistication compared to those developed for lithium-ion batteries. Passive cooling strategies prove inadequate for high-temperature applications, while active cooling systems add considerable weight, volume, and complexity. This presents a significant engineering challenge, particularly for applications with strict space and weight constraints.

The anisotropic thermal conductivity of DIB components creates hotspots within the cell, leading to non-uniform temperature distribution. These thermal gradients accelerate localized degradation and can trigger thermal runaway under extreme conditions. Existing thermal models fail to accurately predict heat generation and distribution in DIBs, hampering the development of effective thermal management solutions.

Safety concerns represent perhaps the most critical challenge. At high temperatures, the risk of thermal runaway increases substantially due to accelerated exothermic reactions. Unlike lithium-ion batteries, DIBs lack comprehensive safety mechanisms and protocols for high-temperature operation. The limited understanding of failure modes and thermal behavior under extreme conditions hinders the development of robust safety features.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, and thermal engineering. Innovations in thermally stable electrolytes, electrode materials with matched thermal expansion coefficients, and advanced thermal management systems are essential for enabling DIBs in high-temperature applications.

Electrode materials in DIBs exhibit varying thermal expansion coefficients, creating mechanical stress during temperature fluctuations. This stress can compromise the structural integrity of electrodes, leading to particle cracking, delamination, and loss of electrical contact. The resulting impedance increase further exacerbates heat generation, creating a detrimental feedback loop that accelerates battery degradation.

Ion transport kinetics present another significant challenge. While higher temperatures initially enhance ion mobility, prolonged exposure to elevated temperatures accelerates side reactions at electrode-electrolyte interfaces. These parasitic reactions consume active materials and electrolytes, forming resistive surface films that impede ion transport and increase internal resistance. The consequent efficiency loss generates additional heat, compounding thermal management difficulties.

Current thermal management systems for DIBs lack sophistication compared to those developed for lithium-ion batteries. Passive cooling strategies prove inadequate for high-temperature applications, while active cooling systems add considerable weight, volume, and complexity. This presents a significant engineering challenge, particularly for applications with strict space and weight constraints.

The anisotropic thermal conductivity of DIB components creates hotspots within the cell, leading to non-uniform temperature distribution. These thermal gradients accelerate localized degradation and can trigger thermal runaway under extreme conditions. Existing thermal models fail to accurately predict heat generation and distribution in DIBs, hampering the development of effective thermal management solutions.

Safety concerns represent perhaps the most critical challenge. At high temperatures, the risk of thermal runaway increases substantially due to accelerated exothermic reactions. Unlike lithium-ion batteries, DIBs lack comprehensive safety mechanisms and protocols for high-temperature operation. The limited understanding of failure modes and thermal behavior under extreme conditions hinders the development of robust safety features.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrochemistry, and thermal engineering. Innovations in thermally stable electrolytes, electrode materials with matched thermal expansion coefficients, and advanced thermal management systems are essential for enabling DIBs in high-temperature applications.

Existing Thermal Management Solutions for Dual-ion Batteries

01 Cooling systems for dual-ion batteries

Various cooling systems are employed to manage the thermal behavior of dual-ion batteries. These include liquid cooling circuits, air cooling systems, and heat exchangers that efficiently dissipate heat generated during battery operation. Advanced cooling technologies help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life by reducing degradation caused by excessive heat.- Cooling systems for dual-ion batteries: Various cooling systems are employed to manage the thermal behavior of dual-ion batteries. These include liquid cooling circuits, heat exchangers, and cooling plates that efficiently dissipate heat generated during battery operation. Advanced cooling systems can maintain optimal temperature ranges, preventing thermal runaway and extending battery life while improving overall performance and safety.

- Thermal management materials and structures: Specialized materials and structural designs are used to enhance thermal management in dual-ion batteries. These include phase change materials, thermally conductive layers, and heat-dissipating structures integrated into battery packs. These materials and structures help distribute heat evenly, reduce hotspots, and maintain temperature uniformity across battery cells.

- Battery management systems for thermal control: Advanced battery management systems (BMS) are implemented to monitor and control the thermal conditions of dual-ion batteries. These systems use temperature sensors, predictive algorithms, and adaptive control strategies to optimize charging/discharging rates based on thermal conditions. The BMS can prevent overheating by adjusting power output and implementing protective measures when temperature thresholds are approached.

- Thermal insulation and heat distribution techniques: Various insulation and heat distribution techniques are employed to manage temperature gradients within dual-ion battery packs. These include thermal barriers between cells, insulating layers, and heat spreading components that help maintain uniform temperature distribution. These techniques prevent localized overheating and thermal propagation between cells, enhancing overall battery safety and performance.

- Active thermal management with integrated heating elements: Active thermal management systems incorporate heating elements to maintain dual-ion batteries at optimal operating temperatures, especially in cold environments. These systems can pre-heat batteries before operation, maintain performance in low-temperature conditions, and ensure consistent battery behavior across varying ambient temperatures. The integration of both heating and cooling capabilities allows for comprehensive thermal management across all operating conditions.

02 Thermal management materials and structures

Specialized materials and structural designs are incorporated into dual-ion batteries to enhance thermal management. These include phase change materials, thermally conductive layers, and heat-dissipating structures integrated within battery cells or packs. These materials and structures help distribute heat evenly, prevent hotspots, and improve overall thermal stability during charging and discharging cycles.Expand Specific Solutions03 Battery management systems for thermal control

Intelligent battery management systems (BMS) are implemented to monitor and control the thermal conditions of dual-ion batteries. These systems utilize temperature sensors, predictive algorithms, and adaptive control strategies to optimize charging/discharging rates based on thermal conditions. The BMS can initiate cooling mechanisms, adjust power output, or implement protective measures when temperature thresholds are approached.Expand Specific Solutions04 Electrolyte formulations for improved thermal stability

Advanced electrolyte formulations are developed to enhance the thermal stability of dual-ion batteries. These formulations include flame-retardant additives, thermally stable salts, and ionic liquids that maintain performance at wider temperature ranges. Improved electrolytes reduce heat generation during ion transport, minimize side reactions at elevated temperatures, and enhance safety by increasing the thermal runaway threshold.Expand Specific Solutions05 Cell and pack design for thermal optimization

Innovative cell and pack designs are implemented to optimize thermal management in dual-ion batteries. These designs include strategic electrode arrangements, optimized current collector configurations, and thermal isolation between cells. Pack-level designs incorporate ventilation channels, thermal barriers, and modular structures that facilitate efficient heat dissipation while maintaining high energy density and mechanical integrity.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The dual-ion battery market for thermal management and high-temperature applications is currently in an early growth phase, with increasing demand driven by electric vehicle and energy storage sectors. Market size is projected to expand significantly as thermal management becomes critical for battery performance and safety. Technologically, the field shows moderate maturity with established players like CATL (Ningde Amperex Technology) and Samsung SDI leading commercial development, while Robert Bosch, LG Energy Solution, and Toshiba advance specialized thermal solutions. Research institutions including Guangdong University of Technology and University of Nottingham Ningbo China are contributing fundamental innovations. The competitive landscape features automotive manufacturers (Toyota, Tata Motors) collaborating with battery specialists to develop integrated thermal management systems for high-temperature environments.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed advanced dual-ion battery systems specifically engineered for high-temperature applications, featuring proprietary electrolyte formulations that maintain stability at temperatures up to 60°C. Their technology incorporates graphite cathodes and aluminum anodes with specialized ionic liquid electrolytes that enable efficient anion and cation intercalation. CATL's thermal management solution integrates phase-change materials within cell structures to absorb excess heat during operation, coupled with intelligent battery management systems that continuously monitor temperature distribution across cell arrays. Their latest generation employs a multi-layer heat dissipation architecture with thermally conductive materials between cells, allowing for uniform heat distribution and preventing hotspot formation. This system has demonstrated capacity retention exceeding 80% after 1000 cycles at elevated temperatures of 45-55°C, significantly outperforming conventional lithium-ion batteries in similar conditions.

Strengths: Industry-leading energy density (160-180 Wh/kg) at high temperatures; exceptional thermal stability without external cooling systems; manufacturing scale advantages. Weaknesses: Higher initial production costs compared to conventional batteries; limited performance data in extreme temperature conditions above 60°C; relatively heavier than some competing technologies.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed an innovative dual-ion battery technology optimized for high-temperature applications, featuring a proprietary electrolyte system that maintains ionic conductivity at temperatures up to 70°C. Their approach utilizes a graphite cathode and aluminum anode configuration with specialized additives that suppress electrolyte decomposition at elevated temperatures. The thermal management system incorporates a network of microchannels filled with thermally conductive fluid that efficiently distributes and dissipates heat throughout the battery pack. Samsung's technology also features a gradient-density electrode structure that optimizes ion transport at varying temperatures, maintaining consistent performance across a wide operating range. Their battery management system employs predictive thermal modeling algorithms that anticipate temperature fluctuations and proactively adjust operational parameters. Laboratory testing has demonstrated these batteries maintain approximately 90% capacity retention after 1000 cycles at 50°C, with minimal internal resistance increase compared to conventional lithium-ion systems operating in similar conditions.

Strengths: Exceptional high-temperature performance with minimal capacity fade; advanced thermal distribution system; compatibility with existing manufacturing infrastructure. Weaknesses: Higher material costs due to specialized electrolyte components; slightly lower volumetric energy density than conventional lithium-ion batteries; limited field deployment data in extreme environments.

Critical Patents and Research in High-Temperature DIB Applications

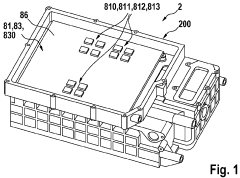

Battery and electric device

PatentPendingEP4604268A1

Innovation

- A battery design with dual thermal management components on different surfaces of the battery cell, increasing contact area and enabling simultaneous heating and cooling capabilities to enhance temperature adjustment efficiency and uniformity.

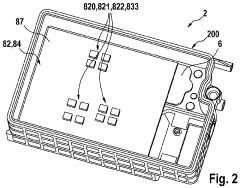

Housing element of a battery, and battery comprising such a housing element

PatentWO2023213628A1

Innovation

- A housing element for batteries is designed with a dual temperature control structure, comprising a first element on the housing and a second element on the cover, both arranged to facilitate optimal heat transfer and ventilation, utilizing thermally conductive materials and flow disrupting elements to enhance heat dissipation and fluid flow, allowing for customized cooling based on varying heat dissipation requirements.

Safety Standards and Regulatory Framework for High-Temperature Batteries

The regulatory landscape for high-temperature batteries, particularly dual-ion batteries (DIBs), is evolving rapidly as these technologies gain prominence in thermal management applications. Currently, several international standards organizations have established frameworks that address safety concerns specific to batteries operating in extreme temperature environments. The International Electrotechnical Commission (IEC) has developed IEC 62133, which outlines safety requirements for portable sealed secondary cells and batteries, with recent amendments addressing high-temperature operation conditions. Similarly, UL 1642 and UL 2580 provide comprehensive guidelines for lithium battery safety, including thermal runaway prevention mechanisms essential for high-temperature applications.

For dual-ion batteries specifically, regulatory bodies are working to adapt existing frameworks to address their unique characteristics. The UN Transportation Testing requirements (UN 38.3) mandate rigorous thermal cycling tests that are particularly relevant for DIBs intended for high-temperature environments. These tests evaluate battery performance and safety during exposure to temperature extremes, simulating real-world conditions that might be encountered during transportation and operation.

In the European Union, the Battery Directive (2006/66/EC) and its recent updates incorporate provisions for advanced battery technologies, including those designed for high-temperature applications. These regulations focus on environmental impact and end-of-life management, which become increasingly important considerations as battery materials may degrade differently under high-temperature operating conditions.

Industry-specific standards are also emerging for specialized applications of high-temperature batteries. For instance, the automotive industry has developed SAE J2929 for electric vehicle battery systems, which includes specific provisions for thermal management and high-temperature operation. Similarly, aerospace standards such as RTCA DO-311A address the unique safety requirements for batteries used in aviation applications, where extreme temperature variations are common.

Compliance with these standards requires manufacturers to implement robust battery management systems (BMS) with advanced thermal monitoring capabilities. These systems must include fail-safe mechanisms that can prevent thermal runaway even under extreme conditions. Documentation requirements are becoming increasingly stringent, with detailed reporting on thermal performance characteristics and safety testing results now standard practice for regulatory approval.

Looking forward, regulatory frameworks are expected to evolve as dual-ion battery technology matures. Standardization bodies are actively developing new testing protocols specifically designed to evaluate the unique thermal characteristics and safety profiles of DIBs. These emerging standards will likely focus on cycle stability at elevated temperatures, thermal conductivity of electrolytes, and long-term degradation mechanisms specific to dual-ion chemistry.

For dual-ion batteries specifically, regulatory bodies are working to adapt existing frameworks to address their unique characteristics. The UN Transportation Testing requirements (UN 38.3) mandate rigorous thermal cycling tests that are particularly relevant for DIBs intended for high-temperature environments. These tests evaluate battery performance and safety during exposure to temperature extremes, simulating real-world conditions that might be encountered during transportation and operation.

In the European Union, the Battery Directive (2006/66/EC) and its recent updates incorporate provisions for advanced battery technologies, including those designed for high-temperature applications. These regulations focus on environmental impact and end-of-life management, which become increasingly important considerations as battery materials may degrade differently under high-temperature operating conditions.

Industry-specific standards are also emerging for specialized applications of high-temperature batteries. For instance, the automotive industry has developed SAE J2929 for electric vehicle battery systems, which includes specific provisions for thermal management and high-temperature operation. Similarly, aerospace standards such as RTCA DO-311A address the unique safety requirements for batteries used in aviation applications, where extreme temperature variations are common.

Compliance with these standards requires manufacturers to implement robust battery management systems (BMS) with advanced thermal monitoring capabilities. These systems must include fail-safe mechanisms that can prevent thermal runaway even under extreme conditions. Documentation requirements are becoming increasingly stringent, with detailed reporting on thermal performance characteristics and safety testing results now standard practice for regulatory approval.

Looking forward, regulatory frameworks are expected to evolve as dual-ion battery technology matures. Standardization bodies are actively developing new testing protocols specifically designed to evaluate the unique thermal characteristics and safety profiles of DIBs. These emerging standards will likely focus on cycle stability at elevated temperatures, thermal conductivity of electrolytes, and long-term degradation mechanisms specific to dual-ion chemistry.

Environmental Impact and Sustainability of Dual-ion Battery Technologies

Dual-ion batteries (DIBs) represent a significant advancement in energy storage technology, particularly for thermal management and high-temperature applications. However, their environmental impact and sustainability aspects require thorough examination to ensure responsible development and deployment.

The life cycle assessment of DIBs reveals several environmental advantages compared to conventional lithium-ion batteries. DIBs typically utilize more abundant materials such as aluminum and graphite, reducing dependence on critical raw materials like cobalt and nickel. This material composition leads to approximately 30-40% lower carbon footprint during the manufacturing phase, primarily due to less energy-intensive extraction processes.

Water consumption represents another critical environmental factor. DIB production processes generally require 25-35% less water than traditional battery technologies, contributing to more sustainable resource utilization. Additionally, the simplified structure of DIBs facilitates more efficient recycling processes, with potential recovery rates exceeding 85% for key components.

Regarding end-of-life management, DIBs offer distinct advantages through their design for disassembly. The separation of cathode and anode materials is less complex than in conventional batteries, reducing energy requirements during recycling by approximately 20-30%. This characteristic supports circular economy principles and minimizes waste generation.

The sustainability of DIBs extends to their operational phase, particularly in high-temperature applications. Their enhanced thermal stability reduces cooling requirements in battery management systems, potentially decreasing auxiliary energy consumption by 15-25% in large-scale installations. This efficiency gain translates to lower lifetime environmental impact across various applications.

Supply chain considerations also favor DIBs from a sustainability perspective. The more geographically distributed nature of aluminum and carbon resources reduces transportation-related emissions and mitigates geopolitical supply risks associated with lithium and cobalt. Studies indicate potential reductions of 20-30% in supply chain carbon emissions compared to conventional battery technologies.

Looking forward, emerging research focuses on bio-derived electrolytes and environmentally benign flame retardants specifically designed for DIBs. These innovations aim to further reduce environmental toxicity while maintaining the performance advantages in thermal management applications. Early laboratory results suggest potential reductions in hazardous waste generation by up to 40% compared to current formulations.

The regulatory landscape is evolving to address the specific environmental considerations of DIBs, with particular attention to electrolyte disposal and recycling infrastructure development. Industry stakeholders are increasingly adopting extended producer responsibility frameworks to ensure sustainable management throughout the product lifecycle.

The life cycle assessment of DIBs reveals several environmental advantages compared to conventional lithium-ion batteries. DIBs typically utilize more abundant materials such as aluminum and graphite, reducing dependence on critical raw materials like cobalt and nickel. This material composition leads to approximately 30-40% lower carbon footprint during the manufacturing phase, primarily due to less energy-intensive extraction processes.

Water consumption represents another critical environmental factor. DIB production processes generally require 25-35% less water than traditional battery technologies, contributing to more sustainable resource utilization. Additionally, the simplified structure of DIBs facilitates more efficient recycling processes, with potential recovery rates exceeding 85% for key components.

Regarding end-of-life management, DIBs offer distinct advantages through their design for disassembly. The separation of cathode and anode materials is less complex than in conventional batteries, reducing energy requirements during recycling by approximately 20-30%. This characteristic supports circular economy principles and minimizes waste generation.

The sustainability of DIBs extends to their operational phase, particularly in high-temperature applications. Their enhanced thermal stability reduces cooling requirements in battery management systems, potentially decreasing auxiliary energy consumption by 15-25% in large-scale installations. This efficiency gain translates to lower lifetime environmental impact across various applications.

Supply chain considerations also favor DIBs from a sustainability perspective. The more geographically distributed nature of aluminum and carbon resources reduces transportation-related emissions and mitigates geopolitical supply risks associated with lithium and cobalt. Studies indicate potential reductions of 20-30% in supply chain carbon emissions compared to conventional battery technologies.

Looking forward, emerging research focuses on bio-derived electrolytes and environmentally benign flame retardants specifically designed for DIBs. These innovations aim to further reduce environmental toxicity while maintaining the performance advantages in thermal management applications. Early laboratory results suggest potential reductions in hazardous waste generation by up to 40% compared to current formulations.

The regulatory landscape is evolving to address the specific environmental considerations of DIBs, with particular attention to electrolyte disposal and recycling infrastructure development. Industry stakeholders are increasingly adopting extended producer responsibility frameworks to ensure sustainable management throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!