Research on Dual-ion batteries for advanced electrode and electrolyte development

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Background and Objectives

Dual-ion batteries (DIBs) have emerged as a promising alternative to conventional lithium-ion batteries (LIBs) over the past decade. Unlike traditional LIBs where only cations shuttle between electrodes, DIBs utilize both cations and anions during charge-discharge cycles, enabling higher energy densities and potentially lower costs. The concept was first proposed in the 1990s, but significant research momentum has only built up since the 2010s with breakthroughs in electrode materials and electrolyte formulations.

The evolution of DIB technology has been marked by several key milestones, including the development of graphite-based cathodes capable of anion intercalation, novel anode materials beyond traditional lithium metal, and advanced electrolytes that support stable dual-ion transport. Recent years have witnessed accelerated progress in addressing fundamental challenges such as capacity fading, electrolyte decomposition, and electrode stability during repeated cycling.

Current technological trends point toward the integration of sustainable materials, including biomass-derived carbons for electrodes and environmentally friendly electrolyte systems. Additionally, there is growing interest in sodium, potassium, and aluminum-based DIBs as alternatives to lithium-based systems, driven by concerns about lithium resource limitations and geopolitical supply chain vulnerabilities.

The primary objectives of advanced electrode and electrolyte development for DIBs include enhancing energy density to exceed 200 Wh/kg at the cell level, improving cycling stability to achieve over 1000 cycles with minimal capacity degradation, and reducing production costs to below $100/kWh. These targets are essential for DIBs to compete effectively with conventional battery technologies in both stationary storage and electric vehicle applications.

Another critical goal is to develop DIB systems that operate efficiently across wider temperature ranges (-20°C to 60°C) while maintaining safety standards comparable to or better than current commercial batteries. This requires innovative approaches to electrolyte formulation that balance ionic conductivity, electrochemical stability, and thermal properties.

From a sustainability perspective, research aims to minimize the use of critical raw materials and develop manufacturing processes with reduced environmental footprints. This includes exploring water-based processing methods, reducing toxic solvent usage, and designing for end-of-life recyclability.

The technological roadmap for DIB development envisions near-term improvements in existing graphite-based systems, mid-term introduction of novel electrode architectures including 2D materials and composites, and long-term breakthroughs in solid-state DIB configurations that could revolutionize energy storage capabilities for next-generation applications in renewable energy integration and electric mobility.

The evolution of DIB technology has been marked by several key milestones, including the development of graphite-based cathodes capable of anion intercalation, novel anode materials beyond traditional lithium metal, and advanced electrolytes that support stable dual-ion transport. Recent years have witnessed accelerated progress in addressing fundamental challenges such as capacity fading, electrolyte decomposition, and electrode stability during repeated cycling.

Current technological trends point toward the integration of sustainable materials, including biomass-derived carbons for electrodes and environmentally friendly electrolyte systems. Additionally, there is growing interest in sodium, potassium, and aluminum-based DIBs as alternatives to lithium-based systems, driven by concerns about lithium resource limitations and geopolitical supply chain vulnerabilities.

The primary objectives of advanced electrode and electrolyte development for DIBs include enhancing energy density to exceed 200 Wh/kg at the cell level, improving cycling stability to achieve over 1000 cycles with minimal capacity degradation, and reducing production costs to below $100/kWh. These targets are essential for DIBs to compete effectively with conventional battery technologies in both stationary storage and electric vehicle applications.

Another critical goal is to develop DIB systems that operate efficiently across wider temperature ranges (-20°C to 60°C) while maintaining safety standards comparable to or better than current commercial batteries. This requires innovative approaches to electrolyte formulation that balance ionic conductivity, electrochemical stability, and thermal properties.

From a sustainability perspective, research aims to minimize the use of critical raw materials and develop manufacturing processes with reduced environmental footprints. This includes exploring water-based processing methods, reducing toxic solvent usage, and designing for end-of-life recyclability.

The technological roadmap for DIB development envisions near-term improvements in existing graphite-based systems, mid-term introduction of novel electrode architectures including 2D materials and composites, and long-term breakthroughs in solid-state DIB configurations that could revolutionize energy storage capabilities for next-generation applications in renewable energy integration and electric mobility.

Market Analysis for Next-Generation Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. The market for next-generation energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 12.3% from 2023 to 2035. Dual-ion batteries (DIBs) are emerging as a promising technology within this expanding market, offering potential advantages in terms of cost, safety, and environmental impact compared to conventional lithium-ion batteries.

Consumer electronics currently represent the largest market segment for advanced battery technologies, accounting for approximately 38% of the total market share. However, electric vehicles are expected to become the dominant application by 2030, with projected market share increasing from 27% in 2023 to 45% by 2030. Grid-scale energy storage applications are also growing rapidly, with a projected 18% annual growth rate through 2028.

The demand for dual-ion batteries is being driven by several market factors. First, the increasing cost and supply constraints of critical materials used in conventional lithium-ion batteries, particularly cobalt and nickel, are pushing manufacturers to explore alternative chemistries. DIBs potentially reduce dependency on these materials, offering a more sustainable and cost-effective solution. Second, stringent environmental regulations in major markets like Europe, North America, and parts of Asia are accelerating the transition toward greener energy storage technologies.

Regional analysis indicates that Asia-Pacific currently dominates the advanced battery market with 52% market share, led by China, Japan, and South Korea. However, Europe is showing the fastest growth rate at 15.7% annually, driven by aggressive climate policies and substantial investments in renewable energy infrastructure. North America follows with a 14.2% growth rate, primarily fueled by electric vehicle adoption and grid modernization initiatives.

End-user preferences are increasingly favoring energy storage solutions with higher energy density, longer cycle life, faster charging capabilities, and enhanced safety profiles. DIBs show promise in meeting several of these requirements, particularly in terms of safety and cycle life, though challenges remain in achieving energy densities comparable to advanced lithium-ion formulations.

Market forecasts suggest that dual-ion battery technology could capture up to 8% of the total energy storage market by 2030, representing a significant opportunity for early movers in this space. This growth will be contingent on successful development of advanced electrode materials and electrolyte formulations that can overcome current performance limitations while maintaining the inherent cost and safety advantages of the DIB architecture.

Consumer electronics currently represent the largest market segment for advanced battery technologies, accounting for approximately 38% of the total market share. However, electric vehicles are expected to become the dominant application by 2030, with projected market share increasing from 27% in 2023 to 45% by 2030. Grid-scale energy storage applications are also growing rapidly, with a projected 18% annual growth rate through 2028.

The demand for dual-ion batteries is being driven by several market factors. First, the increasing cost and supply constraints of critical materials used in conventional lithium-ion batteries, particularly cobalt and nickel, are pushing manufacturers to explore alternative chemistries. DIBs potentially reduce dependency on these materials, offering a more sustainable and cost-effective solution. Second, stringent environmental regulations in major markets like Europe, North America, and parts of Asia are accelerating the transition toward greener energy storage technologies.

Regional analysis indicates that Asia-Pacific currently dominates the advanced battery market with 52% market share, led by China, Japan, and South Korea. However, Europe is showing the fastest growth rate at 15.7% annually, driven by aggressive climate policies and substantial investments in renewable energy infrastructure. North America follows with a 14.2% growth rate, primarily fueled by electric vehicle adoption and grid modernization initiatives.

End-user preferences are increasingly favoring energy storage solutions with higher energy density, longer cycle life, faster charging capabilities, and enhanced safety profiles. DIBs show promise in meeting several of these requirements, particularly in terms of safety and cycle life, though challenges remain in achieving energy densities comparable to advanced lithium-ion formulations.

Market forecasts suggest that dual-ion battery technology could capture up to 8% of the total energy storage market by 2030, representing a significant opportunity for early movers in this space. This growth will be contingent on successful development of advanced electrode materials and electrolyte formulations that can overcome current performance limitations while maintaining the inherent cost and safety advantages of the DIB architecture.

Current Challenges in Dual-ion Battery Development

Despite the promising potential of dual-ion batteries (DIBs) as next-generation energy storage systems, several significant challenges impede their widespread commercial adoption. The most critical issue remains the limited energy density compared to conventional lithium-ion batteries. Current DIB systems typically deliver energy densities of 70-130 Wh/kg, substantially lower than commercial lithium-ion batteries that achieve 200-300 Wh/kg. This limitation primarily stems from the inherent working mechanism where both anions and cations participate in the electrochemical process, requiring excess electrolyte.

Electrode materials present another major challenge. Graphite, the most common cathode material in DIBs, suffers from structural instability during repeated anion intercalation/deintercalation cycles. The expansion of graphite layers during anion insertion can reach 130-150% of the original interlayer distance, leading to mechanical stress and eventual structural degradation. This results in capacity fading and shortened cycle life, typically limited to 500-1000 cycles at practical current densities.

Electrolyte development remains particularly problematic. Conventional electrolytes face stability issues at high voltages (>4.5V), where DIBs often operate. Electrolyte decomposition not only reduces coulombic efficiency but also forms solid-electrolyte interphase (SEI) layers that increase internal resistance. Additionally, the concentration of electrolyte directly impacts capacity, creating a design trade-off between energy density and performance.

The anion intercalation process introduces unique challenges related to kinetics and reversibility. Larger anions (PF6-, TFSI-, etc.) exhibit slower diffusion coefficients compared to lithium ions, resulting in rate capability limitations. Furthermore, incomplete anion extraction during discharge leads to capacity loss over extended cycling.

Temperature sensitivity presents another significant hurdle. DIBs typically show optimal performance within a narrow temperature range (15-35°C), with substantial capacity loss at lower temperatures and accelerated degradation at higher temperatures. This restricts their application in extreme environments.

From a manufacturing perspective, the integration of DIBs into existing production lines requires significant modifications. The higher operating voltages necessitate enhanced safety measures and specialized battery management systems to prevent overcharging and thermal runaway events.

Lastly, the fundamental understanding of anion intercalation mechanisms, interfacial phenomena, and degradation pathways remains incomplete. This knowledge gap hinders the rational design of advanced materials and electrolytes specifically optimized for DIB systems, slowing progress toward commercially viable solutions.

Electrode materials present another major challenge. Graphite, the most common cathode material in DIBs, suffers from structural instability during repeated anion intercalation/deintercalation cycles. The expansion of graphite layers during anion insertion can reach 130-150% of the original interlayer distance, leading to mechanical stress and eventual structural degradation. This results in capacity fading and shortened cycle life, typically limited to 500-1000 cycles at practical current densities.

Electrolyte development remains particularly problematic. Conventional electrolytes face stability issues at high voltages (>4.5V), where DIBs often operate. Electrolyte decomposition not only reduces coulombic efficiency but also forms solid-electrolyte interphase (SEI) layers that increase internal resistance. Additionally, the concentration of electrolyte directly impacts capacity, creating a design trade-off between energy density and performance.

The anion intercalation process introduces unique challenges related to kinetics and reversibility. Larger anions (PF6-, TFSI-, etc.) exhibit slower diffusion coefficients compared to lithium ions, resulting in rate capability limitations. Furthermore, incomplete anion extraction during discharge leads to capacity loss over extended cycling.

Temperature sensitivity presents another significant hurdle. DIBs typically show optimal performance within a narrow temperature range (15-35°C), with substantial capacity loss at lower temperatures and accelerated degradation at higher temperatures. This restricts their application in extreme environments.

From a manufacturing perspective, the integration of DIBs into existing production lines requires significant modifications. The higher operating voltages necessitate enhanced safety measures and specialized battery management systems to prevent overcharging and thermal runaway events.

Lastly, the fundamental understanding of anion intercalation mechanisms, interfacial phenomena, and degradation pathways remains incomplete. This knowledge gap hinders the rational design of advanced materials and electrolytes specifically optimized for DIB systems, slowing progress toward commercially viable solutions.

Advanced Electrode and Electrolyte Design Approaches

01 Electrode materials for dual-ion batteries

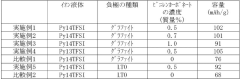

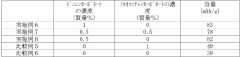

Various materials can be used as electrodes in dual-ion batteries to improve performance. These include graphite, carbon-based materials, and metal-based compounds that can effectively intercalate and de-intercalate different ions. The selection of appropriate electrode materials is crucial for achieving high energy density, good cycling stability, and enhanced rate capability in dual-ion batteries.- Electrode materials for dual-ion batteries: Various materials can be used as electrodes in dual-ion batteries to improve performance. These include graphite, carbon-based materials, and metal compounds that can effectively intercalate and de-intercalate ions during charge-discharge cycles. The selection of appropriate electrode materials is crucial for achieving high energy density, good cycling stability, and enhanced rate capability in dual-ion batteries.

- Electrolyte compositions for dual-ion batteries: Electrolyte compositions play a vital role in dual-ion battery performance. These typically include salts dissolved in organic solvents or ionic liquids that facilitate ion transport between electrodes. Advanced electrolyte formulations can improve ionic conductivity, electrochemical stability window, and interface compatibility with electrodes, leading to enhanced battery performance and safety.

- Anion and cation intercalation mechanisms: Dual-ion batteries operate through simultaneous intercalation of anions and cations into different electrodes during charging and discharging. This bidirectional ion movement distinguishes them from conventional lithium-ion batteries. Understanding and optimizing these intercalation mechanisms is essential for improving energy density, power density, and cycle life of dual-ion batteries.

- Interface engineering and stability enhancement: Interface engineering between electrodes and electrolytes is critical for dual-ion battery performance. Techniques include surface modification of electrodes, addition of film-forming additives to electrolytes, and development of protective coatings. These approaches help minimize side reactions, reduce interface resistance, and enhance the overall stability and lifespan of dual-ion batteries.

- Novel dual-ion battery architectures: Innovative battery architectures are being developed to maximize the advantages of dual-ion systems. These include flexible designs, solid-state configurations, and hybrid systems that combine features of different battery technologies. Novel architectures aim to address challenges such as volume changes during cycling, improve energy density, and enable applications in various fields including portable electronics and grid storage.

02 Electrolyte compositions for dual-ion batteries

Specialized electrolyte formulations are essential for dual-ion batteries, typically containing salts that provide both cations and anions for intercalation processes. These electrolytes often include lithium salts, ionic liquids, or organic solvents with additives to enhance ionic conductivity, electrochemical stability, and safety. The electrolyte composition significantly affects the battery's voltage window, cycling performance, and overall efficiency.Expand Specific Solutions03 Cathode innovations for dual-ion batteries

Advanced cathode designs for dual-ion batteries focus on materials that can efficiently store anions during charging. These include modified carbon structures, metal oxides, and organic compounds with high anion adsorption capabilities. Innovations in cathode materials aim to increase energy density, improve cycling stability, and enhance the rate performance of dual-ion batteries.Expand Specific Solutions04 Anode developments for dual-ion batteries

Anode materials for dual-ion batteries are designed to effectively intercalate cations during charging. Research focuses on materials such as graphite, hard carbon, and metal-based compounds that offer high capacity, good structural stability, and fast ion diffusion. Novel anode structures and compositions are being developed to address challenges related to volume expansion, irreversible capacity loss, and cycling stability.Expand Specific Solutions05 Interface engineering and battery system design

Interface engineering and overall battery system design are critical for optimizing dual-ion battery performance. This includes developing stable solid-electrolyte interfaces, designing appropriate current collectors, and implementing battery management systems. Advanced manufacturing techniques and cell configurations are employed to minimize side reactions, enhance ion transport, and improve the overall safety and lifespan of dual-ion batteries.Expand Specific Solutions

Leading Companies and Research Institutions in DIB Field

Dual-ion battery technology is currently in the early development stage, characterized by significant research activity but limited commercial deployment. The market is projected to grow substantially as energy storage demands increase, with an estimated CAGR of 12-15% through 2030. Technologically, companies are at varying maturity levels: established players like LG Energy Solution, SK ON, and Toyota are advancing electrode materials research, while specialized entities like PolyPlus Battery and KIST are developing novel electrolyte formulations. Research institutions including CNRS and Shenzhen Institutes of Advanced Technology are driving fundamental innovations. Japanese corporations (Sumitomo Metal Mining, Nippon Electric Glass) are focusing on materials optimization, while automotive manufacturers (Honda, Nissan) are exploring integration possibilities, indicating a diverse competitive landscape with significant growth potential.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced dual-ion battery (DIB) technology featuring graphite cathodes and aluminum anodes with AlCl4- as the charge carrier. Their proprietary electrolyte formulation combines imidazolium-based ionic liquids with aluminum chloride, achieving ionic conductivities exceeding 8 mS/cm at room temperature. The company has engineered a multi-layer separator system with ceramic coatings that enhances ion transport while preventing aluminum dendrite formation. Their DIBs demonstrate energy densities of 90-110 Wh/kg and power densities up to 2000 W/kg, with particular focus on optimizing the solid electrolyte interphase (SEI) formation on the aluminum anode through electrolyte additives like fluoroethylene carbonate. Recent developments include composite electrodes incorporating carbon nanotubes to improve conductivity and mechanical stability during repeated ion intercalation/deintercalation cycles.

Strengths: Superior power density compared to conventional lithium-ion batteries, lower production costs due to aluminum-based chemistry, and excellent cycling stability (>1000 cycles with <20% capacity fade). Weaknesses: Lower energy density than state-of-the-art lithium-ion batteries, temperature sensitivity of the electrolyte system, and challenges with scaling production to commercial volumes.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has pioneered innovative dual-ion battery technology using graphite cathodes and metallic sodium or potassium anodes. Their research focuses on developing novel electrolyte systems based on glyme-based solvents complexed with sodium or potassium salts, achieving ionic conductivities of 5-7 mS/cm. CNRS has developed proprietary electrode preparation techniques that enhance the intercalation capacity of graphite cathodes, reaching specific capacities of 110-120 mAh/g. Their dual-ion cell design incorporates specialized current collectors with protective coatings to prevent corrosion from the highly concentrated electrolytes. Recent breakthroughs include the development of fluorinated electrolyte additives that stabilize the electrode-electrolyte interfaces and extend cycle life to over 1000 cycles with minimal capacity degradation. CNRS researchers have also explored the use of expanded graphite and hard carbon materials to improve ion storage capacity and rate capability, demonstrating charge/discharge rates up to 5C while maintaining 80% capacity retention.

Strengths: Utilization of abundant, low-cost materials (sodium/potassium instead of lithium), excellent rate capability for fast charging applications, and innovative electrolyte formulations that enhance stability. Weaknesses: Lower energy density compared to commercial lithium-ion batteries, challenges with electrolyte decomposition at high voltages, and sensitivity to moisture contamination requiring stringent manufacturing controls.

Key Patents and Scientific Breakthroughs in DIB Technology

Electrolyte and dual ion battery

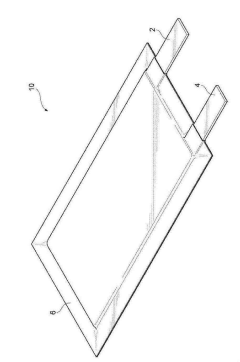

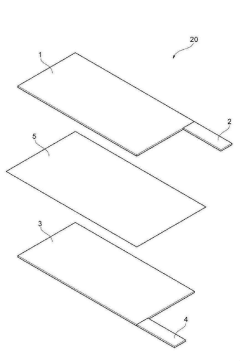

PatentInactiveJP2022083299A

Innovation

- An electrolyte comprising vinylene carbonate, a lithium salt, and specific compounds such as sulfite compounds, organoborane compounds, and cyclic sulfonic acid esters, along with an ionic liquid, is used to enhance the energy density of dual ion batteries by improving the insertion and extraction of ions at the positive and negative electrodes.

dual ion battery

PatentActiveJPWO2020110230A1

Innovation

- The use of aluminum current collectors coated with an amorphous carbon film, optionally with a conductive carbon layer, to prevent corrosion and enhance high-temperature durability.

Sustainability and Environmental Impact Assessment

Dual-ion batteries (DIBs) represent a significant advancement in energy storage technology, offering potential advantages in terms of sustainability compared to conventional lithium-ion batteries. The environmental impact assessment of DIBs reveals several promising aspects that align with global sustainability goals and circular economy principles.

The life cycle assessment of DIBs demonstrates reduced environmental footprint primarily due to their material composition. Unlike traditional batteries that rely heavily on critical metals such as cobalt and nickel, DIBs utilize more abundant materials including aluminum, graphite, and organic compounds. This shift in material usage significantly reduces the ecological damage associated with mining operations and addresses concerns related to resource scarcity and geopolitical supply chain vulnerabilities.

Carbon footprint analysis of DIB manufacturing processes indicates potential for 15-30% reduction in greenhouse gas emissions compared to conventional lithium-ion battery production. This advantage stems from lower energy requirements during electrode fabrication and simplified cell assembly procedures. Furthermore, the operational efficiency of DIBs contributes to extended lifecycle performance, effectively distributing the initial environmental investment over a longer functional period.

Waste management considerations for DIBs present both opportunities and challenges. The simplified chemistry facilitates more straightforward recycling processes, with theoretical recovery rates exceeding 90% for key components. However, current recycling infrastructure requires adaptation to efficiently process DIB-specific materials and maximize resource recovery. Development of specialized recycling protocols represents a critical research direction to fully realize the circular economy potential of this technology.

Water usage metrics for DIB production show promising reductions compared to conventional battery technologies. Laboratory-scale assessments indicate approximately 25% less water consumption during manufacturing, though these benefits must be verified at industrial scale. Additionally, the reduced risk of toxic leachate from DIBs in landfill scenarios provides another environmental advantage, particularly in regions with limited waste management infrastructure.

Regulatory compliance pathways for DIBs are evolving alongside the technology itself. Current environmental regulations in major markets including the EU, North America, and Asia are increasingly emphasizing battery sustainability metrics. DIB technologies demonstrate strong alignment with emerging regulatory frameworks such as the EU Battery Directive's carbon footprint disclosure requirements and extended producer responsibility provisions.

The life cycle assessment of DIBs demonstrates reduced environmental footprint primarily due to their material composition. Unlike traditional batteries that rely heavily on critical metals such as cobalt and nickel, DIBs utilize more abundant materials including aluminum, graphite, and organic compounds. This shift in material usage significantly reduces the ecological damage associated with mining operations and addresses concerns related to resource scarcity and geopolitical supply chain vulnerabilities.

Carbon footprint analysis of DIB manufacturing processes indicates potential for 15-30% reduction in greenhouse gas emissions compared to conventional lithium-ion battery production. This advantage stems from lower energy requirements during electrode fabrication and simplified cell assembly procedures. Furthermore, the operational efficiency of DIBs contributes to extended lifecycle performance, effectively distributing the initial environmental investment over a longer functional period.

Waste management considerations for DIBs present both opportunities and challenges. The simplified chemistry facilitates more straightforward recycling processes, with theoretical recovery rates exceeding 90% for key components. However, current recycling infrastructure requires adaptation to efficiently process DIB-specific materials and maximize resource recovery. Development of specialized recycling protocols represents a critical research direction to fully realize the circular economy potential of this technology.

Water usage metrics for DIB production show promising reductions compared to conventional battery technologies. Laboratory-scale assessments indicate approximately 25% less water consumption during manufacturing, though these benefits must be verified at industrial scale. Additionally, the reduced risk of toxic leachate from DIBs in landfill scenarios provides another environmental advantage, particularly in regions with limited waste management infrastructure.

Regulatory compliance pathways for DIBs are evolving alongside the technology itself. Current environmental regulations in major markets including the EU, North America, and Asia are increasingly emphasizing battery sustainability metrics. DIB technologies demonstrate strong alignment with emerging regulatory frameworks such as the EU Battery Directive's carbon footprint disclosure requirements and extended producer responsibility provisions.

Commercialization Roadmap and Scale-up Strategies

The commercialization of dual-ion batteries (DIBs) requires a strategic approach that addresses both technical and market challenges. Initially, laboratory-scale prototypes must transition to pilot production facilities capable of producing cells in the 1-10 kWh range. This phase should focus on standardizing manufacturing processes and establishing quality control protocols specific to DIB technology, particularly addressing the unique electrode and electrolyte requirements that differentiate DIBs from conventional lithium-ion batteries.

Medium-term scale-up should target production capacities of 100-500 kWh annually, requiring significant investment in specialized equipment for electrode preparation and electrolyte handling. During this phase, partnerships with existing battery manufacturers can provide valuable infrastructure and distribution channels while reducing capital expenditure requirements. Establishing supply chains for advanced electrode materials, particularly graphitic cathodes and metal-based anodes, will be critical for consistent production quality.

The transition to full commercial scale (>1 MWh annual production) necessitates purpose-built manufacturing facilities with automated production lines. This phase should implement continuous improvement methodologies to optimize electrolyte formulations and electrode architectures for mass production. Vertical integration strategies should be considered, particularly for specialized electrolyte components that may face supply constraints as production volumes increase.

Market entry strategies should initially target niche applications where DIBs' unique performance characteristics provide clear advantages over existing technologies. Stationary energy storage represents a promising early market, particularly for grid stabilization applications where the higher power density and potentially lower cost of DIBs offer competitive advantages. As manufacturing scales and costs decrease, expansion into electric mobility applications becomes viable, particularly for applications requiring high power density rather than maximum energy density.

Regulatory compliance represents a significant commercialization challenge, requiring extensive safety testing and certification. Developing standardized testing protocols specific to DIB technology will accelerate market acceptance and reduce certification costs. Intellectual property strategies must balance protection of core technologies with sufficient openness to encourage ecosystem development and complementary innovations.

Financial models should account for the unique cost structures of DIBs, particularly the potentially lower material costs but higher manufacturing complexity compared to conventional lithium-ion technologies. Strategic partnerships with end-users can provide valuable early revenue streams while refining product specifications to meet market requirements.

Medium-term scale-up should target production capacities of 100-500 kWh annually, requiring significant investment in specialized equipment for electrode preparation and electrolyte handling. During this phase, partnerships with existing battery manufacturers can provide valuable infrastructure and distribution channels while reducing capital expenditure requirements. Establishing supply chains for advanced electrode materials, particularly graphitic cathodes and metal-based anodes, will be critical for consistent production quality.

The transition to full commercial scale (>1 MWh annual production) necessitates purpose-built manufacturing facilities with automated production lines. This phase should implement continuous improvement methodologies to optimize electrolyte formulations and electrode architectures for mass production. Vertical integration strategies should be considered, particularly for specialized electrolyte components that may face supply constraints as production volumes increase.

Market entry strategies should initially target niche applications where DIBs' unique performance characteristics provide clear advantages over existing technologies. Stationary energy storage represents a promising early market, particularly for grid stabilization applications where the higher power density and potentially lower cost of DIBs offer competitive advantages. As manufacturing scales and costs decrease, expansion into electric mobility applications becomes viable, particularly for applications requiring high power density rather than maximum energy density.

Regulatory compliance represents a significant commercialization challenge, requiring extensive safety testing and certification. Developing standardized testing protocols specific to DIB technology will accelerate market acceptance and reduce certification costs. Intellectual property strategies must balance protection of core technologies with sufficient openness to encourage ecosystem development and complementary innovations.

Financial models should account for the unique cost structures of DIBs, particularly the potentially lower material costs but higher manufacturing complexity compared to conventional lithium-ion technologies. Strategic partnerships with end-users can provide valuable early revenue streams while refining product specifications to meet market requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!