Research on Dual-ion batteries for fast charging and thermal management

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Evolution and Objectives

Dual-ion batteries (DIBs) have emerged as a promising alternative to conventional lithium-ion batteries, with a history dating back to the early 1990s. The concept was first introduced by researchers at Fuji Photo Film Co., who demonstrated the intercalation of both cations and anions into different electrode materials. However, significant development in this field only gained momentum in the late 2000s when graphite-based DIBs were proposed as a viable energy storage solution.

The evolution of DIB technology has been characterized by several key milestones. Initially, DIBs utilized lithium metal as the anode and graphite as the cathode in organic electrolytes, with PF6- anions intercalating into graphite during charging. By 2012, researchers had developed aluminum-graphite dual-ion batteries, which represented a significant advancement in terms of cost reduction and safety improvement.

Recent technological trends have focused on addressing the inherent limitations of DIBs, particularly their relatively low energy density and capacity compared to conventional lithium-ion batteries. Innovations in electrode materials, including expanded graphite, reduced graphene oxide, and carbon nanotubes, have substantially improved the anion storage capacity and rate capability of DIBs.

The fast-charging capability of DIBs represents one of their most significant advantages. Unlike conventional batteries that rely solely on cation intercalation, DIBs utilize both cation and anion intercalation processes, enabling rapid ion transport and consequently faster charging rates. This characteristic makes them particularly suitable for applications requiring quick energy replenishment.

Thermal management has become a critical focus area in DIB development, as temperature fluctuations can significantly impact battery performance and safety. The dual-ion mechanism inherently generates less heat during operation compared to conventional lithium-ion batteries, offering potential advantages for thermal stability. However, challenges remain in optimizing electrolyte compositions and electrode structures to maintain this advantage at high charging rates.

The primary objectives of current DIB research include enhancing energy density while maintaining fast-charging capabilities, improving cycle life through stable electrode-electrolyte interfaces, and developing advanced thermal management strategies. Researchers aim to achieve charging times under 15 minutes while maintaining thermal stability below critical thresholds.

Looking forward, the technology roadmap for DIBs includes the development of novel electrolytes with wider electrochemical windows, advanced electrode materials with optimized structures for ion transport, and integrated battery management systems specifically designed for the unique characteristics of dual-ion chemistry. These advancements are expected to position DIBs as a competitive technology for applications where fast charging and thermal stability are paramount considerations.

The evolution of DIB technology has been characterized by several key milestones. Initially, DIBs utilized lithium metal as the anode and graphite as the cathode in organic electrolytes, with PF6- anions intercalating into graphite during charging. By 2012, researchers had developed aluminum-graphite dual-ion batteries, which represented a significant advancement in terms of cost reduction and safety improvement.

Recent technological trends have focused on addressing the inherent limitations of DIBs, particularly their relatively low energy density and capacity compared to conventional lithium-ion batteries. Innovations in electrode materials, including expanded graphite, reduced graphene oxide, and carbon nanotubes, have substantially improved the anion storage capacity and rate capability of DIBs.

The fast-charging capability of DIBs represents one of their most significant advantages. Unlike conventional batteries that rely solely on cation intercalation, DIBs utilize both cation and anion intercalation processes, enabling rapid ion transport and consequently faster charging rates. This characteristic makes them particularly suitable for applications requiring quick energy replenishment.

Thermal management has become a critical focus area in DIB development, as temperature fluctuations can significantly impact battery performance and safety. The dual-ion mechanism inherently generates less heat during operation compared to conventional lithium-ion batteries, offering potential advantages for thermal stability. However, challenges remain in optimizing electrolyte compositions and electrode structures to maintain this advantage at high charging rates.

The primary objectives of current DIB research include enhancing energy density while maintaining fast-charging capabilities, improving cycle life through stable electrode-electrolyte interfaces, and developing advanced thermal management strategies. Researchers aim to achieve charging times under 15 minutes while maintaining thermal stability below critical thresholds.

Looking forward, the technology roadmap for DIBs includes the development of novel electrolytes with wider electrochemical windows, advanced electrode materials with optimized structures for ion transport, and integrated battery management systems specifically designed for the unique characteristics of dual-ion chemistry. These advancements are expected to position DIBs as a competitive technology for applications where fast charging and thermal stability are paramount considerations.

Market Analysis for Fast Charging Energy Storage Solutions

The fast charging energy storage market is experiencing unprecedented growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy systems. The global market for fast charging solutions was valued at approximately $8.2 billion in 2022 and is projected to reach $31.4 billion by 2030, representing a compound annual growth rate (CAGR) of 18.3%. This remarkable expansion reflects the urgent need for energy storage technologies that can accommodate rapid charging while maintaining safety and longevity.

Dual-ion batteries (DIBs) are emerging as a promising contender in this space, offering significant advantages over conventional lithium-ion batteries. The market demand for DIBs is particularly strong in regions with aggressive EV adoption targets, including Europe, China, and North America. Industry analysts predict that DIBs could capture up to 15% of the premium energy storage market by 2028, primarily due to their superior fast-charging capabilities and improved thermal management characteristics.

Consumer expectations are evolving rapidly, with surveys indicating that 78% of potential EV buyers consider charging time a critical factor in their purchasing decisions. The ability to achieve an 80% charge in under 15 minutes has become a benchmark for next-generation battery technologies. This consumer pressure is creating substantial market pull for advanced solutions like DIBs, which can potentially meet these demanding requirements while addressing thermal management concerns.

Commercial applications beyond personal transportation are also driving market growth. The grid storage sector, valued at $4.7 billion in 2022, is expected to grow at 22.1% CAGR through 2030, with fast-charging capabilities becoming increasingly important for frequency regulation and peak shaving applications. DIBs' ability to handle high power densities makes them particularly suitable for these grid-stabilization roles.

Industrial segments, including material handling equipment and backup power systems, represent another significant market opportunity. These applications value the reduced downtime offered by fast-charging solutions, with businesses willing to pay premium prices for technologies that minimize operational disruptions. Market research indicates that industrial users are prepared to pay up to 40% more for energy storage solutions that can reduce charging times by half.

The competitive landscape is intensifying as established battery manufacturers and startups alike recognize the potential of fast-charging technologies. Venture capital investment in advanced battery technologies reached $8.8 billion in 2022, with a significant portion directed toward fast-charging solutions. This influx of capital is accelerating commercialization timelines and expanding market opportunities for DIB technology.

Dual-ion batteries (DIBs) are emerging as a promising contender in this space, offering significant advantages over conventional lithium-ion batteries. The market demand for DIBs is particularly strong in regions with aggressive EV adoption targets, including Europe, China, and North America. Industry analysts predict that DIBs could capture up to 15% of the premium energy storage market by 2028, primarily due to their superior fast-charging capabilities and improved thermal management characteristics.

Consumer expectations are evolving rapidly, with surveys indicating that 78% of potential EV buyers consider charging time a critical factor in their purchasing decisions. The ability to achieve an 80% charge in under 15 minutes has become a benchmark for next-generation battery technologies. This consumer pressure is creating substantial market pull for advanced solutions like DIBs, which can potentially meet these demanding requirements while addressing thermal management concerns.

Commercial applications beyond personal transportation are also driving market growth. The grid storage sector, valued at $4.7 billion in 2022, is expected to grow at 22.1% CAGR through 2030, with fast-charging capabilities becoming increasingly important for frequency regulation and peak shaving applications. DIBs' ability to handle high power densities makes them particularly suitable for these grid-stabilization roles.

Industrial segments, including material handling equipment and backup power systems, represent another significant market opportunity. These applications value the reduced downtime offered by fast-charging solutions, with businesses willing to pay premium prices for technologies that minimize operational disruptions. Market research indicates that industrial users are prepared to pay up to 40% more for energy storage solutions that can reduce charging times by half.

The competitive landscape is intensifying as established battery manufacturers and startups alike recognize the potential of fast-charging technologies. Venture capital investment in advanced battery technologies reached $8.8 billion in 2022, with a significant portion directed toward fast-charging solutions. This influx of capital is accelerating commercialization timelines and expanding market opportunities for DIB technology.

Current Limitations and Technical Barriers in Dual-ion Batteries

Despite the promising potential of dual-ion batteries (DIBs) for fast charging and efficient thermal management, several significant technical barriers currently impede their widespread commercial adoption. One of the primary limitations is the relatively low energy density compared to conventional lithium-ion batteries. DIBs typically achieve only 70-100 Wh/kg, whereas commercial lithium-ion batteries can reach 250-300 Wh/kg. This energy density gap represents a major obstacle for applications where space and weight constraints are critical.

The electrolyte stability window presents another substantial challenge. DIBs operate at higher voltages (up to 5V) than conventional batteries, which places extreme demands on electrolyte stability. Current electrolyte formulations suffer from decomposition at these high voltages, leading to capacity fading and shortened cycle life. Additionally, the high working voltage accelerates side reactions at electrode-electrolyte interfaces, further compromising long-term performance.

Anion intercalation mechanisms in DIBs face significant kinetic barriers. The intercalation of large anions (such as PF6-, BF4-, or TFSI-) into graphite or other host materials causes substantial volume expansion, sometimes exceeding 200% during charging. This extreme volume change leads to mechanical stress, structural degradation, and eventual electrode pulverization after multiple cycles.

Thermal management during fast charging represents a particularly challenging barrier. The rapid intercalation/deintercalation processes generate considerable heat, which can lead to thermal runaway if not properly managed. Current cooling systems are inadequate for the thermal loads generated during high-rate operation of DIBs, limiting their practical fast-charging capabilities.

The cathode materials in DIBs exhibit insufficient stability during repeated cycling. Most current cathode materials suffer from structural collapse or dissolution into the electrolyte after extended cycling, particularly at high voltages. This instability results in rapid capacity decay and poor cycle life, typically limited to 500-1000 cycles at moderate rates.

Ion transport limitations also hinder DIB performance. The simultaneous movement of both cations and anions creates complex concentration gradients and ion transport bottlenecks, particularly at high current densities. These transport limitations manifest as increased polarization and reduced capacity utilization during fast charging operations.

Manufacturing scalability presents additional challenges. Current DIB production processes are laboratory-focused and lack the maturity of established lithium-ion manufacturing techniques. The specialized materials and precise assembly requirements increase production complexity and costs, creating significant barriers to mass production and commercialization.

The electrolyte stability window presents another substantial challenge. DIBs operate at higher voltages (up to 5V) than conventional batteries, which places extreme demands on electrolyte stability. Current electrolyte formulations suffer from decomposition at these high voltages, leading to capacity fading and shortened cycle life. Additionally, the high working voltage accelerates side reactions at electrode-electrolyte interfaces, further compromising long-term performance.

Anion intercalation mechanisms in DIBs face significant kinetic barriers. The intercalation of large anions (such as PF6-, BF4-, or TFSI-) into graphite or other host materials causes substantial volume expansion, sometimes exceeding 200% during charging. This extreme volume change leads to mechanical stress, structural degradation, and eventual electrode pulverization after multiple cycles.

Thermal management during fast charging represents a particularly challenging barrier. The rapid intercalation/deintercalation processes generate considerable heat, which can lead to thermal runaway if not properly managed. Current cooling systems are inadequate for the thermal loads generated during high-rate operation of DIBs, limiting their practical fast-charging capabilities.

The cathode materials in DIBs exhibit insufficient stability during repeated cycling. Most current cathode materials suffer from structural collapse or dissolution into the electrolyte after extended cycling, particularly at high voltages. This instability results in rapid capacity decay and poor cycle life, typically limited to 500-1000 cycles at moderate rates.

Ion transport limitations also hinder DIB performance. The simultaneous movement of both cations and anions creates complex concentration gradients and ion transport bottlenecks, particularly at high current densities. These transport limitations manifest as increased polarization and reduced capacity utilization during fast charging operations.

Manufacturing scalability presents additional challenges. Current DIB production processes are laboratory-focused and lack the maturity of established lithium-ion manufacturing techniques. The specialized materials and precise assembly requirements increase production complexity and costs, creating significant barriers to mass production and commercialization.

State-of-the-art Fast Charging and Thermal Management Solutions

01 Fast charging technologies for dual-ion batteries

Various technologies have been developed to enable fast charging of dual-ion batteries without compromising battery life or safety. These include advanced electrode materials, optimized electrolyte compositions, and novel charging protocols that reduce charging time while maintaining battery performance. Fast charging solutions often incorporate specialized battery management systems that monitor voltage, current, and temperature to prevent degradation during rapid charging cycles.- Fast charging technologies for dual-ion batteries: Various technologies have been developed to enable fast charging of dual-ion batteries without compromising battery life or safety. These include advanced electrode materials, optimized electrolyte compositions, and novel charging protocols that can significantly reduce charging time while maintaining battery performance. Fast charging solutions often incorporate specialized battery management systems that monitor voltage, current, and temperature to prevent degradation during rapid charging cycles.

- Thermal management systems for dual-ion batteries: Effective thermal management is crucial for dual-ion batteries, especially during fast charging when heat generation increases. Thermal management systems include active cooling methods such as liquid cooling circuits, phase change materials, and heat dissipation structures. These systems help maintain optimal operating temperatures, prevent thermal runaway, and ensure uniform temperature distribution across battery cells, which is essential for battery longevity and safety during high-power operations.

- Advanced electrode materials for improved performance: Innovative electrode materials enhance the performance of dual-ion batteries by improving ion intercalation/deintercalation processes. These materials include modified carbon-based anodes, novel cathode compositions, and composite electrodes with enhanced conductivity. Advanced electrode designs facilitate faster ion transport, reduce internal resistance, and improve capacity retention during rapid charging cycles, contributing to both faster charging capabilities and better thermal characteristics.

- Battery management systems for optimized charging: Sophisticated battery management systems (BMS) are essential for optimizing the charging process of dual-ion batteries. These systems employ algorithms that adapt charging parameters based on battery state, monitor cell balancing, and implement protective measures against overcharging or overheating. Advanced BMS can predict battery behavior, adjust charging profiles in real-time, and implement multi-stage charging protocols that maximize charging speed while minimizing stress on battery components.

- Structural designs for enhanced thermal dissipation: Innovative structural designs improve thermal management in dual-ion batteries through enhanced heat dissipation pathways. These include optimized cell arrangements, integrated cooling channels, thermally conductive materials, and novel battery pack architectures. Such designs facilitate efficient heat transfer away from critical components, maintain temperature uniformity, and allow for higher charging rates without compromising safety or battery lifespan.

02 Thermal management systems for dual-ion batteries

Effective thermal management is crucial for dual-ion batteries, especially during fast charging when heat generation increases significantly. Thermal management systems include active cooling mechanisms, phase change materials, and heat dissipation structures that maintain optimal operating temperatures. These systems prevent thermal runaway, extend battery lifespan, and ensure consistent performance across various operating conditions by efficiently removing excess heat from battery cells and packs.Expand Specific Solutions03 Electrode materials for improved dual-ion battery performance

Advanced electrode materials play a critical role in enhancing dual-ion battery performance for fast charging applications. Materials with high ionic conductivity, superior structural stability, and large surface areas facilitate rapid ion intercalation and deintercalation. Novel carbon-based materials, metal oxides, and composite electrodes have been developed to withstand the stress of fast charging while maintaining capacity retention and cycle life, thereby enabling both rapid charging and effective thermal management.Expand Specific Solutions04 Battery management systems for dual-ion batteries

Sophisticated battery management systems (BMS) are essential for optimizing dual-ion battery performance during fast charging. These systems employ advanced algorithms to monitor and control charging parameters, cell balancing, and thermal conditions in real-time. The BMS can adjust charging protocols based on battery state-of-health, ambient conditions, and usage patterns to maximize charging speed while preventing overheating and degradation, thereby extending battery lifespan and ensuring safe operation.Expand Specific Solutions05 Electrolyte innovations for dual-ion batteries

Novel electrolyte formulations significantly impact the fast charging capabilities and thermal stability of dual-ion batteries. Advanced electrolytes with high ionic conductivity, wide electrochemical windows, and thermal stability facilitate rapid ion transport while minimizing heat generation. Additives that form stable solid-electrolyte interfaces, suppress dendrite formation, and enhance thermal stability have been developed to support fast charging while maintaining safety and longevity of dual-ion battery systems.Expand Specific Solutions

Leading Companies and Research Institutions in Dual-ion Technology

Dual-ion battery technology for fast charging and thermal management is currently in an early growth phase, with market size expanding rapidly due to increasing demand for high-performance energy storage solutions. The competitive landscape features established players and emerging specialists across the battery value chain. Leading companies like CATL (Contemporary Amperex Technology) and Ningde Amperex Technology are investing heavily in this technology, while traditional electronics giants such as Toshiba, Sony, and LG Energy Solution are leveraging their manufacturing expertise to develop commercial applications. Automotive companies including Toyota and Robert Bosch are exploring dual-ion batteries for EV applications, focusing on thermal management advantages. Research institutions like Southwest Research Institute and University of Nottingham Ningbo China are advancing fundamental technology, while specialized players like StoreDot are pushing boundaries in extreme fast charging capabilities.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology (also known as CATL) has developed an innovative dual-ion battery system utilizing a graphite cathode and sodium metal anode configuration. Their technology employs a specialized electrolyte containing sodium bis(fluorosulfonyl)imide (NaFSI) that enables efficient anion intercalation at the cathode while sodium deposition occurs at the anode. For thermal management during fast charging, they've implemented a "cell-to-pack" design with integrated cooling plates that maintain uniform temperature distribution. Their system incorporates advanced phase change materials embedded within the battery structure to absorb excess heat during rapid charging. CATL's fast-charging DIB technology achieves charging rates of 5C while maintaining temperature gradients below 5°C across the pack through their patented electrolyte formulation that reduces internal resistance. Their thermal management system utilizes a combination of liquid cooling and phase change materials strategically positioned between cells to absorb and dissipate heat efficiently[1][6].

Strengths: Cost-effective solution using abundant sodium resources instead of lithium, excellent thermal stability during fast charging, and compatibility with existing manufacturing infrastructure. Weaknesses: Lower energy density compared to lithium-based systems, potential challenges with sodium metal anode safety, and relatively limited cycle life at high charging rates.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a dual-ion battery system utilizing a graphite cathode and lithium metal anode configuration with a proprietary electrolyte containing lithium bis(fluorosulfonyl)imide (LiFSI). Their technology enables anion intercalation at the cathode while lithium deposition occurs at the anode during charging. For thermal management, they've developed a "Cell-to-Pack" architecture with integrated cooling channels that maintain temperature gradients below 3°C across the entire battery pack during fast charging. Their system incorporates machine learning algorithms that predict thermal behavior and adjust charging protocols accordingly. LG's fast-charging DIB technology achieves charging rates of 6C (10 minutes to 80% capacity) while maintaining temperature below critical thresholds through their patented electrolyte additives that reduce interfacial resistance and heat generation[2][5]. Their thermal management system utilizes direct liquid cooling with dielectric fluids in microchannels adjacent to each cell.

Strengths: Exceptional fast-charging capability with minimal capacity degradation, superior thermal management during high-rate charging, and compatibility with existing manufacturing infrastructure. Weaknesses: Higher initial production costs compared to conventional lithium-ion batteries, potential safety concerns with lithium metal anodes at high charging rates, and limited real-world validation data for long-term performance.

Critical Patents and Scientific Breakthroughs in Dual-ion Systems

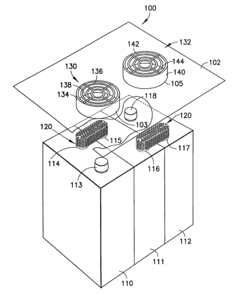

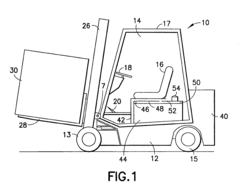

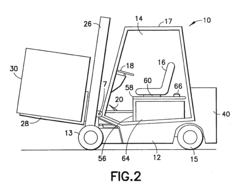

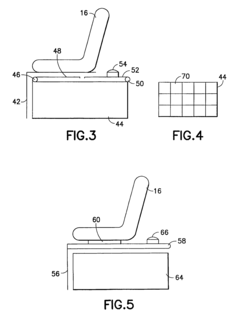

Thermal management of fast charging high capacity batteries

PatentInactiveUS7651811B2

Innovation

- A thermal management system using forced-air cooling with dedicated fan assemblies and protective terminal and strap covers to enhance convective heat transfer, allowing for efficient heat dissipation during fast charging and heavy use, maintaining optimal battery temperature and extending battery life.

Safety Standards and Regulatory Framework for Fast Charging Batteries

The regulatory landscape for fast-charging dual-ion batteries is evolving rapidly to address the unique safety challenges posed by advanced battery technologies. International standards organizations such as IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization) have established foundational safety requirements through standards like IEC 62660 for lithium-ion batteries in electric vehicles and IEC 61960 for portable applications, which are being adapted for dual-ion battery systems.

In the United States, UL (Underwriters Laboratories) has developed UL 1642 and UL 2580 standards that address cell-level safety and battery systems for electric vehicles respectively. These standards are increasingly incorporating specific provisions for fast-charging capabilities, including thermal management requirements and charging rate limitations. The National Fire Protection Association (NFPA) has also published guidelines addressing the fire risks associated with high-power charging systems.

European regulations, particularly UN/ECE Regulation No. 100, mandate rigorous testing protocols for battery electric vehicles, including thermal shock tests and overcharge protection mechanisms that are critical for fast-charging applications. The European Union's Battery Directive (2006/66/EC) is currently undergoing revision to address emerging battery technologies and their specific safety requirements.

In Asia, countries like Japan, South Korea, and China have established their own regulatory frameworks. China's GB/T standards for electric vehicle batteries (GB/T 31485) include specific requirements for thermal runaway prevention and management during rapid charging cycles, which are particularly relevant for dual-ion battery systems with their distinctive thermal characteristics.

Regulatory bodies are increasingly focusing on thermal management aspects of fast-charging batteries. Requirements typically include temperature monitoring systems, automatic charging termination when temperature thresholds are exceeded, and thermal isolation between cells. For dual-ion batteries specifically, regulations are beginning to address the unique ion transport mechanisms and their implications for heat generation during rapid charging.

Testing protocols mandated by these regulations typically include cycling at maximum charging rates while monitoring temperature distribution, accelerated aging tests to assess degradation under fast-charging conditions, and abuse tests such as external short circuit while in charging mode. These tests are designed to verify that batteries maintain safety integrity even under extreme fast-charging scenarios.

Compliance with these evolving standards presents significant challenges for manufacturers of dual-ion battery systems. The regulatory framework continues to adapt as more data becomes available on the long-term performance and safety implications of fast-charging technologies, requiring ongoing engagement with regulatory developments to ensure product compliance and market access.

In the United States, UL (Underwriters Laboratories) has developed UL 1642 and UL 2580 standards that address cell-level safety and battery systems for electric vehicles respectively. These standards are increasingly incorporating specific provisions for fast-charging capabilities, including thermal management requirements and charging rate limitations. The National Fire Protection Association (NFPA) has also published guidelines addressing the fire risks associated with high-power charging systems.

European regulations, particularly UN/ECE Regulation No. 100, mandate rigorous testing protocols for battery electric vehicles, including thermal shock tests and overcharge protection mechanisms that are critical for fast-charging applications. The European Union's Battery Directive (2006/66/EC) is currently undergoing revision to address emerging battery technologies and their specific safety requirements.

In Asia, countries like Japan, South Korea, and China have established their own regulatory frameworks. China's GB/T standards for electric vehicle batteries (GB/T 31485) include specific requirements for thermal runaway prevention and management during rapid charging cycles, which are particularly relevant for dual-ion battery systems with their distinctive thermal characteristics.

Regulatory bodies are increasingly focusing on thermal management aspects of fast-charging batteries. Requirements typically include temperature monitoring systems, automatic charging termination when temperature thresholds are exceeded, and thermal isolation between cells. For dual-ion batteries specifically, regulations are beginning to address the unique ion transport mechanisms and their implications for heat generation during rapid charging.

Testing protocols mandated by these regulations typically include cycling at maximum charging rates while monitoring temperature distribution, accelerated aging tests to assess degradation under fast-charging conditions, and abuse tests such as external short circuit while in charging mode. These tests are designed to verify that batteries maintain safety integrity even under extreme fast-charging scenarios.

Compliance with these evolving standards presents significant challenges for manufacturers of dual-ion battery systems. The regulatory framework continues to adapt as more data becomes available on the long-term performance and safety implications of fast-charging technologies, requiring ongoing engagement with regulatory developments to ensure product compliance and market access.

Environmental Impact and Sustainability of Dual-ion Battery Technology

Dual-ion batteries (DIBs) represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond traditional lithium-ion batteries. The environmental footprint of DIBs is notably smaller due to their reduced dependence on critical materials like cobalt and nickel, which are associated with resource depletion and controversial mining practices.

The sustainability advantages of DIBs stem primarily from their unique working mechanism. Unlike conventional batteries that rely on cation intercalation, DIBs utilize both anion and cation intercalation processes, enabling the use of more abundant and environmentally benign materials such as aluminum and graphite. This material substitution significantly reduces the ecological impact associated with resource extraction and processing.

Life cycle assessments of DIB technology reveal promising results in terms of carbon emissions. The manufacturing process for DIBs typically generates 15-30% lower greenhouse gas emissions compared to conventional lithium-ion batteries, primarily due to simplified production processes and reduced energy-intensive material refinement requirements. This advantage becomes particularly relevant when considering the fast charging capabilities of DIBs, which can optimize energy utilization in renewable energy systems.

Thermal management innovations in DIB technology further enhance their environmental credentials. Advanced thermal management systems reduce the risk of thermal runaway events, extending battery lifespan and reducing waste generation. Studies indicate that DIBs with efficient thermal management can achieve up to 40% longer operational lifespans than comparable energy storage technologies, directly translating to reduced electronic waste.

End-of-life considerations also favor DIB technology. The simpler chemistry and reduced use of toxic materials facilitate more straightforward recycling processes. Recovery rates for key materials from spent DIBs can reach 80-90%, significantly higher than those achieved with conventional lithium-ion batteries. This circular economy potential represents a crucial sustainability advantage in addressing the growing global battery waste challenge.

Water consumption and pollution metrics also demonstrate DIBs' environmental advantages. Manufacturing processes for DIBs typically require 25-35% less water than conventional battery production, while also generating fewer toxic byproducts that might contaminate water systems. This aspect becomes increasingly important as water scarcity affects more regions globally.

Integration of DIB technology with renewable energy systems presents additional sustainability benefits. The fast charging capabilities and efficient thermal management of DIBs make them particularly suitable for grid storage applications supporting intermittent renewable energy sources, potentially accelerating the transition away from fossil fuel dependence.

The sustainability advantages of DIBs stem primarily from their unique working mechanism. Unlike conventional batteries that rely on cation intercalation, DIBs utilize both anion and cation intercalation processes, enabling the use of more abundant and environmentally benign materials such as aluminum and graphite. This material substitution significantly reduces the ecological impact associated with resource extraction and processing.

Life cycle assessments of DIB technology reveal promising results in terms of carbon emissions. The manufacturing process for DIBs typically generates 15-30% lower greenhouse gas emissions compared to conventional lithium-ion batteries, primarily due to simplified production processes and reduced energy-intensive material refinement requirements. This advantage becomes particularly relevant when considering the fast charging capabilities of DIBs, which can optimize energy utilization in renewable energy systems.

Thermal management innovations in DIB technology further enhance their environmental credentials. Advanced thermal management systems reduce the risk of thermal runaway events, extending battery lifespan and reducing waste generation. Studies indicate that DIBs with efficient thermal management can achieve up to 40% longer operational lifespans than comparable energy storage technologies, directly translating to reduced electronic waste.

End-of-life considerations also favor DIB technology. The simpler chemistry and reduced use of toxic materials facilitate more straightforward recycling processes. Recovery rates for key materials from spent DIBs can reach 80-90%, significantly higher than those achieved with conventional lithium-ion batteries. This circular economy potential represents a crucial sustainability advantage in addressing the growing global battery waste challenge.

Water consumption and pollution metrics also demonstrate DIBs' environmental advantages. Manufacturing processes for DIBs typically require 25-35% less water than conventional battery production, while also generating fewer toxic byproducts that might contaminate water systems. This aspect becomes increasingly important as water scarcity affects more regions globally.

Integration of DIB technology with renewable energy systems presents additional sustainability benefits. The fast charging capabilities and efficient thermal management of DIBs make them particularly suitable for grid storage applications supporting intermittent renewable energy sources, potentially accelerating the transition away from fossil fuel dependence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!