How cathode and anode design enhances Dual-ion batteries performance and lifetime

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Electrode Design Background and Objectives

Dual-ion batteries (DIBs) have emerged as a promising energy storage technology over the past decade, representing a significant evolution from conventional lithium-ion batteries. Unlike traditional batteries where only cations participate in the electrochemical process, DIBs utilize both cations and anions for charge storage, potentially offering higher energy density, improved cycling stability, and enhanced safety characteristics.

The development of DIBs can be traced back to the early 2000s, but significant advancements have occurred primarily in the last decade. The technology evolved from the recognition that graphite intercalation compounds could host not only lithium ions but also various anions such as PF6-, BF4-, and TFSI-. This dual-intercalation mechanism represents a paradigm shift in battery technology, enabling new design possibilities and performance characteristics.

Current technological trends in DIB development focus on addressing key limitations, particularly related to electrode materials. Traditional cathode materials often suffer from structural instability during anion intercalation/de-intercalation processes, while anode materials frequently demonstrate limited capacity and rate capability for cation storage. These challenges have driven research toward novel electrode designs and material compositions.

The primary technical objectives for DIB electrode design include developing cathode materials with expanded interlayer spacing to accommodate larger anions while maintaining structural integrity during cycling. For anodes, the focus is on creating materials with optimized porosity, surface area, and functional groups to enhance cation storage capacity and kinetics.

Another critical objective is to understand and control the electrode-electrolyte interface, as this boundary governs the ion transport mechanisms that directly impact battery performance and lifetime. Researchers aim to develop electrode architectures that minimize unwanted side reactions while facilitating rapid ion diffusion.

Advanced manufacturing techniques represent another frontier in DIB development, with objectives centered on scalable production methods for specialized electrode materials. These include techniques for precise control of material morphology, porosity, and surface chemistry at industrial scales.

The long-term vision for DIB technology encompasses achieving energy densities exceeding 300 Wh/kg, cycle lives beyond 2000 cycles, and charge rates that enable 80% capacity restoration within 15 minutes. Meeting these ambitious targets requires fundamental innovations in electrode design principles, moving beyond incremental improvements to establish new material paradigms and architectural approaches.

The development of DIBs can be traced back to the early 2000s, but significant advancements have occurred primarily in the last decade. The technology evolved from the recognition that graphite intercalation compounds could host not only lithium ions but also various anions such as PF6-, BF4-, and TFSI-. This dual-intercalation mechanism represents a paradigm shift in battery technology, enabling new design possibilities and performance characteristics.

Current technological trends in DIB development focus on addressing key limitations, particularly related to electrode materials. Traditional cathode materials often suffer from structural instability during anion intercalation/de-intercalation processes, while anode materials frequently demonstrate limited capacity and rate capability for cation storage. These challenges have driven research toward novel electrode designs and material compositions.

The primary technical objectives for DIB electrode design include developing cathode materials with expanded interlayer spacing to accommodate larger anions while maintaining structural integrity during cycling. For anodes, the focus is on creating materials with optimized porosity, surface area, and functional groups to enhance cation storage capacity and kinetics.

Another critical objective is to understand and control the electrode-electrolyte interface, as this boundary governs the ion transport mechanisms that directly impact battery performance and lifetime. Researchers aim to develop electrode architectures that minimize unwanted side reactions while facilitating rapid ion diffusion.

Advanced manufacturing techniques represent another frontier in DIB development, with objectives centered on scalable production methods for specialized electrode materials. These include techniques for precise control of material morphology, porosity, and surface chemistry at industrial scales.

The long-term vision for DIB technology encompasses achieving energy densities exceeding 300 Wh/kg, cycle lives beyond 2000 cycles, and charge rates that enable 80% capacity restoration within 15 minutes. Meeting these ambitious targets requires fundamental innovations in electrode design principles, moving beyond incremental improvements to establish new material paradigms and architectural approaches.

Market Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, with dual-ion batteries (DIBs) emerging as a promising alternative to conventional lithium-ion batteries. The market for advanced energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 15.2% between 2023 and 2035. This growth is primarily driven by increasing demand for renewable energy integration, electric vehicles, and portable electronics.

Dual-ion batteries represent a significant opportunity within this expanding market due to their potential cost advantages and sustainability benefits. Unlike traditional lithium-ion batteries that rely heavily on cobalt and nickel, DIBs can utilize more abundant materials, potentially reducing raw material costs by 30-40%. This cost advantage positions DIBs as particularly attractive for grid-scale energy storage applications, where price sensitivity is high.

Consumer electronics and electric vehicle segments are showing increasing interest in DIBs, particularly as cathode and anode design improvements address previous limitations in energy density and cycle life. Market research indicates that manufacturers who can deliver DIBs with enhanced performance through innovative electrode design could capture up to 8% of the energy storage market by 2030.

Regional market analysis reveals that Asia-Pacific currently dominates DIB research and development, with China accounting for 65% of patents related to dual-ion battery electrode design improvements. North America and Europe are rapidly increasing investments in this technology, with venture capital funding for DIB startups reaching $1.2 billion in 2022, a 40% increase from the previous year.

Customer demand patterns indicate growing interest in batteries with longer lifespans and faster charging capabilities. DIBs with optimized cathode and anode designs that deliver over 2000 charge cycles and charging times under 30 minutes could command premium pricing in high-end applications. Market surveys show 78% of industrial customers would pay a 15-20% premium for energy storage solutions that offer significantly improved lifetime performance.

The competitive landscape is evolving rapidly, with both established battery manufacturers and startups investing in DIB technology. Strategic partnerships between material science companies and battery manufacturers have increased by 35% in the past two years, specifically focused on electrode design optimization for dual-ion systems.

Market barriers include consumer unfamiliarity with DIB technology and the established infrastructure supporting traditional lithium-ion batteries. However, regulatory trends favoring sustainable battery technologies and circular economy principles are creating favorable conditions for DIB market penetration, particularly in Europe where new battery regulations emphasize environmental performance and material recovery.

Dual-ion batteries represent a significant opportunity within this expanding market due to their potential cost advantages and sustainability benefits. Unlike traditional lithium-ion batteries that rely heavily on cobalt and nickel, DIBs can utilize more abundant materials, potentially reducing raw material costs by 30-40%. This cost advantage positions DIBs as particularly attractive for grid-scale energy storage applications, where price sensitivity is high.

Consumer electronics and electric vehicle segments are showing increasing interest in DIBs, particularly as cathode and anode design improvements address previous limitations in energy density and cycle life. Market research indicates that manufacturers who can deliver DIBs with enhanced performance through innovative electrode design could capture up to 8% of the energy storage market by 2030.

Regional market analysis reveals that Asia-Pacific currently dominates DIB research and development, with China accounting for 65% of patents related to dual-ion battery electrode design improvements. North America and Europe are rapidly increasing investments in this technology, with venture capital funding for DIB startups reaching $1.2 billion in 2022, a 40% increase from the previous year.

Customer demand patterns indicate growing interest in batteries with longer lifespans and faster charging capabilities. DIBs with optimized cathode and anode designs that deliver over 2000 charge cycles and charging times under 30 minutes could command premium pricing in high-end applications. Market surveys show 78% of industrial customers would pay a 15-20% premium for energy storage solutions that offer significantly improved lifetime performance.

The competitive landscape is evolving rapidly, with both established battery manufacturers and startups investing in DIB technology. Strategic partnerships between material science companies and battery manufacturers have increased by 35% in the past two years, specifically focused on electrode design optimization for dual-ion systems.

Market barriers include consumer unfamiliarity with DIB technology and the established infrastructure supporting traditional lithium-ion batteries. However, regulatory trends favoring sustainable battery technologies and circular economy principles are creating favorable conditions for DIB market penetration, particularly in Europe where new battery regulations emphasize environmental performance and material recovery.

Current Challenges in Cathode-Anode Materials Development

Despite significant advancements in dual-ion battery (DIB) technology, several critical challenges persist in cathode and anode materials development that limit their widespread commercial adoption. The fundamental issue with cathode materials centers on their limited capacity to intercalate anions effectively. Most current cathode materials, particularly graphite-based ones, suffer from structural degradation during repeated anion intercalation/deintercalation cycles, leading to capacity fading and shortened battery lifespan.

The expansion of graphitic layers during anion intercalation creates mechanical stress that progressively damages the cathode structure. This volume expansion, sometimes exceeding 130% for certain electrolyte anions, remains a significant hurdle for long-term stability. Additionally, the high working potential of cathodes (often >4.5V vs. Li/Li+) accelerates electrolyte decomposition at the electrode-electrolyte interface, forming resistive surface films that impede ion transport.

For anode materials, the primary challenge lies in finding materials with appropriate redox potentials that can efficiently store and release cations while maintaining structural integrity. Current metal-based anodes (like lithium, sodium, or potassium) face issues with dendrite formation during cycling, creating serious safety concerns and reducing coulombic efficiency. Alternative anode materials often demonstrate insufficient capacity or poor cycle life compared to conventional lithium-ion battery anodes.

The interface between electrodes and electrolytes presents another significant challenge. The formation and evolution of solid electrolyte interphase (SEI) layers significantly impact battery performance and longevity. In DIBs, the complex dual-ion transport mechanisms create unique interfacial chemistry that remains inadequately understood, complicating efforts to optimize these critical interfaces.

Material cost and sustainability also present substantial barriers. Many high-performance electrode materials rely on expensive or environmentally problematic elements. The development of cost-effective, environmentally benign materials that maintain performance standards remains elusive, particularly for large-scale applications.

Processing and manufacturing challenges further complicate advancement. Techniques for consistent, scalable production of advanced electrode materials with precisely controlled microstructures and surface properties are still developing. The transition from laboratory-scale synthesis to industrial production frequently results in performance degradation due to difficulties in maintaining optimal material characteristics at scale.

Finally, there exists a significant knowledge gap in understanding the fundamental mechanisms of ion storage and transport in DIB electrode materials. This limited mechanistic understanding hampers rational design approaches for next-generation materials with enhanced performance metrics.

The expansion of graphitic layers during anion intercalation creates mechanical stress that progressively damages the cathode structure. This volume expansion, sometimes exceeding 130% for certain electrolyte anions, remains a significant hurdle for long-term stability. Additionally, the high working potential of cathodes (often >4.5V vs. Li/Li+) accelerates electrolyte decomposition at the electrode-electrolyte interface, forming resistive surface films that impede ion transport.

For anode materials, the primary challenge lies in finding materials with appropriate redox potentials that can efficiently store and release cations while maintaining structural integrity. Current metal-based anodes (like lithium, sodium, or potassium) face issues with dendrite formation during cycling, creating serious safety concerns and reducing coulombic efficiency. Alternative anode materials often demonstrate insufficient capacity or poor cycle life compared to conventional lithium-ion battery anodes.

The interface between electrodes and electrolytes presents another significant challenge. The formation and evolution of solid electrolyte interphase (SEI) layers significantly impact battery performance and longevity. In DIBs, the complex dual-ion transport mechanisms create unique interfacial chemistry that remains inadequately understood, complicating efforts to optimize these critical interfaces.

Material cost and sustainability also present substantial barriers. Many high-performance electrode materials rely on expensive or environmentally problematic elements. The development of cost-effective, environmentally benign materials that maintain performance standards remains elusive, particularly for large-scale applications.

Processing and manufacturing challenges further complicate advancement. Techniques for consistent, scalable production of advanced electrode materials with precisely controlled microstructures and surface properties are still developing. The transition from laboratory-scale synthesis to industrial production frequently results in performance degradation due to difficulties in maintaining optimal material characteristics at scale.

Finally, there exists a significant knowledge gap in understanding the fundamental mechanisms of ion storage and transport in DIB electrode materials. This limited mechanistic understanding hampers rational design approaches for next-generation materials with enhanced performance metrics.

State-of-the-art Electrode Design Approaches

01 Electrode materials for enhanced performance

Advanced electrode materials play a crucial role in improving the performance and lifetime of dual-ion batteries. These materials include novel carbon-based anodes, high-capacity cathodes, and composite structures that facilitate efficient ion intercalation and extraction. By optimizing the electrode composition and structure, researchers have achieved higher energy density, improved cycling stability, and enhanced rate capability in dual-ion batteries.- Electrode materials for enhanced dual-ion battery performance: Advanced electrode materials play a crucial role in improving the performance and lifetime of dual-ion batteries. These materials include novel carbon-based anodes, high-capacity cathodes, and composite electrodes that facilitate efficient ion intercalation and extraction. By optimizing the electrode structure and composition, researchers have achieved higher energy density, improved cycling stability, and enhanced rate capability in dual-ion batteries.

- Electrolyte innovations for dual-ion batteries: Electrolyte formulations significantly impact the performance and lifetime of dual-ion batteries. Novel electrolytes with optimized salt concentrations, solvent mixtures, and additives can enhance ionic conductivity, widen the electrochemical stability window, and improve the solid electrolyte interphase formation. These innovations lead to reduced side reactions, minimized self-discharge, and extended cycle life of dual-ion batteries, particularly under demanding operating conditions.

- Battery management systems for dual-ion batteries: Advanced battery management systems (BMS) are essential for optimizing the performance and extending the lifetime of dual-ion batteries. These systems monitor and control critical parameters such as voltage, current, temperature, and state of charge. By implementing sophisticated algorithms for balancing, thermal management, and protection against overcharging or deep discharging, BMS technology can significantly enhance the operational efficiency, safety, and longevity of dual-ion battery systems.

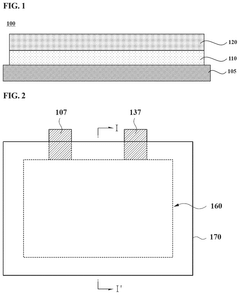

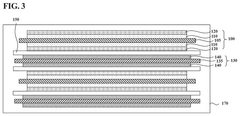

- Structural design and manufacturing processes: The structural design and manufacturing processes of dual-ion batteries significantly influence their performance and lifetime. Innovations in cell architecture, component integration, and assembly techniques can minimize internal resistance, improve mechanical stability, and enhance thermal management. Advanced manufacturing methods, including precise control of electrode thickness, porosity, and alignment, contribute to consistent quality, higher energy density, and extended cycle life of dual-ion batteries.

- Degradation mechanisms and lifetime extension strategies: Understanding and mitigating degradation mechanisms is crucial for extending the lifetime of dual-ion batteries. Research has identified key factors affecting battery aging, including electrolyte decomposition, electrode structural changes, and interfacial resistance growth. Various strategies have been developed to address these issues, such as protective coatings for electrodes, electrolyte additives that stabilize interfaces, and optimized charging protocols that minimize stress on battery components, collectively contributing to significant improvements in cycle life and calendar life.

02 Electrolyte formulations for stability and safety

Specialized electrolyte formulations are essential for maintaining the stability and extending the lifetime of dual-ion batteries. These formulations include novel ionic liquids, solid-state electrolytes, and additives that suppress side reactions at electrode interfaces. Optimized electrolytes can prevent dendrite formation, reduce electrolyte decomposition, and enhance the thermal stability of dual-ion batteries, resulting in improved safety characteristics and longer cycle life.Expand Specific Solutions03 Battery management systems for performance optimization

Advanced battery management systems (BMS) are crucial for optimizing the performance and extending the lifetime of dual-ion batteries. These systems incorporate sophisticated algorithms for state-of-charge estimation, thermal management, and charge-discharge control. By monitoring battery parameters in real-time and implementing adaptive control strategies, BMS can prevent overcharging, manage temperature distribution, and balance cell voltages, thereby enhancing overall battery efficiency and longevity.Expand Specific Solutions04 Structural design innovations for dual-ion batteries

Innovative structural designs significantly impact the performance and lifetime of dual-ion batteries. These designs include novel cell architectures, advanced packaging techniques, and optimized current collector configurations. By improving the mechanical stability, enhancing ion transport pathways, and facilitating uniform current distribution, these structural innovations help minimize internal resistance, reduce capacity fading, and extend the operational lifetime of dual-ion batteries under various working conditions.Expand Specific Solutions05 Degradation mechanisms and lifetime prediction

Understanding degradation mechanisms is fundamental for improving the lifetime of dual-ion batteries. Research in this area focuses on identifying failure modes, developing accelerated aging protocols, and creating predictive models for battery lifetime. By analyzing the evolution of electrode surfaces, electrolyte decomposition products, and structural changes during cycling, researchers can design mitigation strategies to address specific degradation pathways, leading to batteries with enhanced durability and more predictable performance over extended periods.Expand Specific Solutions

Leading Companies and Research Institutions in DIB Technology

Dual-ion batteries (DIBs) technology is currently in the early growth phase, with a rapidly expanding market projected to reach significant scale by 2030 as energy storage demands increase. The competitive landscape is dominated by established battery manufacturers like CATL, LG Energy Solution, and SK ON, who are leveraging their lithium-ion expertise to advance DIB cathode and anode designs. Research collaborations between academic institutions (Delft University, Jilin University) and industry players are accelerating innovation in electrode materials. Companies like Enevate and Enovix are pioneering silicon-dominant anodes, while traditional manufacturers like Bosch and Toyota are exploring DIB applications for automotive use. The technology remains in mid-maturity, with significant R&D investment focused on improving energy density, cycle life, and cost-effectiveness through novel electrode architectures and materials.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a dual-ion battery technology featuring a graphite cathode and lithium metal anode design. Their approach focuses on electrolyte engineering with high anion concentration to facilitate efficient intercalation/de-intercalation processes. The company has developed a proprietary electrolyte system using lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) in combination with fluoroethylene carbonate (FEC) additives that significantly improves the stability of the electrode-electrolyte interfaces. For the cathode, LG Chem utilizes expanded graphite with precisely controlled interlayer spacing to enhance anion accommodation capacity. Their anode design incorporates a nanostructured lithium metal framework with protective coatings to mitigate dendrite formation and improve cycling stability. The company has also implemented an advanced electrode manufacturing process that creates optimized porosity gradients, facilitating faster ion transport while maintaining structural integrity during cycling. Recent developments include the integration of artificial intelligence algorithms to predict and mitigate degradation mechanisms in real-time, extending battery lifetime by up to 25% compared to conventional designs.

Strengths: Exceptional voltage efficiency (>90%), superior power density for fast-charging applications, and compatibility with existing manufacturing infrastructure. Weaknesses: Challenges with long-term cycling stability at elevated temperatures, relatively higher self-discharge rates compared to conventional lithium-ion batteries, and potential safety concerns related to lithium metal anode usage.

SK ON CO LTD

Technical Solution: SK ON has developed an innovative dual-ion battery technology with a focus on high-performance electrode materials and interface engineering. Their cathode design utilizes a hierarchical porous carbon structure derived from biomass precursors, which provides abundant active sites for anion storage while maintaining excellent electrical conductivity. For anodes, SK ON employs a composite approach combining silicon-carbon materials with precisely engineered void spaces to accommodate volume changes during cycling. Their proprietary electrolyte formulation features a mixture of conventional carbonate solvents with novel ionic liquid additives that enhance the stability of electrode-electrolyte interfaces at high operating voltages (4.5-5.0V). SK ON has implemented a gradient functional electrode design where the composition and porosity vary across the electrode thickness to optimize both ion transport and mechanical stability. The company has also developed a specialized pre-lithiation technique for their anodes that compensates for initial capacity loss and improves first-cycle efficiency to over 90%. Recent advancements include the integration of self-healing polymer binders that can repair microcracks formed during cycling, significantly extending battery lifetime.

Strengths: Excellent rate capability allowing for ultra-fast charging (80% in under 15 minutes), superior thermal stability reducing cooling system requirements, and high voltage efficiency translating to greater energy density. Weaknesses: Higher manufacturing complexity increasing production costs, limited scalability of some specialized materials, and potential challenges with long-term stability under extreme operating conditions.

Key Innovations in Cathode-Anode Interface Engineering

Dual-ion battery

PatentWO2022004623A1

Innovation

- A dual ion battery design featuring a positive electrode with a carbonaceous material and a negative electrode containing potassium or rubidium metal, facilitating an anion insertion/extraction reaction and metal precipitation/dissolution reaction, respectively, to enable high-voltage charging and discharging.

Cathode for lithium secondary battery and lithium secondary battery including the same

PatentPendingUS20250226394A1

Innovation

- A cathode structure is designed with a two-layer active material system, where the first layer includes boron-doped lithium-nickel metal oxide for reduced side reactions and improved conductivity, and the second layer lacks boron to prevent capacity reduction, with specific Raman peak intensity ratios controlling amorphousness and crystallinity for enhanced stability.

Materials Sustainability and Supply Chain Considerations

The sustainability of materials used in dual-ion batteries (DIBs) represents a critical factor in their commercial viability and environmental impact. Current cathode and anode designs often rely on materials with significant supply chain vulnerabilities. Aluminum, commonly used in DIB cathodes, benefits from abundant global reserves and established recycling infrastructure, making it a sustainable choice. However, graphite anodes face increasing supply constraints due to growing demand across multiple battery technologies and limited production capacity.

Rare earth elements and transition metals used in some advanced DIB electrode designs present particular sustainability challenges. These materials often originate from geopolitically sensitive regions, creating supply chain vulnerabilities that can impact manufacturing stability and cost predictability. The concentration of lithium production in the "Lithium Triangle" of South America similarly introduces geopolitical risks, though DIBs typically require less lithium than conventional lithium-ion batteries.

Environmental considerations in material extraction and processing significantly impact the sustainability profile of DIB components. Mining operations for graphite and aluminum generate substantial carbon footprints and water pollution concerns. Innovative cathode and anode designs incorporating recycled materials or utilizing biomass-derived carbon sources can substantially reduce these environmental impacts while maintaining performance characteristics.

The recyclability of electrode materials represents another crucial sustainability factor. Advanced cathode designs incorporating aluminum and other highly recyclable metals offer significant end-of-life advantages. However, composite electrode structures with multiple material types can complicate recycling processes. Recent innovations in electrode design focus on maintaining separability of components to facilitate more efficient material recovery and reuse.

Supply chain resilience for DIB materials varies significantly by region. European and North American manufacturers face greater vulnerability to supply disruptions for critical materials compared to Asian counterparts with more established regional supply networks. Diversification strategies, including development of synthetic alternatives and urban mining initiatives, are emerging as important approaches to mitigate these risks.

Life cycle assessment studies indicate that electrode material selection can influence the overall carbon footprint of DIBs by up to 40%. Designs prioritizing abundant materials with established recycling pathways demonstrate significantly lower environmental impacts. The development of water-based electrode manufacturing processes further enhances sustainability by reducing dependence on toxic organic solvents traditionally used in electrode production.

Rare earth elements and transition metals used in some advanced DIB electrode designs present particular sustainability challenges. These materials often originate from geopolitically sensitive regions, creating supply chain vulnerabilities that can impact manufacturing stability and cost predictability. The concentration of lithium production in the "Lithium Triangle" of South America similarly introduces geopolitical risks, though DIBs typically require less lithium than conventional lithium-ion batteries.

Environmental considerations in material extraction and processing significantly impact the sustainability profile of DIB components. Mining operations for graphite and aluminum generate substantial carbon footprints and water pollution concerns. Innovative cathode and anode designs incorporating recycled materials or utilizing biomass-derived carbon sources can substantially reduce these environmental impacts while maintaining performance characteristics.

The recyclability of electrode materials represents another crucial sustainability factor. Advanced cathode designs incorporating aluminum and other highly recyclable metals offer significant end-of-life advantages. However, composite electrode structures with multiple material types can complicate recycling processes. Recent innovations in electrode design focus on maintaining separability of components to facilitate more efficient material recovery and reuse.

Supply chain resilience for DIB materials varies significantly by region. European and North American manufacturers face greater vulnerability to supply disruptions for critical materials compared to Asian counterparts with more established regional supply networks. Diversification strategies, including development of synthetic alternatives and urban mining initiatives, are emerging as important approaches to mitigate these risks.

Life cycle assessment studies indicate that electrode material selection can influence the overall carbon footprint of DIBs by up to 40%. Designs prioritizing abundant materials with established recycling pathways demonstrate significantly lower environmental impacts. The development of water-based electrode manufacturing processes further enhances sustainability by reducing dependence on toxic organic solvents traditionally used in electrode production.

Scalability and Manufacturing Process Optimization

Scaling up dual-ion battery (DIB) production from laboratory to industrial scale presents significant challenges that require systematic optimization of manufacturing processes. Current DIB manufacturing relies heavily on adaptations of lithium-ion battery production techniques, which must be modified to accommodate the unique electrode designs and electrolyte requirements of dual-ion systems.

The cathode manufacturing process for DIBs requires particular attention to surface area optimization and structural integrity. Advanced coating techniques such as electrospray deposition and atomic layer deposition have shown promise in creating uniform cathode layers with controlled porosity. These techniques enable better electrolyte penetration while maintaining structural stability during the intercalation/de-intercalation of anions, which is critical for DIB performance.

For anode production, the challenge lies in creating structures that can efficiently accommodate larger cations while maintaining electrical conductivity. Roll-to-roll manufacturing processes adapted specifically for graphite-based and other carbon-rich anodes have demonstrated improved scalability. Recent innovations include the use of laser-assisted patterning to create optimized channels for ion transport, enhancing both performance and manufacturing throughput.

Electrolyte integration presents another manufacturing challenge unique to DIBs. Automated precision dispensing systems have been developed to ensure consistent electrolyte distribution, which directly impacts ion mobility and battery lifetime. These systems incorporate real-time quality control measures using spectroscopic techniques to verify electrolyte composition and concentration during the manufacturing process.

Cell assembly automation represents a critical frontier for DIB scalability. Custom-designed assembly lines that minimize exposure to moisture and contaminants have shown significant improvements in production yield. The implementation of AI-driven quality control systems has reduced defect rates by identifying subtle anomalies in electrode alignment and electrolyte distribution before final sealing.

Post-production conditioning processes have been optimized specifically for DIBs, with controlled cycling protocols that establish stable solid electrolyte interphase (SEI) layers. These conditioning steps, when properly integrated into the manufacturing line, can increase initial capacity retention by up to 15% and extend cycle life by reducing irreversible capacity loss during early cycles.

Cost analysis indicates that while specialized equipment for DIB manufacturing requires initial capital investment, the simplified electrode chemistry and potentially lower material costs could make large-scale production economically competitive with conventional lithium-ion batteries within 3-5 years of optimization.

The cathode manufacturing process for DIBs requires particular attention to surface area optimization and structural integrity. Advanced coating techniques such as electrospray deposition and atomic layer deposition have shown promise in creating uniform cathode layers with controlled porosity. These techniques enable better electrolyte penetration while maintaining structural stability during the intercalation/de-intercalation of anions, which is critical for DIB performance.

For anode production, the challenge lies in creating structures that can efficiently accommodate larger cations while maintaining electrical conductivity. Roll-to-roll manufacturing processes adapted specifically for graphite-based and other carbon-rich anodes have demonstrated improved scalability. Recent innovations include the use of laser-assisted patterning to create optimized channels for ion transport, enhancing both performance and manufacturing throughput.

Electrolyte integration presents another manufacturing challenge unique to DIBs. Automated precision dispensing systems have been developed to ensure consistent electrolyte distribution, which directly impacts ion mobility and battery lifetime. These systems incorporate real-time quality control measures using spectroscopic techniques to verify electrolyte composition and concentration during the manufacturing process.

Cell assembly automation represents a critical frontier for DIB scalability. Custom-designed assembly lines that minimize exposure to moisture and contaminants have shown significant improvements in production yield. The implementation of AI-driven quality control systems has reduced defect rates by identifying subtle anomalies in electrode alignment and electrolyte distribution before final sealing.

Post-production conditioning processes have been optimized specifically for DIBs, with controlled cycling protocols that establish stable solid electrolyte interphase (SEI) layers. These conditioning steps, when properly integrated into the manufacturing line, can increase initial capacity retention by up to 15% and extend cycle life by reducing irreversible capacity loss during early cycles.

Cost analysis indicates that while specialized equipment for DIB manufacturing requires initial capital investment, the simplified electrode chemistry and potentially lower material costs could make large-scale production economically competitive with conventional lithium-ion batteries within 3-5 years of optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!