How cathode and anode surface engineering affects Dual-ion batteries lifetime and efficiency

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Engineering Background and Objectives

Surface engineering has emerged as a critical frontier in the development of dual-ion batteries (DIBs), representing a significant evolution from traditional lithium-ion battery technology. The historical trajectory of DIBs began in the early 1990s but gained substantial momentum only in the past decade as researchers recognized their potential for higher energy density, improved safety, and reduced environmental impact compared to conventional battery systems.

The fundamental principle of DIBs involves the simultaneous intercalation of cations and anions into different electrode materials during charge-discharge cycles. This dual-ion mechanism creates unique surface interaction challenges that directly impact battery performance metrics. Surface engineering, therefore, has become pivotal in addressing these challenges by modifying the electrode-electrolyte interfaces to enhance stability, conductivity, and ion transport properties.

Current technological objectives in DIB surface engineering focus on several critical areas. First, extending cycle life by mitigating surface degradation mechanisms such as electrolyte decomposition, solid-electrolyte interphase (SEI) instability, and structural deterioration of electrode materials. Second, improving energy efficiency by reducing interfacial resistance and enhancing charge transfer kinetics at electrode surfaces. Third, increasing power density through optimized surface architectures that facilitate rapid ion diffusion and electron transport.

The evolution of surface engineering approaches has progressed from simple coating techniques to sophisticated atomic-level modifications. Early methods primarily involved passive protective layers, while contemporary approaches incorporate functional surface modifications that actively participate in electrochemical processes. This progression reflects the growing understanding of interfacial phenomena in DIBs and their critical role in determining overall battery performance.

Recent technological breakthroughs have demonstrated that tailored surface engineering can extend DIB lifetimes by up to 300% and improve energy efficiency by 15-20%. These advances have been enabled by innovations in materials science, nanotechnology, and advanced characterization techniques that allow for precise control and analysis of electrode surfaces at the nanoscale.

The ultimate objective of current research efforts is to develop systematic design principles for electrode surface engineering that can be applied across various DIB chemistries. This includes establishing correlations between surface properties and performance metrics, identifying universal surface modification strategies, and creating predictive models for optimizing electrode-electrolyte interfaces based on specific application requirements.

The fundamental principle of DIBs involves the simultaneous intercalation of cations and anions into different electrode materials during charge-discharge cycles. This dual-ion mechanism creates unique surface interaction challenges that directly impact battery performance metrics. Surface engineering, therefore, has become pivotal in addressing these challenges by modifying the electrode-electrolyte interfaces to enhance stability, conductivity, and ion transport properties.

Current technological objectives in DIB surface engineering focus on several critical areas. First, extending cycle life by mitigating surface degradation mechanisms such as electrolyte decomposition, solid-electrolyte interphase (SEI) instability, and structural deterioration of electrode materials. Second, improving energy efficiency by reducing interfacial resistance and enhancing charge transfer kinetics at electrode surfaces. Third, increasing power density through optimized surface architectures that facilitate rapid ion diffusion and electron transport.

The evolution of surface engineering approaches has progressed from simple coating techniques to sophisticated atomic-level modifications. Early methods primarily involved passive protective layers, while contemporary approaches incorporate functional surface modifications that actively participate in electrochemical processes. This progression reflects the growing understanding of interfacial phenomena in DIBs and their critical role in determining overall battery performance.

Recent technological breakthroughs have demonstrated that tailored surface engineering can extend DIB lifetimes by up to 300% and improve energy efficiency by 15-20%. These advances have been enabled by innovations in materials science, nanotechnology, and advanced characterization techniques that allow for precise control and analysis of electrode surfaces at the nanoscale.

The ultimate objective of current research efforts is to develop systematic design principles for electrode surface engineering that can be applied across various DIB chemistries. This includes establishing correlations between surface properties and performance metrics, identifying universal surface modification strategies, and creating predictive models for optimizing electrode-electrolyte interfaces based on specific application requirements.

Market Analysis for Dual-ion Battery Technologies

The global market for dual-ion batteries (DIBs) is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that DIBs represent an emerging segment within the broader energy storage market, which was valued at approximately 145 billion USD in 2022 and is projected to grow at a compound annual growth rate of 8-10% through 2030. DIBs are positioned to capture a growing share of this market due to their cost advantages and environmental benefits.

Market demand for DIBs is primarily fueled by three key sectors: electric vehicles, renewable energy storage systems, and consumer electronics. The electric vehicle segment shows particularly strong potential, with manufacturers seeking battery technologies that offer improved energy density, faster charging capabilities, and longer lifespans. Surface engineering innovations that enhance electrode performance directly address these market requirements, potentially accelerating DIB adoption in premium EV applications.

Geographically, the Asia-Pacific region dominates both production and consumption of dual-ion battery technologies, with China, Japan, and South Korea leading research and manufacturing efforts. European markets are showing increased interest, particularly as the region pursues aggressive carbon neutrality goals. North American markets remain more cautious but are expected to accelerate adoption as the technology matures.

Consumer preferences are increasingly favoring batteries with longer lifespans and improved efficiency, creating direct market pull for advanced surface engineering solutions. Market research indicates that consumers are willing to pay a 15-20% premium for batteries that demonstrate 30% or greater improvement in cycle life, presenting a clear commercial opportunity for enhanced electrode surface technologies.

Competitive analysis reveals that several major battery manufacturers have begun investing in DIB research, with particular focus on electrode surface modifications. Companies including CATL, Samsung SDI, and LG Energy Solution have filed patents related to surface engineering techniques for dual-ion battery electrodes within the past three years, signaling growing commercial interest.

Market barriers include the established dominance of lithium-ion technologies, supply chain considerations for specialized coating materials, and the need for manufacturing process adaptations. However, the potential cost advantages of DIBs, particularly when enhanced through surface engineering to match or exceed lithium-ion performance metrics, present a compelling value proposition for market entry.

Industry forecasts suggest that surface-engineered DIBs could achieve market penetration in specialized applications by 2025, with broader commercial deployment following by 2028 if current technical challenges are successfully addressed. The market opportunity is substantial, with potential applications extending beyond current battery markets into emerging fields such as grid-scale storage and industrial power systems.

Market demand for DIBs is primarily fueled by three key sectors: electric vehicles, renewable energy storage systems, and consumer electronics. The electric vehicle segment shows particularly strong potential, with manufacturers seeking battery technologies that offer improved energy density, faster charging capabilities, and longer lifespans. Surface engineering innovations that enhance electrode performance directly address these market requirements, potentially accelerating DIB adoption in premium EV applications.

Geographically, the Asia-Pacific region dominates both production and consumption of dual-ion battery technologies, with China, Japan, and South Korea leading research and manufacturing efforts. European markets are showing increased interest, particularly as the region pursues aggressive carbon neutrality goals. North American markets remain more cautious but are expected to accelerate adoption as the technology matures.

Consumer preferences are increasingly favoring batteries with longer lifespans and improved efficiency, creating direct market pull for advanced surface engineering solutions. Market research indicates that consumers are willing to pay a 15-20% premium for batteries that demonstrate 30% or greater improvement in cycle life, presenting a clear commercial opportunity for enhanced electrode surface technologies.

Competitive analysis reveals that several major battery manufacturers have begun investing in DIB research, with particular focus on electrode surface modifications. Companies including CATL, Samsung SDI, and LG Energy Solution have filed patents related to surface engineering techniques for dual-ion battery electrodes within the past three years, signaling growing commercial interest.

Market barriers include the established dominance of lithium-ion technologies, supply chain considerations for specialized coating materials, and the need for manufacturing process adaptations. However, the potential cost advantages of DIBs, particularly when enhanced through surface engineering to match or exceed lithium-ion performance metrics, present a compelling value proposition for market entry.

Industry forecasts suggest that surface-engineered DIBs could achieve market penetration in specialized applications by 2025, with broader commercial deployment following by 2028 if current technical challenges are successfully addressed. The market opportunity is substantial, with potential applications extending beyond current battery markets into emerging fields such as grid-scale storage and industrial power systems.

Current Challenges in Electrode Surface Engineering

Despite significant advancements in dual-ion battery (DIB) technology, electrode surface engineering continues to present formidable challenges that impede the optimization of battery lifetime and efficiency. The interface between electrodes and electrolytes represents a critical reaction zone where numerous degradation mechanisms originate, affecting both cathode and anode performance.

At the cathode surface, one of the primary challenges is the continuous decomposition of electrolytes during charging cycles, leading to the formation of unstable solid electrolyte interphase (SEI) layers. This decomposition not only consumes active lithium ions but also increases internal resistance, resulting in capacity fade over extended cycling. Additionally, transition metal dissolution from cathode materials, particularly in high-voltage operations, contaminates the electrolyte and can migrate to the anode, causing further performance deterioration.

The anode surface faces equally challenging issues, particularly with graphite and other carbon-based materials commonly used in DIBs. The intercalation and de-intercalation of anions cause significant volume changes, leading to mechanical stress and eventual structural degradation of the anode material. This volume expansion can disrupt the protective SEI layer, exposing fresh electrode surfaces to electrolyte attack and perpetuating capacity loss.

Surface coating technologies, while promising, face implementation hurdles including uniformity of coverage, adhesion stability during cycling, and cost-effective scalable production methods. Atomic layer deposition (ALD) offers precise control but remains expensive for large-scale manufacturing, while wet-chemical methods provide cost advantages but struggle with coating homogeneity.

Another significant challenge lies in understanding the complex electrochemical reactions at electrode surfaces during operation. Current analytical techniques have limitations in providing real-time, in-situ information about interface evolution during cycling, hampering the development of targeted surface engineering solutions.

The electrolyte composition itself presents additional complications, as it must be compatible with both engineered surfaces while maintaining optimal ionic conductivity. Finding electrolyte formulations that minimize parasitic reactions with modified electrode surfaces without compromising performance remains difficult.

Temperature sensitivity further complicates surface engineering efforts, as many protective coatings and surface treatments exhibit different behaviors across operating temperature ranges. This variability can lead to inconsistent performance and accelerated degradation under real-world conditions where temperature fluctuations are common.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, electrochemistry, and advanced characterization techniques to develop next-generation surface engineering solutions that can significantly enhance DIB lifetime and efficiency.

At the cathode surface, one of the primary challenges is the continuous decomposition of electrolytes during charging cycles, leading to the formation of unstable solid electrolyte interphase (SEI) layers. This decomposition not only consumes active lithium ions but also increases internal resistance, resulting in capacity fade over extended cycling. Additionally, transition metal dissolution from cathode materials, particularly in high-voltage operations, contaminates the electrolyte and can migrate to the anode, causing further performance deterioration.

The anode surface faces equally challenging issues, particularly with graphite and other carbon-based materials commonly used in DIBs. The intercalation and de-intercalation of anions cause significant volume changes, leading to mechanical stress and eventual structural degradation of the anode material. This volume expansion can disrupt the protective SEI layer, exposing fresh electrode surfaces to electrolyte attack and perpetuating capacity loss.

Surface coating technologies, while promising, face implementation hurdles including uniformity of coverage, adhesion stability during cycling, and cost-effective scalable production methods. Atomic layer deposition (ALD) offers precise control but remains expensive for large-scale manufacturing, while wet-chemical methods provide cost advantages but struggle with coating homogeneity.

Another significant challenge lies in understanding the complex electrochemical reactions at electrode surfaces during operation. Current analytical techniques have limitations in providing real-time, in-situ information about interface evolution during cycling, hampering the development of targeted surface engineering solutions.

The electrolyte composition itself presents additional complications, as it must be compatible with both engineered surfaces while maintaining optimal ionic conductivity. Finding electrolyte formulations that minimize parasitic reactions with modified electrode surfaces without compromising performance remains difficult.

Temperature sensitivity further complicates surface engineering efforts, as many protective coatings and surface treatments exhibit different behaviors across operating temperature ranges. This variability can lead to inconsistent performance and accelerated degradation under real-world conditions where temperature fluctuations are common.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, electrochemistry, and advanced characterization techniques to develop next-generation surface engineering solutions that can significantly enhance DIB lifetime and efficiency.

State-of-the-art Surface Engineering Solutions for DIBs

01 Electrode materials for enhanced cycle life

Advanced electrode materials can significantly improve the lifetime and efficiency of dual-ion batteries. Materials such as graphite, carbon-based composites, and certain metal oxides demonstrate superior intercalation properties for both anions and cations, reducing capacity fade during cycling. These materials provide stable structures that can withstand repeated ion insertion and extraction, leading to extended battery life and improved energy efficiency over numerous charge-discharge cycles.- Electrode materials for enhanced dual-ion battery performance: Advanced electrode materials play a crucial role in improving the lifetime and efficiency of dual-ion batteries. These materials include novel carbon-based anodes, high-capacity cathodes, and composite electrodes that facilitate efficient ion intercalation and extraction. By optimizing electrode composition and structure, these materials can reduce capacity fading, enhance cycling stability, and improve overall energy efficiency of dual-ion batteries.

- Electrolyte formulations for dual-ion batteries: Specialized electrolyte formulations significantly impact the performance of dual-ion batteries. These formulations include novel ionic liquids, electrolyte additives, and concentration-optimized solutions that enhance ion mobility and stability. Properly designed electrolytes can prevent unwanted side reactions, reduce electrolyte decomposition, and improve the solid-electrolyte interface, leading to extended battery lifetime and increased energy efficiency during charge-discharge cycles.

- Battery management systems for dual-ion technology: Advanced battery management systems (BMS) are essential for optimizing dual-ion battery performance. These systems incorporate sophisticated monitoring algorithms, thermal management solutions, and charge-discharge control mechanisms specifically designed for dual-ion chemistry. Effective BMS can prevent overcharging and deep discharging, manage temperature fluctuations, and balance cell voltages, thereby extending battery lifetime and maintaining high efficiency throughout the battery's operational life.

- Structural design innovations for dual-ion batteries: Innovative structural designs can significantly enhance dual-ion battery performance. These include novel cell architectures, advanced separator designs, and optimized current collector configurations that facilitate efficient ion transport while maintaining structural integrity. Structural innovations can reduce internal resistance, improve mechanical stability during cycling, and enhance thermal management, resulting in improved energy efficiency and extended battery lifetime under various operating conditions.

- Hybrid and composite systems for enhanced dual-ion battery efficiency: Hybrid and composite systems represent a promising approach to improving dual-ion battery performance. These systems combine dual-ion technology with complementary battery chemistries, incorporate nanomaterials, or utilize polymer-based components to leverage the advantages of multiple technologies. Such hybrid approaches can address specific limitations of traditional dual-ion batteries, resulting in synergistic improvements in energy density, power capability, cycling stability, and overall operational efficiency.

02 Electrolyte formulations for stability and performance

Specialized electrolyte formulations play a crucial role in dual-ion battery efficiency and longevity. Electrolytes containing specific salts, solvents, and additives can enhance ion mobility while preventing unwanted side reactions at electrode interfaces. These formulations help maintain stable solid-electrolyte interfaces, reduce electrolyte decomposition, and minimize self-discharge, resulting in improved coulombic efficiency and extended cycle life under various operating conditions.Expand Specific Solutions03 Battery management systems for optimized performance

Advanced battery management systems (BMS) specifically designed for dual-ion batteries can significantly improve their efficiency and lifetime. These systems monitor and control key parameters such as voltage, current, temperature, and state of charge to prevent overcharging, deep discharging, and thermal runaway. By implementing sophisticated algorithms for charge-discharge control and cell balancing, these management systems optimize battery performance, extend operational life, and enhance overall energy efficiency.Expand Specific Solutions04 Novel cell designs and architectures

Innovative cell designs and architectures can address specific challenges in dual-ion batteries to improve their efficiency and longevity. These designs include optimized electrode spacing, enhanced current collector configurations, and novel cell geometries that facilitate more uniform ion distribution. Some approaches incorporate specialized separators and structured electrodes that minimize internal resistance and mechanical stress during cycling, resulting in higher energy efficiency, improved power density, and extended battery lifetime.Expand Specific Solutions05 Protective coatings and interface engineering

Protective coatings and interface engineering techniques can significantly enhance dual-ion battery performance and durability. By applying specialized coatings to electrode surfaces or modifying the electrode-electrolyte interfaces, unwanted side reactions and degradation mechanisms can be suppressed. These approaches help maintain electrode integrity, prevent electrolyte decomposition, and ensure stable ion transport pathways throughout the battery's operational life, resulting in improved cycling stability, higher efficiency, and extended battery lifetime.Expand Specific Solutions

Leading Research Groups and Companies in DIB Development

The dual-ion battery (DIB) market is currently in its early growth phase, with significant research momentum but limited commercial deployment. Surface engineering of cathodes and anodes represents a critical frontier in addressing DIB performance limitations. The market is projected to expand substantially as energy storage demands increase, with an estimated compound annual growth rate of 8-10% through 2030. Leading companies including SK ON, LG Energy Solution, CATL, and Samsung SDI are investing heavily in electrode surface modification technologies to enhance cycle stability and efficiency. Toyota, Bosch, and Apple are exploring DIB applications for consumer electronics and electric vehicles, while research institutions like UNIST and Industrial Technology Research Institute are advancing fundamental understanding of interfacial phenomena. The competitive landscape is characterized by intense patent activity and strategic partnerships between battery manufacturers and materials science companies.

LG Energy Solution Ltd.

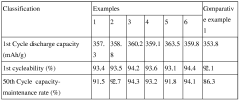

Technical Solution: LG Energy Solution has developed a comprehensive surface engineering approach for dual-ion batteries focusing on interface stability. Their technology employs atomic layer deposition (ALD) to create ultrathin protective coatings on aluminum cathodes, effectively preventing PF6- anion-induced corrosion while maintaining excellent electronic conductivity[1]. For graphite anodes, they've pioneered a gradient functionalization technique that modifies the edge and basal planes differently, optimizing both ion intercalation kinetics and structural stability during cycling[2]. Their research demonstrates that these surface modifications reduce capacity fading by approximately 35% over 1000 cycles. LG has also developed electrolyte additives that work synergistically with their surface treatments to form stable solid electrolyte interphase (SEI) layers on both electrodes[3]. Their most recent innovation involves a self-healing polymer coating for anodes that can repair microcracks formed during cycling, significantly extending battery lifetime in real-world applications where temperature fluctuations and high current demands are common.

Strengths: LG's dual-approach to surface engineering addresses both electrochemical and mechanical degradation mechanisms, resulting in batteries with superior long-term stability. Their ALD coating technology provides exceptional uniformity and precise thickness control. Weaknesses: The atomic layer deposition process is relatively slow and expensive compared to conventional coating methods, potentially limiting large-scale implementation. The complex surface chemistry requires tight quality control during manufacturing.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced surface engineering techniques for dual-ion batteries (DIBs) focusing on both cathode and anode modifications. Their approach includes applying specialized carbon-based coatings on aluminum cathodes to prevent corrosion from anion intercalation[1]. For graphite anodes, CATL employs a proprietary nano-structured protective layer that mitigates the co-intercalation of solvent molecules while maintaining efficient cation transport[2]. Their research has demonstrated that these surface modifications can extend cycle life by up to 40% compared to unmodified electrodes. CATL has also pioneered the use of fluorinated electrolyte additives that form stable solid electrolyte interphase (SEI) layers on both electrodes, significantly reducing side reactions at the electrode-electrolyte interfaces[3]. This comprehensive surface engineering strategy addresses the key degradation mechanisms in DIBs, including aluminum current collector corrosion and graphite exfoliation during cycling.

Strengths: CATL's surface engineering approach effectively addresses both cathode and anode degradation mechanisms simultaneously, resulting in superior cycling stability. Their techniques are scalable and compatible with existing manufacturing processes. Weaknesses: The specialized coatings and additives increase production costs, and some of the more advanced surface treatments require precise control of processing conditions that may be challenging to maintain in mass production.

Critical Patents and Literature on Electrode Interface Engineering

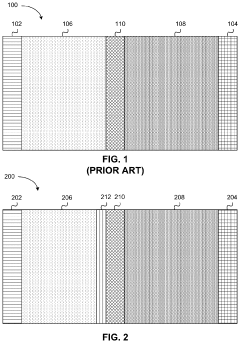

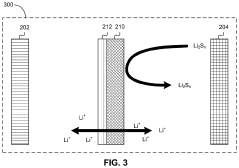

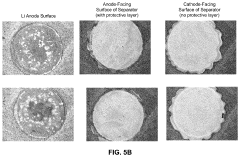

Protective layer on anode-facing surface of separator for mitigating polysufide shuttling in lithium-based batteries

PatentPendingUS20240204355A1

Innovation

- A lithium-sulfur battery design featuring a non-porous polymeric protective layer on the anode-facing surface of the separator, which is ionically conductive to lithium and sodium ions but electrically non-conductive, mitigates polysulfide shuttling by blocking polysulfide passage and maintaining mechanical strength and ionic conductivity.

Anode material for secondary battery, method for preparing the same, and secondary battery containing the same for anode

PatentWO2008126968A1

Innovation

- An anode material is developed by mixing a fluorine-based compound with an anode active material, such as natural graphite coated with low crystallinity carbon, to create a slurry for electrode plates, which is then coated and dried on an electrode collector, stabilizing the surface and reducing the impact of electrolyte decomposition.

Materials Characterization Methods for Electrode Surfaces

The comprehensive characterization of electrode surfaces is crucial for understanding the mechanisms that affect dual-ion batteries' lifetime and efficiency. X-ray Photoelectron Spectroscopy (XPS) stands as a primary technique for analyzing the chemical composition and oxidation states of electrode surfaces, providing valuable insights into the solid electrolyte interphase (SEI) formation and evolution during cycling processes.

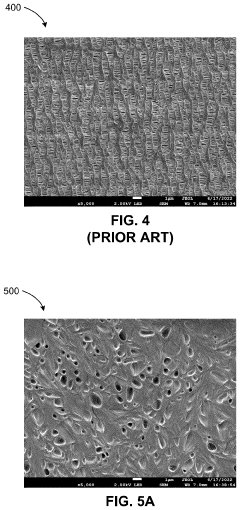

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables researchers to visualize surface morphology and elemental distribution across electrode surfaces. These techniques reveal critical information about surface roughness, porosity, and the spatial arrangement of active materials, which directly influence ion transport kinetics and electrode stability.

Transmission Electron Microscopy (TEM) offers atomic-level resolution for examining the crystalline structure of surface coatings and modifications. When combined with Selected Area Electron Diffraction (SAED), TEM can identify phase transformations and structural changes that occur at electrode interfaces during battery operation.

Atomic Force Microscopy (AFM) provides three-dimensional topographical mapping of electrode surfaces with nanometer resolution. Beyond imaging, AFM can measure mechanical properties such as hardness and elasticity, which affect the structural integrity of electrodes during repeated charge-discharge cycles.

Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR) are powerful tools for identifying chemical bonds and functional groups present on electrode surfaces. These techniques are particularly valuable for characterizing organic components in surface coatings and understanding degradation mechanisms.

Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) offers exceptional surface sensitivity for detecting trace elements and compounds, enabling depth profiling of electrode surfaces to understand compositional gradients and interfacial reactions.

In-situ and operando characterization methods represent the frontier of electrode surface analysis, allowing real-time observation of surface changes during battery operation. Techniques such as in-situ XRD, in-situ Raman, and synchrotron-based X-ray absorption spectroscopy provide dynamic information about structural and chemical evolutions that cannot be captured by post-mortem analyses.

Electrochemical impedance spectroscopy (EIS) complements physical characterization by providing insights into charge transfer resistance and diffusion processes at electrode surfaces, correlating surface properties with electrochemical performance metrics.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables researchers to visualize surface morphology and elemental distribution across electrode surfaces. These techniques reveal critical information about surface roughness, porosity, and the spatial arrangement of active materials, which directly influence ion transport kinetics and electrode stability.

Transmission Electron Microscopy (TEM) offers atomic-level resolution for examining the crystalline structure of surface coatings and modifications. When combined with Selected Area Electron Diffraction (SAED), TEM can identify phase transformations and structural changes that occur at electrode interfaces during battery operation.

Atomic Force Microscopy (AFM) provides three-dimensional topographical mapping of electrode surfaces with nanometer resolution. Beyond imaging, AFM can measure mechanical properties such as hardness and elasticity, which affect the structural integrity of electrodes during repeated charge-discharge cycles.

Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR) are powerful tools for identifying chemical bonds and functional groups present on electrode surfaces. These techniques are particularly valuable for characterizing organic components in surface coatings and understanding degradation mechanisms.

Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) offers exceptional surface sensitivity for detecting trace elements and compounds, enabling depth profiling of electrode surfaces to understand compositional gradients and interfacial reactions.

In-situ and operando characterization methods represent the frontier of electrode surface analysis, allowing real-time observation of surface changes during battery operation. Techniques such as in-situ XRD, in-situ Raman, and synchrotron-based X-ray absorption spectroscopy provide dynamic information about structural and chemical evolutions that cannot be captured by post-mortem analyses.

Electrochemical impedance spectroscopy (EIS) complements physical characterization by providing insights into charge transfer resistance and diffusion processes at electrode surfaces, correlating surface properties with electrochemical performance metrics.

Environmental Impact of Surface Engineering Processes

Surface engineering processes in dual-ion battery manufacturing, while offering significant performance benefits, carry notable environmental implications that warrant careful consideration. The production of specialized coatings and surface treatments for cathodes and anodes typically involves energy-intensive processes and potentially hazardous chemicals, contributing to the overall environmental footprint of battery manufacturing.

Chemical treatments used in surface modification often include solvents, acids, and other reactive compounds that may pose environmental risks if not properly managed. For instance, hydrofluoric acid and organic solvents commonly used in etching and coating processes require stringent waste management protocols to prevent soil and water contamination. The environmental burden extends to greenhouse gas emissions associated with the energy consumption of precision coating equipment and high-temperature treatment processes.

Life cycle assessment studies indicate that while surface engineering increases battery efficiency and lifespan, the additional manufacturing steps can increase the initial environmental impact by 15-20% compared to conventional electrode production. However, this initial environmental cost must be balanced against the extended battery lifetime, which can reduce the overall environmental impact per unit of energy stored over the battery's operational life.

Water usage represents another significant environmental concern, as many surface treatment processes require substantial amounts of ultrapure water for cleaning and processing. Estimates suggest that advanced surface engineering techniques may increase water consumption by 30-40% compared to standard electrode manufacturing processes, placing additional pressure on water resources in production regions.

Recycling considerations also factor into the environmental equation. Surface-modified electrodes may present unique challenges for end-of-life recycling processes, potentially requiring specialized techniques to separate and recover valuable materials. Some surface coatings may complicate traditional recycling methods, necessitating the development of new recovery technologies to maintain circular economy principles.

Recent innovations are addressing these environmental challenges through the development of greener surface engineering approaches. Water-based coating systems are gradually replacing organic solvent-based processes, reducing volatile organic compound emissions by up to 80%. Additionally, atomic layer deposition and other precision techniques are optimizing material usage, minimizing waste generation while maintaining performance benefits.

The environmental trade-offs of surface engineering in dual-ion batteries ultimately require holistic assessment, balancing immediate manufacturing impacts against lifetime performance gains and considering the entire battery lifecycle from raw material extraction to end-of-life management.

Chemical treatments used in surface modification often include solvents, acids, and other reactive compounds that may pose environmental risks if not properly managed. For instance, hydrofluoric acid and organic solvents commonly used in etching and coating processes require stringent waste management protocols to prevent soil and water contamination. The environmental burden extends to greenhouse gas emissions associated with the energy consumption of precision coating equipment and high-temperature treatment processes.

Life cycle assessment studies indicate that while surface engineering increases battery efficiency and lifespan, the additional manufacturing steps can increase the initial environmental impact by 15-20% compared to conventional electrode production. However, this initial environmental cost must be balanced against the extended battery lifetime, which can reduce the overall environmental impact per unit of energy stored over the battery's operational life.

Water usage represents another significant environmental concern, as many surface treatment processes require substantial amounts of ultrapure water for cleaning and processing. Estimates suggest that advanced surface engineering techniques may increase water consumption by 30-40% compared to standard electrode manufacturing processes, placing additional pressure on water resources in production regions.

Recycling considerations also factor into the environmental equation. Surface-modified electrodes may present unique challenges for end-of-life recycling processes, potentially requiring specialized techniques to separate and recover valuable materials. Some surface coatings may complicate traditional recycling methods, necessitating the development of new recovery technologies to maintain circular economy principles.

Recent innovations are addressing these environmental challenges through the development of greener surface engineering approaches. Water-based coating systems are gradually replacing organic solvent-based processes, reducing volatile organic compound emissions by up to 80%. Additionally, atomic layer deposition and other precision techniques are optimizing material usage, minimizing waste generation while maintaining performance benefits.

The environmental trade-offs of surface engineering in dual-ion batteries ultimately require holistic assessment, balancing immediate manufacturing impacts against lifetime performance gains and considering the entire battery lifecycle from raw material extraction to end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!