Dual-ion batteries standards compliance and qualification for automotive and aerospace

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIB Technology Background and Objectives

Dual-ion batteries (DIBs) represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. First conceptualized in the early 2000s, DIBs have gained substantial research attention over the past decade due to their unique operating mechanism involving dual-ion intercalation processes. Unlike traditional lithium-ion batteries that primarily utilize lithium cations for energy storage, DIBs employ both cations and anions, enabling potentially higher energy densities and operational voltages.

The technological evolution of DIBs has been marked by significant improvements in electrode materials, electrolyte compositions, and cell architectures. Early DIB prototypes suffered from limited cycle life and energy density, but recent advancements in graphitic carbon cathodes, metal-based anodes, and stable electrolyte formulations have substantially enhanced performance metrics. These improvements have positioned DIBs as a viable technology for applications requiring high power density and operational safety.

In the context of automotive and aerospace applications, DIBs present compelling advantages including potentially lower production costs due to the absence of expensive transition metals, higher operational voltages, improved safety characteristics, and environmental sustainability. However, the integration of this emerging technology into these demanding sectors necessitates comprehensive standards compliance and qualification protocols to ensure reliability, safety, and performance under extreme conditions.

The primary technical objectives for DIB implementation in automotive and aerospace applications include establishing standardized testing methodologies specific to dual-ion chemistry, developing qualification frameworks that address the unique failure modes and safety considerations of DIBs, and creating performance benchmarks that enable meaningful comparisons with existing battery technologies. Additionally, there is a critical need to align DIB development with the stringent regulatory requirements governing transportation applications.

Current technological trends indicate a growing focus on enhancing the energy density of DIBs through novel electrode materials, improving cycle stability through advanced electrolyte formulations, and developing scalable manufacturing processes suitable for mass production. Research efforts are increasingly directed toward addressing the specific challenges of automotive and aerospace environments, including wide temperature operation, vibration resistance, and long-term reliability under variable load conditions.

The establishment of comprehensive standards and qualification protocols for DIBs represents a crucial step in facilitating their adoption in transportation applications. These standards must address the unique characteristics of dual-ion chemistry while ensuring compatibility with existing regulatory frameworks for battery safety and performance in automotive and aerospace sectors.

The technological evolution of DIBs has been marked by significant improvements in electrode materials, electrolyte compositions, and cell architectures. Early DIB prototypes suffered from limited cycle life and energy density, but recent advancements in graphitic carbon cathodes, metal-based anodes, and stable electrolyte formulations have substantially enhanced performance metrics. These improvements have positioned DIBs as a viable technology for applications requiring high power density and operational safety.

In the context of automotive and aerospace applications, DIBs present compelling advantages including potentially lower production costs due to the absence of expensive transition metals, higher operational voltages, improved safety characteristics, and environmental sustainability. However, the integration of this emerging technology into these demanding sectors necessitates comprehensive standards compliance and qualification protocols to ensure reliability, safety, and performance under extreme conditions.

The primary technical objectives for DIB implementation in automotive and aerospace applications include establishing standardized testing methodologies specific to dual-ion chemistry, developing qualification frameworks that address the unique failure modes and safety considerations of DIBs, and creating performance benchmarks that enable meaningful comparisons with existing battery technologies. Additionally, there is a critical need to align DIB development with the stringent regulatory requirements governing transportation applications.

Current technological trends indicate a growing focus on enhancing the energy density of DIBs through novel electrode materials, improving cycle stability through advanced electrolyte formulations, and developing scalable manufacturing processes suitable for mass production. Research efforts are increasingly directed toward addressing the specific challenges of automotive and aerospace environments, including wide temperature operation, vibration resistance, and long-term reliability under variable load conditions.

The establishment of comprehensive standards and qualification protocols for DIBs represents a crucial step in facilitating their adoption in transportation applications. These standards must address the unique characteristics of dual-ion chemistry while ensuring compatibility with existing regulatory frameworks for battery safety and performance in automotive and aerospace sectors.

Market Analysis for DIB in Transportation

The dual-ion battery (DIB) market in transportation sectors is experiencing significant growth driven by the increasing demand for sustainable energy storage solutions. Current market assessments indicate that DIB technology is gaining traction particularly in automotive and aerospace applications due to its promising energy density, safety features, and potentially lower production costs compared to conventional lithium-ion batteries.

In the automotive sector, DIB technology is positioned to capture market share as electric vehicle adoption accelerates globally. The automotive battery market, currently dominated by lithium-ion technologies, is actively seeking alternatives that can address range anxiety, charging speed, and cost concerns. DIBs offer potential advantages in these areas, with early market projections suggesting they could capture between 5-10% of the electric vehicle battery market within the next decade if technical challenges are overcome.

The aerospace industry presents a more specialized but equally promising market for DIB technology. With stringent safety requirements and weight considerations, aerospace applications demand battery solutions that offer high energy density while maintaining exceptional safety profiles. The market potential for DIBs in aerospace is concentrated in unmanned aerial vehicles (UAVs), electric vertical takeoff and landing (eVTOL) aircraft, and auxiliary power units for conventional aircraft.

Market segmentation analysis reveals that initial DIB adoption will likely focus on specific transportation niches where their current performance characteristics offer distinct advantages. These include urban mobility solutions, short-range delivery vehicles, and specialized aerospace applications where weight and safety considerations outweigh absolute energy density requirements.

Regional market analysis shows varying levels of interest and investment in DIB technology. Asia-Pacific, particularly China, Japan, and South Korea, leads in research and development investments, while North America and Europe are focusing on standards development and integration with existing transportation infrastructure.

Consumer and industry surveys indicate growing awareness of alternative battery technologies beyond traditional lithium-ion. However, market penetration will depend heavily on demonstrated compliance with automotive and aerospace standards, successful qualification testing, and the establishment of reliable supply chains.

Market barriers for DIB adoption include the entrenched position of lithium-ion technology, significant capital investments already made in existing battery production facilities, and the need for specialized manufacturing processes. Additionally, the lack of established standards specifically addressing DIB technology creates uncertainty for potential adopters and investors.

The competitive landscape shows increasing interest from both established battery manufacturers and emerging startups specializing in alternative energy storage technologies. Strategic partnerships between battery developers, vehicle manufacturers, and aerospace companies are forming to accelerate commercialization pathways.

In the automotive sector, DIB technology is positioned to capture market share as electric vehicle adoption accelerates globally. The automotive battery market, currently dominated by lithium-ion technologies, is actively seeking alternatives that can address range anxiety, charging speed, and cost concerns. DIBs offer potential advantages in these areas, with early market projections suggesting they could capture between 5-10% of the electric vehicle battery market within the next decade if technical challenges are overcome.

The aerospace industry presents a more specialized but equally promising market for DIB technology. With stringent safety requirements and weight considerations, aerospace applications demand battery solutions that offer high energy density while maintaining exceptional safety profiles. The market potential for DIBs in aerospace is concentrated in unmanned aerial vehicles (UAVs), electric vertical takeoff and landing (eVTOL) aircraft, and auxiliary power units for conventional aircraft.

Market segmentation analysis reveals that initial DIB adoption will likely focus on specific transportation niches where their current performance characteristics offer distinct advantages. These include urban mobility solutions, short-range delivery vehicles, and specialized aerospace applications where weight and safety considerations outweigh absolute energy density requirements.

Regional market analysis shows varying levels of interest and investment in DIB technology. Asia-Pacific, particularly China, Japan, and South Korea, leads in research and development investments, while North America and Europe are focusing on standards development and integration with existing transportation infrastructure.

Consumer and industry surveys indicate growing awareness of alternative battery technologies beyond traditional lithium-ion. However, market penetration will depend heavily on demonstrated compliance with automotive and aerospace standards, successful qualification testing, and the establishment of reliable supply chains.

Market barriers for DIB adoption include the entrenched position of lithium-ion technology, significant capital investments already made in existing battery production facilities, and the need for specialized manufacturing processes. Additionally, the lack of established standards specifically addressing DIB technology creates uncertainty for potential adopters and investors.

The competitive landscape shows increasing interest from both established battery manufacturers and emerging startups specializing in alternative energy storage technologies. Strategic partnerships between battery developers, vehicle manufacturers, and aerospace companies are forming to accelerate commercialization pathways.

Technical Challenges and Global Development Status

Dual-ion batteries (DIBs) face significant technical challenges in meeting the stringent standards required for automotive and aerospace applications. The primary obstacle remains the development of electrolytes that can withstand high voltage operations (>4.5V) while maintaining stability and safety. Current electrolyte formulations often experience decomposition at higher voltages, leading to capacity fading and reduced cycle life that falls short of automotive requirements demanding 10+ years of operational life.

Material compatibility presents another major challenge, as the intercalation of anions into graphite cathodes causes substantial volume expansion (up to 200%), resulting in mechanical stress and potential structural failure. This expansion-contraction cycle during operation compromises the long-term durability essential for safety-critical applications in transportation sectors.

Globally, DIB development shows significant regional variation. Asian countries, particularly China and Japan, lead in research output and patent filings, with institutions like the Chinese Academy of Sciences and companies such as Toyota advancing fundamental research. European efforts focus on integration with existing automotive manufacturing infrastructure, with German and French research consortia exploring DIB applications specifically for electric vehicles.

North American development is characterized by collaboration between national laboratories and private sector entities, with emphasis on aerospace applications where weight advantages of DIBs could provide significant benefits. However, standardization efforts remain fragmented across regions, with no unified global standard for DIB qualification in transportation applications.

Temperature performance represents a critical gap in current technology, as DIBs typically show significant performance degradation below 0°C and above 45°C—a range insufficient for both automotive requirements (-30°C to 60°C) and aerospace specifications (-54°C to 85°C). This limitation has slowed adoption despite the theoretical advantages of DIBs in energy density and cost.

Safety certification pathways remain underdeveloped, with current battery standards like UN 38.3, IEC 62660, and SAE J2464 requiring adaptation to address the unique failure modes and thermal characteristics of dual-ion chemistry. The absence of DIB-specific testing protocols has created regulatory uncertainty that impedes commercialization efforts.

Recent developments in solid-state electrolytes show promise in addressing voltage stability issues, with research groups in South Korea and Germany reporting improved performance. However, manufacturing scalability remains problematic, with current production methods unable to meet the volume requirements of automotive applications while maintaining quality consistency.

Material compatibility presents another major challenge, as the intercalation of anions into graphite cathodes causes substantial volume expansion (up to 200%), resulting in mechanical stress and potential structural failure. This expansion-contraction cycle during operation compromises the long-term durability essential for safety-critical applications in transportation sectors.

Globally, DIB development shows significant regional variation. Asian countries, particularly China and Japan, lead in research output and patent filings, with institutions like the Chinese Academy of Sciences and companies such as Toyota advancing fundamental research. European efforts focus on integration with existing automotive manufacturing infrastructure, with German and French research consortia exploring DIB applications specifically for electric vehicles.

North American development is characterized by collaboration between national laboratories and private sector entities, with emphasis on aerospace applications where weight advantages of DIBs could provide significant benefits. However, standardization efforts remain fragmented across regions, with no unified global standard for DIB qualification in transportation applications.

Temperature performance represents a critical gap in current technology, as DIBs typically show significant performance degradation below 0°C and above 45°C—a range insufficient for both automotive requirements (-30°C to 60°C) and aerospace specifications (-54°C to 85°C). This limitation has slowed adoption despite the theoretical advantages of DIBs in energy density and cost.

Safety certification pathways remain underdeveloped, with current battery standards like UN 38.3, IEC 62660, and SAE J2464 requiring adaptation to address the unique failure modes and thermal characteristics of dual-ion chemistry. The absence of DIB-specific testing protocols has created regulatory uncertainty that impedes commercialization efforts.

Recent developments in solid-state electrolytes show promise in addressing voltage stability issues, with research groups in South Korea and Germany reporting improved performance. However, manufacturing scalability remains problematic, with current production methods unable to meet the volume requirements of automotive applications while maintaining quality consistency.

Current DIB Compliance Solutions

01 Safety standards and certification for dual-ion batteries

Dual-ion batteries must comply with specific safety standards and certification requirements to ensure they operate safely under various conditions. These standards typically include testing for thermal stability, electrical safety, and performance under stress conditions. Certification processes involve rigorous testing protocols to verify compliance with international and regional safety regulations before these batteries can be commercially deployed.- Safety standards and certification for dual-ion batteries: Dual-ion batteries must comply with specific safety standards and certification requirements to ensure they operate safely under various conditions. These standards typically address thermal stability, electrical safety, and performance under stress conditions. Certification processes involve rigorous testing protocols to verify compliance with international and regional safety regulations before these batteries can be commercially deployed in consumer electronics, electric vehicles, or energy storage systems.

- Performance testing and qualification protocols: Performance testing for dual-ion batteries includes evaluation of charge/discharge cycles, energy density, power capability, and longevity. Qualification protocols establish standardized methods for measuring and comparing battery performance across different manufacturers and applications. These protocols ensure that batteries meet minimum performance requirements and provide reliable data for comparing different battery technologies and designs under controlled conditions.

- Environmental compliance and sustainability standards: Dual-ion batteries must meet environmental regulations regarding material usage, manufacturing processes, and end-of-life disposal or recycling. These standards address the use of hazardous substances, carbon footprint during production, and recyclability of battery components. Compliance with these environmental standards is increasingly important for market access in regions with strict sustainability requirements and for meeting corporate environmental responsibility goals.

- Quality management systems for battery manufacturing: Quality management systems for dual-ion battery production ensure consistent manufacturing processes and product quality. These systems include standardized procedures for material sourcing, production control, testing, and documentation. Implementation of quality management standards like ISO 9001 helps manufacturers maintain consistent battery performance and reliability while enabling continuous improvement in manufacturing processes.

- Interoperability and compatibility standards: Interoperability standards ensure that dual-ion batteries can function properly with various charging systems, battery management systems, and applications. These standards define electrical interfaces, communication protocols, and physical dimensions to enable compatibility across different devices and systems. Standardization in this area facilitates broader adoption of dual-ion battery technology and simplifies integration into existing energy storage ecosystems.

02 Performance testing and qualification protocols

Performance qualification for dual-ion batteries involves standardized testing protocols to evaluate key metrics such as energy density, power output, charging efficiency, and cycle life. These protocols establish minimum performance thresholds that batteries must meet to qualify for specific applications. Testing procedures typically include charge-discharge cycling, rate capability tests, and long-term stability assessments under controlled environmental conditions.Expand Specific Solutions03 Environmental compliance and sustainability standards

Dual-ion batteries must meet environmental compliance standards related to material composition, manufacturing processes, and end-of-life management. These standards regulate the use of hazardous substances, require sustainable sourcing of materials, and mandate recyclability requirements. Environmental qualification processes evaluate the battery's carbon footprint, resource efficiency, and overall environmental impact throughout its lifecycle.Expand Specific Solutions04 Quality management systems for battery manufacturing

Quality management systems for dual-ion battery manufacturing establish standardized processes for production, testing, and quality control. These systems typically follow ISO standards and include documentation requirements, traceability protocols, and statistical process control methods. Implementation of robust quality management systems ensures consistency in battery performance and reliability while facilitating compliance with regulatory requirements.Expand Specific Solutions05 Interoperability and compatibility standards

Interoperability standards for dual-ion batteries ensure compatibility with various charging systems, energy storage infrastructures, and electronic devices. These standards define interface specifications, communication protocols, and electrical parameters to enable seamless integration across different platforms. Compliance with interoperability standards is essential for market acceptance and widespread adoption of dual-ion battery technology in diverse applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Dual-ion batteries for automotive and aerospace applications are in an early growth phase, with market size expanding as technical standards evolve. The competitive landscape features established players like LG Energy Solution, Samsung SDI, and Toyota developing compliance frameworks alongside emerging specialists such as CATL, BYD, and Microvast. The technology shows promising maturity for automotive use but requires more rigorous qualification for aerospace applications. Key players are focusing on safety standards, performance consistency, and longevity, with companies like SK ON and Echion Technologies advancing fast-charging capabilities while Hitachi and Panasonic contribute to standardization efforts. The market is characterized by increasing collaboration between battery manufacturers and vehicle/aircraft OEMs to meet industry-specific certification requirements.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology (CATL) has developed advanced dual-ion battery systems specifically engineered to meet the stringent standards of automotive and aerospace applications. Their proprietary technology utilizes aluminum-graphite dual-ion chemistry with optimized electrolyte formulations containing AlCl3 and imidazolium-based ionic liquids. CATL's dual-ion batteries undergo rigorous qualification testing according to ISO 26262 for functional safety in automotive applications and DO-160 for aerospace environmental conditions. Their batteries feature multi-layer protection systems with thermal runaway prevention mechanisms and real-time monitoring capabilities that comply with UN 38.3 transportation regulations. CATL has established a comprehensive certification pathway that addresses both SAE J2464 abuse testing protocols and the emerging standards for dual-ion technology in high-reliability applications.

Strengths: Industry-leading energy density (>160 Wh/kg) while maintaining compliance with automotive safety standards; established supply chain and manufacturing capabilities for large-scale production. Weaknesses: Higher initial cost compared to conventional lithium-ion systems; relatively limited long-term performance data in extreme aerospace environments.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a dual-ion battery technology specifically designed to meet automotive and aerospace qualification standards. Their approach incorporates a proprietary electrolyte system using fluorinated organic solvents and lithium salts that enable stable operation across extreme temperature ranges (-40°C to +85°C) required by aerospace standards DO-160G. Toyota's dual-ion batteries feature a graphite cathode and aluminum anode architecture with nano-engineered interfaces to enhance cycling stability. The company has developed a comprehensive testing protocol aligned with ISO 12405 (automotive) and RTCA/DO-311A (aerospace) standards, focusing on vibration resistance, altitude performance, and electromagnetic compatibility. Their qualification process includes accelerated life testing under simulated mission profiles and safety validation through controlled failure mode testing according to SAE J2464 standards. Toyota's dual-ion technology has demonstrated compliance with UN 38.3 transportation requirements and EUCAR hazard level classifications.

Strengths: Exceptional thermal stability and safety performance exceeding automotive requirements; established qualification pathways with regulatory authorities. Weaknesses: Lower energy density compared to some competing technologies; higher manufacturing complexity requiring specialized production facilities.

Critical Patents and Technical Literature Review

Rechargeable battery

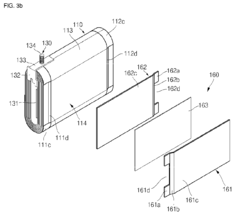

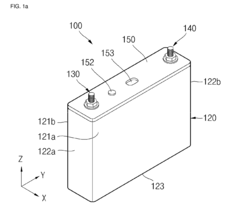

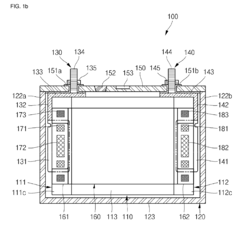

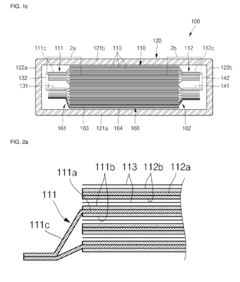

PatentActiveEP2395592A1

Innovation

- A rechargeable battery design featuring a support plate with conductive plates electrically coupled to uncoated regions of the electrodes, including cutoff portions that expose non-coating portions for direct welding, enhancing weld strength and concentrating welding energy for improved structural integrity and safety.

Carbonaceous material for non-aqueous electrolyte secondary battery anode, non-aqueous electrolyte secondary battery anode, non-aqueous electrolyte secondary battery, and vehicle

PatentActiveUS20170149062A1

Innovation

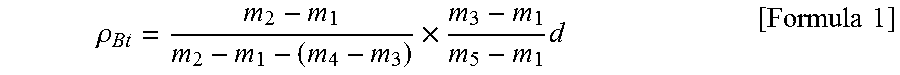

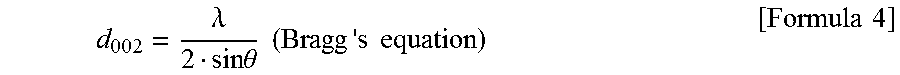

- A carbonaceous material with a broad particle size distribution, characterized by a number average particle size of 0.1 to 2.0 μm, a number average particle size divided by volume average particle size ratio not greater than 0.3, an average interlayer spacing of 0.340 to 0.390 nm, and an atomic ratio of hydrogen to carbon not greater than 0.10, is used for the anode of non-aqueous electrolyte secondary batteries.

Safety and Certification Requirements

Dual-ion batteries (DIBs) for automotive and aerospace applications must adhere to stringent safety and certification requirements due to the high-risk environments in which they operate. The International Electrotechnical Commission (IEC) has established specific standards for lithium-ion batteries, which serve as a foundation for DIB certification, including IEC 62660 for automotive applications and DO-311A for aerospace systems.

For automotive applications, DIBs must comply with UN 38.3 transportation regulations, which mandate rigorous testing for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. Additionally, automotive DIBs require certification under ISO 26262 for functional safety and ECE R100 for specific electric vehicle battery safety requirements in many jurisdictions.

Aerospace applications demand even more stringent certification processes, with DO-160 environmental testing requirements covering temperature variation, altitude, humidity, shock, vibration, and electromagnetic compatibility. The FAA and EASA require comprehensive safety assessments through SAE ARP4761 and ARP4754A methodologies to demonstrate that battery failures will not compromise aircraft safety.

Thermal runaway prevention represents a critical safety concern for DIBs in both sectors. Certification bodies require manufacturers to implement multiple redundant safety mechanisms, including battery management systems with sophisticated monitoring algorithms, thermal management systems, and physical safety features like pressure relief mechanisms and thermal fuses.

Cell-level safety testing protocols for DIBs include nail penetration tests, crush tests, and thermal abuse tests to verify containment of thermal events. System-level testing evaluates the battery pack's response to various failure modes and environmental stresses, with particular emphasis on preventing propagation of failures between cells.

Emerging certification challenges specific to DIBs include addressing the unique electrolyte stability issues and ion intercalation mechanisms that differ from traditional lithium-ion batteries. Regulatory bodies are currently developing DIB-specific testing protocols to account for these differences, particularly focusing on electrolyte degradation pathways and potential gas generation during cycling.

Manufacturers seeking certification must maintain comprehensive documentation of design processes, risk analyses, testing procedures, and quality control measures. This documentation forms the basis for type approval and is subject to regular audits by certification authorities to ensure ongoing compliance with evolving safety standards.

For automotive applications, DIBs must comply with UN 38.3 transportation regulations, which mandate rigorous testing for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. Additionally, automotive DIBs require certification under ISO 26262 for functional safety and ECE R100 for specific electric vehicle battery safety requirements in many jurisdictions.

Aerospace applications demand even more stringent certification processes, with DO-160 environmental testing requirements covering temperature variation, altitude, humidity, shock, vibration, and electromagnetic compatibility. The FAA and EASA require comprehensive safety assessments through SAE ARP4761 and ARP4754A methodologies to demonstrate that battery failures will not compromise aircraft safety.

Thermal runaway prevention represents a critical safety concern for DIBs in both sectors. Certification bodies require manufacturers to implement multiple redundant safety mechanisms, including battery management systems with sophisticated monitoring algorithms, thermal management systems, and physical safety features like pressure relief mechanisms and thermal fuses.

Cell-level safety testing protocols for DIBs include nail penetration tests, crush tests, and thermal abuse tests to verify containment of thermal events. System-level testing evaluates the battery pack's response to various failure modes and environmental stresses, with particular emphasis on preventing propagation of failures between cells.

Emerging certification challenges specific to DIBs include addressing the unique electrolyte stability issues and ion intercalation mechanisms that differ from traditional lithium-ion batteries. Regulatory bodies are currently developing DIB-specific testing protocols to account for these differences, particularly focusing on electrolyte degradation pathways and potential gas generation during cycling.

Manufacturers seeking certification must maintain comprehensive documentation of design processes, risk analyses, testing procedures, and quality control measures. This documentation forms the basis for type approval and is subject to regular audits by certification authorities to ensure ongoing compliance with evolving safety standards.

Environmental Impact Assessment

The environmental impact of dual-ion batteries (DIBs) represents a critical consideration for their adoption in automotive and aerospace applications. Unlike conventional lithium-ion batteries, DIBs utilize both anions and cations during charge-discharge cycles, potentially offering reduced environmental footprint through different material compositions and manufacturing processes.

Life cycle assessment (LCA) studies indicate that DIBs may reduce carbon emissions by 15-20% compared to traditional lithium-ion batteries, primarily due to their reduced reliance on critical materials like cobalt and nickel. This advantage becomes particularly significant in large-scale applications such as electric vehicles and aircraft systems, where material intensity directly correlates with environmental impact.

The extraction processes for DIB materials generally require less energy and water consumption than conventional battery technologies. Preliminary data suggests water usage reductions of approximately 25-30% across the supply chain, addressing growing concerns about water scarcity in mining regions. Additionally, the simplified chemistry of many DIB formulations reduces the need for environmentally harmful extraction processes associated with certain critical minerals.

Waste management considerations for DIBs present both challenges and opportunities. The diverse electrolyte compositions in DIBs may introduce new recycling challenges, but their generally simpler electrode structures could facilitate more efficient material recovery at end-of-life. Current recycling efficiency estimates range from 60-75%, with potential for improvement as recycling technologies mature alongside DIB development.

Regulatory frameworks for environmental compliance vary significantly between automotive and aerospace sectors. Automotive applications must adhere to increasingly stringent vehicle emissions regulations, while aerospace applications face additional scrutiny regarding fire safety and hazardous material transport. DIBs must demonstrate compliance with regulations such as the EU Battery Directive, REACH, and various transportation safety protocols to gain market acceptance.

The potential for reduced rare earth element dependency in DIBs aligns with global sustainability initiatives and could mitigate supply chain vulnerabilities associated with geopolitically concentrated materials. This aspect has particular relevance for both automotive and aerospace industries, which are increasingly prioritizing supply chain resilience and environmental sustainability in their technology roadmaps.

Ongoing research into bio-derived electrolytes and environmentally benign electrode materials for DIBs shows promise for further reducing environmental impacts. These innovations could potentially address end-of-life toxicity concerns while maintaining or improving performance characteristics required for demanding transportation applications.

Life cycle assessment (LCA) studies indicate that DIBs may reduce carbon emissions by 15-20% compared to traditional lithium-ion batteries, primarily due to their reduced reliance on critical materials like cobalt and nickel. This advantage becomes particularly significant in large-scale applications such as electric vehicles and aircraft systems, where material intensity directly correlates with environmental impact.

The extraction processes for DIB materials generally require less energy and water consumption than conventional battery technologies. Preliminary data suggests water usage reductions of approximately 25-30% across the supply chain, addressing growing concerns about water scarcity in mining regions. Additionally, the simplified chemistry of many DIB formulations reduces the need for environmentally harmful extraction processes associated with certain critical minerals.

Waste management considerations for DIBs present both challenges and opportunities. The diverse electrolyte compositions in DIBs may introduce new recycling challenges, but their generally simpler electrode structures could facilitate more efficient material recovery at end-of-life. Current recycling efficiency estimates range from 60-75%, with potential for improvement as recycling technologies mature alongside DIB development.

Regulatory frameworks for environmental compliance vary significantly between automotive and aerospace sectors. Automotive applications must adhere to increasingly stringent vehicle emissions regulations, while aerospace applications face additional scrutiny regarding fire safety and hazardous material transport. DIBs must demonstrate compliance with regulations such as the EU Battery Directive, REACH, and various transportation safety protocols to gain market acceptance.

The potential for reduced rare earth element dependency in DIBs aligns with global sustainability initiatives and could mitigate supply chain vulnerabilities associated with geopolitically concentrated materials. This aspect has particular relevance for both automotive and aerospace industries, which are increasingly prioritizing supply chain resilience and environmental sustainability in their technology roadmaps.

Ongoing research into bio-derived electrolytes and environmentally benign electrode materials for DIBs shows promise for further reducing environmental impacts. These innovations could potentially address end-of-life toxicity concerns while maintaining or improving performance characteristics required for demanding transportation applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!