Dual-ion batteries for large scale energy storage and renewable integration

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIB Technology Background and Objectives

Dual-ion batteries (DIBs) have emerged as a promising technology for large-scale energy storage systems, evolving from the traditional lithium-ion battery architecture. The concept of DIBs was first introduced in the early 2000s, but significant research momentum has only built up over the past decade as the demand for grid-scale energy storage solutions has intensified.

The fundamental operating principle of DIBs differs from conventional batteries as both anions and cations participate in the electrochemical process, enabling higher energy densities and potentially lower costs. This dual-ion intercalation mechanism allows for a more efficient utilization of electrode materials and electrolytes, addressing key limitations of traditional battery technologies.

The evolution of DIB technology has been driven by the growing need for sustainable and efficient energy storage solutions to complement renewable energy sources. As wind and solar power generation continues to expand globally, the intermittent nature of these resources necessitates robust storage systems that can balance supply and demand fluctuations, making DIBs particularly relevant in the current energy landscape.

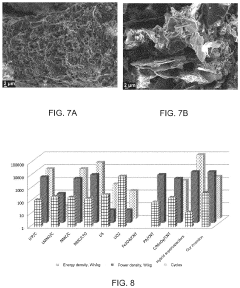

Technical objectives for DIB development focus on several critical parameters: increasing energy density beyond 200 Wh/kg, extending cycle life to over 5,000 cycles, reducing cost to below $100/kWh, and ensuring operational safety under various environmental conditions. These targets are essential for DIBs to compete with and potentially surpass existing technologies such as lithium-ion, sodium-sulfur, and flow batteries in grid-scale applications.

Recent technological breakthroughs in electrode materials, particularly graphite-based cathodes and various metal-based anodes, have significantly enhanced DIB performance. Innovations in electrolyte formulations have also addressed previous limitations related to voltage windows and ionic conductivity, pushing the technology closer to commercial viability.

The trajectory of DIB development aligns with global energy transition goals, particularly the increasing integration of renewable energy sources into power grids. As countries worldwide commit to carbon neutrality targets, the demand for efficient, sustainable, and scalable energy storage solutions continues to grow, positioning DIBs as a potentially transformative technology in the energy storage landscape.

Research institutions and industry players are increasingly focusing on DIB technology, with significant investments being directed toward overcoming remaining technical challenges and scaling up production capabilities. The ultimate goal is to develop DIB systems that can be deployed at utility scale, providing gigawatt-hour capacity storage solutions that enable higher penetration of renewable energy while maintaining grid stability and reliability.

The fundamental operating principle of DIBs differs from conventional batteries as both anions and cations participate in the electrochemical process, enabling higher energy densities and potentially lower costs. This dual-ion intercalation mechanism allows for a more efficient utilization of electrode materials and electrolytes, addressing key limitations of traditional battery technologies.

The evolution of DIB technology has been driven by the growing need for sustainable and efficient energy storage solutions to complement renewable energy sources. As wind and solar power generation continues to expand globally, the intermittent nature of these resources necessitates robust storage systems that can balance supply and demand fluctuations, making DIBs particularly relevant in the current energy landscape.

Technical objectives for DIB development focus on several critical parameters: increasing energy density beyond 200 Wh/kg, extending cycle life to over 5,000 cycles, reducing cost to below $100/kWh, and ensuring operational safety under various environmental conditions. These targets are essential for DIBs to compete with and potentially surpass existing technologies such as lithium-ion, sodium-sulfur, and flow batteries in grid-scale applications.

Recent technological breakthroughs in electrode materials, particularly graphite-based cathodes and various metal-based anodes, have significantly enhanced DIB performance. Innovations in electrolyte formulations have also addressed previous limitations related to voltage windows and ionic conductivity, pushing the technology closer to commercial viability.

The trajectory of DIB development aligns with global energy transition goals, particularly the increasing integration of renewable energy sources into power grids. As countries worldwide commit to carbon neutrality targets, the demand for efficient, sustainable, and scalable energy storage solutions continues to grow, positioning DIBs as a potentially transformative technology in the energy storage landscape.

Research institutions and industry players are increasingly focusing on DIB technology, with significant investments being directed toward overcoming remaining technical challenges and scaling up production capabilities. The ultimate goal is to develop DIB systems that can be deployed at utility scale, providing gigawatt-hour capacity storage solutions that enable higher penetration of renewable energy while maintaining grid stability and reliability.

Market Analysis for Large-Scale Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. As of 2023, the large-scale energy storage market was valued at approximately $12 billion, with projections indicating a compound annual growth rate (CAGR) of 24% through 2030, potentially reaching $58 billion by the end of the decade. This remarkable expansion reflects the critical role that energy storage technologies play in addressing the intermittency challenges associated with renewable energy generation.

Dual-ion batteries (DIBs) are emerging as a promising contender in this rapidly evolving market landscape. Unlike conventional lithium-ion batteries that primarily utilize lithium ions, DIBs employ both cations and anions during charge-discharge cycles, potentially offering higher energy densities and lower production costs. Market analysis indicates that DIBs could capture up to 15% of the utility-scale storage market by 2028 if current technical challenges are overcome.

Regional market dynamics reveal significant variations in adoption patterns. Asia-Pacific currently leads the large-scale energy storage market with approximately 45% market share, followed by North America (30%) and Europe (20%). China dominates the Asia-Pacific region, having deployed over 40 GWh of grid-scale storage capacity. However, the United States is accelerating deployments, with recent legislation including the Inflation Reduction Act providing substantial incentives for energy storage projects.

Customer segmentation within the large-scale storage market shows utilities as the primary adopters (65%), followed by independent power producers (20%) and commercial/industrial users (15%). The utility segment is particularly interested in long-duration storage solutions that can provide 8+ hours of discharge capacity, an area where DIBs show considerable promise due to their potential cost advantages at scale.

Price sensitivity analysis reveals that large-scale storage solutions must achieve costs below $150/kWh to compete effectively with peaker plants and other grid management alternatives. Current DIB prototypes demonstrate potential for reaching $100-120/kWh at scale, significantly undercutting conventional lithium-ion systems that typically range from $200-300/kWh for grid-scale applications.

Market forecasts suggest that by 2030, the demand for large-scale energy storage could exceed 300 GWh annually, driven by renewable integration requirements and grid resilience initiatives. DIBs are well-positioned to address this demand, particularly in applications requiring 4-12 hour duration storage, which represents approximately 60% of the projected market need.

Dual-ion batteries (DIBs) are emerging as a promising contender in this rapidly evolving market landscape. Unlike conventional lithium-ion batteries that primarily utilize lithium ions, DIBs employ both cations and anions during charge-discharge cycles, potentially offering higher energy densities and lower production costs. Market analysis indicates that DIBs could capture up to 15% of the utility-scale storage market by 2028 if current technical challenges are overcome.

Regional market dynamics reveal significant variations in adoption patterns. Asia-Pacific currently leads the large-scale energy storage market with approximately 45% market share, followed by North America (30%) and Europe (20%). China dominates the Asia-Pacific region, having deployed over 40 GWh of grid-scale storage capacity. However, the United States is accelerating deployments, with recent legislation including the Inflation Reduction Act providing substantial incentives for energy storage projects.

Customer segmentation within the large-scale storage market shows utilities as the primary adopters (65%), followed by independent power producers (20%) and commercial/industrial users (15%). The utility segment is particularly interested in long-duration storage solutions that can provide 8+ hours of discharge capacity, an area where DIBs show considerable promise due to their potential cost advantages at scale.

Price sensitivity analysis reveals that large-scale storage solutions must achieve costs below $150/kWh to compete effectively with peaker plants and other grid management alternatives. Current DIB prototypes demonstrate potential for reaching $100-120/kWh at scale, significantly undercutting conventional lithium-ion systems that typically range from $200-300/kWh for grid-scale applications.

Market forecasts suggest that by 2030, the demand for large-scale energy storage could exceed 300 GWh annually, driven by renewable integration requirements and grid resilience initiatives. DIBs are well-positioned to address this demand, particularly in applications requiring 4-12 hour duration storage, which represents approximately 60% of the projected market need.

Current State and Technical Challenges of DIBs

Dual-ion batteries (DIBs) have emerged as a promising technology for large-scale energy storage systems, offering several advantages over conventional lithium-ion batteries. Currently, DIBs are in the early commercialization stage with several research institutions and companies developing prototypes and small-scale demonstration projects. The technology has gained significant attention due to its potential cost-effectiveness, environmental friendliness, and compatibility with renewable energy integration.

The current state of DIB technology shows promising energy densities ranging from 70-120 Wh/kg, which is lower than conventional lithium-ion batteries but potentially sufficient for stationary storage applications. Cycle life performance has reached 2000-3000 cycles in laboratory settings, with some advanced prototypes demonstrating up to 5000 cycles under optimal conditions. Power density capabilities typically range from 300-500 W/kg, making them suitable for grid-level applications requiring moderate power output.

Despite these advancements, DIBs face several critical technical challenges that hinder their widespread adoption. The most significant challenge is the limited energy density compared to conventional lithium-ion batteries, primarily due to the intercalation mechanism involving both anions and cations. This fundamental limitation restricts their application in portable electronics but remains acceptable for stationary storage systems.

Electrolyte stability presents another major challenge, as DIBs typically operate at higher voltages (up to 5V), which can lead to electrolyte decomposition and capacity fading. Current electrolyte formulations struggle to maintain stability over extended cycling, particularly at elevated temperatures. Research efforts are focused on developing novel electrolyte compositions with wider electrochemical stability windows and improved thermal stability.

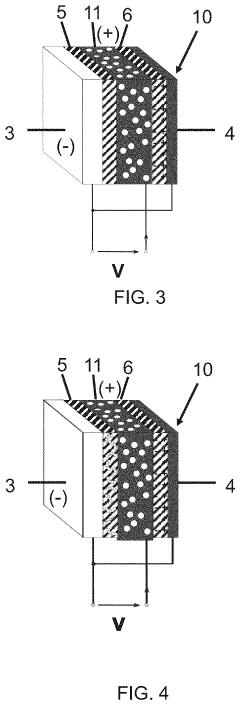

Electrode materials pose additional challenges, with graphite being the most common cathode material but suffering from structural degradation during repeated anion intercalation/deintercalation processes. Alternative materials such as expanded graphite, graphene, and carbon nanotubes show promise but face scalability and cost issues for large-scale production.

The rate capability of DIBs remains insufficient for applications requiring rapid response times, such as frequency regulation in power grids. This limitation stems from the slower diffusion kinetics of larger anions compared to lithium ions. Researchers are exploring hierarchical electrode structures and novel cell designs to address this constraint.

Safety concerns, though less pronounced than in conventional lithium-ion batteries, still exist due to the flammable organic electrolytes typically employed. The development of non-flammable electrolytes or solid-state configurations represents an active research direction to enhance safety profiles for large-scale deployment.

Manufacturing scalability presents a significant hurdle, as current production methods are primarily laboratory-based and not optimized for mass production. The transition to industrial-scale manufacturing while maintaining performance metrics and cost advantages remains a critical challenge for commercialization.

The current state of DIB technology shows promising energy densities ranging from 70-120 Wh/kg, which is lower than conventional lithium-ion batteries but potentially sufficient for stationary storage applications. Cycle life performance has reached 2000-3000 cycles in laboratory settings, with some advanced prototypes demonstrating up to 5000 cycles under optimal conditions. Power density capabilities typically range from 300-500 W/kg, making them suitable for grid-level applications requiring moderate power output.

Despite these advancements, DIBs face several critical technical challenges that hinder their widespread adoption. The most significant challenge is the limited energy density compared to conventional lithium-ion batteries, primarily due to the intercalation mechanism involving both anions and cations. This fundamental limitation restricts their application in portable electronics but remains acceptable for stationary storage systems.

Electrolyte stability presents another major challenge, as DIBs typically operate at higher voltages (up to 5V), which can lead to electrolyte decomposition and capacity fading. Current electrolyte formulations struggle to maintain stability over extended cycling, particularly at elevated temperatures. Research efforts are focused on developing novel electrolyte compositions with wider electrochemical stability windows and improved thermal stability.

Electrode materials pose additional challenges, with graphite being the most common cathode material but suffering from structural degradation during repeated anion intercalation/deintercalation processes. Alternative materials such as expanded graphite, graphene, and carbon nanotubes show promise but face scalability and cost issues for large-scale production.

The rate capability of DIBs remains insufficient for applications requiring rapid response times, such as frequency regulation in power grids. This limitation stems from the slower diffusion kinetics of larger anions compared to lithium ions. Researchers are exploring hierarchical electrode structures and novel cell designs to address this constraint.

Safety concerns, though less pronounced than in conventional lithium-ion batteries, still exist due to the flammable organic electrolytes typically employed. The development of non-flammable electrolytes or solid-state configurations represents an active research direction to enhance safety profiles for large-scale deployment.

Manufacturing scalability presents a significant hurdle, as current production methods are primarily laboratory-based and not optimized for mass production. The transition to industrial-scale manufacturing while maintaining performance metrics and cost advantages remains a critical challenge for commercialization.

Current DIB Solutions for Grid-Scale Applications

01 Electrode materials for dual-ion batteries

Various materials can be used as electrodes in dual-ion batteries to improve performance. These include graphite, carbon-based materials, and metal compounds that can intercalate both cations and anions. The selection of appropriate electrode materials is crucial for enhancing energy density, cycle life, and charge-discharge efficiency of dual-ion batteries.- Electrode materials for dual-ion batteries: Various materials can be used as electrodes in dual-ion batteries to improve performance. These include carbon-based materials, metal oxides, and composite materials that can intercalate both cations and anions. The selection of appropriate electrode materials is crucial for enhancing energy density, cycling stability, and rate capability of dual-ion batteries.

- Electrolyte compositions for dual-ion batteries: Electrolyte formulations play a critical role in dual-ion battery performance. Specialized electrolytes containing specific salts, solvents, and additives can facilitate efficient ion transport, improve electrode-electrolyte interface stability, and enhance the overall electrochemical performance. The electrolyte composition directly affects the battery's voltage window, cycling stability, and safety characteristics.

- Battery management systems for dual-ion batteries: Advanced battery management systems are designed specifically for dual-ion batteries to monitor and control charging/discharging processes. These systems help optimize battery performance, prevent overcharging or deep discharging, manage thermal conditions, and extend battery lifespan through intelligent algorithms and sensing technologies.

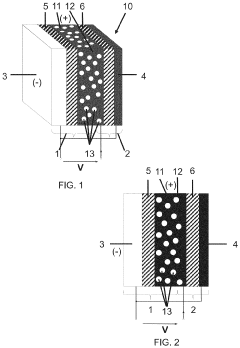

- Structural designs for dual-ion batteries: Innovative structural designs for dual-ion batteries focus on cell architecture, component arrangement, and packaging to maximize energy density and improve performance. These designs include novel separator configurations, electrode structures, and cell assembly methods that enhance ion transport, reduce internal resistance, and improve mechanical stability during cycling.

- Manufacturing processes for dual-ion batteries: Advanced manufacturing techniques for dual-ion batteries include specialized coating methods, electrode preparation processes, and assembly procedures. These processes aim to improve production efficiency, ensure consistent quality, reduce costs, and enhance the scalability of dual-ion battery technology for commercial applications.

02 Electrolyte compositions for dual-ion batteries

Specialized electrolyte formulations are essential for dual-ion batteries, as they must support the simultaneous transport of both cations and anions. These electrolytes typically contain specific salts dissolved in organic solvents or ionic liquids. The composition of the electrolyte significantly affects the battery's voltage window, ionic conductivity, and overall performance.Expand Specific Solutions03 Battery management systems for dual-ion batteries

Advanced battery management systems are developed specifically for dual-ion batteries to monitor and control the unique charging and discharging processes. These systems help optimize performance, prevent overcharging or deep discharging, and extend battery life by managing the bidirectional ion flow characteristic of dual-ion batteries.Expand Specific Solutions04 Structural designs for dual-ion batteries

Innovative structural designs for dual-ion batteries focus on optimizing the arrangement of electrodes, separators, and current collectors. These designs aim to facilitate efficient ion transport, minimize internal resistance, and enhance energy density. Various cell configurations, including pouch, prismatic, and cylindrical formats, are adapted specifically for dual-ion battery technology.Expand Specific Solutions05 Applications and integration of dual-ion batteries

Dual-ion batteries are being developed for various applications including portable electronics, electric vehicles, and grid-scale energy storage. Their integration into these systems requires specific adaptations to address thermal management, safety features, and compatibility with existing power management systems. The unique characteristics of dual-ion batteries, such as potentially lower cost and higher voltage, make them attractive alternatives to conventional lithium-ion batteries in certain applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Dual-ion batteries (DIBs) for large-scale energy storage are currently in an early growth phase, with the market expected to expand significantly due to increasing renewable energy integration demands. The global DIB market is projected to reach substantial scale by 2030, driven by advantages in cost-effectiveness and sustainability compared to traditional lithium-ion technologies. Technologically, DIBs are advancing rapidly but remain less mature than conventional batteries. Leading players include established corporations like CATL, Panasonic Energy, and Toyota, which are investing heavily in R&D, while research institutions such as the Chinese Academy of Sciences and Central South University are pioneering fundamental innovations. Specialized companies like Hong Kong Times New Energy Technology and Shenzhen Jiana Energy are emerging with focused DIB solutions, indicating a diversifying competitive landscape as the technology approaches commercial viability for grid-scale applications.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology has developed an innovative dual-ion battery technology utilizing aluminum as the anode material and a specialized graphite-based cathode structure. Their approach incorporates a novel electrolyte system based on ionic liquids that enables stable operation at wider temperature ranges (-20°C to 60°C) than conventional batteries. The institute has engineered a proprietary cathode material with expanded graphite layers and nitrogen-doped carbon interfaces that facilitate anion intercalation while minimizing structural degradation during cycling. Their dual-ion battery design achieves operating voltages of 3.8-4.3V with demonstrated cycle life exceeding 3000 cycles at 80% capacity retention. For large-scale energy storage applications, they've developed modular battery systems with integrated thermal management and sophisticated battery management systems that enable dynamic power adjustment for grid frequency regulation and peak shaving applications. The technology has been demonstrated in pilot projects with capacities ranging from 100kWh to 1MWh, showing promising results for renewable energy integration.

Strengths: Excellent thermal stability and safety characteristics compared to lithium-ion batteries; uses abundant and low-cost materials (aluminum, carbon); high power capability suitable for frequency regulation applications. Weaknesses: Lower energy density compared to commercial lithium-ion batteries; ionic liquid electrolytes have higher viscosity which can limit low-temperature performance; manufacturing processes for specialized electrode materials may increase production costs.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has pioneered a novel dual-ion battery system utilizing a graphite cathode and sodium metal anode with an optimized electrolyte composition. Their research has focused on the fundamental mechanisms of anion intercalation chemistry, developing proprietary electrolyte additives that form stable solid-electrolyte interphase layers on both electrodes. The institute has engineered a hierarchical porous carbon cathode structure with tailored pore size distribution that facilitates rapid anion transport while maintaining structural integrity during cycling. Their dual-ion technology employs a sodium-based chemistry that achieves operating voltages of 4.2-4.7V with energy densities approaching 130-150 Wh/kg at the cell level. The institute has demonstrated prototype grid-scale storage systems with capacity retention exceeding 80% after 2000 cycles, utilizing their patented electrolyte formulations containing fluorinated salts and ether-based solvents that enable stable high-voltage operation.

Strengths: Utilizes abundant sodium resources instead of lithium, significantly reducing raw material costs; high operating voltage provides good energy density; excellent rate capability suitable for grid applications requiring rapid response. Weaknesses: Sodium metal anode presents safety challenges that require additional protection systems; electrolyte stability at high voltages remains a concern for very long-term operation; lower volumetric energy density compared to commercial lithium-ion systems.

Core Patents and Technical Literature on DIBs

dual ion battery

PatentActiveJPWO2020110230A1

Innovation

- The use of aluminum current collectors coated with an amorphous carbon film, optionally with a conductive carbon layer, to prevent corrosion and enhance high-temperature durability.

High power and high energy self-switching electrochemical storage device

PatentInactiveUS20210218092A1

Innovation

- A hybrid device with a single shared cathode for both an electrochemical cell and a supercapacitor, where current flows based on energy needs, allowing for direct connection and self-management of high energy and high power conditions, exploiting the disadvantages of Lithium-Sulphur batteries by using a sulphur-rich and carbon-rich surface configuration.

Renewable Integration Capabilities and Case Studies

Dual-ion batteries (DIBs) have demonstrated significant potential for integration with renewable energy systems, offering a promising solution for the intermittency challenges associated with renewable power generation. Field implementations across various regions showcase DIBs' adaptability to different renewable energy contexts and grid requirements.

In Germany, a notable pilot project integrated a 5 MW DIB system with a wind farm, demonstrating effective power smoothing capabilities during variable wind conditions. The system successfully reduced output fluctuations by up to 78%, providing consistent power delivery to the grid despite gusty weather patterns. This implementation highlighted DIBs' rapid response time of less than 100 milliseconds, outperforming many conventional battery technologies in frequency regulation applications.

The Australian outback hosts another significant case study where a 3 MW DIB installation supports a remote solar farm. This system effectively bridges the gap between peak solar production and evening demand peaks, storing excess daytime generation and releasing it during high-demand periods. Performance data indicates 92% round-trip efficiency under optimal conditions, with minimal degradation observed after 1,000 cycles.

In urban microgrids, smaller DIB installations have demonstrated exceptional capabilities in demand response scenarios. A commercial district in Singapore implemented a 500 kW DIB system that reduced peak demand charges by 35% while providing critical backup during grid instability events. The system's compact footprint—approximately 40% smaller than equivalent lithium-ion installations—proved particularly valuable in space-constrained urban environments.

Grid-scale applications in California have tested DIBs' black start capabilities, where a 2 MW system successfully restored power to a sectioned-off portion of the grid following a simulated outage. The DIB system maintained stable voltage and frequency parameters throughout the restoration process, demonstrating potential for enhancing grid resilience.

Rural electrification projects in India have leveraged DIBs' wide operating temperature range (-20°C to 60°C) to support solar mini-grids in challenging climatic conditions. These installations have maintained over 85% capacity retention after two years of operation in environments where conventional batteries experienced accelerated degradation.

These diverse implementations collectively demonstrate DIBs' versatility across different scales, applications, and environmental conditions, positioning them as a viable technology for addressing the integration challenges of variable renewable energy sources.

In Germany, a notable pilot project integrated a 5 MW DIB system with a wind farm, demonstrating effective power smoothing capabilities during variable wind conditions. The system successfully reduced output fluctuations by up to 78%, providing consistent power delivery to the grid despite gusty weather patterns. This implementation highlighted DIBs' rapid response time of less than 100 milliseconds, outperforming many conventional battery technologies in frequency regulation applications.

The Australian outback hosts another significant case study where a 3 MW DIB installation supports a remote solar farm. This system effectively bridges the gap between peak solar production and evening demand peaks, storing excess daytime generation and releasing it during high-demand periods. Performance data indicates 92% round-trip efficiency under optimal conditions, with minimal degradation observed after 1,000 cycles.

In urban microgrids, smaller DIB installations have demonstrated exceptional capabilities in demand response scenarios. A commercial district in Singapore implemented a 500 kW DIB system that reduced peak demand charges by 35% while providing critical backup during grid instability events. The system's compact footprint—approximately 40% smaller than equivalent lithium-ion installations—proved particularly valuable in space-constrained urban environments.

Grid-scale applications in California have tested DIBs' black start capabilities, where a 2 MW system successfully restored power to a sectioned-off portion of the grid following a simulated outage. The DIB system maintained stable voltage and frequency parameters throughout the restoration process, demonstrating potential for enhancing grid resilience.

Rural electrification projects in India have leveraged DIBs' wide operating temperature range (-20°C to 60°C) to support solar mini-grids in challenging climatic conditions. These installations have maintained over 85% capacity retention after two years of operation in environments where conventional batteries experienced accelerated degradation.

These diverse implementations collectively demonstrate DIBs' versatility across different scales, applications, and environmental conditions, positioning them as a viable technology for addressing the integration challenges of variable renewable energy sources.

Environmental Impact and Sustainability Assessment

Dual-ion batteries (DIBs) represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond traditional lithium-ion systems. The life cycle assessment of DIBs reveals considerably lower environmental impacts compared to conventional batteries, particularly in terms of greenhouse gas emissions and resource depletion. This advantage stems primarily from their simpler structure and reduced dependence on critical raw materials like cobalt and nickel.

The manufacturing process of DIBs demonstrates a smaller carbon footprint, with studies indicating up to 30% reduction in CO2 emissions compared to lithium-ion battery production. This improvement is attributed to less energy-intensive electrode preparation and the utilization of more abundant materials. Additionally, the absence of toxic heavy metals in many DIB formulations significantly reduces the risk of environmental contamination during production, use, and disposal phases.

Water consumption represents another critical environmental metric where DIBs excel. The production of DIBs typically requires 25-40% less water than conventional battery technologies, contributing to more sustainable manufacturing practices in regions facing water scarcity challenges. This reduced water footprint enhances the overall sustainability profile of large-scale energy storage implementations using DIB technology.

From a circular economy perspective, DIBs offer promising end-of-life management opportunities. The simpler chemistry and material composition facilitate more efficient recycling processes, with potential recovery rates exceeding 80% for key components. This recyclability addresses growing concerns about battery waste management and aligns with global sustainability initiatives aimed at minimizing resource extraction through closed-loop material flows.

When integrated with renewable energy systems, DIBs contribute to substantial environmental benefits through grid stabilization and renewable energy utilization optimization. Quantitative analyses suggest that large-scale DIB deployment could enable an additional 15-20% integration of intermittent renewable sources like solar and wind, potentially displacing fossil fuel generation and avoiding associated emissions.

Land use considerations also favor DIBs in large-scale applications. Their higher energy density compared to some alternative storage technologies translates to smaller physical footprints for equivalent storage capacity. This space efficiency becomes particularly valuable in densely populated areas where land availability presents constraints for renewable energy infrastructure development.

Despite these advantages, challenges remain regarding the long-term environmental implications of certain electrolytes used in DIBs, particularly those containing fluorinated compounds. Ongoing research focuses on developing environmentally benign alternatives that maintain performance while eliminating persistent pollutants, representing a critical pathway toward truly sustainable large-scale energy storage solutions.

The manufacturing process of DIBs demonstrates a smaller carbon footprint, with studies indicating up to 30% reduction in CO2 emissions compared to lithium-ion battery production. This improvement is attributed to less energy-intensive electrode preparation and the utilization of more abundant materials. Additionally, the absence of toxic heavy metals in many DIB formulations significantly reduces the risk of environmental contamination during production, use, and disposal phases.

Water consumption represents another critical environmental metric where DIBs excel. The production of DIBs typically requires 25-40% less water than conventional battery technologies, contributing to more sustainable manufacturing practices in regions facing water scarcity challenges. This reduced water footprint enhances the overall sustainability profile of large-scale energy storage implementations using DIB technology.

From a circular economy perspective, DIBs offer promising end-of-life management opportunities. The simpler chemistry and material composition facilitate more efficient recycling processes, with potential recovery rates exceeding 80% for key components. This recyclability addresses growing concerns about battery waste management and aligns with global sustainability initiatives aimed at minimizing resource extraction through closed-loop material flows.

When integrated with renewable energy systems, DIBs contribute to substantial environmental benefits through grid stabilization and renewable energy utilization optimization. Quantitative analyses suggest that large-scale DIB deployment could enable an additional 15-20% integration of intermittent renewable sources like solar and wind, potentially displacing fossil fuel generation and avoiding associated emissions.

Land use considerations also favor DIBs in large-scale applications. Their higher energy density compared to some alternative storage technologies translates to smaller physical footprints for equivalent storage capacity. This space efficiency becomes particularly valuable in densely populated areas where land availability presents constraints for renewable energy infrastructure development.

Despite these advantages, challenges remain regarding the long-term environmental implications of certain electrolytes used in DIBs, particularly those containing fluorinated compounds. Ongoing research focuses on developing environmentally benign alternatives that maintain performance while eliminating persistent pollutants, representing a critical pathway toward truly sustainable large-scale energy storage solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!