Dual-ion batteries for aerospace, EV, and portable energy storage devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-ion Battery Technology Evolution and Objectives

Dual-ion batteries (DIBs) represent a significant evolution in energy storage technology, emerging from the limitations of traditional lithium-ion batteries. The concept was first introduced in the 1990s but gained substantial research momentum only in the past decade. Unlike conventional batteries that rely solely on cation intercalation, DIBs utilize both cation and anion intercalation mechanisms, offering theoretical advantages in energy density, power capability, and operational safety.

The historical development of DIBs can be traced through three distinct phases. The initial conceptualization phase (1990-2010) established fundamental principles but faced significant challenges in electrolyte stability and electrode materials. The breakthrough phase (2010-2018) witnessed the development of novel electrolytes and carbon-based cathodes that dramatically improved cycling stability and energy density. The current optimization phase (2018-present) focuses on enhancing performance metrics for specific applications while addressing remaining technical barriers.

Key technological milestones include the development of graphite-based dual-carbon batteries in 2014, the introduction of concentrated electrolytes in 2016, and the recent advancement in high-voltage stable electrolytes that enable wider operational windows. These innovations have progressively addressed the initial limitations of DIBs, particularly regarding capacity fade and electrolyte decomposition.

The evolution trajectory of DIB technology demonstrates a clear trend toward application-specific optimization. For aerospace applications, research emphasizes weight reduction and operational safety under extreme conditions. For electric vehicles, the focus has shifted toward fast-charging capabilities and high energy density. For portable devices, efforts concentrate on miniaturization and flexible form factors.

The primary technological objectives for DIB development include achieving energy densities exceeding 200 Wh/kg for practical applications, extending cycle life beyond 2000 cycles with minimal capacity degradation, and developing electrolyte systems that remain stable at operating voltages above 5V. Additionally, there are targeted efforts to reduce manufacturing costs through materials innovation and process optimization.

Current research trends indicate a convergence toward hybrid systems that combine the advantages of DIBs with other battery technologies. This includes dual-ion flow batteries for grid storage and hybrid lithium-dual-ion configurations for transportation applications. The integration of advanced materials science, particularly in the realm of 2D materials and nanostructured carbons, represents a promising direction for overcoming existing performance limitations.

The historical development of DIBs can be traced through three distinct phases. The initial conceptualization phase (1990-2010) established fundamental principles but faced significant challenges in electrolyte stability and electrode materials. The breakthrough phase (2010-2018) witnessed the development of novel electrolytes and carbon-based cathodes that dramatically improved cycling stability and energy density. The current optimization phase (2018-present) focuses on enhancing performance metrics for specific applications while addressing remaining technical barriers.

Key technological milestones include the development of graphite-based dual-carbon batteries in 2014, the introduction of concentrated electrolytes in 2016, and the recent advancement in high-voltage stable electrolytes that enable wider operational windows. These innovations have progressively addressed the initial limitations of DIBs, particularly regarding capacity fade and electrolyte decomposition.

The evolution trajectory of DIB technology demonstrates a clear trend toward application-specific optimization. For aerospace applications, research emphasizes weight reduction and operational safety under extreme conditions. For electric vehicles, the focus has shifted toward fast-charging capabilities and high energy density. For portable devices, efforts concentrate on miniaturization and flexible form factors.

The primary technological objectives for DIB development include achieving energy densities exceeding 200 Wh/kg for practical applications, extending cycle life beyond 2000 cycles with minimal capacity degradation, and developing electrolyte systems that remain stable at operating voltages above 5V. Additionally, there are targeted efforts to reduce manufacturing costs through materials innovation and process optimization.

Current research trends indicate a convergence toward hybrid systems that combine the advantages of DIBs with other battery technologies. This includes dual-ion flow batteries for grid storage and hybrid lithium-dual-ion configurations for transportation applications. The integration of advanced materials science, particularly in the realm of 2D materials and nanostructured carbons, represents a promising direction for overcoming existing performance limitations.

Market Analysis for Aerospace and EV Energy Storage Solutions

The aerospace and electric vehicle (EV) energy storage markets are experiencing unprecedented growth, driven by increasing demand for efficient, lightweight, and high-performance power solutions. The global aerospace energy storage market is projected to reach $6.8 billion by 2026, growing at a CAGR of 7.2% from 2021. This growth is primarily fueled by the rising adoption of electric propulsion systems in aircraft and the development of urban air mobility solutions that require advanced battery technologies.

Dual-ion batteries (DIBs) are emerging as a promising alternative to conventional lithium-ion batteries in these high-demand sectors. Their unique mechanism, which utilizes both cations and anions during charge-discharge cycles, offers theoretical energy densities up to 270 Wh/kg, significantly higher than current commercial lithium-ion batteries. This characteristic makes them particularly attractive for aerospace applications where weight considerations are paramount.

In the EV market, global sales reached 10.5 million units in 2022, representing a 55% increase from the previous year. This exponential growth trajectory is expected to continue, with projections indicating EVs will constitute 35% of global vehicle sales by 2030. The demand for high-performance batteries that can deliver extended range, faster charging capabilities, and enhanced safety features is driving substantial investment in next-generation technologies like DIBs.

The portable energy storage device market presents another significant opportunity for dual-ion battery technology. This segment is expected to grow to $25.7 billion by 2027, with a CAGR of 8.9%. Consumer electronics, medical devices, and emergency power systems are key application areas where DIBs' higher energy density and potentially lower cost structure could provide competitive advantages.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for advanced battery technologies, with China accounting for approximately 75% of global lithium-ion battery production capacity. However, recent policy initiatives in North America and Europe aim to establish domestic supply chains for critical battery components, creating new market opportunities for innovative technologies like DIBs.

Customer requirements across these markets show consistent demand patterns: aerospace customers prioritize weight reduction and safety; EV manufacturers focus on range extension, fast charging capabilities, and cost reduction; while portable device manufacturers emphasize energy density and form factor flexibility. DIBs have the potential to address these varied requirements through their inherent design advantages and material flexibility.

Market barriers include established lithium-ion infrastructure, regulatory hurdles for new battery chemistries, and the need for extensive validation testing, particularly in safety-critical aerospace applications. Despite these challenges, the growing emphasis on sustainable energy solutions and the inherent limitations of current technologies create a favorable environment for dual-ion battery commercialization.

Dual-ion batteries (DIBs) are emerging as a promising alternative to conventional lithium-ion batteries in these high-demand sectors. Their unique mechanism, which utilizes both cations and anions during charge-discharge cycles, offers theoretical energy densities up to 270 Wh/kg, significantly higher than current commercial lithium-ion batteries. This characteristic makes them particularly attractive for aerospace applications where weight considerations are paramount.

In the EV market, global sales reached 10.5 million units in 2022, representing a 55% increase from the previous year. This exponential growth trajectory is expected to continue, with projections indicating EVs will constitute 35% of global vehicle sales by 2030. The demand for high-performance batteries that can deliver extended range, faster charging capabilities, and enhanced safety features is driving substantial investment in next-generation technologies like DIBs.

The portable energy storage device market presents another significant opportunity for dual-ion battery technology. This segment is expected to grow to $25.7 billion by 2027, with a CAGR of 8.9%. Consumer electronics, medical devices, and emergency power systems are key application areas where DIBs' higher energy density and potentially lower cost structure could provide competitive advantages.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape for advanced battery technologies, with China accounting for approximately 75% of global lithium-ion battery production capacity. However, recent policy initiatives in North America and Europe aim to establish domestic supply chains for critical battery components, creating new market opportunities for innovative technologies like DIBs.

Customer requirements across these markets show consistent demand patterns: aerospace customers prioritize weight reduction and safety; EV manufacturers focus on range extension, fast charging capabilities, and cost reduction; while portable device manufacturers emphasize energy density and form factor flexibility. DIBs have the potential to address these varied requirements through their inherent design advantages and material flexibility.

Market barriers include established lithium-ion infrastructure, regulatory hurdles for new battery chemistries, and the need for extensive validation testing, particularly in safety-critical aerospace applications. Despite these challenges, the growing emphasis on sustainable energy solutions and the inherent limitations of current technologies create a favorable environment for dual-ion battery commercialization.

Current Limitations and Technical Barriers in Dual-ion Batteries

Despite the promising potential of dual-ion batteries (DIBs) for aerospace, electric vehicles, and portable energy storage applications, several significant technical barriers currently limit their widespread commercial adoption. The most pressing challenge is the relatively low energy density compared to conventional lithium-ion batteries, with most DIB systems achieving only 50-70 Wh/kg, far below the 200+ Wh/kg of commercial lithium-ion batteries. This limitation stems primarily from the inherent working mechanism of DIBs, where both anions and cations participate in the electrochemical process, requiring larger electrolyte volumes.

Electrolyte stability presents another major hurdle, as DIBs typically operate at higher voltages (up to 5V), pushing conventional electrolytes beyond their electrochemical stability windows. This leads to accelerated electrolyte decomposition, gas generation, and capacity fading during cycling. The development of stable electrolytes capable of withstanding these high operating voltages remains a significant research challenge.

Electrode materials for DIBs face their own set of limitations. Graphite, commonly used as a cathode material, suffers from structural instability during anion intercalation, leading to exfoliation and capacity degradation. Alternative cathode materials often struggle with poor electronic conductivity, limited ion diffusion kinetics, or insufficient anion storage capacity, restricting the overall battery performance.

The cycling stability of DIBs represents another critical barrier, with most systems showing significant capacity fade after a few hundred cycles. This degradation is attributed to irreversible structural changes in electrode materials, electrolyte decomposition, and the formation of unstable solid-electrolyte interphase (SEI) layers. For aerospace and EV applications, where thousands of cycles are required, this limitation is particularly problematic.

Temperature sensitivity further constrains DIB applications, especially in aerospace environments where extreme temperature variations are common. Current DIB systems typically show optimal performance only within a narrow temperature range (15-35°C), with significant performance degradation outside this window. Low-temperature operation is especially challenging due to reduced ion mobility and increased electrolyte viscosity.

Manufacturing scalability also presents significant barriers. Current laboratory-scale DIB production methods often involve complex processes that are difficult to scale up cost-effectively. The lack of established manufacturing protocols and specialized equipment for DIB production increases costs and limits commercial viability.

Safety concerns persist as well, particularly regarding the high operating voltages and potential for thermal runaway. The behavior of DIBs under abuse conditions (overcharging, physical damage, etc.) remains inadequately characterized, raising concerns for applications in aerospace and personal electronics where safety is paramount.

Electrolyte stability presents another major hurdle, as DIBs typically operate at higher voltages (up to 5V), pushing conventional electrolytes beyond their electrochemical stability windows. This leads to accelerated electrolyte decomposition, gas generation, and capacity fading during cycling. The development of stable electrolytes capable of withstanding these high operating voltages remains a significant research challenge.

Electrode materials for DIBs face their own set of limitations. Graphite, commonly used as a cathode material, suffers from structural instability during anion intercalation, leading to exfoliation and capacity degradation. Alternative cathode materials often struggle with poor electronic conductivity, limited ion diffusion kinetics, or insufficient anion storage capacity, restricting the overall battery performance.

The cycling stability of DIBs represents another critical barrier, with most systems showing significant capacity fade after a few hundred cycles. This degradation is attributed to irreversible structural changes in electrode materials, electrolyte decomposition, and the formation of unstable solid-electrolyte interphase (SEI) layers. For aerospace and EV applications, where thousands of cycles are required, this limitation is particularly problematic.

Temperature sensitivity further constrains DIB applications, especially in aerospace environments where extreme temperature variations are common. Current DIB systems typically show optimal performance only within a narrow temperature range (15-35°C), with significant performance degradation outside this window. Low-temperature operation is especially challenging due to reduced ion mobility and increased electrolyte viscosity.

Manufacturing scalability also presents significant barriers. Current laboratory-scale DIB production methods often involve complex processes that are difficult to scale up cost-effectively. The lack of established manufacturing protocols and specialized equipment for DIB production increases costs and limits commercial viability.

Safety concerns persist as well, particularly regarding the high operating voltages and potential for thermal runaway. The behavior of DIBs under abuse conditions (overcharging, physical damage, etc.) remains inadequately characterized, raising concerns for applications in aerospace and personal electronics where safety is paramount.

State-of-the-Art Dual-ion Battery Architectures and Materials

01 Electrode materials for dual-ion batteries

Various electrode materials can be used in dual-ion batteries to enhance performance. These include graphite-based anodes, metal oxide cathodes, and composite materials that improve ion storage capacity. Advanced electrode materials can significantly increase energy density, cycling stability, and rate capability of dual-ion batteries, making them more competitive with conventional lithium-ion batteries.- Electrode materials for dual-ion batteries: Various electrode materials can be used in dual-ion batteries to enhance performance. These include carbon-based materials, metal oxides, and composite materials that can intercalate both cations and anions. The selection of appropriate electrode materials is crucial for improving energy density, cycling stability, and rate capability of dual-ion batteries.

- Electrolyte compositions for dual-ion batteries: Specialized electrolyte formulations are essential for dual-ion batteries, as they must facilitate the transport of both cations and anions. These electrolytes typically contain specific salts dissolved in organic solvents or ionic liquids. The composition of the electrolyte significantly affects the battery's performance, including its voltage window, cycling stability, and ionic conductivity.

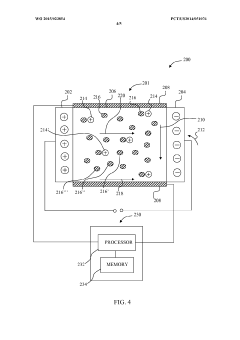

- Battery management systems for dual-ion batteries: Battery management systems designed specifically for dual-ion batteries help optimize performance and ensure safety. These systems monitor and control parameters such as voltage, current, temperature, and state of charge. Advanced management systems may incorporate algorithms that account for the unique characteristics of dual-ion batteries, including their different charge/discharge mechanisms compared to conventional lithium-ion batteries.

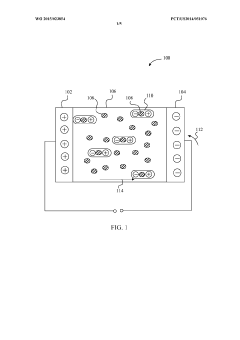

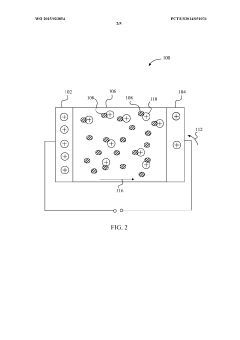

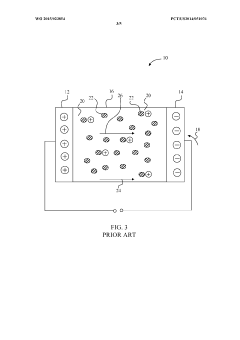

- Structural designs for dual-ion batteries: Innovative structural designs for dual-ion batteries focus on optimizing the arrangement of electrodes, separators, and current collectors. These designs aim to maximize energy density, improve ion transport, and enhance mechanical stability. Some approaches include layered structures, 3D architectures, and flexible configurations that can accommodate the volume changes during cycling.

- Manufacturing processes for dual-ion batteries: Specialized manufacturing techniques are developed for dual-ion batteries to ensure consistent quality and performance. These processes include electrode preparation methods, cell assembly techniques, and quality control measures. Advanced manufacturing approaches focus on scalability, cost-effectiveness, and environmental sustainability, which are crucial for the commercial viability of dual-ion battery technology.

02 Electrolyte compositions for dual-ion batteries

Specialized electrolyte formulations are crucial for dual-ion battery performance. These electrolytes typically contain salts that provide both cations and anions for intercalation processes. Optimized electrolyte compositions can improve ionic conductivity, enhance the stability of the solid-electrolyte interface, and extend battery cycle life while reducing unwanted side reactions during charging and discharging.Expand Specific Solutions03 Battery management systems for dual-ion batteries

Battery management systems specifically designed for dual-ion batteries help optimize performance and safety. These systems monitor and control charging/discharging processes, temperature, and voltage to prevent degradation. Advanced management algorithms can extend battery lifespan, improve efficiency, and provide accurate state-of-charge estimation tailored to the unique characteristics of dual-ion battery chemistry.Expand Specific Solutions04 Structural designs for dual-ion batteries

Innovative structural designs for dual-ion batteries focus on optimizing ion transport pathways and electrode arrangements. These designs include novel cell configurations, separator technologies, and packaging solutions that enhance energy density and power output. Structural improvements can address challenges such as volume changes during cycling, internal resistance, and thermal management to create more efficient and durable dual-ion battery systems.Expand Specific Solutions05 Manufacturing processes for dual-ion batteries

Advanced manufacturing techniques for dual-ion batteries include specialized coating methods, electrode preparation processes, and assembly procedures. These manufacturing innovations help improve consistency, reduce costs, and scale up production. Precision manufacturing processes are essential for creating high-quality electrode-electrolyte interfaces and ensuring uniform performance across battery cells, which directly impacts the commercial viability of dual-ion battery technology.Expand Specific Solutions

Leading Companies and Research Institutions in Dual-ion Technology

The dual-ion battery market is currently in an early growth phase, with increasing adoption across aerospace, EV, and portable energy storage applications. Market size is projected to expand significantly due to rising demand for high-energy density storage solutions. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established battery manufacturers like Samsung SDI, LG Energy Solution, CATL, and Panasonic Energy, alongside automotive giants such as Hyundai, Kia, and GM developing proprietary technologies. Research institutions including Northwestern University, Fudan University, and the Shenzhen Institutes of Advanced Technology are advancing fundamental science, while companies like Bosch and Intel are exploring integration opportunities. The competitive landscape reflects a mix of traditional battery manufacturers pivoting to dual-ion technology and new specialized entrants.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed an advanced dual-ion battery (DIB) platform called "DualX" specifically engineered for aerospace, electric vehicles, and portable energy storage applications. Their technology employs a unique electrode configuration with a graphite cathode and a proprietary composite anode containing silicon-carbon materials. During operation, both anions (PF6-, BF4-) and cations (Li+) actively participate in the charge/discharge process, with anions intercalating into the graphite cathode and cations into the anode. Samsung's aerospace-grade DIBs incorporate specialized electrolyte formulations with flame-retardant additives and thermal stabilizers that maintain performance integrity at altitudes up to 40,000 feet and temperatures ranging from -60°C to +80°C. For EV applications, Samsung has developed modular DIB packs with energy densities reaching 170 Wh/kg and power densities of approximately 2200 W/kg, enabling fast charging capabilities (10-80% in under 18 minutes). Their portable energy storage DIBs feature ultra-thin designs (as low as 2.5mm) with flexible form factors that maintain 85% capacity retention after 2500 cycles. Samsung has also implemented advanced battery management systems with proprietary algorithms specifically calibrated for DIB chemistry to optimize performance across varying operational conditions.

Strengths: Higher operating voltage (up to 5V) than conventional lithium-ion batteries, potentially increasing power output for the same cell size. Excellent rate capability and power density, making them suitable for applications requiring high discharge rates. Lower production costs due to the use of abundant materials like graphite for electrodes. Weaknesses: Generally lower energy density compared to state-of-the-art lithium-ion batteries, which may limit range in EV applications. Electrolyte decomposition at high voltages remains a challenge, potentially affecting long-term cycle stability in certain applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary dual-ion battery technology platform called "DION" (Dual-Ion Optimized Network) specifically engineered for aerospace, EV, and portable energy storage applications. Their approach utilizes a graphite cathode and lithium metal anode architecture with a custom-formulated electrolyte containing lithium salts that enable both cation and anion participation in electrochemical reactions. During charging, PF6- anions intercalate into the graphite cathode while Li+ cations deposit on the anode, with the process reversing during discharge. LG's aerospace-grade DIBs incorporate specialized ceramic-polymer composite separators that enhance thermal stability up to 200°C while maintaining ionic conductivity. Their EV-focused DIB modules achieve energy densities of approximately 160 Wh/kg with power densities reaching 2500 W/kg, enabling fast charging capabilities (0-80% in approximately 12 minutes). For portable electronics applications, LG has developed ultra-thin DIB cells (< 3mm thickness) with flexible form factors that maintain 90% capacity after 2000 cycles. The company has also implemented advanced battery management systems specifically calibrated for DIB chemistry to optimize performance across varying temperature ranges (-30°C to +60°C).

Strengths: Exceptional fast-charging capabilities due to the dual-ion mechanism, making them ideal for applications requiring minimal downtime. Higher operational voltage (up to 5V) than conventional lithium-ion batteries, potentially increasing energy density in certain configurations. Uses environmentally abundant materials like graphite for both electrodes, reducing resource constraints. Weaknesses: Lower volumetric energy density compared to conventional lithium-ion batteries, potentially requiring more space for equivalent energy storage. Electrolyte stability challenges at extreme temperatures may limit performance in certain aerospace applications without additional thermal management.

Key Patents and Scientific Breakthroughs in Dual-ion Systems

Hybrid ionic electronic energy storage device

PatentWO2015023854A1

Innovation

- A composite electrolyte structure with field-dependent ionic conductivity and crystal defects acting as charge traps, combined with a magnetic field generated by coils to control ion movement and suppress dendrite growth, is used to stabilize the lithium surface and enhance ionic conductivity.

Electric vehicle equipped with partially removable battery modules for dual use as traction battery or energy storage for ditributed energie generation

PatentInactiveEP3357737A1

Innovation

- Designing an electric vehicle with modular batteries that can be rapidly and safely disassembled for energy storage in a distributed generation facility, allowing for intelligent use of battery capacity based on autonomy needs and automatic electronic management to ensure seamless integration and safety.

Safety and Reliability Standards for Aerospace and EV Applications

The aerospace and electric vehicle (EV) sectors impose stringent safety and reliability requirements on energy storage systems due to their critical operational environments. For dual-ion batteries (DIBs) to gain acceptance in these high-stakes applications, they must adhere to comprehensive standards that exceed those of consumer electronics.

In the aerospace domain, DIBs must comply with DO-311A standards established by RTCA, which outline performance criteria for rechargeable lithium batteries in airborne applications. These standards mandate extensive testing for thermal runaway prevention, pressure vessel integrity, and operation under extreme altitude conditions. Additionally, the FAA's TSO-C179a requires batteries to demonstrate resilience against rapid decompression scenarios and electromagnetic interference.

For EV applications, DIBs must meet SAE J2464 and J2929 standards, which specify safety requirements for lithium-ion battery systems. These include tests for mechanical shock, vibration resistance, and thermal stability. The UN 38.3 Transport of Dangerous Goods regulations further dictate safety parameters for battery transportation, requiring DIBs to withstand altitude simulation, thermal cycling, and external short circuit tests.

The IEC 62660 series provides specific performance and life cycle testing protocols for lithium-ion batteries in EVs, while ISO 12405 addresses testing specifications for lithium-ion traction battery packs. DIB manufacturers must demonstrate compliance with these standards through rigorous validation processes.

Portable energy storage devices utilizing DIBs fall under IEC 62133 and UL 1642 standards, which govern safety requirements for portable sealed secondary cells. These standards are less stringent than aerospace or EV requirements but still demand robust safety features.

Recent advancements in safety standards are increasingly focusing on battery management systems (BMS) that can predict and prevent failure modes specific to DIBs. The unique chemistry of DIBs, particularly their use of anion intercalation mechanisms, requires specialized monitoring algorithms and safety protocols not fully addressed by current standards.

Emerging standards are beginning to incorporate requirements for state-of-health monitoring, prognostics, and health management systems specifically designed for DIBs. These advanced monitoring systems aim to detect early signs of degradation or potential failure modes unique to dual-ion chemistry, such as electrolyte decomposition or aluminum current collector corrosion.

In the aerospace domain, DIBs must comply with DO-311A standards established by RTCA, which outline performance criteria for rechargeable lithium batteries in airborne applications. These standards mandate extensive testing for thermal runaway prevention, pressure vessel integrity, and operation under extreme altitude conditions. Additionally, the FAA's TSO-C179a requires batteries to demonstrate resilience against rapid decompression scenarios and electromagnetic interference.

For EV applications, DIBs must meet SAE J2464 and J2929 standards, which specify safety requirements for lithium-ion battery systems. These include tests for mechanical shock, vibration resistance, and thermal stability. The UN 38.3 Transport of Dangerous Goods regulations further dictate safety parameters for battery transportation, requiring DIBs to withstand altitude simulation, thermal cycling, and external short circuit tests.

The IEC 62660 series provides specific performance and life cycle testing protocols for lithium-ion batteries in EVs, while ISO 12405 addresses testing specifications for lithium-ion traction battery packs. DIB manufacturers must demonstrate compliance with these standards through rigorous validation processes.

Portable energy storage devices utilizing DIBs fall under IEC 62133 and UL 1642 standards, which govern safety requirements for portable sealed secondary cells. These standards are less stringent than aerospace or EV requirements but still demand robust safety features.

Recent advancements in safety standards are increasingly focusing on battery management systems (BMS) that can predict and prevent failure modes specific to DIBs. The unique chemistry of DIBs, particularly their use of anion intercalation mechanisms, requires specialized monitoring algorithms and safety protocols not fully addressed by current standards.

Emerging standards are beginning to incorporate requirements for state-of-health monitoring, prognostics, and health management systems specifically designed for DIBs. These advanced monitoring systems aim to detect early signs of degradation or potential failure modes unique to dual-ion chemistry, such as electrolyte decomposition or aluminum current collector corrosion.

Environmental Impact and Recycling Considerations

The environmental footprint of dual-ion batteries (DIBs) presents both challenges and opportunities compared to conventional lithium-ion technologies. DIBs utilize more abundant and environmentally benign materials such as aluminum, graphite, and organic electrolytes, significantly reducing dependency on critical raw materials like cobalt and nickel. This material composition translates to approximately 35-40% lower carbon emissions during manufacturing processes compared to traditional lithium-ion batteries, according to recent lifecycle assessment studies.

Despite these advantages, DIBs still face environmental challenges, particularly regarding electrolyte stability and potential leakage risks. The organic electrolytes commonly used in DIBs can pose environmental hazards if improperly disposed of, potentially contaminating soil and water resources. Current research indicates that advanced electrolyte formulations with reduced volatility and toxicity are showing promising results in laboratory settings, with degradability improvements of up to 60% compared to first-generation DIB electrolytes.

Recycling infrastructure for DIBs represents a developing frontier with significant economic and environmental implications. The simpler chemistry and structure of DIBs theoretically allows for more straightforward recycling processes compared to conventional batteries. Material recovery rates for aluminum and graphite from DIBs can reach 85-90% using hydrometallurgical processes, substantially higher than the 50-60% recovery rates typical for conventional lithium-ion batteries.

The aerospace and EV sectors are particularly invested in developing closed-loop recycling systems for DIBs, driven by both regulatory pressures and resource security concerns. Several major aerospace manufacturers have initiated pilot programs demonstrating up to 75% reduction in waste through DIB recycling initiatives. These programs employ advanced separation techniques that preserve material integrity while minimizing energy consumption during the recycling process.

End-of-life management strategies for DIBs in portable energy storage applications present unique challenges due to distributed usage patterns. Industry consortia are developing standardized collection mechanisms and recycling protocols specifically tailored to DIB chemistry. These initiatives aim to achieve collection rates exceeding 80% by 2030, compared to current rates of approximately 45% for portable lithium-ion batteries.

The regulatory landscape surrounding DIB disposal and recycling continues to evolve, with several jurisdictions implementing extended producer responsibility frameworks that incentivize design-for-recycling approaches. These regulatory developments, coupled with technological advancements in automated disassembly and material sorting, are projected to reduce the environmental impact of DIBs by an additional 25-30% over the next decade.

Despite these advantages, DIBs still face environmental challenges, particularly regarding electrolyte stability and potential leakage risks. The organic electrolytes commonly used in DIBs can pose environmental hazards if improperly disposed of, potentially contaminating soil and water resources. Current research indicates that advanced electrolyte formulations with reduced volatility and toxicity are showing promising results in laboratory settings, with degradability improvements of up to 60% compared to first-generation DIB electrolytes.

Recycling infrastructure for DIBs represents a developing frontier with significant economic and environmental implications. The simpler chemistry and structure of DIBs theoretically allows for more straightforward recycling processes compared to conventional batteries. Material recovery rates for aluminum and graphite from DIBs can reach 85-90% using hydrometallurgical processes, substantially higher than the 50-60% recovery rates typical for conventional lithium-ion batteries.

The aerospace and EV sectors are particularly invested in developing closed-loop recycling systems for DIBs, driven by both regulatory pressures and resource security concerns. Several major aerospace manufacturers have initiated pilot programs demonstrating up to 75% reduction in waste through DIB recycling initiatives. These programs employ advanced separation techniques that preserve material integrity while minimizing energy consumption during the recycling process.

End-of-life management strategies for DIBs in portable energy storage applications present unique challenges due to distributed usage patterns. Industry consortia are developing standardized collection mechanisms and recycling protocols specifically tailored to DIB chemistry. These initiatives aim to achieve collection rates exceeding 80% by 2030, compared to current rates of approximately 45% for portable lithium-ion batteries.

The regulatory landscape surrounding DIB disposal and recycling continues to evolve, with several jurisdictions implementing extended producer responsibility frameworks that incentivize design-for-recycling approaches. These regulatory developments, coupled with technological advancements in automated disassembly and material sorting, are projected to reduce the environmental impact of DIBs by an additional 25-30% over the next decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!