Comparative analysis of electrolysis under variable renewable inputs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolysis Technology Background and Objectives

Electrolysis technology has evolved significantly since its discovery in the early 19th century, transforming from a laboratory curiosity to a cornerstone technology for clean energy systems. The fundamental principle remains unchanged: using electrical energy to split water into hydrogen and oxygen. However, the efficiency, scale, and applications have undergone remarkable advancement, particularly in recent decades as global focus shifts toward decarbonization strategies.

The evolution of electrolysis technologies has followed three main pathways: alkaline electrolysis (AEL), proton exchange membrane electrolysis (PEMEL), and solid oxide electrolysis (SOEL). Each represents a distinct technological generation with specific operational characteristics, efficiency profiles, and integration capabilities with renewable energy sources. AEL represents mature technology with extensive industrial deployment, while PEMEL offers faster response times critical for variable renewable integration, and SOEL promises higher efficiency but at elevated temperatures.

Current technological development is primarily driven by the urgent need to produce green hydrogen at scale as a versatile energy carrier and industrial feedstock. The International Energy Agency projects hydrogen demand could increase tenfold by 2050 in net-zero scenarios, with electrolysis expected to supply a significant portion of this demand. This creates both technological opportunities and challenges that must be addressed through focused research and development.

The integration of electrolysis systems with variable renewable energy sources presents unique technical challenges. Unlike conventional industrial processes designed for steady-state operation, electrolyzers paired with solar or wind generation must function efficiently under fluctuating power inputs. This operational paradigm affects system durability, hydrogen production costs, and overall energy efficiency, creating a distinct technological frontier requiring innovative solutions.

The primary objective of current electrolysis technology development is achieving economic viability through reduced capital costs, increased operational efficiency, and enhanced durability under variable loads. Current green hydrogen production costs range from $4-6/kg, while fossil-based hydrogen costs approximately $1-2/kg. Reaching cost parity requires significant technological breakthroughs in electrocatalysts, membrane materials, and system design optimization.

Secondary objectives include improving system responsiveness to accommodate increasingly variable renewable generation profiles, extending stack lifetimes under dynamic operation, and developing standardized approaches to system integration that maximize efficiency across the renewable-to-hydrogen value chain. These objectives align with broader energy transition goals while addressing specific technical barriers to widespread adoption.

The evolution of electrolysis technologies has followed three main pathways: alkaline electrolysis (AEL), proton exchange membrane electrolysis (PEMEL), and solid oxide electrolysis (SOEL). Each represents a distinct technological generation with specific operational characteristics, efficiency profiles, and integration capabilities with renewable energy sources. AEL represents mature technology with extensive industrial deployment, while PEMEL offers faster response times critical for variable renewable integration, and SOEL promises higher efficiency but at elevated temperatures.

Current technological development is primarily driven by the urgent need to produce green hydrogen at scale as a versatile energy carrier and industrial feedstock. The International Energy Agency projects hydrogen demand could increase tenfold by 2050 in net-zero scenarios, with electrolysis expected to supply a significant portion of this demand. This creates both technological opportunities and challenges that must be addressed through focused research and development.

The integration of electrolysis systems with variable renewable energy sources presents unique technical challenges. Unlike conventional industrial processes designed for steady-state operation, electrolyzers paired with solar or wind generation must function efficiently under fluctuating power inputs. This operational paradigm affects system durability, hydrogen production costs, and overall energy efficiency, creating a distinct technological frontier requiring innovative solutions.

The primary objective of current electrolysis technology development is achieving economic viability through reduced capital costs, increased operational efficiency, and enhanced durability under variable loads. Current green hydrogen production costs range from $4-6/kg, while fossil-based hydrogen costs approximately $1-2/kg. Reaching cost parity requires significant technological breakthroughs in electrocatalysts, membrane materials, and system design optimization.

Secondary objectives include improving system responsiveness to accommodate increasingly variable renewable generation profiles, extending stack lifetimes under dynamic operation, and developing standardized approaches to system integration that maximize efficiency across the renewable-to-hydrogen value chain. These objectives align with broader energy transition goals while addressing specific technical barriers to widespread adoption.

Market Analysis for Green Hydrogen Production

The global green hydrogen market is experiencing unprecedented growth, driven by the urgent need for decarbonization across industries. Current market valuations place green hydrogen at approximately $2.5 billion in 2022, with projections indicating a compound annual growth rate of 39.5% through 2030, potentially reaching a market value of $60 billion. This exponential growth trajectory is primarily fueled by governmental commitments to net-zero emissions and substantial investments in renewable energy infrastructure.

The demand landscape for green hydrogen spans multiple sectors. Industrial applications, particularly in ammonia production and petroleum refining, currently constitute the largest market segment, accounting for roughly 55% of total demand. Transportation represents an emerging high-potential sector, with fuel cell vehicles gaining traction in commercial fleets and heavy-duty transport. Energy storage applications are also expanding rapidly as power grid operators seek solutions for intermittent renewable energy integration.

Regional market dynamics reveal significant variations. Europe leads in policy support and deployment, with Germany, the Netherlands, and Denmark establishing comprehensive hydrogen strategies backed by substantial funding. The European Union has committed €470 billion to hydrogen development by 2050. Asia-Pacific demonstrates the fastest growth rate, with Japan, South Korea, and Australia making strategic investments in production capacity and export infrastructure.

Cost considerations remain central to market development. Current production costs for green hydrogen range between $3-8 per kilogram, significantly higher than gray hydrogen's $1-2 per kilogram. However, analysis of cost reduction pathways suggests potential price parity by 2030, driven by declining electrolyzer costs (projected 60% reduction) and cheaper renewable electricity (forecast to decrease by 40-70% depending on technology and region).

Market barriers include infrastructure limitations, with hydrogen transport and storage facilities remaining underdeveloped. Regulatory frameworks are still evolving, creating investment uncertainty. Additionally, the intermittent nature of renewable energy sources presents technical challenges for continuous electrolysis operations, with system efficiency losses of 10-30% observed during variable input conditions.

Investment trends indicate growing confidence in the sector, with venture capital funding increasing by 145% in 2021 compared to the previous year. Strategic partnerships between technology providers, energy companies, and end-users are accelerating commercialization efforts, with over 30 major collaborative projects announced in the past 18 months focusing specifically on electrolysis under variable renewable inputs.

The demand landscape for green hydrogen spans multiple sectors. Industrial applications, particularly in ammonia production and petroleum refining, currently constitute the largest market segment, accounting for roughly 55% of total demand. Transportation represents an emerging high-potential sector, with fuel cell vehicles gaining traction in commercial fleets and heavy-duty transport. Energy storage applications are also expanding rapidly as power grid operators seek solutions for intermittent renewable energy integration.

Regional market dynamics reveal significant variations. Europe leads in policy support and deployment, with Germany, the Netherlands, and Denmark establishing comprehensive hydrogen strategies backed by substantial funding. The European Union has committed €470 billion to hydrogen development by 2050. Asia-Pacific demonstrates the fastest growth rate, with Japan, South Korea, and Australia making strategic investments in production capacity and export infrastructure.

Cost considerations remain central to market development. Current production costs for green hydrogen range between $3-8 per kilogram, significantly higher than gray hydrogen's $1-2 per kilogram. However, analysis of cost reduction pathways suggests potential price parity by 2030, driven by declining electrolyzer costs (projected 60% reduction) and cheaper renewable electricity (forecast to decrease by 40-70% depending on technology and region).

Market barriers include infrastructure limitations, with hydrogen transport and storage facilities remaining underdeveloped. Regulatory frameworks are still evolving, creating investment uncertainty. Additionally, the intermittent nature of renewable energy sources presents technical challenges for continuous electrolysis operations, with system efficiency losses of 10-30% observed during variable input conditions.

Investment trends indicate growing confidence in the sector, with venture capital funding increasing by 145% in 2021 compared to the previous year. Strategic partnerships between technology providers, energy companies, and end-users are accelerating commercialization efforts, with over 30 major collaborative projects announced in the past 18 months focusing specifically on electrolysis under variable renewable inputs.

Current Electrolysis Technologies and Challenges

Electrolysis technologies have evolved significantly over the past decades, with three main types currently dominating the market: Alkaline Electrolysis (AEL), Proton Exchange Membrane Electrolysis (PEMEL), and Solid Oxide Electrolysis (SOEL). Each technology presents distinct characteristics that determine its suitability for integration with variable renewable energy sources.

Alkaline electrolysis represents the most mature technology, operating at 70-90°C with efficiencies ranging from 65-82%. Its advantages include relatively low capital costs, proven durability with lifetimes exceeding 60,000 hours, and the absence of precious metal catalysts. However, AEL systems exhibit limited dynamic response capabilities, with typical ramp rates of 0.2-10% per second and minimum loads of 10-40%, constraining their performance under rapidly fluctuating renewable inputs.

PEMEL technology operates at similar temperatures (50-80°C) but offers superior dynamic performance, with ramp rates reaching 100% per second and minimum loads as low as 5-10%. This makes PEMEL particularly suitable for coupling with intermittent renewables like solar and wind. The technology achieves efficiencies of 65-84% but faces challenges including higher capital costs due to precious metal catalysts (primarily platinum and iridium) and shorter stack lifetimes of approximately 20,000-60,000 hours.

SOEL operates at significantly higher temperatures (700-850°C), achieving exceptional efficiencies of 85-95% but requiring substantial thermal energy. While this technology shows promise for integration with industrial processes that generate waste heat, its high-temperature operation presents challenges for rapid cycling under variable renewable inputs, with limited load flexibility and slower response times.

The primary technical challenges facing electrolysis under variable renewable inputs include degradation mechanisms accelerated by dynamic operation, system-level integration complexities, and economic viability. Frequent start-stop cycles and power fluctuations can significantly reduce stack lifetimes, particularly for PEMEL systems where membrane degradation and catalyst dissolution are exacerbated by variable operation.

System-level challenges include thermal management during power fluctuations, pressure control systems capable of maintaining safe operation during rapid changes, and balance-of-plant components that can withstand dynamic conditions. Additionally, hydrogen storage and compression systems must be designed to accommodate variable production rates.

Cost remains a critical barrier, with current hydrogen production costs from electrolysis ranging from $4-6/kg, significantly higher than conventional methods ($1-2/kg). The capital-intensive nature of electrolyzers requires high utilization rates to achieve economic viability, creating tension with the inherently variable nature of renewable energy sources.

Alkaline electrolysis represents the most mature technology, operating at 70-90°C with efficiencies ranging from 65-82%. Its advantages include relatively low capital costs, proven durability with lifetimes exceeding 60,000 hours, and the absence of precious metal catalysts. However, AEL systems exhibit limited dynamic response capabilities, with typical ramp rates of 0.2-10% per second and minimum loads of 10-40%, constraining their performance under rapidly fluctuating renewable inputs.

PEMEL technology operates at similar temperatures (50-80°C) but offers superior dynamic performance, with ramp rates reaching 100% per second and minimum loads as low as 5-10%. This makes PEMEL particularly suitable for coupling with intermittent renewables like solar and wind. The technology achieves efficiencies of 65-84% but faces challenges including higher capital costs due to precious metal catalysts (primarily platinum and iridium) and shorter stack lifetimes of approximately 20,000-60,000 hours.

SOEL operates at significantly higher temperatures (700-850°C), achieving exceptional efficiencies of 85-95% but requiring substantial thermal energy. While this technology shows promise for integration with industrial processes that generate waste heat, its high-temperature operation presents challenges for rapid cycling under variable renewable inputs, with limited load flexibility and slower response times.

The primary technical challenges facing electrolysis under variable renewable inputs include degradation mechanisms accelerated by dynamic operation, system-level integration complexities, and economic viability. Frequent start-stop cycles and power fluctuations can significantly reduce stack lifetimes, particularly for PEMEL systems where membrane degradation and catalyst dissolution are exacerbated by variable operation.

System-level challenges include thermal management during power fluctuations, pressure control systems capable of maintaining safe operation during rapid changes, and balance-of-plant components that can withstand dynamic conditions. Additionally, hydrogen storage and compression systems must be designed to accommodate variable production rates.

Cost remains a critical barrier, with current hydrogen production costs from electrolysis ranging from $4-6/kg, significantly higher than conventional methods ($1-2/kg). The capital-intensive nature of electrolyzers requires high utilization rates to achieve economic viability, creating tension with the inherently variable nature of renewable energy sources.

Technical Solutions for Variable Renewable Integration

01 Electrode materials and configurations for improved electrolysis efficiency

The choice of electrode materials and their configurations significantly impacts electrolysis performance. Advanced materials such as noble metals, metal oxides, and composite electrodes can enhance catalytic activity and durability. Optimized electrode configurations, including surface area modifications and novel geometries, can improve reaction kinetics and energy efficiency in electrolysis systems.- Electrode materials and configurations for improved electrolysis efficiency: The choice of electrode materials and their configurations significantly impacts electrolysis performance. Advanced materials such as noble metals, metal oxides, and composite electrodes can enhance catalytic activity and durability. Optimized electrode geometries, surface treatments, and spacing can reduce energy consumption and increase hydrogen production rates. These innovations help overcome traditional limitations in electrolysis systems by improving electron transfer and reducing overpotential requirements.

- Membrane and separator technologies for electrolysis cells: Specialized membranes and separators play a crucial role in electrolysis performance by facilitating ion transport while preventing gas crossover. Advanced polymer electrolyte membranes, ceramic separators, and composite materials can enhance conductivity, mechanical stability, and chemical resistance. These components help maintain efficiency under varying operating conditions and extend the operational lifetime of electrolysis systems while enabling higher current densities and production rates.

- Electrolyte composition and additives for enhanced performance: The composition of electrolytes and incorporation of specific additives can significantly improve electrolysis performance. Optimized electrolyte formulations with controlled pH, conductivity enhancers, and stabilizing agents can reduce resistance and increase reaction rates. Additives that prevent electrode fouling, reduce bubble adhesion, or catalyze reactions can lead to more efficient gas evolution and energy utilization in various electrolysis applications.

- System design and operating parameters optimization: Overall system design and operating parameter optimization are essential for maximizing electrolysis performance. Factors such as temperature control, pressure management, flow dynamics, and current density distribution significantly impact efficiency. Advanced designs incorporating heat recovery systems, pressure balancing mechanisms, and optimized flow fields can reduce energy consumption and increase production rates. Automated control systems that adjust operating parameters in real-time help maintain optimal performance under varying conditions.

- Integration of renewable energy sources with electrolysis systems: Integrating renewable energy sources with electrolysis systems presents unique challenges and opportunities for performance enhancement. Specialized power electronics, energy storage solutions, and control algorithms can manage the variable nature of renewable inputs while maintaining stable electrolysis operation. Hybrid systems that combine different energy sources and storage technologies enable continuous operation and improved efficiency. These integrated approaches are particularly important for green hydrogen production and energy conversion applications.

02 Membrane technology advancements for electrolysis cells

Specialized membrane technologies play a crucial role in separating reaction products and maintaining efficiency in electrolysis processes. Innovations in ion-exchange membranes, polymer electrolyte membranes, and composite membrane structures can reduce electrical resistance, enhance ion selectivity, and improve overall system durability under various operating conditions.Expand Specific Solutions03 Electrolyte composition optimization for enhanced performance

The composition of electrolytes significantly affects electrolysis efficiency and product selectivity. Tailored electrolyte formulations with specific additives, pH modifiers, and ionic conductivity enhancers can reduce energy consumption, increase reaction rates, and extend the operational lifetime of electrolysis systems while maintaining product purity.Expand Specific Solutions04 Control systems and process parameters for electrolysis optimization

Advanced control systems and precise management of process parameters are essential for optimizing electrolysis performance. Intelligent monitoring of temperature, pressure, current density, and flow rates allows for real-time adjustments that maximize efficiency, reduce energy consumption, and ensure consistent product quality across varying operational conditions.Expand Specific Solutions05 Scale-up and industrial implementation of electrolysis technologies

Scaling electrolysis technologies from laboratory to industrial scale presents unique challenges that impact performance. Innovations in cell design, stack configuration, and system integration address issues related to heat management, pressure distribution, and uniform current density. These advancements enable cost-effective, large-scale electrolysis operations with maintained or improved efficiency compared to smaller systems.Expand Specific Solutions

Key Industry Players in Electrolysis Market

The electrolysis under variable renewable inputs market is currently in a growth phase, with increasing adoption driven by the global push for green hydrogen production. The market size is expanding rapidly, projected to reach significant scale as hydrogen becomes central to decarbonization strategies. Technologically, the field shows moderate maturity with established players like Siemens Energy, Johnson Matthey, and Mitsubishi Heavy Industries offering commercial solutions, while innovative companies such as DynElectro and Convion are advancing specialized technologies for intermittent renewable integration. Academic institutions including Caltech, EPFL, and USC are contributing fundamental research to improve efficiency and durability. The competitive landscape features traditional industrial conglomerates expanding their electrolysis portfolios alongside specialized startups developing novel catalysts and control systems specifically optimized for variable renewable energy inputs.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced PEM (Proton Exchange Membrane) electrolysis systems specifically designed to operate efficiently under variable renewable energy inputs. Their Silyzer series incorporates dynamic response capabilities that can ramp from 0% to 100% load within seconds, making it highly compatible with fluctuating renewable sources like wind and solar. The system employs sophisticated power electronics with grid-forming capabilities that stabilize input power fluctuations, while their proprietary control algorithms continuously optimize operation parameters based on the quality and quantity of incoming power. Siemens has implemented machine learning models that predict renewable energy availability patterns and preemptively adjust electrolysis parameters to maximize hydrogen production efficiency. Their systems have demonstrated stable operation under power input variations of up to 60% within minutes while maintaining electrolyzer stack integrity and performance.

Strengths: Industry-leading rapid response capabilities (0-100% in seconds), sophisticated power electronics that stabilize grid fluctuations, and AI-driven predictive operation optimization. Weaknesses: Higher capital costs compared to conventional electrolyzers, complex system integration requirements, and potential accelerated degradation under extremely frequent cycling conditions.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed an integrated electrolysis solution specifically designed for variable renewable energy inputs, focusing on both PEM and solid oxide electrolysis cell (SOEC) technologies. Their hybrid approach combines the rapid response capabilities of PEM systems with the higher efficiency of SOEC systems operating at elevated temperatures. MHI's technology incorporates advanced thermal management systems that maintain optimal operating conditions despite power fluctuations, while their proprietary control algorithms continuously adjust operating parameters based on input power characteristics. The company has implemented innovative electrode materials that demonstrate enhanced durability under cycling conditions, with demonstrated degradation rates below 0.5% per 1000 hours even under variable loads. Their systems include integrated power conditioning equipment that smooths renewable input variations while maintaining electrolyzer efficiency. MHI has deployed this technology in several demonstration projects in Japan, including a 10MW system paired with offshore wind generation that has achieved overall system efficiencies exceeding 75% despite highly variable wind patterns.

Strengths: Innovative hybrid technology approach combining benefits of multiple electrolysis methods, advanced thermal management systems that maintain efficiency during transitions, and robust materials with demonstrated cycling durability. Weaknesses: Higher system complexity requiring sophisticated control systems, challenges with thermal cycling in SOEC components, and higher capital costs compared to single-technology approaches.

Core Patents in Electrolysis Efficiency Optimization

Method for producing synthesis gas by co-electrolysis

PatentWO2015082130A1

Innovation

- A process involving recycling a fraction of synthesis gas from the outlet back to the inlet of the co-electrolyzer, with adjustments to regulate temperature and maintain constant dihydrogen to carbon monoxide ratios, to stabilize the co-electrolyzer's operation and broaden its power range.

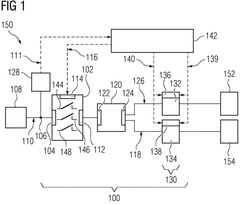

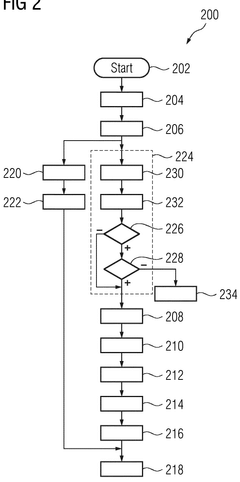

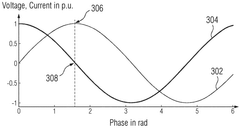

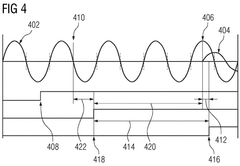

Electrolysis system and energy conversion arrangement with inrush current mitigation

PatentWO2025131620A1

Innovation

- An energy conversion arrangement with inrush current mitigation, comprising a switching module, a transformer system, a sensor module, an AC to DC converter system, and a controller unit that provides synchronized switching signals based on switching delay times to ensure each phase current flow starts or stops at positive or negative maximum peak values of the phase voltage signals.

Renewable Energy Integration Strategies

The integration of renewable energy sources with electrolysis systems presents unique challenges and opportunities for optimizing hydrogen production. Effective integration strategies must address the inherent variability of renewable energy sources while maintaining efficient electrolysis operations. These strategies can be categorized into technical, operational, and market-based approaches.

Technical integration strategies focus on system design and hardware solutions. Hybrid power systems combining multiple renewable sources (solar, wind, hydro) can reduce overall variability by leveraging their complementary generation profiles. Energy storage technologies, including batteries and supercapacitors, serve as buffers between variable renewable generation and electrolysis systems, enabling more consistent operation. Advanced power electronics and control systems allow for rapid response to fluctuations, protecting electrolyzer stacks from damaging power transients.

Operational strategies emphasize flexible management approaches. Dynamic operation protocols enable electrolyzers to adjust their production rates in response to renewable availability, operating at partial loads during low-generation periods and ramping up during peak production. Predictive control algorithms utilizing weather forecasting and machine learning can anticipate renewable generation patterns, optimizing operation schedules hours or days in advance. Load-following capabilities allow electrolyzers to track renewable generation in real-time, maximizing renewable energy utilization.

Market-based integration strategies leverage economic mechanisms to optimize system performance. Time-of-use electricity pricing enables operators to prioritize hydrogen production during periods of abundant renewable generation and low electricity costs. Grid services participation allows electrolysis systems to provide valuable ancillary services such as frequency regulation and demand response, creating additional revenue streams. Virtual power plant arrangements can coordinate multiple distributed electrolysis units, optimizing their collective operation across broader geographical areas.

Geographical considerations also play a crucial role in integration strategies. Co-location of electrolysis facilities with renewable generation assets minimizes transmission losses and infrastructure requirements. Regional resource complementarity can be exploited by strategically positioning electrolysis facilities in areas with diverse renewable resources, reducing overall variability.

The most successful renewable energy integration approaches typically combine elements from multiple strategy categories, creating holistic solutions tailored to specific project requirements, local renewable resources, and market conditions. As renewable penetration increases globally, these integration strategies will become increasingly sophisticated, enabling more efficient and economical green hydrogen production.

Technical integration strategies focus on system design and hardware solutions. Hybrid power systems combining multiple renewable sources (solar, wind, hydro) can reduce overall variability by leveraging their complementary generation profiles. Energy storage technologies, including batteries and supercapacitors, serve as buffers between variable renewable generation and electrolysis systems, enabling more consistent operation. Advanced power electronics and control systems allow for rapid response to fluctuations, protecting electrolyzer stacks from damaging power transients.

Operational strategies emphasize flexible management approaches. Dynamic operation protocols enable electrolyzers to adjust their production rates in response to renewable availability, operating at partial loads during low-generation periods and ramping up during peak production. Predictive control algorithms utilizing weather forecasting and machine learning can anticipate renewable generation patterns, optimizing operation schedules hours or days in advance. Load-following capabilities allow electrolyzers to track renewable generation in real-time, maximizing renewable energy utilization.

Market-based integration strategies leverage economic mechanisms to optimize system performance. Time-of-use electricity pricing enables operators to prioritize hydrogen production during periods of abundant renewable generation and low electricity costs. Grid services participation allows electrolysis systems to provide valuable ancillary services such as frequency regulation and demand response, creating additional revenue streams. Virtual power plant arrangements can coordinate multiple distributed electrolysis units, optimizing their collective operation across broader geographical areas.

Geographical considerations also play a crucial role in integration strategies. Co-location of electrolysis facilities with renewable generation assets minimizes transmission losses and infrastructure requirements. Regional resource complementarity can be exploited by strategically positioning electrolysis facilities in areas with diverse renewable resources, reducing overall variability.

The most successful renewable energy integration approaches typically combine elements from multiple strategy categories, creating holistic solutions tailored to specific project requirements, local renewable resources, and market conditions. As renewable penetration increases globally, these integration strategies will become increasingly sophisticated, enabling more efficient and economical green hydrogen production.

Economic Viability Assessment

The economic viability of electrolysis systems under variable renewable inputs presents a complex landscape of cost factors and operational considerations. Current levelized cost of hydrogen (LCOH) from electrolysis ranges from $4-6/kg when powered by dedicated renewable sources, significantly higher than the $1-2/kg benchmark for conventional steam methane reforming. This cost differential represents the primary barrier to widespread adoption of green hydrogen production technologies.

Capital expenditure (CAPEX) for electrolysis systems varies substantially by technology type, with alkaline electrolyzers averaging $800-1,200/kW, PEM electrolyzers at $1,400-2,100/kW, and solid oxide electrolyzers still commanding premium prices of $2,000-3,000/kW due to their early commercial stage. These upfront costs constitute 30-50% of the total LCOH, making technological advancement and manufacturing scale critical to economic feasibility.

Operational expenditure (OPEX) under variable renewable inputs introduces additional complexity. Systems operating with intermittent power sources typically achieve capacity factors of 30-60%, compared to 90%+ for grid-connected systems. This reduced utilization significantly impacts amortization of fixed costs. Analysis of real-world installations demonstrates that electrolyzer systems require minimum annual operation of 3,000-4,000 hours to achieve reasonable economic returns, creating tension between maximizing renewable energy utilization and equipment efficiency.

Electricity costs remain the dominant operational expense, representing 60-80% of LCOH. Renewable electricity price volatility directly impacts production economics, with optimal operation often requiring sophisticated control systems that enable production during periods of electricity surplus and corresponding low prices. Recent modeling studies indicate that systems designed to operate flexibly can achieve 15-25% lower LCOH compared to constant-load systems, despite the higher initial investment in oversized capacity.

The economic equation is further influenced by emerging revenue streams, including grid balancing services and oxygen sales. Electrolyzers providing demand response services can generate additional revenue of $50-200/kW annually in mature markets, potentially offsetting 5-15% of operational costs. This value proposition strengthens as renewable penetration increases, creating greater grid volatility and demand for flexible loads.

Sensitivity analysis reveals that economic viability thresholds vary significantly by application and region. Industrial applications with high natural gas prices and carbon taxes show break-even potential at $4-5/kg hydrogen, while transportation applications require further cost reductions to compete with conventional fuels without substantial policy support. Regional variations in renewable resource quality create geographic advantages, with optimal locations potentially achieving 20-30% lower production costs than average sites.

Capital expenditure (CAPEX) for electrolysis systems varies substantially by technology type, with alkaline electrolyzers averaging $800-1,200/kW, PEM electrolyzers at $1,400-2,100/kW, and solid oxide electrolyzers still commanding premium prices of $2,000-3,000/kW due to their early commercial stage. These upfront costs constitute 30-50% of the total LCOH, making technological advancement and manufacturing scale critical to economic feasibility.

Operational expenditure (OPEX) under variable renewable inputs introduces additional complexity. Systems operating with intermittent power sources typically achieve capacity factors of 30-60%, compared to 90%+ for grid-connected systems. This reduced utilization significantly impacts amortization of fixed costs. Analysis of real-world installations demonstrates that electrolyzer systems require minimum annual operation of 3,000-4,000 hours to achieve reasonable economic returns, creating tension between maximizing renewable energy utilization and equipment efficiency.

Electricity costs remain the dominant operational expense, representing 60-80% of LCOH. Renewable electricity price volatility directly impacts production economics, with optimal operation often requiring sophisticated control systems that enable production during periods of electricity surplus and corresponding low prices. Recent modeling studies indicate that systems designed to operate flexibly can achieve 15-25% lower LCOH compared to constant-load systems, despite the higher initial investment in oversized capacity.

The economic equation is further influenced by emerging revenue streams, including grid balancing services and oxygen sales. Electrolyzers providing demand response services can generate additional revenue of $50-200/kW annually in mature markets, potentially offsetting 5-15% of operational costs. This value proposition strengthens as renewable penetration increases, creating greater grid volatility and demand for flexible loads.

Sensitivity analysis reveals that economic viability thresholds vary significantly by application and region. Industrial applications with high natural gas prices and carbon taxes show break-even potential at $4-5/kg hydrogen, while transportation applications require further cost reductions to compete with conventional fuels without substantial policy support. Regional variations in renewable resource quality create geographic advantages, with optimal locations potentially achieving 20-30% lower production costs than average sites.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!